Textile-to-textile – Lignin reinforcement enhances PLA biopolymer functionality 24-01-2024 - Arhive

Crafted from recycled high-performance plastic, these polymer slides are both cost-effective and environmentally sustainable, offering a greener alternative for linear systems commonly used in adjustable retail displays and similar applications.

The drylin Econ series is a game-changer, providing a solution that is over 80% more affordable than traditional machined aluminum counterparts. The slides, injection-molded from regranulated plastic, boast integrated compensating bearings, enabling smooth cornering on curved aluminum rails. Textile-to-textile

Ideal for tasks such as adjusting retail store monitors or fine-tuning grippers in snack vending machines, the drylin Econ series offers a cost-effective alternative to linear guides with recirculating ball bearings and steel components, eliminating unnecessary expenses.

“As companies face pressures like inflation, high energy costs, and disrupted supply chains, saving costs has become imperative. In response to these challenges, we are proud to introduce the drylin Econ series,” says Rob Dumayne, drylin and bearings director at igus UK. Textile-to-textile

“This entry-level series is tailored for simple adjustment tasks, providing a cost-effective and sustainable solution, even for non-linear profiles.”

The drylin Econ series not only reduces costs by around 80%, but it also contributes to sustainability efforts. Manufactured from injection molding production waste, the slides utilize iglidur ECO P, a regranulate plastic composed of 100% recycled materials, including production sprues and damaged parts.

This not only lowers material costs but also promotes a circular economy by diverting plastic waste from incineration or landfill. Textile-to-textile

Additionally, the drylin Econ series stands out for its operational efficiency. Microscopic solid lubricants integrated into the high-performance plastic bearing facilitate dry running without additional lubrication, reducing maintenance time and costs.

The lightweight construction, combining plastic and aluminum, makes it suitable for various applications, including those requiring inconspicuous and quiet operation.

With the ability to effortlessly glide around curved rails, the drylin Econ series ensures ease of movement, making it particularly suitable for vending machines in public spaces. In embracing sustainability and cost-effectiveness, igus continues to lead the way in providing innovative solutions for the evolving needs of industries worldwide.

Textile-to-textile

Precision Textiles, a leading supplier to mattress manufacturers, is pioneering an industry-first collaboration with Unifi, Inc., makers of REPREVE® recycled performance fiber

This strategic partnership aims to address the surging consumer demand for eco-friendly mattresses.

Precision Textiles is committed to reducing its carbon footprint, and by incorporating REPREVE® recycled polyester yarn into all filler cloth products, it becomes the sole bedding component manufacturer utilizing this innovative fiber.

REPREVE®, the world’s premier recycled polyester fiber brand, tackles environmental concerns related to plastic waste by spinning yarns from recycled plastic bottles.

This partnership not only marks a milestone for Precision Textiles but also positions the company at the forefront of sustainability in the mattress industry.

Every 100-yard roll of the company’s ENDURE IFR and ADVANTAGE SB non-woven products will now include REPREVE® fiber, derived from 228 recycled water bottles, eliminating over 20 million plastic bottles annually. Textile-to-textile

Gerry Welkley, national sales manager at Precision Textiles, expresses pride in being the first FR nonwoven component supplier to embrace REPREVE® technology, emphasizing its positive impact on sustainability initiatives.

Bob O’Connell, executive vice president marketing and merchandising, underscores the customer-driven nature of this collaboration, providing mattress manufacturers with an eco-friendly solution to meet consumer expectations.

Precision Textiles’ longstanding commitment to environmental stewardship is reflected in its USDA Bio-Preferred and UL Greenguard GOLD certified FR solution product lines, demonstrating a dedication to a sustainable future. Textile-to-textile

This groundbreaking partnership not only exemplifies Precision Textiles’ dedication but also resonates with conscientious consumers expecting responsible product manufacturing.

Lignin reinforcement enhances PLA biopolymer functionality

As the Process Engineering Development and Project Manager at KraussMaffei Extrusion, Lars Darnedde has played a pivotal role in a groundbreaking collaboration between Synergy Horizon Poland and KraussMaffei, resulting in the development of a 100% bio-based-reinforced thermoplastic: lignin-reinforced polylactic acid (PLA). This innovative process incorporates 30% hydrolyzed lignin during extrusion, creating a compound with natural antioxidant capacity, enhanced mechanical properties, and controlled biodegradability. Textile-to-textile

The Synergy Horizon group, focused on lignin valorization, strives to transform lignin, often discarded in bioethanol production, into valuable products for diverse applications. With expertise in lignin purification, chemical modification, and functionalization, the group offers lignin-derived products for industries ranging from oil and gas extraction to water treatment.

Synergy Horizon Poland has developed a commercial production line for free-flowing lignin powder, a milestone in utilizing this abundant natural substance.

KraussMaffei’s technical center demonstrated successful incorporation of up to 30% lignin into PLA matrix using specialized equipment, resulting in a significant increase in flexural and tensile modulus. Textile-to-textile

Extensive mechanical tests have shown that the lignin-reinforced PLA not only enhances mechanical properties but also exhibits a biodegradation rate of over 90% in 99 days, making it ideal for environmentally conscious applications such as food packaging. The unique combination of antioxidant capacity, lack of odor, and improved biodegradability sets this lignin-reinforced PLA apart in the industry, showcasing a sustainable and functional alternative in the realm of biopolymers.

I am a highly skilled chemical engineer with a proven track record in the innovative development of sustainable technologies

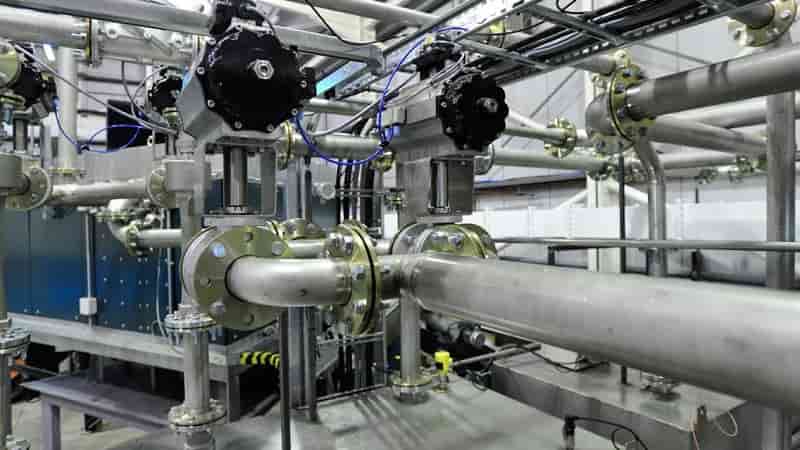

In my most recent role, I played a pivotal role in the inauguration and optimization of a groundbreaking demonstration unit for bio-butadiene synthesis from bioethanol at the Michelin factory in Bassens, France. Textile-to-textile

This achievement marked the first-ever plant of its kind in the country, a project I have been dedicated to for the past five years.

Collaborating closely with IFP Energies Nouvelles (Ifpen) and Axens, I successfully completed the construction of the unit within the Michelin facility as part of the BioButterfly project. This cutting-edge facility, finalized in July of last year, boasts a production capacity of up to 30 tonnes per year. My responsibilities include overseeing the unit’s operations to fine-tune the technology, aiming for a seamless transition to an industrial scale. Textile-to-textile

As an integral part of the project, I have contributed to securing investments exceeding 80 million euros, with substantial support from the French Environment and Energy Agency (Ademe), the Nouvelle Aquitaine region, and the Urban Community of Bordeaux. Additionally, I have played a crucial role in the creation of approximately twenty jobs at the Michelin site in Bassens. Textile-to-textile

Beyond the immediate success of the project, my focus aligns with Michelin’s commitment to using renewable or recycled raw materials entirely by 2050. I am particularly interested in the commercialization of the bio-butadiene synthesis process by Axens, with Michelin leveraging this sustainable resource in the production of tire compounds.

My expertise extends beyond butadiene production, as evidenced by my involvement in the development of styrene butadiene rubber (SBR) using styrene monomer obtained from chemical recycling. I am dedicated to advancing environmentally responsible practices within the chemical engineering field and contributing to the tire industry’s sustainable evolution. Textile-to-textile

The “Waste Plastic Pyrolysis Processing Plant Project Report 2024” by IMARC Group serves as a comprehensive guide for entrepreneurs and stakeholders interested in establishing a waste plastic pyrolysis processing plant

The report covers a wide range of aspects, providing valuable insights into industry trends, plant setup, machinery requirements, raw material specifications, investment opportunities, costs, and revenue projections. Textile-to-textile

Waste plastic pyrolysis is an innovative recycling method that transforms plastic waste into valuable resources through a thermal decomposition process conducted in an oxygen-free environment. The report delves into the intricacies of this process, detailing the heating temperatures, reactor types (fixed beds, fluidized beds, and rotary kilns), and the distinction between fast and slow pyrolysis methods. It highlights the significance of converting non-recyclable plastics into useful products, presenting a sustainable waste management solution.

The global market for waste plastic pyrolysis is driven by the increasing adoption of circular economy principles, encouraging industries to embrace waste-to-value approaches. Textile-to-textile

Technological advancements in pyrolysis processes are enhancing efficiency and output quality, making the technology more attractive to investors and users. The report emphasizes the market’s growth fueled by the rising price of crude oil, which boosts demand for alternative fuels derived from plastic waste.

Moreover, the growing emphasis on sustainable and eco-friendly practices, coupled with the awareness of environmental issues, is driving the acceptance and adoption of waste plastic pyrolysis. The report identifies additional factors contributing to market growth, including the commitment of companies to sustainability goals, rapid expansion in developing regions, advancements in waste sorting and pre-treatment technologies, and extensive research and development activities. Textile-to-textile

Entrepreneurs and stakeholders can leverage the detailed financial analysis provided in the report, covering capital investments, project funding, operating expenses, income and expenditure projections, ROI, net present value, and profit and loss accounts. Armed with this comprehensive roadmap, individuals can make informed decisions, ensuring the success of their waste plastic pyrolysis processing units in the evolving landscape of sustainable waste management.

Textile-to-textile