Biodegradable plastics Pollution – Braskem will become the largest producer of bio-ethylene? 27-07-2023 - Arhive

Biodegradable plastics Pollution

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

China’s stance on biodegradable plastics has undergone a significant shift, moving from a proactive approach to a more cautious and wait-and-see approach

The country’s ambitious drive to reduce single-use plastics started in January 2020, with bans and restrictions on non-biodegradable single-use plastic products. This sudden ban created a surge in the production of alternatives, especially biodegradable plastics. By 2025, China is expected to account for two-thirds of global biodegradable plastic output.

However, recent plans published by the National Development and Reform Commission and the Ministry of Ecology and Environment for tackling plastic pollution in 2021–2025 showed a lack of emphasis on biodegradable plastics. Instead, the focus shifted towards researching the impact and applicability of these materials and cautioned against blind expansion.

One of the challenges with biodegradable plastics lies in the unclear definitions and standards in China. The existing national standard from 2006 identifies four types of degradable plastic, but there have been no updates since then. Moreover, the 2020 guidance on categorizing and labeling degradable plastics lacked the binding force of a national standard, contributing to uneven product quality.

Degradable plastics also pose concerns regarding their actual degradation capabilities. Even certified biodegradable plastics break down only under specific conditions, and the rate of degradation depends on factors like oxygen levels, humidity, temperature, and microorganisms’ presence. Some biodegradable plastics, like PLA, require industrial composting facilities to break down effectively, while others like PBAT barely degrade in water, making them no better for the environment than traditional plastics when they end up in water bodies.

Moreover, the lack of an efficient waste management system for degradable plastics hinders their proper disposal and degradation. The cost of degradable plastics is considerably higher than traditional plastics, making large-scale implementation financially challenging. Additionally, the absence of a reliable logistics system to handle degradable plastics from households to appropriate waste-handling facilities further complicates the matter.

As a result, policymakers have cooled their enthusiasm for biodegradable plastics. The focus has shifted towards reducing plastic consumption in other areas, such as e-commerce packaging and government procurement. For instance, the agricultural sector’s usage of mulching films, most of which end up as “white pollution” in the environment, is seen as a more promising application for biodegradable plastics.

In conclusion, the future of biodegradable plastics in China remains uncertain due to various challenges. The lack of clear definitions and standards, coupled with the limited degradation capabilities and inefficient waste management, have led policymakers to reevaluate their stance. While there might be potential for biodegradable plastics in specific applications, it is evident that more research and improvements are needed to ensure their effectiveness and environmental benefits. Meanwhile, efforts to reduce plastic consumption in other areas are gaining momentum to tackle the pressing issue of plastic pollution. Biodegradable plastics Pollution

Limited Consumer Knowledge Hinders Bioplastics Adoption in Japan: A Study

Introduction

A recent study conducted by researchers at Japan’s College of Policy Science at Ritsumeikan University sheds light on the limited consumer knowledge and attitudes towards bioplastics in Japan. Led by Professor Takuro Uehara, the study aimed to understand consumer behavior and preferences regarding bioplastics, with a focus on factors influencing their choices and the impact of educational interventions on their decisions. The findings are crucial for promoting the adoption of bioplastics and transitioning towards a more sustainable bioeconomy.

Understanding Consumer Knowledge and Preferences

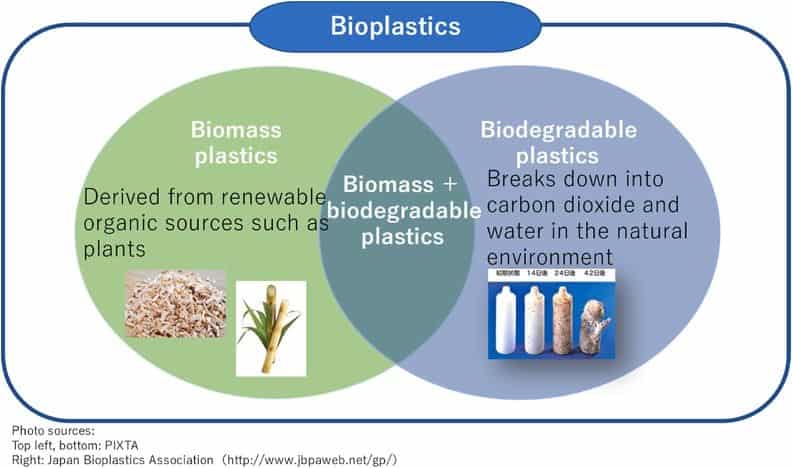

The study commenced with an assessment of consumers’ familiarity with bioplastics in Japan. Surprisingly, the majority of respondents demonstrated a lack of understanding about the distinctions between bio-based, biodegradable, and bioplastics. Many were unaware that not all bioplastics were biodegradable or bio-based, revealing a significant knowledge gap.

Furthermore, the research delved into the factors influencing consumers’ preferences for bioplastics. The participants were presented with three different products: 500 ml PET water bottles, three-color ballpoint pens, and 500 ml shampoo bottles. While respondents showed limited enthusiasm for products made from biomass feedstocks, they exhibited a preference for sugarcane over wood chips, with waste cooking oil ranking last. Quality considerations seemed to outweigh environmental trade-offs in their decision-making process.

Key Drivers of Consumer Choice

The reduction in carbon dioxide emissions associated with the use of bioplastics emerged as the most valued attribute across all three products and both groups. Biodegradability also received positive responses from the participants. Notably, respondents expressed a preference for domestic products, driven primarily by safety, quality, and reliability concerns rather than environmental considerations.

Effect of Educational Interventions

To gauge the impact of education on consumer choices, the researchers divided the respondents into two groups: one receiving educational interventions and the other serving as the control group. The results revealed that informed consumers were more willing to pay for environmentally friendly products, considering both feedstock sources and carbon emission levels. This highlights the importance of awareness campaigns in influencing consumer preferences for bioplastic products. Biodegradable plastics Pollution

Implications for Japanese Industries and Government

The study’s findings hold significant implications for Japanese industries and government initiatives. Understanding the type of bioplastics preferred and accepted by consumers provides valuable insights for developing and promoting more sustainable products. The results can serve as an impetus for further innovation in bioplastics, encouraging industries to produce eco-friendly alternatives that align with consumer demands.

Importance of Information Dissemination

Professor Takuro Uehara emphasizes the importance of information dissemination in influencing consumer preferences for bioplastics. Awareness campaigns play a crucial role in closing the knowledge gap among consumers and fostering a more environmentally conscious society. By increasing public awareness of bioplastics’ benefits and differentiating them from conventional plastics, consumers can make more informed and sustainable choices. Biodegradable plastics Pollution

Conclusion

The study conducted by Ritsumeikan University researchers underscores the need to improve consumers’ understanding of bioplastics in Japan. With a limited grasp of bio-based, biodegradable, and bioplastic distinctions, consumers are less likely to make sustainable choices. However, educational interventions have shown promise in encouraging more environmentally friendly product preferences. By disseminating information about bioplastics and emphasizing their benefits, Japanese industries and government agencies can drive positive change, paving the way for a greener and more sustainable future.

Consumer preferences and understanding of bio-based and biodegradable plastics, Journal of Cleaner Production; Professor Takuro Uehara, Ritsumeikan University, Japan

This study was funded by the Environment Research and Technology Development Fund of the Environmental Restoration and Conservation Agency of Japan [JPMEERF21S11920].

Antimicrobial Packaging: Paving the Way Towards Sustainable and Clean Solutions

Introduction

The growing concern over plastic waste and its environmental impact has pushed sustainability initiatives to seek alternative solutions to single-use food and drink containers. While reusable and refillable options are encouraged, consumers often face challenges in maintaining their cleanliness due to residual bacteria, molds, and mildews. Uncontrolled microbial growth not only leads to premature degradation and unpleasant odors but also deters consumers from reusing these items. Fortunately, the incorporation of antimicrobial technologies into plastic packaging offers a promising solution to these problems, promoting a throwaway culture shift and contributing to a cleaner, more sustainable future. Biodegradable plastics Pollution

The Challenge of Microbial Growth

Plastic packaging constitutes a significant portion of household waste, primarily due to its widespread use in single-use containers. Despite efforts to promote reusable alternatives, the presence of leftover residues in such packaging leads to the rapid growth of bacteria, molds, and mildews. This unchecked microbial growth results in degradation, discoloration, and undesirable odors, rendering the plastic items unsuitable for further use. Furthermore, consumer awareness of unseen microbial growth has grown significantly, with a large majority expressing concerns about exposure to harmful bacteria. As a result, maintaining plastic packaging at a high standard of cleanliness becomes challenging, prompting many to opt for disposal and replacement with readily available, inexpensive options.

The Solution: Antimicrobial Technology

Built-in antimicrobial technologies present an effective solution to combat microbial growth on plastic surfaces, extending the usability and visual appeal of products. These technologies remain active throughout the entire lifecycle of the product, providing continuous protection against microbes from the moment of production until the end of its use. As a result, consumers are encouraged to reuse products, effectively reducing the unnecessary disposal and downcycling of high-quality plastics.

Accessibility and Adaptability

Antimicrobial chemistries can be seamlessly incorporated into various plastic and polymer substrates, ensuring compatibility with existing manufacturing processes. This accessibility enables the widespread adoption of antimicrobial technology in numerous applications and industries. Biodegradable plastics Pollution

Manufacturers can collaborate with globally-trusted antimicrobial technology companies to develop the right chemistry for each specific application, backed by extensive laboratory testing to ensure efficacy and safety.

Driving Packaging Trends and Marketability

With mounting pressure to reduce plastic waste, antimicrobial packaging offers a valuable and marketable advantage for manufacturers. By providing consumers with cleaner and longer-lasting products, manufacturers can align themselves with sustainability goals and attract environmentally-conscious consumers. This shift towards antimicrobial packaging can lead to a positive disruption in various markets, contributing to the ongoing trend of adopting more sustainable and durable packaging solutions. Biodegradable plastics Pollution

Conclusion

As global attitudes and behaviors continue to evolve towards sustainability, the quest for durable and eco-friendly packaging options intensifies. The integration of antimicrobial technologies into plastic packaging emerges as a compelling solution to combat the growth of harmful microbes, encouraging a culture of reuse and minimizing the accumulation of plastic waste. By collaborating with trusted antimicrobial technology companies, manufacturers can develop effective and safe chemistries that resonate with environmentally-conscious consumers. Embracing antimicrobial packaging is a crucial step towards a cleaner, more sustainable future.

Plastic recycling is a minefield. Here’s why it’s so difficult and how we can make it easier

Why is it that after nearly 40 years of kerbside recycling in this country, figuring out which plastics can and can’t go in your recycling is still so difficult?

A major problem is that plastics just aren’t plastics.

PET is different to HDPE, which is different to PVC, PP and PS, and then soft plastics (LDPEs) are something else altogether.

There’s also no unified national standard for dealing with plastic — the processing facilities and guidelines vary from council to council.

To that end the best we can do is give you a rough guide to what’s in and what’s out when it comes to your recycling bin. Biodegradable plastics Pollution

Because of their different chemistry, some types of plastic are pretty easy to recycle, whereas until something changes, landfill is the only destination for others.

So we’ve enlisted polymer chemist Bronwyn Laycock to help us understand what plastics we’re dealing with, and whether they’re broadly recyclable or not.

- PET or polyethylene terephthalate

First up, there’s a reason PET or polyethylene terephthalate tops this list. Because it’s literally number “1”.

You know the little triangles made from arrows with the number inside, that you find stamped on plastic things? That triangle doesn’t mean the product can or cannot go in your recycling bin. It’s a code for the type of plastic the thing is made from.

The numbers range from 1 to 7, and PET which is used for everything from water and food containers to sleeping bags, is designated 1.

It’s also, as far as plastics go, one of the easiest to recycle in its pure form.

On that note, for each plastic type we’re going to test your recycling chops. Here’s the first challenge:

Does your clear, single-use plastic water bottle stamped with a 1 go in the recycling bin or landfill?

Of course it goes in the recycling. Biodegradable plastics Pollution

Braskem, a leading Brazilian company, has achieved a significant milestone by completing a 30% increase in biobased ethylene capacity at its Triunfo facility in Rio Grande do Sul

This $87-million expansion marks a crucial step in the company’s ongoing commitment to sustainable development and innovation. The bolstered capacity will play a pivotal role in supporting Braskem’s ambitious goals, including scaling up annual biopolymer capacity to 1 million tons by 2030 and achieving carbon neutrality by 2050.

Walmir Soller, the Vice President for Europe and Asia in the O/P division at Braskem, expressed his enthusiasm about the expansion. He highlighted how this move reinforces the company’s dedication to sustainable practices and exemplifies the success of their strategy initiated thirteen years ago. Biodegradable plastics Pollution

Back then, Braskem pioneered the world’s first industrial-scale production of bio-based polyethylene, utilizing their proprietary technology. Since then, the company has been steadfast in its pursuit of developing products with less impact on the environment, meeting the ever-growing demands of society and customers alike.

Braskem’s commitment to sustainability and eco-friendly solutions has garnered them a widespread customer base. Over 250 renowned brands, including Allbirds, DUO UK, Grupo Boticário, Johnson & Johnson, Natura & Co, Nissin, and Tetra Pak, rely on Braskem’s biobased resins for their products. This widespread adoption is a testament to the quality and reliability of Braskem’s sustainable materials.

The biobased ethylene capacity increase at the Triunfo site is not merely a business expansion; it represents a vital step towards a greener future. By ramping up production, Braskem can offer more sustainable alternatives to traditional plastics, which are notorious for their negative impact on the environment. Biobased resins, derived from renewable sources, play a crucial role in reducing greenhouse gas emissions and dependency on fossil fuels.

Braskem’s drive to achieve 1 million tons of biopolymer capacity by 2030 is in line with global efforts to mitigate climate change and transition towards a circular economy. Biopolymers, being compostable or biodegradable, present a compelling solution to the growing plastic waste crisis.

By significantly increasing their production capacity, Braskem is positioning itself as a key player in the battle against plastic pollution.

Moreover, the company’s bold vision of becoming carbon neutral by 2050 sets a high standard for the industry. Carbon neutrality involves balancing carbon emissions with carbon removal or offsetting, effectively resulting in a net-zero carbon footprint. Achieving such an ambitious goal requires continuous innovation, investment in renewable energy, and sustainable practices throughout the company’s operations. Biodegradable plastics Pollution

As Braskem forges ahead with its sustainability initiatives, it also demonstrates the potential of the bioeconomy in Brazil and beyond. The bioeconomy refers to the sustainable production and utilization of biological resources, such as agricultural and forestry residues, for industrial processes and products. By tapping into Brazil’s abundant bioresources, Braskem showcases how industries can drive economic growth while prioritizing environmental protection.

In conclusion, Braskem’s 30% increase in biobased ethylene capacity at its Triunfo site is a significant accomplishment that exemplifies the company’s commitment to sustainable development and innovation. By offering biobased resins to a wide range of global brands, Braskem plays a crucial role in meeting the demand for environmentally friendly products. The company’s ambitious goals of scaling up biopolymer capacity and achieving carbon neutrality further solidify its position as a sustainability leader in the industry. As Braskem continues to pioneer the bioeconomy, it serves as an inspiring model for other companies looking to make a positive impact on the planet. Biodegradable plastics Pollution

Swancor, a leading specialty chemicals company based in Nantou, Taiwan, has achieved a groundbreaking milestone in the realm of sustainable materials

The company proudly announces the successful attainment of Global Recycle Standard (GRS)-certified recycled fibers from composite components manufactured with their cutting-edge thermoset resin, EzCiclo. Through a simple degradation process, Swancor has accomplished the production of 100% recyclable fibers, making it the world’s first GRS-certified 100% recycled carbon fiber.

The Global Recycle Standard is a widely recognized benchmark that upholds the principles of the circular economy. For a product to obtain GRS certification, it must contain a minimum of 20% recycled fibers and must be entirely free of any pollutants. This standard aligns with the ultimate goal of building sustainable products with zero waste and zero emissions, promoting environmental conservation and responsible manufacturing practices.

The attainment of GRS certification signifies Swancor’s commitment to research and development in innovative products and emerging technologies. By achieving this milestone, the company demonstrates its dedication to fostering a sustainable circular economy. Through the integration of EzCiclo into their materials portfolio, Swancor aims to provide their customers with reliable product declarations, full traceability, and adherence to the stringent environmental and social responsibility requirements prevalent in various industries. Biodegradable plastics Pollution

EzCiclo stands out as a remarkable recyclable and reusable thermosetting epoxy resin, spearheading the charge toward a greener circular economy. Swancor’s forward-thinking approach has led them to establish a robust business model and value chain dedicated to the recycling of thermosetting materials. As an example of their dedication to sustainability, Swancor entered a collaboration with Siemens Gamesa in July 2022 to develop recyclable wind blades, utilizing the revolutionary EzCiclo technology.

This achievement not only elevates Swancor’s standing in the specialty chemicals industry but also reinforces their position as an environmental steward. ion

By creating a pioneering solution like EzCiclo, the company offers a tangible pathway for businesses and industries to reduce their carbon footprint and adopt eco-friendly practices.

The successful production of GRS-certified recycled carbon fibers marks a significant stride in the pursuit of a cleaner, greener future. Swancor’s dedication to innovation and sustainability sets an inspiring example for other companies to follow suit. As the world continues to grapple with pressing environmental challenges, the importance of developing and adopting recyclable materials cannot be overstated.

With Swancor’s achievements, we are presented with a glimpse of the potential of circular economy principles and their positive impact on the environment. As more companies embrace similar sustainable practices, we move closer to a world where waste is minimized, resources are conserved, and the planet thrives. Swancor’s pioneering efforts, such as obtaining GRS-certified recycled carbon fiber, serve as a beacon of hope for a better, cleaner, and more sustainable future. Biodegradable plastics Pollution

A Global Push to Combat Plastic Pollution: Towards a Sustainable Future

In July 2023, representatives from 180 countries convened in Paris, France, for a momentous United Nations summit to address the pressing issue of plastic pollution plaguing our planet. This historic gathering marked the first step towards crafting a comprehensive and legally binding treaty aimed at eradicating global plastic pollution. With the core elements of the treaty provisionally agreed upon, the delegates embarked on the monumental task of developing a first draft, with the ambitious goal of putting it into effect by 2025.

This landmark effort by the UN is just one part of a larger global movement to combat the escalating problem of plastic consumption and waste.

Recognizing the urgency and scale of the challenge, nations across the world have taken initiatives to address plastic pollution on both national and international levels. The United States, for instance, unveiled the draft of its “National Strategy to Prevent Plastic Pollution,” accompanied by the establishment of a White House Interagency Policy Committee (IPC) dedicated to Plastic Pollution and Circular Economy. This collaborative approach aims to harmonize federal efforts in tackling plastic pollution, mitigating its adverse effects on the environment and public health.

Across the Atlantic, European countries are taking decisive action to curb single-use plastic consumption. The Netherlands, at the forefront of innovation, has mandated that businesses charge an extra fee for single-use plastics, while promoting the use of eco-friendly alternatives. Meanwhile, the United Kingdom is poised to implement a ban on certain types of single-use plastic items, a significant step towards reducing plastic waste, starting in October 2023. Biodegradable plastics Pollution

The private sector also wields considerable power in the fight against plastic pollution. Retailers and brands are increasingly adopting internal sustainability pledges, creating a growing demand for alternative packaging materials that are environmentally friendly. This shift in demand cascades through the supply chain and incentivizes chemical and polymer companies to set their own ambitious goals for sustainable production, ultimately contributing to the reduction of plastic waste.

However, it is the combined efforts of governmental regulations, monitoring, and enforcement that exert the most substantial impact on compelling polymer producers and packaging companies to embrace sustainable practices.

Government intervention sets a clear roadmap for the industry, reinforcing the urgency of addressing plastic pollution and holding businesses accountable for their environmental footprints. Biodegradable plastics Pollution

Beyond governmental actions, the impassioned advocacy of non-governmental organizations (NGOs), activists, and the public serves as a driving force for change. These stakeholders apply relentless pressure on brands and retailers to adopt more sustainable practices, creating a ripple effect throughout the entire supply chain. By encouraging transparency and accountability, these efforts promote environmentally responsible practices and push corporations to prioritize sustainable alternatives over single-use plastics. Biodegradable plastics Pollution

In addition to addressing plastic waste, the issue of plastic production and its life cycle must also be taken into account. Transitioning towards a circular economy, where products are designed to be reused, repaired, or recycled, is crucial in the long-term battle against plastic pollution. The circular economy model ensures that plastics have extended lifespans, reducing the demand for virgin plastic production and alleviating the burden on our environment.

In conclusion, the global endeavor to combat plastic pollution is witnessing unprecedented collaboration between governments, international organizations, NGOs, businesses, and the public.

The 2023 UN summit in Paris is a significant milestone, signifying a united effort to create a binding treaty that could transform the way we produce, consume, and manage plastic materials. Concurrently, individual nations, such as the United States, the Netherlands, and the United Kingdom, are taking decisive actions to regulate and limit single-use plastics, setting examples for others to follow.

With governments, businesses, and individuals committed to sustainability, we have the opportunity to reverse the course of plastic pollution and forge a cleaner, greener, and more sustainable future. By nurturing a global culture of responsible consumption and production, we can ensure that future generations inherit a planet free from the suffocating grip of plastic pollution. Biodegradable plastics Pollution

Together, we can embrace innovative solutions and foster a world where plastic pollution is relegated to the history books.