BRICS Bio-Based Plastics – Exploring Innovations in Bio-Based Plastics for Sustainable Packaging 01-09-2023 - Arhive

BRICS Bio-Based Plastics

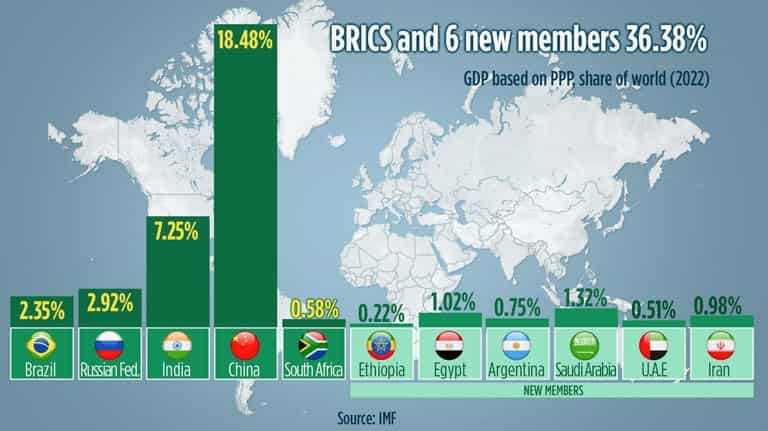

Here’s how BRICS expansion could shake the world economy

The expanded BRICS membership will wield significant power due to their control of essential resources such as oil, iron ore, coal, and bauxite, as well as their role in global agriculture. With developed nations reliant on cooperation for addressing climate change and environmental concerns, discussions will likely center around technology, investment, trade, and bridging gaps in environmental priorities. While countries like Saudi Arabia and the United Arab Emirates are increasingly focused on sustainable growth, the challenge lies in aligning their interests with the existing BRICS members.

Amid discussions of expanding collaboration, questions about the possibility of a common currency for the BRICS arise. While a universal currency remains uncertain, the prospects of increasing bilateral trade and settlement in respective currencies are more plausible. Russia and China have already established such a system, although it took years for their central banks to develop the necessary mechanisms. BRICS Bio-Based Plastics

Further expansion of the bloc remains a possibility, with countries like Kazakhstan and Thailand reportedly expressing interest in membership. Established regional groups like the Eurasian Economic Union and the Shanghai Cooperation Organization might also receive invitations to join. The next year will shed light on the challenges and potentials the expanded BRICS will bring to the forefront, with the subsequent summit scheduled for Kazan in October 2024 serving as a platform for further exploration.

Agr International is set to showcase its innovative handheld measurement gauge, the ThicknessPen, during the upcoming Pack Expo Las Vegas event

This cutting-edge portable device has been meticulously designed to cater to a wide array of thickness measurement needs within the production environment. Whether utilized within a laboratory setting, on the bustling plant floor, or even in challenging wet conditions at remote job sites, the ThicknessPen proves to be an invaluable tool.

One of the standout features of this device is its patent-pending dual-mode functionality, which grants users the flexibility to operate with or without a target ball. This dual-mode capability not only sets it apart but also enhances its adaptability.

Agr emphasizes that this distinctive design balances the precision indispensable for laboratory applications with the mobility, sturdiness, and safety crucial for real-world production settings. BRICS Bio-Based Plastics

When operating in capacitance mode, the ThicknessPen performs single-sided measurements effortlessly through a “touch and go” approach, all without the need for a target ball. This mode caters especially well to scenarios within the plant, as well as situations where using a target ball might not be practical. This encompasses tasks along production lines and measurements involving oversized containers, buckets, thermoformed products, panels, sheet materials, and similar items.

In contrast, the magnetic mode necessitates the presence of a target ball during measurements. Nevertheless, this mode elevates precision to levels comparable to, if not surpassing, traditional hall-effect devices, all while boasting a simpler setup. Here, the device employs only a single target ball, circumventing the use of potent magnetic fields. The magnetic mode shines when gauging non-ferrous materials of all kinds, excelling in intricate measurements and assessments of heavy-walled containers.

What truly enhances the allure of the ThicknessPen is its versatility in application. Users have the option to employ the measurement gauge within its docking station for benchtop measurements. BRICS Bio-Based Plastics

On the other hand, the device can seamlessly function as a standalone, portable tool, facilitating critical measurements wherever they are required most urgently.

Enthusiasts and professionals eager to witness the capabilities of the ThicknessPen firsthand will have the opportunity to do so at Agr’s booth, conveniently located at SU-7459 within the Pack Expo Las Vegas event venue. This interactive demonstration promises to unveil the myriad ways in which this handheld gauge can revolutionize thickness measurements across diverse industries.

For those interested in delving further into Agr’s groundbreaking offerings, a visit to their exhibition area will undoubtedly prove insightful. Exploring their array of advanced solutions and technologies can provide a deeper understanding of the company’s commitment to pushing the boundaries of measurement and quality control.

In conclusion, the imminent debut of the ThicknessPen from Agr International at Pack Expo Las Vegas heralds a new era in portable thickness measurement devices. Its dual-mode functionality, combining capacitance and magnetic modes, ensures unmatched adaptability and precision. BRICS Bio-Based Plastics

Whether in laboratory conditions or on bustling production floors, this gauge promises to be an indispensable asset for a wide spectrum of industries. Experience its capabilities firsthand by visiting Agr’s booth at the event and discover how the ThicknessPen is set to redefine thickness measurement standards.

Exploring Innovations in Bio-Based Plastics for Sustainable Packaging

Welcome to an insightful exploration of the transformative world of bio-based plastics, poised to revolutionize the packaging industry through their sustainable attributes. Derived from resources like vegetable oils, corn, and starches, these eco-friendly alternatives are shifting paradigms in packaging design and material choices.

In collaboration with Packaging World, the Emerging Brands Alliance presents “Sustainable Packaging Explained,” an informative guide to sustainable materials, methodologies, and package design. Today, our journey takes us into the dynamic realm of bio-based plastics, uncovering their advantages, challenges, and applications in the packaging sector.

One of the most remarkable features of bio-based plastics is their unique ability to sequester carbon rather than emit it, thus contributing positively to the environment. Furthermore, the continued advancements in developing bio-based plastics with properties akin to petroleum-based plastics have paved the way for “drop-in” replacements. These innovative materials can now be seamlessly integrated into existing recycling streams, promoting a circular economy and reducing environmental impact.

Let’s explore the real-world applications of these sustainable solutions.

In 2021, Frito Lay introduced an industrially compostable bag for its ‘Off The Eaten Path’ chip brand. BRICS Bio-Based Plastics

This breakthrough marked a significant stride in the pursuit of compostable packaging materials. In 2022, global giants Coca-Cola and Suntory demonstrated their commitment to sustainability by unveiling beverage bottle prototypes crafted entirely from 100% bio-based PET. These trailblazing initiatives signify a shift towards materials that are both functional and environmentally responsible.

Reflecting on the past, we recall the pioneering yet ill-fated attempt by PepsiCo’s Frito-Lay division in 2010 with its SunChips brand’s compostable bioplastic bag. Despite the initial challenges, PepsiCo persisted in its mission to create a viable alternative to conventional single-use snack bags. This persistence bore fruit in the form of an industrially compostable bag for the ‘Off The Eaten Path’ chip brand. The collaboration between Frito-Lay and Printpack resulted in a bag primarily composed of 85% PLA (polylactic acid) derived from proprietary, non-food plant-based materials. Notably, noise reduction features were incorporated to address the infamous crinkling noise associated with compostable bags. BRICS Bio-Based Plastics

Coca-Cola and Suntory’s endeavors stand as monumental achievements. After over a decade of rigorous research and substantial investments, both companies unveiled pioneering beverage bottle prototypes crafted entirely from 100% bio-based PET. Coca-Cola’s breakthrough included the utilization of wood-based biochemicals for producing bio-based Monoethylene Glycol (bMEG), heralding a new era in sustainable packaging. Not long after, Suntory revealed its successful creation of a prototype bPET bottle, utilizing non-food feedstocks like wood chips, thus sidestepping any competition with the food supply chain.

The reach of bio-based plastics extends beyond beverages, penetrating diverse sectors including food, cosmetics, and personal care products. Futamura’s NatureFlex cellulose, designed to replace fossil-based plastics, offers a biodegradable alternative that can be safely composted at home. Canadian pharmaceutical brand Jones Healthcare Group embraced bio-plastics, launching three blister packs with foil-free backings to facilitate recycling. BRICS Bio-Based Plastics

However, bio-based plastics face a series of challenges, including production costs, compatibility with existing packaging machinery, and concerns about diverting food resources for plastic production. While these hurdles exist, the benefits of bioplastic packaging, such as recyclability and biodegradability, cannot be ignored. As always, a comprehensive life-cycle analysis is essential to determine the suitability of bio-based packaging for specific applications.

As we conclude this exploration, we invite you to join us on a continued journey towards sustainable packaging practices. Subscribe to our YouTube channel for more enlightening content on packaging and operational scalability. Additionally, become a part of the Emerging Brands Alliance, where year-round resources await to nurture the growth of your brand within the realm of sustainability and innovation.

Thank you for joining us on this transformative expedition into the realm of bio-based plastics and sustainable packaging. BRICS Bio-Based Plastics

Viridor shuts down polymer recycling facility in the UK

Viridor, a prominent UK-based plastic recycling entity under the ownership of the U.S. investment firm KKR, has made the strategic decision to close its polymer recycling facility situated in Skelmersdale, a town in the northern region of England. Although the cessation of operations at this facility transpired in January 2023, this development has only recently come to light with the publication of Viridor’s comprehensive financial report for the fiscal year 2022/2023.

The released report reveals that the company’s actions stem from a meticulous evaluation of its business operations, coupled with the escalating performance achievements at the Avonmouth polymers facility. As a consequence of this analysis, Viridor chose to halt operations at its Skelmersdale polymer facility during the aforementioned financial year. Notably, the Avonmouth resource recovery center, inaugurated in March 2022, has played a pivotal role in Viridor’s strategic landscape. BRICS Bio-Based Plastics

Functioning as a co-located hub for plastic reprocessing and energy reclamation via waste incineration, the Avonmouth facility possesses an impressive annual processing capacity exceeding 80,000 tons. In tandem with this capacity, the facility harnesses an energy output ranging from 70 GWh to 105 GWh annually.

Despite the unfolding developments, Viridor declined to provide commentary on the matter when approached by Sustainable Plastics for insight. Nonetheless, the company’s official financial report for the fiscal year 2022/2023 sheds light on their rationale. Viridor cites its commitment to an ambitious polymers strategy that aspires to transform the company into a fully circular plastics recycling and reprocessing enterprise by the year 2025.

The decision to shutter the Skelmersdale facility is aligned with this forward-looking strategy. BRICS Bio-Based Plastics

It’s important to underscore that the discontinuation of operations at the Skelmersdale facility hasn’t exerted any discernible impact on Viridor’s financial performance indicators. As indicated in the financial report, this strategic maneuver hasn’t influenced the overall loss sustained during the fiscal year, nor has it influenced key financial statements such as the consolidated statement of comprehensive income, the consolidated statement of financial position, or the consolidated statement of changes in equity. The company elucidates that this decision primarily constitutes a change in presentation, involving the reclassification of specific line items within the consolidated income statement and adjustments to the cash generated from operations, as documented in the consolidated statement of cash flows.

Viridor’s recent action follows closely on the heels of its financial statement for the fiscal year 2021/2022, wherein its subsidiary Viridor Polymers reported a loss of GBP 13 million. This financial setback prompted a reevaluation of the company’s operational landscape.

In a remarkable turnaround, Viridor managed to achieve a commendable overall profit amounting to GBP 167.2 million in the subsequent fiscal year 2022/2023.

During this period, the company facilitated the recycling of over 86,000 tons of plastic, building on the momentum from the recycling of more than 85,000 tons in the preceding year, 2022. BRICS Bio-Based Plastics

In conclusion, Viridor’s strategic decision to cease operations at its Skelmersdale polymer recycling facility underscores the company’s commitment to reshaping its polymers strategy in alignment with its circular plastics recycling and reprocessing vision. This move, illuminated by the company’s comprehensive financial report, reflects the increasing emphasis on optimized performance at its Avonmouth facility. Notably, this strategic shift has transpired without significant ramifications on Viridor’s financial standing, culminating in an impressive overall profit amidst their endeavors to remain at the vanguard of sustainable plastics management.

Transformation of Plastic and Cardboard Beverage Packaging Collection System in Switzerland: A Step Towards Circular Economy

Switzerland is gearing up for a significant shift in the management of plastic and cardboard beverage packaging. The nation is moving towards a unified collection system and embracing a closed-loop approach, aimed at fostering a more circular economy. Known as “Collection 2025,” this groundbreaking initiative has garnered support from approximately seventy companies and organizations within the packaging supply chain. This coalition includes major brands, distributors, retailers, prominent supermarket chains, recyclers, as well as waste transport and management entities. BRICS Bio-Based Plastics

Swiss Recycling, a prominent advocate for recycling in Switzerland, is spearheading the effort. The central objective of Collection 2025 is to introduce a standardized collection bag that will be adopted nationwide. This bag will be uniform in terms of color, size, and messaging. The purpose of this bag is to streamline the gathering of around 110,000 tonnes of plastic and cardboard liquid packaging that enters the Swiss market each year. Complementing this effort will be a consistent tariff system, coupled with a nationwide communication campaign to educate and engage the public.

The financial framework for this ambitious collection and recycling system is set to be hybrid, relying on three primary pillars. First, funding will be sourced from the sale of waste bags. Second, distributors will be required to make a financial contribution to the system. Finally, revenue generated from the sale of recycled materials will play a vital role in sustaining the initiative. This multifaceted approach aims to comprehensively cover all expenses, ranging from the collection and sorting stages to the final recycling of waste.

The vision of the stakeholders is to have this system fully operational by 2030, overseen by a coordinating body that ensures its seamless functioning. The ultimate target of Collection 2025 is to recycle a minimum of 55% of plastic packaging and 70% of beverage cartons. These targets align harmoniously with the mandates of the novel EU legislation designed to bolster sustainability efforts across the region. BRICS Bio-Based Plastics

The endeavor holds great promise for Switzerland’s environmental landscape. By establishing a unified collection mechanism, the nation is poised to significantly increase its recycling rates and mitigate the environmental impact of plastic and cardboard waste. Through the adoption of a closed-loop system, materials will be repurposed, reducing the demand for virgin resources and minimizing the ecological footprint.

Collection 2025 stands as a testament to Switzerland’s commitment to innovation and sustainability. With widespread collaboration among key players in the packaging industry, the nation is embarking on a transformative journey towards a more circular and eco-friendly future. BRICS Bio-Based Plastics

As the initiative gains momentum and the proposed changes take shape, Switzerland is likely to set an inspiring example for other countries striving to enhance their waste management practices and embrace the principles of a circular economy.

Chemical recycling tracker

The following is a time chart tracking the chemical recycling innovations and investments announced within the plastics industry.

Details include a brief description along with a link to read more about each announcement.

The following is a time chart tracking the chemical recycling innovations and investments announced within the plastics industry. BRICS Bio-Based Plastics

Details include a brief description along with a link to read more about each announcement. Sustainable Plastics will continue to follow and log these developments as they evolve. To help keep us up to date, we invite you to send your announcements, information or news to Sustainable Plastics, at klaird@crain.com and beatriz.santos@crain.com

EQUATE Declares September 2023 MEG India Contract Price at $474/tonne CFR

EQUATE, a prominent player in the worldwide monoethylene glycol (MEG) production sector, has unveiled its nominated MEG India Contract Price (ICP) for September 2023. The company’s announcement places the ICP at $474 per tonne CFR (cost & freight), applicable to India Main Ports.

In comparison to the preceding month, this September nomination exhibits a marginal increase of $2 per tonne. This adjustment reflects the company’s responsive approach to the dynamic nature of market conditions and its commitment to ensuring a consistent supply of MEG.

EQUATE’s pivotal role as a global MEG producer underscores its influence in shaping the pricing landscape. MEG, a vital chemical compound with diverse industrial applications, is a key component in the production of various commodities ranging from textiles to packaging materials. BRICS Bio-Based Plastics

The deliberation behind setting the MEG ICP involves a comprehensive analysis of multiple factors. Market trends, availability of feedstock, demand-supply dynamics, and geopolitical influences collectively contribute to the determination of this price point. EQUATE’s strategic decision to peg the September ICP at $474/tonne CFR demonstrates a strategic balance between maximizing profitability and upholding customer relationships.

This incremental uptick from August’s figure illustrates the complex interplay between global economic shifts and industrial intricacies. As the MEG industry continues to evolve, such price notifications not only reflect EQUATE’s commercial acumen but also the intricate web of factors that define the modern economic landscape.

In conclusion, EQUATE’s declaration of the MEG India Contract Price for September 2023 elucidates the company’s proactive pricing strategy in a multifaceted market. The modest increase from the previous month underscores EQUATE’s adaptability and its dedication to facilitating stable MEG supplies to its valued customers in India. BRICS Bio-Based Plastics

BRICS Bio-Based Plastics