Chemical recycling biopolymers – Can the fashion industry move from recycled bottles to reused threads? 31-08-2023 - Arhive

Chemical recycling biopolymers

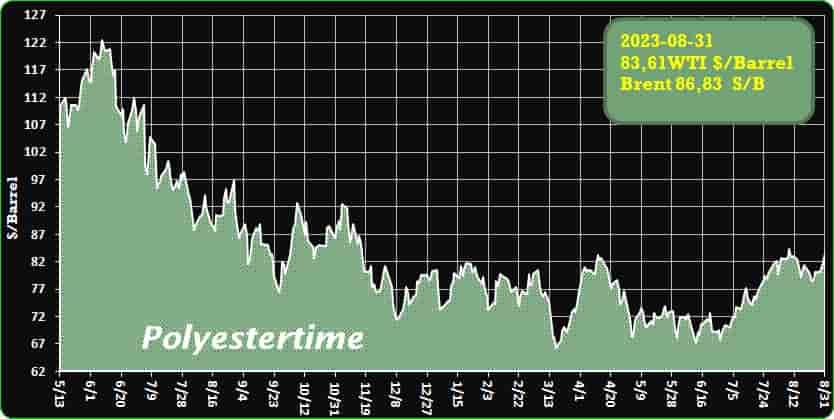

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Amcor and Mondelēz International, two major players in the global packaging industry, have taken a significant stride towards advancing the construction of an Australian chemical recycling plant

This groundbreaking facility harnesses the innovative Catalytic Hydrothermal Reactor (Cat-HTR) technology developed by Australia-based Licella, heralding a new era in sustainable plastic waste management.

Amcor, headquartered in Australia, had previously solidified its commitment by signing a Memorandum of Understanding (MOU) with Licella Holdings in December 2022. This strategic move paved the way for investments that would contribute to the realization of Licella’s first advanced recycling facility in Australia. Although similar projects employing Licella’s technology are already nearing completion in Canada and the UK, this Australian plant—named Advanced Recycling Victoria—holds the promise of being a vital cornerstone in the global effort to combat plastic waste.

The Cat-HTR technology, a form of hydrothermal liquefaction (HTL), revolves around subjecting ‘unrecyclable’ end-of-life plastics to high temperatures and pressures within water-based environments. This transformative process converts these plastics into a crude oil substitute, which can subsequently be utilized to manufacture new food-grade plastic packaging. By reimagining the potential of plastics that would otherwise end up in landfills or polluting the environment, Cat-HTR offers a revolutionary approach to plastic recycling. Chemical recycling biopolymers

The planned Australian facility is slated to initially process around 20,000 tons of end-of-life plastic annually, with ambitious plans to scale up its capacity to an impressive 120,000 tons per year. This scaling up of operations underscores the urgency and commitment behind addressing the plastic waste crisis. Amcor’s Vice President of Corporate Venturing and Open Innovation, Frank Lehmann, highlighted the company’s recognition of its role within the circular economy. The partnership with Licella amplifies Amcor’s ability to provide innovative solutions, aligning with the objectives of its customer Mondelēz International.

The collaboration between Amcor, Mondelēz International, and Licella stands as a testament to the potential of industry leadership in driving sustainability initiatives. Through this partnership, Mondelēz International gains access to the recycled output of the plant via Amcor, which in turn allows the company to significantly reduce its reliance on virgin plastic for soft packaging in Australia. The move is especially crucial given the existing gap in sustainable local recycling solutions, as emphasized by Christine Montenegro McGrath, Senior Vice President and Chief Global Impact and Sustainability Officer at Mondelēz International. Chemical recycling biopolymers

Mike Cash, President of Amcor Flexibles Asia Pacific, highlighted the investment’s dual benefits of meeting growing customer demands for recycled content and contributing to Amcor’s overarching goal of achieving 30% recycled content across its portfolio by 2030. The collaboration is poised to propel Amcor’s sustainability commitments forward while also capitalizing on the surging demand for eco-conscious products.

Dr. Len Humphreys, the CEO of Licella, stressed the critical role of industry leadership in propelling Australia toward sustainable plastic waste solutions. He underlined that this investment not only advances Licella’s Australian facility but also addresses the increasing demand for sustainable plastic alternatives that align with both economic and environmental goals.

In a recent development, Dr. Len Humphreys, a co-founder and co-inventor of the Cat-HTR platform, announced changes within Licella’s senior leadership team and board. After 16 years as CEO, he will transition to the role of Executive Chairman, signifying his continued commitment to Licella’s global commercialization efforts. Alan Nicholl, the current Managing Director of Licella, is set to assume the position of CEO, effective from September 1, 2023. Furthermore, the company is expanding its leadership team with appointments such as Don DeFosset as a non-executive director on Licella’s board and Victoria Sherwood as the Executive General Manager – Asia & Australasia, a newly created role.

In conclusion, the strategic investments from industry giants Amcor and Mondelēz International in Licella’s cutting-edge Cat-HTR technology signify a pivotal advancement in sustainable plastic waste management. The establishment of the Advanced Recycling Victoria facility in Australia holds the promise of transforming ‘unrecyclable’ plastics into a valuable resource for new packaging, contributing to the global drive for a more sustainable future. Through innovative solutions and collaborative efforts, these companies are shaping a circular economy that prioritizes both economic growth and environmental stewardship. Chemical recycling biopolymers

Ampacet Unveils ProVitalTM+ Permstat: Advanced Medical-Grade Permanent Antistatic Masterbatch

Ampacet, a prominent global leader in masterbatch solutions, has launched ProVital+ Permstat, an innovative non-migratory antistatic masterbatch meticulously designed to confer enduring and immediate antistatic characteristics to polyolefin films utilized in pharmaceutical operations.

The scene depicts the operation of an automated plastic bag production machine illuminated by a gentle glow. The focus is on the intricate mechanism of the machine’s roller set against a backdrop of soft blue light.

By integrating Ampacet’s ProVital+ Permstat into the outer layers of packaging films, a dissipative polymeric network is established within the film’s core structure. This architecture facilitates the dispersion of electrostatic charges that accumulate on the film’s surface throughout the external layer. The antistatic efficacy is promptly noticeable, remains constant throughout the film’s lifespan, and endures as long as the film is in service. Chemical recycling biopolymers

Notably, the remarkable dissipative attributes of ProVital+ Permstat enable effective evacuation of powders from packaging materials, mitigating the tendency of particles to adhere to bag interiors due to static forces. In hermetically sealed bags, the application of ProVital+ Permstat obviates the occurrence of static-induced powder accumulation in the sealing region. This revolutionary masterbatch can seamlessly integrate into polyethylene cleanroom films, commonly employed for safekeeping and conveyance of pharmaceutical raw materials as well as active ingredients utilized in drug synthesis.

ProVital+ Permstat guarantees the unvarying uniformity of its formulation, maintaining an unalterable raw material policy at both the CAS and commercial levels. Manufacturing adheres to consistent process parameters, and production within controlled environments minimizes potential risks of cross-contamination.

For additional insights into the Ampacet ProVital+ product line, please reach out via email to marketing.europe@ampacet.com.

The BRICS and the Quest for De-Dollarization: A Complex Endeavor

The recent summit of the BRICS nations – Brazil, Russia, India, China, and South Africa – concluded with both optimism and challenges surrounding the much-discussed notion of de-dollarization in international payment transactions. The objective of liberating the Global South from the dominance of the American dollar remained elusive, revealing the intricate nature of the task at hand. The aspirations for an alternative system encountered hurdles, leading to a different focus: enhancing trade in local currencies instead.

The summit’s culmination in Johannesburg, South Africa, saw the leaders of BRICS announce their intention to task their finance ministers with exploring matters related to local currencies, payment instruments, and platforms.

While the de-dollarization agenda held particular significance for Russia, mired in economic hardship due to Western sanctions and exclusion from the Swift system in the aftermath of the Ukraine invasion, the African continent’s economic interactions also factored into the equation. Chemical recycling biopolymers

Russia’s motivation for pursuing de-dollarization stemmed from both geopolitical and economic pressures. South Africa’s Finance Minister Enoch Godongwana clarified that the BRICS group aimed not to replace existing international payment systems like Swift, but rather to establish a mechanism that would facilitate trade in local currencies. However, the creation of a unified BRICS currency, a proposal raised by Brazil’s then-President Luiz Inacio Lula da Silva, did not find a place on the summit’s agenda.

The complexity of the de-dollarization endeavor became apparent through discussions. Establishing an anti-dollar system would necessitate creating a central bank, which, in turn, would potentially compromise countries’ monetary policy independence. South Africa’s specific context highlighted this challenge, given constitutional implications and the intricate ties to raw material transactions in dollars, both within South Africa and across the broader African continent. Chemical recycling biopolymers

The prospect of a circulating currency akin to the dollar or the euro was deemed overly ambitious and was not pursued. Instead, the focus shifted toward a currency of account, analogous to the European Currency Unit (ECU) used before the adoption of the euro. President Cyril Ramaphosa of South Africa emphasized the importance of collective action to advance the interests of the African continent, which has often been subjected to exploitation and devastation.

The enduring dominance of the American dollar, established through institutions such as the IMF and the World Bank, appears increasingly outdated and disconnected from the evolving multipolar reality. While the notion of undermining dollar hegemony gains traction, the journey toward a unified BRICS currency remains largely theoretical and intricate. Notably, these countries still predominantly conduct their commodity transactions in dollars or euros.

Against the backdrop of geopolitical dynamics, a potential BRICS currency could primarily serve Russia’s efforts to alleviate financial isolation. Yet, the summit revealed a measured response to Russia’s actions in Ukraine, with limited support for President Vladimir Putin. South Africa’s stance demonstrated the balance between internal and international affairs. For African nations, however, the idea of a BRICS currency resonates, particularly in the face of weakening local currencies, shortages of hard currency, and the escalating interest rates on public debt. Chemical recycling biopolymers

Amid these challenges, the pursuit of alternatives to the dollar gains momentum in Africa. The continent grapples with a chronic dearth of hard currency for international transactions, prompting discussions about a pan-African payment system that could facilitate trade within the continent. At the African Free Trade Area Summit in Nairobi, Kenyan President William Ruto urged his counterparts to initiate steps toward moving away from the US dollar, fostering the creation of a unified payment framework.

Ruto’s call to mobilize central and commercial banks for a pan-African payment system marks a decisive step toward charting a new course for the continent’s economic interactions. The aspiration for de-dollarization, though complex and fraught with challenges, underscores the determination of emerging economies to reshape the global economic landscape and diminish the stranglehold of established financial norms. As discussions continue and initiatives unfold, the BRICS countries, along with their African counterparts, navigate the intricate path toward a more multipolar and equitable international financial system. Chemical recycling biopolymers

MBA Polymers UK, a pioneering force in plastics recycling, has unveiled an ambitious expansion plan that involves the inauguration of a state-of-the-art plastics recycling facility in Wimblington, Cambridgeshire

The strategic move aligns seamlessly with the company’s overarching growth strategy and propels it closer to realizing its ultimate aspiration: the establishment of a comprehensive nationwide plastic recycling network that caters to the surging customer demand for environmentally conscientious, low-carbon products. This latest addition stands as MBA Polymers UK’s fourth operational site within the UK, complementing its original Worksop site in Nottinghamshire, a strategically acquired separation line in Dover in 2019, and the inception of the Duddeston site in West Midlands in 2022.

Forefront in MBA Polymers’ vision is the pursuit of attaining a prodigious production capacity of 100,000 tonnes of recycled plastics by 2030, catering effectively to the evolving needs of its clientele. Chemical recycling biopolymers

The company is steadfast in its mission to rescue plastic materials destined for landfill, employing a decade’s worth of technological innovations and expertise to engineer sustainable, recycled plastics that showcase an astounding carbon reduction of up to 85% when juxtaposed with their virgin counterparts. A testament to their unwavering commitment, over the course of the past ten years, MBA Polymers UK has successfully diverted a staggering 250,000 tonnes of plastic waste away from the confines of landfills, championing a more responsible approach to waste management.

However, the significance of this expansion surpasses mere quantitative measurements. Beyond the evident reduction in the necessity to transport feedstock across extensive distances, this enlargement empowers MBA Polymers UK to elevate its capacity to deliver a higher quantum of recycled polymers, aligning precisely with the burgeoning demand from its discerning customer base. Moreover, this strategic augmentation aptly accommodates the organization’s expanding product portfolio, particularly in the realm of color variety, a vital attribute in the dynamic landscape of plastics application.

Paul Mayhew, the accomplished General Manager of MBA Polymers UK, aptly articulates the far-reaching implications of this new establishment: “The integration of our fourth operational site will substantially augment our recycling capabilities by a commendable 35%, signifying the diversion of vast quantities of plastic waste from landfills. This, in turn, enables us to channel premium-grade recycled polymers back into the circular economy, amplifying the virtuous cycle of sustainability.” Chemical recycling biopolymers

MBA Polymers UK has solidified its position as a preeminent supplier of robust, high-quality plastics, encompassing an array of variants like rPP, rPE, rPS, and ABS. These materials find their application across diverse sectors, including but not limited to electronics, automotive manufacturing, and logistics management. Noteworthy is the remarkable environmental impact of these materials, contributing to carbon savings ranging from 75% to an impressive 86%. Such an accomplishment has earned them the distinct privilege of being the first recycled plastics to be bestowed with the coveted Low CO2 certification from the Carbon Trust.

Anticipated to commence operations in September 2023, the Cambridgeshire plant stands as a beacon of progress, poised to generate a manifold of 23 new employment opportunities. This expansion is not merely an augmentation in physical terms; it symbolizes MBA Polymers UK’s unwavering dedication to fostering a greener, more sustainable future, one polymer at a time. Chemical recycling biopolymers

Advancing Towards Sustainable Plastic Alternatives: Navigating a Complex Landscape

In an era marked by convenience and rapid technological progress, the transformative impact of plastics on modern life cannot be understated. The sheer versatility of their applications has catalyzed industrial and economic growth. Yet, the widespread use of plastics has given rise to a profound environmental predicament. As the detrimental consequences of plastic waste become increasingly evident, the imperative to discover sustainable alternatives gains urgency. This urgency has spurred exploration into the realm of bio-based and oxo-degradable plastics as potential solutions, backed by a mounting body of research and empirical evidence. By delving into the intricate complexities of these two categories, a more nuanced understanding emerges of the realities and challenges that underpin their pivotal roles in shaping the trajectory of plastics in the years to come. Chemical recycling biopolymers

The global demand for plastics has undergone a meteoric rise since the mid-20th century, resulting in an unprecedented surge in environmental pollution. Plastic waste, now ubiquitous in oceans and landfills, poses multifaceted threats to ecosystems, economies, and public health. The cumulative emissions stemming from plastic production, processing, and disposal released a staggering 1781 million metric tons of CO2 equivalents into the atmosphere in 2015. This alarming figure is projected to balloon to an astonishing 6500 million metric tons by 2050 if trends persist. Notably, the production of fossil fuel-derived plastics soared from a mere 2 million tons in 1950 to a staggering 454 million tons in 2018, reflecting an insatiable appetite for convenience and functionality. Astonishingly, humanity generated an astounding 9.7 billion tons of plastics between 1950 and 1980 alone, a quantity predicted to double by 2025 and triple by 2050.

Within this broader context, the challenges faced by individual nations serve as potent reminders of the global urgency to tackle plastic waste. Pakistan, for instance, discards over 3.3 million tons of plastic annually, underscoring the magnitude of the issue. The management of plastic waste presents not only infrastructural hurdles but also intricate behavioral challenges. While policies like the ban on single-use plastic bags are commendable, they often overlook the complex interplay of human behavior. In countries like Pakistan, which generated approximately 3.9 million tons of plastic waste in 2020, a deeper comprehension of behavioral motivations is imperative. The success of such policies hinges on addressing underlying behaviors and fostering a sense of ownership among the population. Chemical recycling biopolymers

In the face of the deluge of plastic waste, a paradigm shift is underway as society grapples with the necessity of a sustainable plastic economy. This transition heralds the emergence of bio-based plastics, heralded as innovative breakthroughs in the realm of plastics. Unlike their fossil fuel-derived counterparts, bio-based plastics derive from renewable sources, ranging from plant-based constituents to microorganisms and algae. This shift towards renewable feedstocks marks a significant departure from the finite and ecologically taxing nature of fossil fuels.

Among these alternatives, starch-based polymers have emerged as particularly transformative contenders. Starch, a ubiquitous carbohydrate sourced from crops like corn and potatoes, offers a potential blueprint for reshaping the landscape of biopolymers. Researchers have ingeniously addressed inherent limitations such as brittleness and suboptimal mechanical properties. The blending of starch with biopolymers like polylactic acid (PLA) and polycaprolactone (PCL) paves the way for a symbiotic synthesis of attributes. This strategic amalgamation not only enhances mechanical properties but also expands the spectrum of applications, spanning from single-use plastics to cutting-edge food packaging solutions.

Polylactic acid (PLA), an exemplar of synthetic biopolymers, encapsulates the fusion of innovation and sustainability. Derived from starch materials, PLA boasts biodegradability, non-toxicity, and a significantly reduced carbon footprint. Its mechanical characteristics mirror those of conventional plastics, positioning it as a formidable eco-conscious substitute across a diverse range of applications, from disposable cutlery to intricate medical devices. Chemical recycling biopolymers

However, the significance of PLA transcends its material attributes, embodying a profound shift towards plastics sourced from renewable and natural origins, thereby contributing to the critical endeavor of mitigating greenhouse gas emissions.

Polycaprolactone (PCL), a biodegradable thermoplastic polyester, serves as a testament to the potency of strategic blending in polymer design. With attributes like superior heat processability and low viscosity, PCL presents an attractive material choice. Nonetheless, its isolated application encounters challenges due to weak barrier and mechanical properties. The skillful integration of PCL with materials like cellulose acetate sulfate and polyacetic acid offers a solution to these hurdles. This approach underscores the profound significance of holistic material engineering, where the synergistic interactions among components surpass the sum of their individual contributions.

The narrative of bio-based plastics expands with the introduction of polyhydroxyalkanoates (PHAs), a family of biodegradable thermoplastic polyesters derived from bacterial synthesis. These nature-inspired plastics, stored within bacteria as intracellular carbon and energy reservoirs, epitomize the elegance of natural polymerization processes. Within this family, polyhydroxybutyrate (PHB) stands out, boasting remarkable mechanical properties akin to polyethylene. Importantly, PHB holds great potential in food packaging due to its melting point proximity to PLA, enabling fusion in their molten states. As the world confronts the challenge of plastic waste, PHAs offer a glimpse into nature-inspired solutions that can coexist harmoniously with ecosystems.

While bio-based plastics pave the way toward a more environmentally conscious future, oxo-degradable plastics emerge as intriguing yet contentious alternatives.

Marketed as a bridge between conventional plastics and biodegradable options, these plastics undergo oxidative fragmentation, ostensibly hastening their degradation.

However, the rapid breakdown poses a significant predicament—fragmentation into micro-sized particles. Chemical recycling biopolymers

If not meticulously managed, these particles risk exacerbating the microplastic pollution crisis and endangering ecosystems. The discourse surrounding oxo-degradable plastics hinges on a delicate equilibrium between biodegradation and fragmentation. While these plastics exhibit accelerated disintegration, questions persist about the comprehensiveness of biodegradation, especially without molecular weight reduction. Furthermore, understanding the marine ecosystem’s response to fragmented plastics remains an ongoing area of research, necessitating a holistic grasp of potential ecological ramifications.

In the intricate fabric of plastics, the journey toward sustainability is a multi-dimensional odyssey guided by robust research, innovative technology, and a collective commitment to change. The challenges extend beyond technical innovations, encompassing behavioral shifts, systemic waste management transformations, and holistic policy implementations. As society stands at the crossroads, choices become pivotal, their echoes resonating through generations. Data-driven insights serve as guiding stars, steering humanity toward a more harmonious and sustainable coexistence with our planet.

The intricate dance of bio-based and oxo-degradable plastics encapsulates the complexity of the plastic predicament. These innovative alternatives offer a potential respite from the ecological toll of conventional plastics, yet they are not panaceas. The transition to a sustainable plastic economy demands a comprehensive approach encompassing material science, behavioral change, policy reform, and societal engagement. As we forge ahead, empowered by data and fueled by collective determination, we inch closer to a future where plastics coexist harmoniously with the planet. Chemical recycling biopolymers

In the relentless pursuit of alternatives to single-use plastics, a profusion of innovative ideas has sprouted, aiming to revolutionize consumption patterns and waste management systems. From advanced materials to transformative business models, these concepts possess

BOPP Film fibre-to-fibre – High-quality recycling loops are best for circular economy 30-08-2023

Chemical recycling biopolymers