Enzymatic technologies – Indorama IVL 06-03-2023 - Arhive

Enzymatic technologies – Indorama IVL

Petrochemicals – Bottle-PET – Ny66

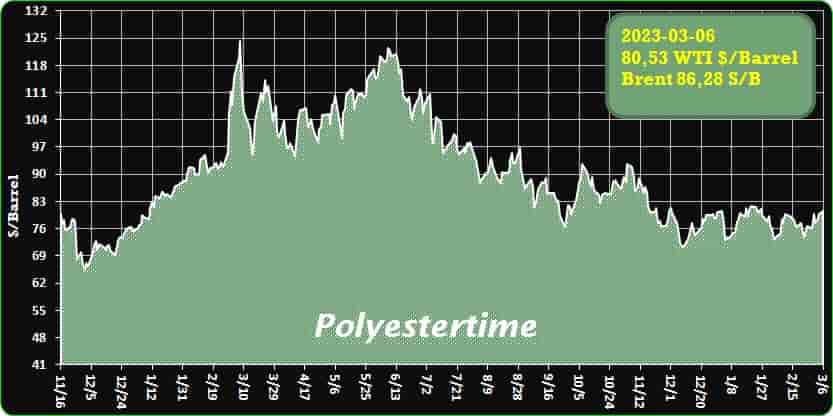

Crude Oil Prices Trend

Crude Oil Prices Trend

-Carbios doubles its number of granted patents in two years for its proprietary Ee

Carbios announced that it has doubled its number of issued patents since the last review published at the end of 2020.

Carbios (and its subsidiary Carbiolice) currently holds 336 titles worldwide divided into 53 patent families. In 2022, several titles protecting the proprietary PET-degrading enzymes were granted in countries of interest such as the United States and also in Asian countries including Indonesia, South Korea, China, Japan and India.

Carbios has also obtained grants within its patent families protecting the biodegradable plastics production process, notably the masterbatch containing the enzyme or its production process. Enzymatic technologies – Indorama IVL

“Over the past two years, we have mainly focused on strengthening the protection of our PET biorecycling process and its proprietary enzymes,” commented Lise Lucchesi, Director of Intellectual Property at Carbios. “For the coming years, we will continue to consolidate the protection of this process, and that of our PLA biodegradation process, by filing new patent applications. We will also actively follow up on our filed patent applications in order to obtain granted patents.”

-First PET Bottle-to-Bottle Recycling Line in Kenya

T3 (EPZ) Limited, a member of Megh Group, ordered a Starlinger Recostar PET bottle-to-bottle recycling line for its new plant in Athi River, Kenya.

Driven by the need to stop pollution of the environment in the country, preserve natural resources, and increasing awareness about the benefits of recycling, the market for recycled PET in Kenya is growing.

Megh Group company T3 (EPZ) Limited is going to install the first PET recycling system for bottle-grade rPET and resin in Kenya and Eastern Africa, a Starlinger recoSTAR PET 165 HC iV+ recycling line, in Athi River just outside Nairobi. Enzymatic technologies – Indorama IVL

The food-safe rPET will be used in bottle preform production and for polyester fibre production in the textile and garment industries as well as for the group’s automotive trims and textile business Megh Singh Cushion Makers.

T3 sources the post-consumer PET bottles for recycling through various collection strategies. Enzymatic technologies – Indorama IVL

With thorough collection and sorting methods and processing on the FDA and EFSA-approved Starlinger recycling system T3 ensures that the produced rPET resin will be of highest quality to meet the standards of global brand owners such as Coca-Cola.

“As we were trying to develop a project to produce our own textiles for the automotive sector, we realized that there is a big need for recycled materials in the textile and packaging industry”, explained Gurpreet Kaur Kenth, COO of T3.

-Mura’s HydroPRS technology 80% less carbon intensive than incineration

New study backs up the technology’s sustainability claims

Warwick Manufacturing Group (WMG) at the University of Warwick in the UK has published a peer-reviewed Life Cycle Assessment that analysed the environmental impact of using hydrothermal treatment to recycle waste plastics into a feedstock suitable for producing new plastics – the technology Mura Technology calls HydroPRS.

HydroPRS utilises supercritical water to convert post-consumer flexible, multi layered and rigid plastics into high yields of petrochemical feedstocks.

Among others, the study compared the use of hydrothermal treatment to dispose of plastic waste to incineration, the most common disposal route today for the hard-to-recycle films and flexibles that HydroPRS targets. Mura HydroPRS technology

It was found that, tonne for tonne, hydrothermal treatment of plastic waste yields an approximate reduction in carbon impact of 80%, compared to incineration. Furthermore, unlike incineration, chemical recycling via HydroPRS conserves the material within the system, leading to a reduction in consumption of fossil-based resource.

-Audi shows end-of-life vehicles offer a rich source of materials

MaterialLoop project tests circular economy potential of EOL vehicles

MaterialLoop, a project headed by Audi in which currently 15 participants from the research, recycling, and supplier sectors are taking part, aims to explore the development of a more sustainable approach to end-of-life vehicle recycling.Up to now, very few of the materials used in the production of new vehicles are recovered from scrapped cars. Steel, for example, usually ends up as structural steel after end-of-life vehicle recycling.

As part of its circular economy strategy, the company is now looking at the possibilities of reusing secondary materials taken from end-of-life vehicles and recycling them to build new cars. Saving valuable materials and reusing them for production, also reduces emissions and waste, lowering Enzymatic technologies – Indorama IVL

the vehicle’s environmental footprint. Within the scope of the MaterialLoop project, the partners are seeking solutions to avoid downcycling, which inevitably leads to a lower material quality. The project will run through April 2023.

-New plant to boost plastics recycling

On Friday, March 3, 2023, the groundbreaking ceremony was held for the new sorting plant, which is scheduled to go into operation at the beginning of 2024. In Ennshafen, Upper Austria, Altstoff Recycling Austria AG (ARA), Bernegger GmbH and Der Grüne Punkt Holding GmbH & Co KG are building a high-tech sorting plant for lightweight packaging.

With a sorting capacity of 100,000 tons per year, the facility is three times larger than existing plants in Austria. The new sorting plant can cover 50% of Austria’s lightweight packaging sorting capacity. The cross-border recycling partnership of ARA, Bernegger and Der Grüne Punkt is thus an important step for the European circular economy and a milestone for plastics recycling in Austria. Enzymatic technologies – Indorama IVL

As part of a strategic partnership, ARA, Bernegger and Der Grüne Punkt are building a sorting facility for lightweight plastic and metal packaging. With the groundbreaking ceremony today on March 3, 2023, construction work on the high-tech sorting plant will now begin. “The adapted recycling targets of the EU Circular Economy Package require a fundamental increase in collection as well as a significant improvement in sorting depth. With this state-of-the-art sorting plant, we are ideally equipped to handle the increasing volumes of waste and raw materials,” explains ARA CEO Martin Prieler.

The yield of collected lightweight packaging can be strongly increased in the new sorting plant. The current plant infrastructure in Austria ensures a sorting depth of 58% for plastic packaging ; the plant from ARA, Bernegger and Der Grüne Punkt is expected to achieve 80%. Enzymatic technologies – Indorama IVL

The sorting capacity of the plant is essential for achieving the recycling rates for plastic packaging, which Austria must double from the current 25% to 50% by 2025. With the sorting capacity of 100,000 tons per year, the plant plays a key role in achieving the EU recycling target and can cover 50% of the required sorting capacity for lightweight packaging in Austria.

-Indorama Ventures outlines plan for disciplined, sustainable growth at Capital Markets Day

Indorama Ventures Public Company Limited (IVL), a global sustainable chemical producer, outlined its business strategy at its 2023 Capital Markets Day in Bangkok, including enhancing competitiveness and applying a disciplined and sustainable approach to new opportunities as demand for the company’s products continues to grow globally, said the company.

Since 2019 – a three-year period that included unprecedented pandemic-related disruptions – Indorama Ventures’ revenue grew 65% to a record USD18.7 billion in FY2022, while EBITDA rose 160% to $2.4 billion. The company forecast continued high demand for its diversified, global portfolio of products – more than 70% of which are used in daily consumer necessities that are resistant to economic downturns, including in packaging, clothes, tires, baby diapers, and chemicals used in shampoos.

Mr. Aloke Lohia, Indorama Ventures Group CEO, said “The company is developing and empowering the next generation of leaders with a ‘growth mindset’ as a cornerstone of a program to enhance competitiveness and create value through disciplined and sustainable growth.” Enzymatic technologies – Indorama IVL

“We are, and always will be a growth company, and we are embedding this entrepreneurial mindset into the next generation of leaders who can build agile, fast, precise and innovative businesses that can deliver value in an increasingly volatile world,” Mr Lohia said.