Global-plastic-treaty – PET preform 27-01-2023 - Arhive

Global-plastic-treaty – PET preform

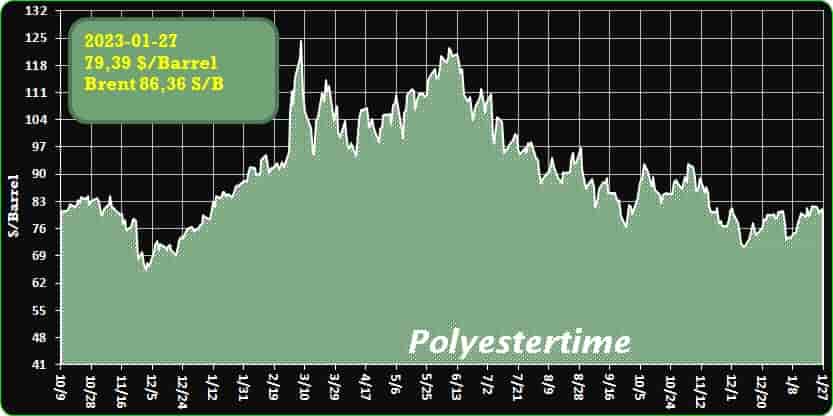

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-Toray Industries : Develops Recycled Nylon 66 Recovered from Silicone-Coated Airbags

Toray Industries, Inc., announced today that it has developed recycled nylon 66 recovered from silicone-coated airbag fabric scrap cuttings.

This material achieves the same flowability and mechanical properties as injection molding grades from virgin nylon 66.

The company created this product by combining particular additives with resin that REFINVERSE Group, Inc., recycled by stripping silicone from airbag fabric scrap cuttings. and thereafter washed. Global-plastic-treaty – PET preform

The new offering will debut as Ecouse AMILAN™. Toray looks for that offering to accelerate the expansion of Ecouse (pronounced Eco-Use), a proprietary integrated brand for eco-friendly recycled materials and products that it rolled out worldwide in 2015.

The nylon 66 fabric of airbags can be silicone-coated or non-coated.

Manufacturers normally recycle the scrap cuttings of non-coated fabrics. Recycling coated airbag fabric scrap cuttings requires removing the silicone. REFINVERSE was the first in Japan to achieve commercial-scale silicone-coated fabric recycling.

Recycling through stripping and washing has typically left silicone traces, however, degrading the resin and contaminating molds during injection molding. Another issue has been that the high viscosity of airbag yarn limits applications in thin-wall and other injection molding processes in which high fluidity is vital.

Toray accordingly combined particular additives so residual silicone resin would not migrate to the surface of molded products. It also greatly reduced mold adhesion. That is why the flowability and mechanical properties of recycled nylon 66 with Toray’s technique are on par with those of virgin nylon 66.

Toray plans to start full-fledged sample work in April 2023 or later. It ultimately looks to procure recycled raw materials at its overseas sites to establish a global supply system.

It will also explore commercializing recycled nylon 66 products made from airbags recovered from end-of-life vehicles.

The company has cultivated recycled plastic products derived primarily from post industrial scrap materials from in-house production processes, undertaking such efforts as recycling used air conditioner parts into new ones. It aims to extend recycling to used automotive parts and industrial equipment. Plastic-pollution-in-Asia

Toray intends to launch Ecouse TORAYCON™ as a chemically-recycled polybutylene terephthalate resin product that has properties equivalent to virgin materials. It will keep assessing material recycling and chemical recycling for its own polymers in driving to expand the Ecouse lineup by bringing out such products as Ecouse TOYOLAC™ acrylonitrile butadiene styrene, Ecouse TORELINA™ polyphenylene sulfide

One goal of the Toray Group Sustainability Vision is to help the world manage resources sustainably by 2050. It will keep catering to customer demand for eco-friendly resins to materialize its corporate philosophy of contributing to social progress by delivering new value. Global-plastic-treaty – PET preform

-Study shows bioplastic processing via AD reduces environmental impact

In Belgium, the study “Anaerobic digestion of organic waste allows recovering energy and enhancing the subsequent bioplastic degradation in soil” illustrates that the processing of bioplastics through anaerobic digestion contributes to prevent bioplastics accumulation and reduce their leakage into the environment.

According to the paper, the residual bioplastic remaining in the digestate, a co-product of biogas production used as organic fertiliser, does not accumulate in soils.

The figures show that bioplastics degrade between 50% and 70% in the soil after 120 days, and are fully biodegradable within less than two years. This digestate can therefore be used as fertiliser in agricultural soils without ecological risks.

In addition, the degradation of bioplastics via anaerobic digestion also contributes to the energy recovery of waste by producing renewable energy for our households and industries. Global-plastic-treaty – PET preform

-Would a global plastic treaty solve plastic pollution in Asia?

That depends on whether the region has an important seat at the treaty’s negotiating table, say experts at the World Oceans Summit.

A senior executive from recycling company Tomra said Asia needs to have greater representation at plastic treaty negotiations.to tackle plastic pollution in the region more effectively.

Also Annupa Ahi, who is Tomra’s vice president and head of public affairs, said, “If we want to make so much as a dent [in the global plastic problem], we have to solve Asia’s problems first and foremost. Plastic-pollution-in-Asia

-Sipa goes off-limits to maximise PET preform mould capabilities

There is a well-known rule of progression when it comes to cavitation in medium and large-sized PET preform molds: 72, then 96, 128, 144.

Sipa has demonstrated on numerous occasions that, with some clever hot runner configurations and ingenious tool engineering

This is perfectly possible to squeeze more cavities into a given mould space, with no loss of preform quality. Global-plastic-treaty – PET preform

Unconventional cavity numbers for better output/capital ratio

Think about a “workhorse” 72-cavity mould: this is considered a good choice for low-to-medium output production on a 250-tonne machine like Sipa’s Xform 250.

-Avantium, Henkel sign 5-year FDCA agreement

Henkel to develop adhesives with FDCA for electronic applications

Renewable chemistry company Avantium N.V. and Henkel, a leading manufacturer of, amongst others, adhesives, sealants and functional coatings, have signed a 5-year offtake agreement. Global plastic treaty – PET preform

So under this Avantium will supply Henkel with FDCA (furandicarboxylic acid) from the flagship plant that is currently under construction in Delfzijl, the Netherlands.

Production at the new facility – the world’s first commercial facility for the production of FDCA from plant-based sugars – is expected to commence in 2024.

Henkel and Avantium have been partners since 2019, when Henkel joined the PEFerence consortium; a multi-company initiative coordinated by Avantium to establish a viable supply chain for FDCA and PEF (polyethylene furanoate).

Other partners include, for example, Carlsberg, LVMH, Nestle Water and LEGO.Global-plastic-treaty – PET preform

As a participant in the consortium, Henkel tested the feasibility of FDCA for use in polyurethane adhesives. The positive outcome of those tests led to Henkel’s decision to further commercialise the development. The company now plans to market the new adhesives for use in electronic applications, such as consumer devices

The fact that, after LVMH and Carlsberg, yet another PEFerence partner has entered into an offtake agreement for FDCA is good news, according to Bineke Posthumus, Director of Business Development of Avantium Renewable Polymers.

“One of the benefits of working with such a diverse group of reputable companies within the PEFerence consortium is that it enables us to create new applications for FDCA and PEF.Global-plastic-treaty – PET preform

The decision of Henkel to use FDCA for polyurethane adhesives for use in electronics applications is a great example of the possibility to use our high-quality, plant-based chemical building block FDCA in various markets and applications,” she said.

-Closed Loop Partners, U.S. Composters and Composting Industry launch degradation tests for compostable packaging

The Composting Consortium, a collaboration of industry partners managed by Closed Loop Partners, has announced the launch of a new pilot designed to provide more in-depth insights into the compostability of compostable packaging.

It aims to improve available data on what happens to certified, food-contact compostable foodware and packaging at various types of composting facilities––from static piles to worms to GORE covers. Global-plastic-treaty – PET preform

Called the Compostable Packaging Degradation Pilot, the initiative is the most comprehensive collaborative study of real-world compostable packaging disintegration in the U.S. to date.

The facilities participating in the project include Ag Choice; Atlas Organics; Black Earth Compost; The Foodbank, Inc. of Dayton, Ohio; Happy Trash Can Curbside Composting; Napa Recycling; Specialized Environmental Technologies, Inc.’s Empire Facility; Veteran Compost and Windham Solid Waste Management. Global-plastic-treaty – PET preform

-Geminor and Quantafuel set up plastics recycling firm

Geminor and chemical recycling company Quantafuel ASA have established a plastics recycling company and aim to take a “leading position in the value chain for plastics” in the Nordics and the UK.

Named ‘Polynate’, the company’s “main operation” will be to supply Quantafuel’s existing facilities in Norway and Denmark and its planned facilities in the UK, waste fuel specialist Geminor said this morning (25 January).

Quantafuel, which owns a 40% stake in Geminor, said last year it hoped to have its 12-acre chemical recycling plant in Sunderland operational in 2024, subject to planning permission (see letsrecycle.com story). Global-plastic-treaty – PET preform

Kjetil Vikingstad, chief executive of Geminor, said: “Polynate will be an important contributor in the sustainable treatment and handling of international plastic waste.

“Establishing Polynate together with Quantafuel is strategically important for Geminor. Our ambition is to increase our market share and secure new downstream solutions for plastics.

Global-plastic-treaty – PET preform