Indorama-PET -PET-flake – HeiQ – PLA 18-11-2022 - Arhive

Indorama-PET -PET-flake – HeiQ – PLA

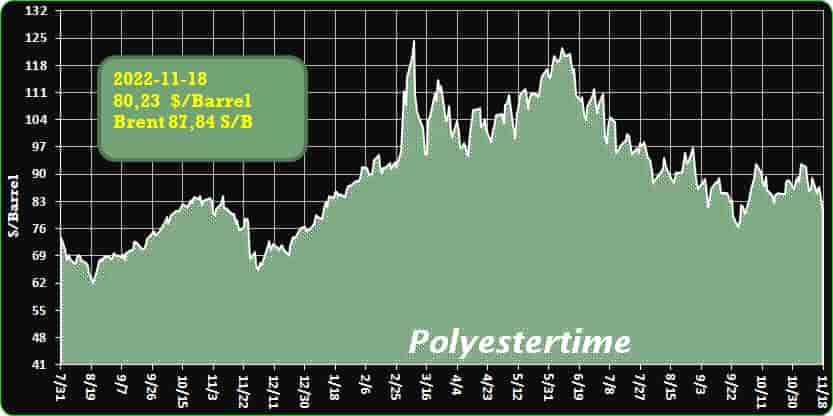

Crude Oil Prices Trend

-Indorama Ventures is considering the possibility of building a secondary PET production facility in Thailand

Indorama Ventures is considering building a second polyethylene terephthalate (R-PET) recycling plant in Thailand, the company said.

The company currently has one recycled PET plant in Thailand, which can produce up to 30,000 tonnes a year to make bottles and threads and fibers.

In mid-October this year, Indoramaopened aPET recycling facility in Cavite, Philippines, which is a joint venture with Coca-Cola Beverages Philippines (CCBPI).

Construction of a secondary PET plant in Indonesia is also ongoing, with a start-up date expected towards the end of 2023.

According to theScanPlast review, in August the total estimated consumption of PET in Russia for the reporting month amounted to 77.71 thousand tons, which is 15% higher than last year’s figure. In January-August of this year, the total estimated consumption of PET decreased by 2% compared to the same period a year earlier and amounted to 542.80 thousand tons.

Indorama Ventures PLS is one of the world’s leading manufacturers of PET, TPA, MEG (in the USA), as well as polyester yarns and fibers. IVL acquired TPT Petrochemicals in 2008.

-Plastipak’s Major Recycling Investment in Spain Officially Opens

Investing In The Circular Economy

Plastipak, a global leader in the design, manufacture and recycling of plastic containers has announced the formal opening of a major recycling investment at its manufacturing site in Toledo, Spain by Don Emiliano García-Page, President of the Castilla-La Mancha Region. The new recycling facility converts PET flake into food-grade recycled PET (rPET) pellets suitable for direct use in new preforms, bottles and containers.

The new recycling plant will produce 20,000 tonnes of food-grade recycled pellet per year and will eliminate recycled resin transport-related emissions since it is co-located at Plastipak’s current preform manufacturing site. The recycling plant is Plastipak’s fifth recycling facility, with other recycling plants located in USA, France, Luxembourg and United Kingdom. In Europe, Plastipak is the largest producer of food-grade rPET, with well over 150,000 tonnes of rPET capacity per annum. Indorama-PET -PET-flake – HeiQ – PLA

Driving Down Emissions

Pedro Martins, Plastipak’s Executive Managing Director Europe, said “The use of rPET is a key tool in reducing our customer’s Scope 3 related emissions and forms an important part of their ESG-packaging related commitments. As well as supporting our customers to reduce their financial obligations under the planned Spanish plastics tax, the plant will also contribute to the meeting the minimum recycled content levels mandated by the Single Use Plastics Directive.”

To support on-site energy generation, the state-of-the-art facility incorporates advanced energy-saving technologies and equipment that includes the rooftop installation of over 1800 photovoltaic (PV) solar panels. The PV panels are expected to generate more than 1339 MWh of electricity per year that will be consumed entirely on-site, saving more than 443 tonnes of CO2 per year through the avoidance of consumption of electricity from the national grid. This is in addition to the CO2 avoided by using 20,000 tonnes of recycled resin instead of virgin resin.

-The LYCRA Company and HeiQ Introduce New LYCRA® naturalFX™ Technology That Offers Durable Comfort Stretch and Fit for 100% Cotton Knitwear

The LYCRA Company, a global leader in developing innovative and sustainable fiber and technology solutions for the apparel and personal care industries, today announced the launch of LYCRA® naturalFX™ technology, a proprietary textile finishing process for 100% cotton knit garments designed for mass market applications. Developed in collaboration with HeiQ, an industry leader in performance finish technologies, this application is the latest example of both companies’ ongoing efforts to bring more innovative and sustainable textile technologies to consumers worldwide.

LYCRA® naturalFX™ technology enhances the stretch and recovery properties of cotton knit fabrics and does so in a durable way with outstandingly soft hand”

LYCRA® naturalFX™ technology, powered by HeiQ, enhances cotton knitwear, addressing critical consumer pain points, and improving the consumer’s overall wearing experience. This technology provides durable comfort stretch, fit, and soft hand-feel to 100% cotton knitwear compared to conventional finishes. Indorama-PET -PET-flake – HeiQ – PLA

Even after repeated washing and wearing, LYCRA® naturalFX™ technology helps knitwear retain its shape, which helps extend the garment’s lifespan and potentially reduce its environmental impact.

“LYCRA® naturalFX™ technology enhances the stretch and recovery properties of cotton knit fabrics and does so in a durable way with outstandingly soft hand,” said Nicolas Banyols, chief commercial officer at The LYCRA Company. “This breakthrough innovation not only improves the performance of everyday 100% cotton knitwear but is easy for mills to implement as it requires no investment in new equipment. We value HeiQ’s technical expertise and are excited to collaborate on the commercialization of this technology.”

All knits that use LYCRA® naturalFX™ technology can be submitted to The LYCRA Company’s labs for quality control testing to ensure all consumer benefits are delivered, including comfort stretch, breathability, and durable fit. New logos will feature both the LYCRA® and HeiQ brands and will be supported by customizable co-branded POS materials featuring the tagline, “In Sync with Nature’s Rhythm,” which are also available to brands and retailers.

While The LYCRA Company is leading the commercialization of this technology, HeiQ will collaborate and support the introduction through their brand network as well as manufacturing and selling the finishing directly to textile mills, leveraging their established global technical services to deliver optimized performance.

“Combining The LYCRA Company’s expertise in stretch fibers with HeiQ’s renowned innovation in textile chemical finishing has resulted in a truly unique, added-value technology that offers enhanced performance to cotton knitwear,” added Mike Mordente, head of the business unit textiles at HeiQ. “I am confident that LYCRA® naturalFX™ technology will open up a new generation of enhanced stretch and recovery garments with comfort and durability.” Indorama-PET -PET-flake – HeiQ – PLA

-TotalEnergies Corbion and BGF make it official

Two bioplastics manufacturers – South Korea-based Be Good Friends (BGF) and TotalEnergies Corbion, in Gorinchem, Netherlands – have announced they have entered a long-term collaborative arrangement, formalising what had already been a good working relationship The two companies, both focused on the development and production of biodegradable materials and products, will work together on the application development . They will also cooperate on the supply of Luminy PLA, the biobased material produced by TotalEnergies Corbion. Indorama-PET -PET-flake – HeiQ – PLA

BGF recently launched a 100% bio-based and compostable single-use noodle cup on the South Korean market. The lightweight, foamed noodle cup minimises the use of materials and is produced using high heat Luminy PLA as a base resin.

The development of the cup is the result of joint development efforts between the two companies, and more developments are set to follow in the future.

“The collaboration with TotalEnergies Corbion is supporting our long-term growth strategy,” said Mr. Hong, Chief Executive Officer of BGF.

Moreover, as Thomas Philipon, Chief Executive Officer of TotalEnergies Corbion, pointed out, the biopolymers market is experiencing strong growth and customers are requesting ‘innovative solutions tailor-made to their market needs’.

PLA is an ingredient in several of the compounds that formulated by BGF to meet specific customers’ functionality needs for different applications.

“We are delighted to have signed this long-term collaboration agreement with BGF.

-Alliance to End Plastic Waste commits US$36 million to Indonesian projects

Investment aims to enable up to 5x catalytic funding

The Alliance to End Plastic Waste announced this week a US$36 million commitment to develop a range of sustainable solutions and projects in Indonesia, intended to advance the country’s national goals to reduce 70% ocean plastic pollution by 2025 and achieve near zero leakage by 2040.

According to the Alliance, the launch of this seed fund can, in turn, catalyse up to five times more public and private sector investment to end plastic waste in the environment.

As the first country to establish a National Plastic Action Partnership, Indonesia has demonstrated a strong commitment to addressing the plastic waste challenge and the country is a designated priority for the Alliance. Various projects across the archipelago will receive support. Indorama-PET -PET-flake – HeiQ – PLA

The Alliance has been cctive in the country since 2019. Its first project was Project STOP Jembrana in partnership with Systemiq, which is still operating. That project aims to develop a collection, sorting, processing, and recycling system to serve 150,000 people in the regency.

The flagship programme of the Alliance is Bersih Indonesia: Eliminasi Sampah Plastik, which has started with Phase One in Malang. Bersih Indonesia in Kabupaten Malang will establish an integrated waste management system, including household collection services for 500,000 households. The Alliance is providing a US$29 million grant to build infrastructure including five transfer stations, five materials recovery facilities, and a fleet of over 1,100 vehicles.

The focus is on diverting up to 60,000 tonnes of plastic waste from the environment by 2025; achieving a recycling rate for plastic waste of up to 50% by 2025 for its projects; and engaging with up to 2.7 million Indonesians through behavioural change programmes.

With the programme, the Alliance aims to demonstrate a financially sustainable waste management system for emerging markets that includes household collection fees; the sale of collected plastic waste material to off-takers in a competitive market; and government contribution to operating expenses. If successful, the model can be replicated nationally.

Another thrust will be to run broader education campaigns on waste management and household waste segregation to enhance waste management literacy, as well as enable better collection and sorting.

According to Jacob Duer, President and CEO of the Alliance, mobilising philanthropic financing is a key first step to develop, deploy and derisk sustainable solutions that can be scaled and replicated for greater impact.

“No one organisation can solve a challenge of this size alone. Therefore, one of our goals is to catalyse additional funding from governments and development banks as blended finance that will mobilise private funds to improve waste management and advance a circular economy for plastic,” he said.

The Alliance has also supported Systemiq’s research of an investable blended finance model for waste collection and sortation infrastructure. A white paper will be published soon. Co-developed with the Government of Indonesia, this is a first attempt at designing a viable and replicable financing scheme for waste management systems in underserved areas. Indorama-PET -PET-flake – HeiQ – PLA

“Ending plastic waste is a complex challenge that requires holistic action, underpinned by strong public-private-people collaboration to address various systemic gaps for sustainable waste management.

-Sinarmas Cepsa signs agreement to expand bio-based chemicals production

Sinarmas Cepsa Pte Ltd (SCPL) and its parent companies, the chemicals business of CEPSA and agribusiness Golden Agri-Resources (GAR), signed an agreement to expand the production of bio-based chemicals at SCPL’s site in Lubuk Gaung, Indonesia, said Chemindigest. Indorama-PET -PET-flake – HeiQ – PLA

The site is ideally positioned to serve customers worldwide and the existing facility, which started production in 2017, is fully utilised.

SCPL has a strong ambition to grow along the fatty alcohols value chain, with sustainable development at the heart of its strategy and operations. Global demand for fatty acids and natural alcohols is driven by growing demand for home and personal care products, as well as increasing demand for sustainable, bio-based solutions across a variety of the industries SCPL serves.

The expansion is expected to advance SCPL’s growth strategy, to contribute to solving environmental challenges, including climate change, and to support sustainable farming practices in Indonesia. Pending final investment decisions, this incremental production will bring additional employment and economic benefits to the local community.

“Sustainably sourced, bio-based alternatives are key requirements for our customers and the markets we serve” says Kung Chee Wan, CEO of SCPL. Wan adds, “We are excited to grow with our customers and increase the scale of our sustainable and traceable integrated supply chains”.

-OQ strengthens its bottles & closures portfolio with new solutions

OQ, the multifaceted Oman-based enterprise that specialises in flexible and rigid packaging solutions, continues to advance its portfolio in response to key market trends.

Specifically, the company has strengthened its presence in the bottles & closures industry with a broad offering for HDPE blow moulded bottles, and Luban EP 2348R and DNDA 8320 for closures. Moreover, new high-flow random copolymer grades like Luban RP 2251T and impact copolymer EP 2348T ideal for customised closures are on the way towards imminent launch.

Customers are seeking enhanced performance and value addition across a range of metrics. In terms of durability, there is heightened demand for superior environmental stress cracking resistance (ESCR) to protect bottles from cracks caused by the chemicals they are storing. Indorama-PET -PET-flake – HeiQ – PLA

On top of this important performance indicator, customers are looking for increased convenience, customisation, and improved aesthetics. Offering solutions to meet a range of end-uses and applications is essential. In today’s competitive environment, converters require a variety of grades to fit different bottle and closure combinations designed for B2C and B2B end users.

OQ announces to deliver more innovation across its rigid packaging portfolio in the near future. Another six grades are in development and are close to launch, which focus on high performance in bottles and customised closures fulfilling functional needs, delivering benefits across a range of parameters, including stiffness, flexibility, transparency, hinge performance and impact resistance.

Indorama-PET -PET-flake – HeiQ – PLA