Petrochemicals Closed Loop textiles recycled plastic Omicron 03-01-2022 - Arhive

Petrochemicals Closed Loop textiles recycled plastic Omicron

-Closed Loop Partners acquires majority stake in Sims Municipal Recycling

Sims sold its majority stake in Sims Municipal Recycling for $45.4 million.

Australia-based Sims Ltd. has agreed to sell a majority stake in Sims Municipal Recycling of New York LLC (SMR) to a group of investors, including investment funds managed by New York-based Closed Loop Partners. Under terms of the transaction, Sims will sell 50.46 percent of Sims Municipal Recycling for $45.4 million and will hold two of the five Sims Municipal Recycling board seats.

According to a news release from Sims Ltd., this transaction is expected to close in the third quarter of 2022. Petrochemicals Closed Loop textiles recycled plastic Omicron

Sims Municipal Recycling was formed in 2003 and offers curbside recycling, processing and marketing services in New York City. It operates four recycling facilities, three of which are in the New York-New Jersey metro area and one in Florida. This past year, Sims Municipal Recycling processed 660,000 metric tons of municipal curbside materials.

Closed Loop Partners manages venture capital, growth equity, private equity and project-based finance funds all focused on building the circular economy. Investors in Closed Loop Partners include pension funds, foundations, consumer goods companies and family offices focused on environmental, social and governance investing and the circular economy.

According to a statement from Closed Loop Partners to Recycling Today, Closed Loop Partners expects the acquisition to accelerate its focus on its investments in modernizing recycling facilities across the U.S. and closing the loop on materials.

“This transaction demonstrates Sims’ leadership and commitment to innovate quickly—and at scale—and to maximize opportunities within the circular economy,” says Alistair Field, CEO and managing director of Sims Ltd. “I am delighted that we have been able to secure a high-quality, like-minded joint venture partner who will work alongside us to create a world without waste to preserver our planet. Closed Loop Partners has the strategic management focus and expertise to help more rapidly take [Sims Municipal Recycling] to the next level in expanding recycling beyond New York City. Together, we look to expand materials accepted by SMR, optimize recycling accessibility across New York City and significantly grow SMR’s service areas across the United States.”

-GST on textiles: States demand to put tax hike on hold in pre-budget meeting

Several states have flagged higher tax rate on textile products from January 1.

Ahead of the GST Council meeting, several states on Thursday flagged higher tax rate on textile products from January 1 and demanded that the rate hike be put on hold. Petrochemicals Closed Loop textiles recycled plastic Omicron

In the pre-budget meeting chaired by Union Finance Minister Nirmala Sitharaman, states like Gujarat, West Bengal, Delhi, Rajasthan and Tamil Nadu said that they are not in favour of a hike in Goods and Services Tax (GST) rate on textiles to 12 per cent, from 5 per cent currently, with effect from January 1, 2022.

The 46th meeting of the GST Council, chaired by Sitharaman and comprising state FMs, is scheduled on December 31, with a single agenda to consider Gujarat’s demand of putting the rate hike “decision on hold”, as also representations received from trade in this regard.

Delhi Deputy Chief Minister Manish Sisodia said the move to raise GST on textiles from 5 per cent to 12 per cent is not people friendly and this should be withdrawn. If a common man buy clothes of Rs 1,000, he has to pay GST of Rs 120. “Delhi is not in favour of this,” said Sisodia, who is also the Delhi Finance Minister.

Tamil Nadu Finance Minister P Thiaga Rajan said, “It is one point agenda (for tomorrow’s Council meet).

It is an agenda that many states have raised. In the agenda item it says that it was raised by Gujarat but I know that many states raised it. .. It should be stalled (move to raise GST rate on textile)”. Petrochemicals Closed Loop textiles recycled plastic Omicron

-A car made from recycled plastic? This could be the future

What comes around goes around: Your discarded plastic water bottle may soon become part of your next car.

Automakers are racing to make their vehicles more sustainable — the industry’s favorite buzzword — by turning environmentally unfriendly materials into seat cushions, floors, door panels and dashboard trims. First it was reclaimed wood. Then “vegan” leather. Petrochemicals Closed Loop textiles recycled plastic Omicron

Now, plastic waste from the ocean, rice hulls, flaxseeds and agave are transforming the manufacturing process.

“Everyone is awakening to the problems of plastic and waste,” Deborah Mielewski, a technical fellow of sustainability at Ford, told ABC News.

Ford in particular has been championing the use of renewable materials in its vehicles. In 2008 it replaced the petroleum-based polyol foam in its Mustang sports car with seat cushions made from soy, an industry first. More recently Mielewski and her team started examining how to transform some of the 13 million metric tons of ocean plastic, which threaten marine life and pollute shorelines, into parts for future Ford vehicles. The result? Wiring harness clips in the new Ford Bronco Sport that were once nylon fishing nets.

“Two years ago there was a lot of publicity around ocean pollution and we felt an obligation to do something,” Mielewski said.

Ford acquires the recycled plastic from its supplier DSM, which collects the nets from fishermen who are paid to return them. The nets are harvested, sorted, washed and dried before they’re cut into small pellets and injection-molded into harness clips, which weigh about 5 grams and guide wires that power side-curtain airbags in the Bronco Sport.

Mielewski said Ford is currently testing the recycled plastic’s durability for the Bronco Sport’s wire shields, floor side rails and transmission brackets.

“My hope is we can replace many parts with this material,” she said, adding that more than half of Ford customers “care deeply about the environment and want to understand what companies are trying to minimize their footprint.”

Brian Moody, executive editor of Autotrader, said automakers like Ford have been attempting to produce environmentally responsible vehicles for years. He recalled Ford’s Model U concept which premiered on Jan. 5, 2003, at Detroit’s North American International Auto Show.

It had a hybrid engine and its door panels were built with a natural fiber-filled composite material.Petrochemicals Closed Loop textiles recycled plastic Omicron

“This is not just a passing trend. Sustainability is here to stay,” Moody told ABC News. “Environmental regulations are likely to become more strict in the years to come [and it’s] another incentive for automakers to start looking for a solution right now.”

Automakers deliberately added plastics to reduce the weight and cost of vehicles and increase performance and fuel economy, according to Gregory Keoleian, director of the Center for Sustainable Systems at the University of Michigan.

-OUTLOOK ’22: Omicron surge dampens Europe investor confidence but chems M&A to continue

Portfolio optimisation, private equity interest, and the intensifying pressure of sustainability targets are likely to continue to drive the chemicals mergers and acquisitions (M&A) market, despite the battering that investor confidence took in late 2021 when the Omicron COVID-19 variant emerged.

Despite the chronic and intense issues seen in global supply chains and inflation rising to the highest levels since the 2008 financial crisis in Europe, market confidence had been growing steadily since late 2020.

The demand resurgence seen by chemicals producers in the second half of last year continued through much of 2021, buoyed by industrial output growth rising at the fastest pace in decades in the wake of easing lockdown measures.

With vaccination campaigns – at least in the western world – progressing at a brisk pace through the year, a perception was gradually coalescing for investors and policymakers that a corner had been turned in the pandemic, and that the kind of radically disruptive measures like lockdowns and travel bans would no longer be necessary. Petrochemicals Closed Loop textiles recycled plastic Omicron

The discovery of the Omicron variant and the wildfire pace that it has spread through even thoroughly vaccinated populations had a massive impact on the global economy by the end of 2021.

Players are gingerly dusting themselves off, with economists and central bankers already moving to characterise the impact as transitory, while warning of a bleak early 2022.

“Returning to our crystal ball in early December 2021, I have a strong deja vu feeling from last year when we were looking at a still fairly bleak future,” said Carsten Brzeski, analyst at ING Germany.

The unpredictability of coronavirus waves and the frighteningly brief time it takes a new surge to dominate a population make gauging the future difficult, but this has proven far less of a dampener on acquisitions and divestments than initially feared.

BROKEN CALCULUS Petrochemicals Closed Loop textiles recycled plastic Omicron

Acquisitions are based on extremely granular analyses of likely future earnings, with an over-generous purchase price potentially making it impossible for an asset to recoup the cost of buying it in the first place.

With the pandemic reducing some key chemicals end markets such as the automotive sector to demand levels last seen in the 1940s and the direction of travel for future purchasing difficult to map, valuing businesses has never been more difficult.

This led to some early freezes to sales processes earlier in the pandemic, with Clariant putting the divestment of its pigments business on hold in April 2020, but the hit to dealflow in general proved not to be as dire as players had feared.

-Innovative Recycling – More Reuse, Less Plastic Waste

Plastic – it’s a material that can help shape a brighter future. But all too often, plastic products become waste at the end of their lives. This needs to change because plastic is far too valuable to be thrown away. Used plastics are a resource-efficient source of raw materials. That’s why Covestro is developing innovative recycling technologies to keep plastic inside the value cycle.

Plastics are the materials of our time. They help us cope with global challenges, such as aligning economy and society with climate-neutrality, developing new mobility concepts, or addressing the growth of the world’s population and making our cities more livable. Petrochemicals Closed Loop textiles recycled plastic Omicron

However, in order to achieve a truly sustainable future and protect our environment in the long run, our attitude towards consumption and understanding of plastic waste – and waste as a whole – must change. Since 1970, global resource consumption has more than tripled. The natural resources for the whole of 2020 were already exhausted after eight months. At the same time, humanity does not utilize products in a sustainable way. According to a scientific study, only around 9 percent of all plastics manufactured between 1950 and 2015 have been recycled.

This must change. Produce, consume, dispose – this pattern has had its day, particularly in regard to plastics. They must be used more and for longer periods of time. And at their end of lives, they should be systematically and effectively reused and recycled in large quantities.

However, much remains to be done to achieve an effective and resource-efficient circular economy. For example, waste recycling systems and solutions must be improved or even set up across the world. Currently, about two billion people – one quarter of the world’s population – do not have access to regular waste disposal.

Change can only succeed if all market players work closely together. The plastics industry can and wants to play a decisive role in this – for example in the Alliance to End Plastic Waste.

-Current Topics in Plastic Recycling

This chapter presents an overview of current trends in plastic recycling and focuses on specific topics of interest. Firstly, there are presented all methods used for plastic recycling, along with the advantages and disadvantages of each method. Extra attention is paid to chemical recycling and especially, pyrolysis (thermal and catalytic), which is an environmentally friendly method that results in the formation of value-added products. Petrochemicals Closed Loop textiles recycled plastic Omicron

Emphasis is given on three case studies where there are difficulties as regards the recycling of the plastic part: polymeric blends, since the existence of mixed plastic wastes may be challenging for their recycling; plastics originating in multilayer packaging, since the multilayer packaging consists of various materials, including plastics, paper, and metals that may be an obstacle for the recycling of the plastic part; and brominated flame-retarded plastics from waste electric and electronic equipment (WEEE), since in this case safe handling is required in order to avoid environmental contamination and a pretreatment step before recycling may be of paramount importance. These three case studies along with the mentioned difficulties and suggestions in order to overcome them are presented here, with the aim of offering insights for future studies on the management of plastic materials.

Undoubtedly, plastics play a major role in our everyday life, since plastic parts are used in numerous applications, such as packaging (for instance, food containers), automotive industry, electric and electronic equipment (EEE), etc., due to their unique properties [1].Petrochemicals Closed Loop textiles recycled plastic Omicron

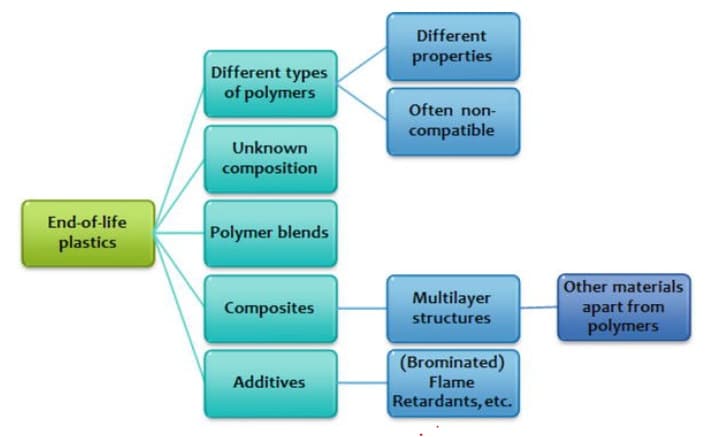

Some of their most important characteristics that necessitate their use in these applications are lightness, ease of processing, resistance to corrosion, transparency, and others. Nevertheless, their wide use in various applications in combination with the short life span of many plastic products leads to large amounts of end-of-life plastics. Taking all these into account, along with plastic nonbiodegradability, research has focused on exploring environmentally friendly approaches for their safe disposal [2]. Plastic handling involves collection, treatment, and afterward recycling. Unfortunately, finding environmentally friendly approaches for their disposal is no mean feat (Figure 1); due to the variation in types of plastics, which are often of unknown composition, the existence of polymer blends, or composites, multilayer structures with other materials apart from polymers, as well as the wide range of additives (such as UV and thermal stabilizers, antistatic agents, (brominated) flame retardants, colorants, plasticizers, etc.) they may contain [3, 4].

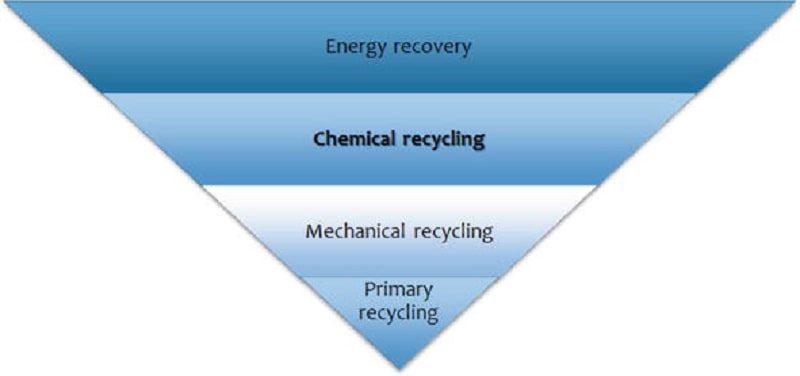

The disposal of post-consumer plastics occurs via landfilling, primary recycling, energy recovery, mechanical recycling, and chemical recycling [2]. Although landfilling is an undesirable, non-recycling method, since it results in serious environmental problems, such as soil and groundwater contamination, until now large amounts of end-of-life plastics still end up in landfilling [5, 6]. With a view to eliminating plastic landfilling, research has focused on recycling methods (Figure 2) that can be applied, which are primary recycling, recycling without quality losses, energy recovery-quaternary, mechanical or secondary recycling-downcycling into lower qualities and chemical or tertiary recycling-recovery of chemical constituents [7]: Petrochemicals Closed Loop textiles recycled plastic Omicron

In primary recycling (re-extrusion), the plastic scrap is reinserted in the heating cycle of the processing line in order to increase the production [8]. It remains a very popular method, because of its simplicity and low cost. However, it can be applied only in case of clean, uncontaminated single-type waste [2].

Mechanical recycling involves reprocessing and modification of plastic waste using mechanical-physical means with the aim of forming similar, plastic products, at nearly the same or lower performance level when compared with the original products [6]. Since mechanical recycling can be used only in case of homogeneous plastics, heterogeneous plastics require sorting and separation before their recycling. In mechanical recycling, the presence of brominated flame retardant (BFR) incorporated in plastics must be identified before its application, in order to avoid the possible formation of toxic substances, such as polybrominated dibenzo-p-dioxins/furans (PBDD/Fs) [9, 10]. Petrochemicals Closed Loop textiles recycled plastic Omicron

Its main drawback is the fact that product’s properties are deteriorated during every cycle [2]; and it should be underlined that each polymer can endure only a limited number of reprocessing cycles [11]. An additional challenge is the existence of mixed plastic waste (polymer blends), since different polymer types have different melting points and processing temperatures. In such cases, the processing temperature is usually set to the highest melting component. Nevertheless, this may result in overheating and possible degradation of the lower melting components and so, in reduced final properties [12].

Petrochemicals Closed Loop textiles recycled plastic Omicron