Solid-state battery – Lotte Chemical introduces a groundbreaking translucent polypropylene (PP) compound tailored for innovative automotive designs 01-04-2024 - Arhive

Solid-state battery

PET Bottle Polymers -EU beverage bottles: 24% recycled content, progress towards circularity, but more work for 2025 targets

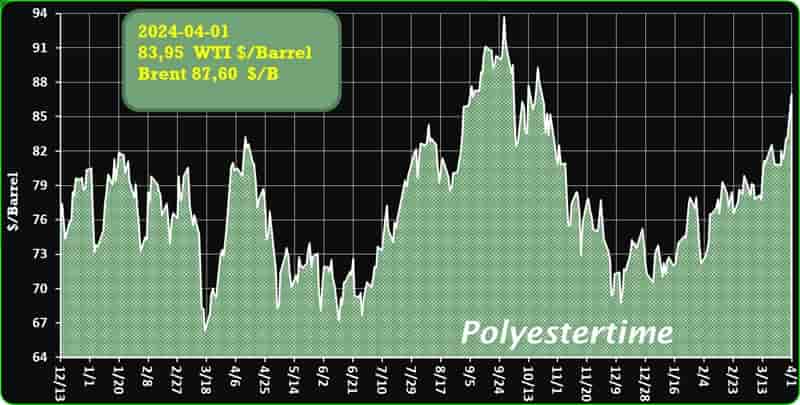

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

PP market suffers from a surge in excess production capacity

The PP market has also been suffering from a surge in excess production capacity, said Pooja Jain, associate director at S&P Global Commodity Insights, as per Chemweek.

She noted that while the current PP investment cycle began in 2019, the initial overbuild was relatively modest, totaling around 3 MMt per year (MMt/y) through 2021.

“It wasn’t until 2022 that we started to feel the heat,” said Jain.

Demand growth dropped close to zero that year while new capacity surged, and though demand rallied in 2023, more than twice as much new capacity came online, resulting in another 8.5 million metric tons of excess capacity in just two years.

“It’s going to take us some time to absorb, and thus, in our estimation, we expect the market to remain long for at least two more years before showing any strong signs of recovery,” Jain said. Solid-state battery

Rationalization will be necessary, and S&P Global expects close to 2 million metric tons of capacity to be shut down in 2024, much of it in China.

“China has this long tail of very small, old, nonintegrated assets running at suboptimal [rates],” said Jain.

“Will that help with prices? Not so much. … Northeast Asia prices have essentially bottomed out, and we don’t expect any strong recovery, at least this year.”

More…

SABIC Fujian Petrochemicals, in partnership with Lummus Technology, is advancing a significant ethylene project in Fujian Province, China

Lummus, renowned for its process technologies and energy solutions, will provide ethylene and co-monomer technologies for the grassroots complex. Solid-state battery

Established in 2022, SABIC Fujian Petrochemicals is a joint venture between SABIC Industrial Investment Company and Fujian Fuhua Gulei Petrochemical Co., Ltd. Majority-owned by SABIC, the venture announced its final investment decision on January 22, 2024, for the SABIC Fujian Petrochemical Complex. Construction is set to commence this year, with completion expected in 2026, marking the largest foreign investment joint venture in Fujian Province.

Leon de Bruyn, President and CEO of Lummus Technology, commended SABIC Fujian Petrochemicals for their investment decision, expressing anticipation for future milestones. Lummus’ involvement encompasses technology licensing, basic design engineering for ethylene and propylene units, a butene-1 unit, and BTX products. Additionally, Lummus will supply proprietary heater equipment and CDModules®. Solid-state battery

As a leading licensor of ethylene technology globally, Lummus has licensed over 200 ethylene plants, constituting 45% of global ethylene capacity. Moreover, Lummus has completed over 250 ethylene projects, including grassroots, revamp, and expansion designs, surpassing other technology licensors in this field.

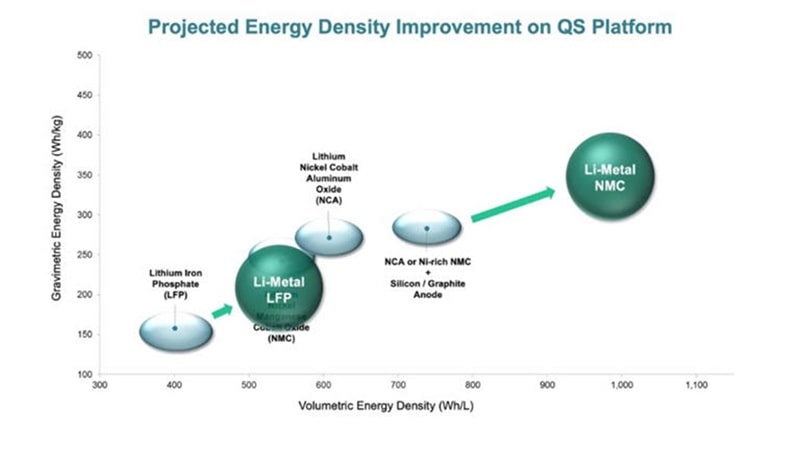

New solid-state battery prototypes shipped for testing and evaluation

QuantumScape, an American innovator in solid-state batteries, has initiated deliveries of their latest prototype, Alpha-2, to their customer companies, marking a significant step forward in their journey towards commercialization. These batteries, designed for electric cars, bridge the gap between the initial A0 prototypes and the forthcoming QSE-5 B0 models, serving as a crucial testing ground for refining the final product.

Compared to their predecessors, the Alpha-2 samples boast a reduction in layers from 24 to 6, resulting in a remarkable enhancement in energy density.

This improvement is attributed to advancements such as higher load cathodes and more efficient packaging techniques, optimizing both materials and space within the battery cells. Solid-state battery

Looking ahead, QuantumScape plans to leverage customer feedback, notably from major investors like the Volkswagen Group, to iterate on their product design and production processes. Their commitment to continuous improvement is underscored by President and CEO Siva Sivaram, who emphasizes the importance of customer input in refining their offerings. With ongoing advancements in production techniques like Raptor and Cobra slated for 2025, QuantumScape remains steadfast in their pursuit of bringing cutting-edge solid-state battery technology to the automotive industry.

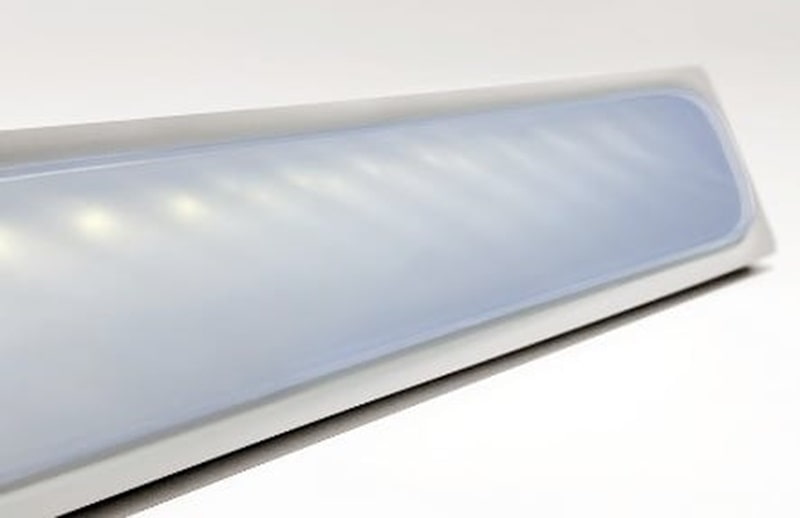

Lotte Chemical introduces a groundbreaking translucent polypropylene (PP) compound tailored for innovative automotive designs

Engineered to offer superior light transmission and minimal opacity, this compound presents unprecedented possibilities for electric and self-driving vehicles.

Designed with versatility in mind, Lotte’s translucent PP compound finds its niche in the automotive realm, particularly in crafting front-end modules including bumpers and light grilles. Solid-state battery

These components boast enhanced aesthetics and functionality, accommodating concealed lighting elements for visual effects and integrating sensors for advanced driving assistance systems seamlessly into the vehicle’s structure.

The compound’s formulation not only prioritizes light transmission but also reinforces rigidity and durability, essential for structural integration within the vehicle.

Unlike traditional materials like polycarbonate or PMMA, which compromise impact resistance, Lotte’s PP compound ensures robust protection while maintaining transparency.

Beyond frontal modules, Lotte Chemical envisions applications extending to exterior panels and interior trim, offering design opportunities for next-generation vehicles. By pushing the boundaries of material innovation, Lotte paves the way for automotive designers to explore new realms of creativity and functionality, ultimately enhancing both the aesthetics and performance of modern automobiles. Solid-state battery

Sacmi brings AI to NPE 2024

Sacmi is set to revolutionize NPE 2024 with cutting-edge AI integration into cap and preform molding, even accommodating 100% recycled materials. This digitalization-focused showcase promises groundbreaking advancements in artificial intelligence.

Advanced Controls: Sacmi unveils Smart Pack 2, elevating control capabilities in continuous compression molding (CCM) of plastic caps. This suite enables comprehensive machine control, incorporating hydraulic management, consumption monitoring, and self-adapting processes. Predictive maintenance functionality forecasts potential issues, minimizing downtime risks. Solid-state battery

AI Virtual Assistants: Introducing Classy AI for automated defect identification and classification, seamlessly integrated into SACMI Computer Vision systems. Gilda AI, a chatbot expert, offers real-time troubleshooting assistance based on years of accumulated technical expertise.

Recycled Caps and Preforms: Highlighted hardware includes the CCM64 cap press with vision system and PVS156, alongside the IPS 300 preform press. These innovations enable compression molding of FDA-compliant, food-grade recycled HDPE caps, fostering closed-loop polyethylene capsule recovery. The IPS press, showcased at NPE 2024, produces 96 11.5g preforms in 100% rPET within 6.6 seconds, advocating for a transition to 26/22 mm neck-cap standards, particularly in the tethered sector. Solid-state battery

Aliplast has initiated the establishment of an upcycling facility in Modena, in collaboration with NextChem

The plant aims to recycle up to 30,000 tons annually of polyolefin-based rigid packaging waste. The project, totaling about 50 million euros, with 7.7 million euros financed through PNRR funds, is set to conclude by the end of 2025.

Located within the Modena plant hub, owned by Herambiente, a Hera Group company, the construction site commenced recently. It will utilize water from the waste water purification plant and energy from the waste-to-energy plant for operations. The incoming plastic waste will largely originate from Hera Group’s existing processing lines or local sources, ensuring zero-kilometer material. Solid-state battery

NextChem Tech, a subsidiary of the Maire group, has been chosen as the engineering and technological partner for the project. Leveraging their expertise in upcycling, they will transform waste into high-quality recycled polymers suitable for various industrial applications.

The Modena plant aligns with Hera Group’s commitment to decarbonization and plastic recycling, outlined in their 2022-2026 Industrial Plan.

Aliplast’s investments also extend to expanding PET recycling capacity and establishing a chemical recycling plant in Imola for carbon fiber from composite materials used in the Emilia-Romagna automotive district. Solid-state battery

Solid-state battery