Chemicals Biotechnology Recycling Hydrogen 01-03-2021 - Arhive

Chemicals Biotechnology Recycling Hydrogen

Petrochemicals Naphtha PETRecycling Polyester Trend

Crude Oil Prices Trend

-Investing in Better – Klöckner Pentaplast launches its new sustainability strategy

Klöckner Pentaplast (kp or the company), a leading global manufacturer of high barrier protective packaging solutions with industry-leading use of recycled content, announced the launch of its new sustainability strategy, ‘Investing in Better’. This follows on from the recent announcement of the successful completion of kp’s entire capital structure refinancing, which is the first of its kind to incorporate an ESG-Ratchet Linked Term Loan marketed to U.S. investors. Chemicals Biotechnology Recycling Hydrogen

With the new ‘Investing in Better’ sustainability strategy, the company has set itself ten clear targets for long-term improvement grouped into three key objectives: Close the Loop, which commits kp to using more recycled material, closing the packaging loop and taking every opportunity to make packaging recyclable. Work Smarter encompasses targets that focus on using less energy, cutting carbon emissions and ending landfill. And Act Responsibly, builds on the cornerstone of kp culture of continuous improvement in the areas of employee engagement, safety, and will enable kp to become a more diverse and inclusive company.

Carbon-fiber reinforced polyphthalamides (PPA) with outstanding mechanical properties for the replacement of aluminum and magnesium

For structural automotive applications, consumer electronics and loaded industrial equipment Chemicals Biotechnology Recycling Hydrogen

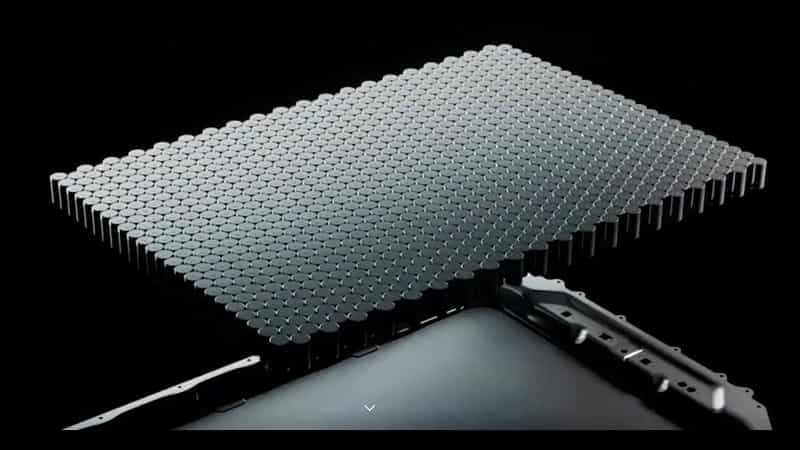

BASF is now expanding its polyphthalamide (PPA) portfolio of Ultramid® Advanced with carbon-fiber reinforced grades with fillings of 20, 30 and 40 percent. The benefits of these new materials: They make for extremely lightweight parts, can safely replace aluminum and magnesium without loss in stiffness and strength and are electrically conductive. The new grades combine these properties with the advantages of Ultramid® Advanced N (PA9T) which makes them unique among carbon-fiber reinforced PPAs already available in the market: high dimensional stability due to low water uptake, excellent chemical and hydrolysis resistance, high strength and modulus. The new carbon-fiber (CF) reinforced grades can be used to manufacture automotive structural parts for body, chassis and powertrain, for pumps, fans, gears and compressors in industrial applications as well as for stable and ultra-lightweight components in consumer electronics. With this offering, BASF complements its PPA portfolio of more than 50 grades already available on the market.

-Itochu, Air Liquide eye hydrogen supply chain in Japan

Japanese trading house Itochu and its energy trading subsidiary Itochu Enex have agreed with French industrial gas supplier Air Liquide to develop a hydrogen supply chain near major Japanese cities and tap potential growth in demand to supply fuel cell electric vehicles (FCEVs). Chemicals Biotechnology Recycling Hydrogen

The three firms are planning to jointly discuss the possibility of a project located in major Japanese cities to produce cost-competitive hydrogen for consumption in nearby areas and supply local hydrogen fuelling stations. They are also targeting to expand hydrogen supplies to the manufacturing sector and for industrial mobility use, such as trucks and buses.

Japan has pledged to ban sales of new gasoline-only cars and only sell electric vehicles by 2035 under its roadmap to achieve a decarbonised society by 2050. The policy is expected to increase demand for FCEVs, as well as fuel cell transport trucks for commercial use. Japan is projected to require 3mn t/yr of hydrogen in 2030.

-Optimism returns to European plastics industry

The European plastics industry remains largely optimistic about the months ahead, but a full return to pre-pandemic business levels anytime soon seems unlikely, a survey has found. Chemicals Biotechnology Recycling Hydrogen

Although initial vaccine rollouts have yet to have led to an easing of lockdowns in most European countries, just around half (47 per cent) of European plastics industry companies across all sectors expected their business performance in the first half of 2021 to outpace results from the previous six months, according to the survey by Plastics Information Europe (PIE).

Another 42 per cent foresaw a stable business situation in the coming months compared with H2 2020, while the remaining 11 per cent were anticipating declines.

Optimism is highest in German-speaking Europe and Scandinavia, where more than 58 per cent and 56 per cent of firms respectively forecasted business improvement. Southeastern European and French respondents were more pessimistic – probably a consequence of being hit harder by Covid-19, PIE suggested. Nearly 26 per cent of companies in Ireland and the UK projected declines.

- TECHSYN combines chemically optimised synthetic rubber with tailor-made silica to create tyres with up to 30% better wear efficiency and a rolling resistance that is reduced by up to 6%.1

- As a result, TECHSYN reduces overall fuel consumption and CO2 emissions2, enhances tread mileage3 to extend a tyre’s designed life and cuts raw material consumption in the long term.

- TECHSYN went from concept to reality in just 24 months, thanks to the unique expertise and close collaboration between partners Bridgestone, ARLANXEO and Solvay. Chemicals Biotechnology Recycling Hydrogen

Bridgestone, a global leader in sustainable mobility and advanced solutions, ARLANXEO, a world-leading synthetic rubber producer, and Solvay, one of the world´s top science companies and worldwide leader in Highly Dispersible Silica (HDS), both for innovation and for manufacturing, have today announced the launch of TECHSYN, a new, co-developed tyre technology platform enabling tyres to deliver unrivalled strength and environmental performance.

Unlocking a new era of sustainable mobility

TECHSYN combines chemically optimised synthetic rubber with tailormade silica, interacting at a molecular level, to deliver outstanding performance with no trade-offs.

Each material found in TECHSYN was developed in parallel by the three companies to create a tyre technology platform that provides unrivalled performance. TECHSYN enables tyres to achieve up to 30 per cent better wear efficiency and a rolling resistance that is reduced by up to six per cent, compared to other conventional Bridgestone EMIA4 summer products, without compromising any other performance areas. With the goal of ensuring less tyre wear material loss, extra focus was placed on performance improvements in tyre wear throughout the development of TECHSYN. Chemicals Biotechnology Recycling Hydrogen

As a result of these improvements, TECHSYN augments the sustainable performance of the tyres it’s applied to by reducing overall fuel consumption and CO2 emissions and enhancing tread mileage.2 TECHSYN’s durability extends the designed lifespan of tyres made with it by approximately 30 per cent3, to ultimately result in a tyre that needs to be changed less frequently and reduces the consumption of raw materials in the long-term.

-LG Chem Developing Pilot Production Line For Tesla’s 4680 Batteries: Report

It’s the third player after Tesla itself and Panasonic to work on 4680-type batteries.

LG Chem’s LG Energy Solution is busy at work building its pilot manufacturing line for the 4680 cylindrical battery cells (announced by Tesla during Battery Day), according to unofficial media reports from South Korea. The shift to a 4680 form factor has been expected since October 2020, when we first heard about it and wondered whether Tesla is licensing its 4680 cell technology to the Korean company?

The Elec (via Teslarati) reports that the company already installed some equipment at its Ochang plant in South Korea and intends to start pilot production as soon as possible, maybe even beating Panasonic. Chemicals Biotechnology Recycling Hydrogen

The Japanese competitor is also working on its pilot production line – at the Osaka plant in Japan – with a target for production as early as 2021.

-Mideast chemicals supply tight amid US outages, strong China demand

Supply tightness prevails in the Middle East chemicals markets and it remains a challenge to scour the region for cargoes amid winter storm-related outages in the US and strong demand coming from China. Chemicals Biotechnology Recycling Hydrogen

The ramifications are felt keenly in the polymer markets.

For both polyethylene (PE) and polypropylene (PP), selling sentiment is strong on expectations that demand from the US and Latin American buyers will surge, which would affect the Middle East’s allocations to other regions.

Market sentiment has firmed on expectations of tighter supply conditions emerging in March as strong deep-sea demand on account of US outages coincides with pre-Ramadan restocking taking place within the Middle East.

The Muslim fasting month of Ramadan begins on 12 April.

Sellers in the Middle East are also optimistic on improved uptake from China after the country’s week-long Lunar New Year holiday on 11-17 February.

“I see prices continue to skyrocket and in China, things are more bullish than expected,” said ICIS senior consultant Fabrizio Galie.

-Recycled polyester staple fibre reports regular price rise

From the beginning of December 2020, the prices of recycled polyester staple fibre (PSF) have been increasing with growing PSF futures and downstream yarn demand, supported by the polyester feedstock market. The PSF price rose 9.22 per cent to 5,450.00 CNY/mt in February 2021 (2nd week) compared to 4,990.00 CNY/mt in the last week of November 2020. Chemicals Biotechnology Recycling Hydrogen

In October 2020, the recycled PSF prices improved 7.36 per cent to 5,250.00 CNY/mt (end of month) from 4,890.00 CNY/mt (beginning of month). However, in November the prices declined 4.95 per cent to 4,990.00 CNY/mt.

-TreeToTextile Builds Demonstration Plant For Upscaling New Sustainable Textile Fiber

TreeToTextile, owned by H&M Group, Inter IKEA Group, Stora Enso, and LSCS Invest, now invests €35 million in constructing a demonstration plant in Sweden. It is a critical next step towards commercializing a new sustainable textile fiber, with scalable technology and low manufacturing cost. The aim is to make sustainable textile fibers available to all. Chemicals Biotechnology Recycling Hydrogen

All over the world, sustainable textile fibers are in growing demand. TreeToTextile is committed to enabling brands, companies, and others with a progressive agenda, to have access to sustainable textile fibers. TreeToTextile offers a new technology to produce biobased textile fibers with a low environmental footprint at an attractive cost level. The new fiber is a regenerated cellulosic fiber, produced from renewable and sustainably sourced raw materials from the forest.

-The Mars parachute rover is woven on the Picanol machine – KW.be

Ypres played a role that should not be underestimated in the safe landing of NASA’s persevering rover on Mars. A heat-resistant canopy, designed to slow the supersonic rover, is woven into a Picanol.

The parachute was tested extensively in a wind tunnel. © T. Wayne. NASA

NASA shared the first images of the successful landing of the persistent rover on Mars Monday evening. Chemicals Biotechnology Recycling Hydrogen

The photos spread around the world and were studied in detail at the Ypres headquarters of the Picanol Group, where the parachute was woven before landing.

“We sell thousands of textile machinery annually to clients in more than 100 countries, but this is the first: Picanol’s first space project,” says company spokesman Frederick Dreiwell.

Heathcoat Fabrics Limited, a UK-based Picanol Group customer, was selected by NASA’s Jet Propulsion Laboratory to design and manufacture the canopy.

To weave the parachute, Heathcoat turned into Picanol. “We have the most advanced machines in the world for such technical tasks,” says Dryhoel. “We have a long client relationship with Heathcoat, as Picanol is also looking for the best textile job solution.” Braking: The canopy is woven by OptiMax-i. The “New Standard in Sword Weaving” can be read in a brochure from Picanol. “The fabric of the canopy is woven with such a machine, but also the fabric of the airbags, sails, and bulletproof vests.

Chemicals Biotechnology Recycling Hydrogen