Chemicals Polyamide Recycling Hydrogen 26-02-2021 - Arhive

Chemicals Polyamide Recycling Hydrogen

Crude Oil Prices Trend

-PET bottle chip price soars above 7000yuanmt, why and how will it trend later on

In merely 3 working days, PET bottle chip price has breached above previous high, rising more than 12%. If compared with 2020 low of 4650yuan/mt and $645/mt, PET bottle chip RMB and USD price has hiked 44% and 48.8% as of Feb 22, which both surpassed 2020 high point. On Feb 23, quote has moved up to 7200-7400yuan/mt by cash EXW, and some large plant even raised offer for 3 times, traders generally stopped quoting or continuously revising up offer.

How long could PET resin sustain its uptrend?

From feedstock side, WTI and Brent oil futures both hiked above previous high, driving up polyester feedstock cost. Some international evaluation institutions have also raised their high estimates. Such rising trend stimulated by the inflation may not end within short term. From industry side, average operating rate of the polyester plants is around 85.9%, which is still in the recovery, and O/R of PTA plants is also near this level. Hence, PTA stock level still inched higher. Hence after the holiday, despite expanding PTA turnover, PTA futures price rise is less than that of PX. PTA-PX spread squeezed significantly. Later, PTA may move in line with PX trend. MEG plant in US delayed restart due to the cold wave, hence fundamental was a bit strong. Market may substantially destock in Mar.

-Textile Sector May Lose 50% Of Its Employment In 2021

Covid-19 is sinking the Spanish textile sector, one of the most dynamic sectors of the national economy until the pandemic, which threatens to destroy 50% of employment this year (100,000 jobs) and 50% of companies in some weeks. This is stated by both the president of the Acotex employer, Eduardo Zamácola, and the business consultancy Dipcom Corporate. Chemicals Polyamide Recycling Hydrogen

Specifically, according to the president of Acotex, half of the textile and accessories trade that was registered before the pandemic will close before mid-March, which would mean an additional 25% to the bankruptcies already consummated in 2020.

Sales fell 53% in January due to Covid and Filomena

The Business Association of Textile, Accessories and Leather Trade (Acotex) reported that sales of textile, home and accessories garments fell by 53.2% in January compared to the same month in 2020. The restrictions due to the third wave of the coronavirus and the storm Filomena left the sales without effect, which is the period when commerce makes cash.

A person advances on the snow this Saturday in Madrid.A person walks on the snow in Madrid.EFE

Destruction of 100,000 jobs

According to data from Dipcom Corporate, the sector could end 2021 with just 100,000 textile jobs, compared to 200,000 at the beginning of 2020.

-Sumitomo Chemical licenses high-pressure PE technology to Russian petchem firm

Sumitomo Chemical has concluded an agreement with Kazanorgsintez (KOS), in the Republic of Tatarstan of the Russian Federation, to license out its high-pressure production process for low-density polyethylene (LDPE) and ethylene-vinyl acetate (EVA) to boost KOS’s polyethylene production, said the company.

KOS started manufacturing polyethylene in 1965. Among the leading Russian petrochemical companies, it is now one of the largest domestic producers of polyethylene. With the goal of increasing production capacity and further diversifying the product mix at its manufacturing site in Kazan, the capital city of Tatarstan, KOS is removing part of its existing manufacturing facilities and installing a state-of-the-art facility. For this facility, KOS has adopted Sumitomo Chemical’s high-pressure production process. The new facility will have an annual production capacity of 100KTA. Chemicals Polyamide Recycling Hydrogen

Sumitomo Chemical’s high pressure polyethylene technology is a proprietary autoclaving polyethylene production process, which is switchable between LDPE and EVA in one manufacturing facility. For EVA, a wide range of product grades can be accommodated by adjusting the spike level of vinyl acetate. The technology is also energy efficient because of its high monomer reaction efficiency, and offers excellent operational stability. These points were highly regarded and led to the conclusion of this license agreement.

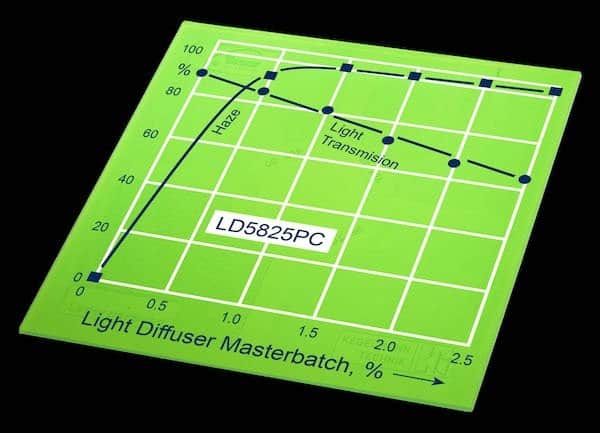

-Light-diffusing masterbatch for evenly backlit surfaces

Many LED light sources have a problem with creating uniform diffused light, resulting in brightness concentrations, or ‘hot spots’, on backlit surfaces. Light-diffusing (LD) masterbatches from Tosaf Color Service effectively prevent this.

In extensive laboratory trials, the micro-fillers it contains were optimised with regard to material, refractive index, transparency, geometry and dimensions.

As a result, only very small amounts of masterbatch (1-2%) are needed to effectively scatter the light in originally transparent material, predominantly polymethylmethacrylate (PMMA) and polycarbonate (PC). Chemicals Polyamide Recycling Hydrogen

At the same time, the light transmission and mechanical properties of the base material are largely retained. In addition to color-neutral grades, combinations with specific colorings and other functional properties such as UV stabilisers are available.

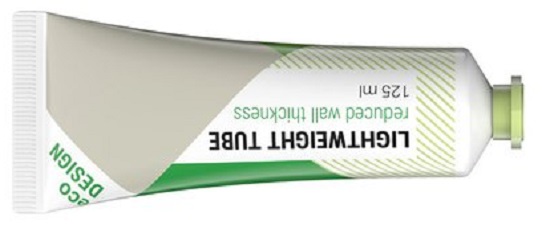

-Neopac develops plastic tube with reduced wall thickness

Hoffmann Neopac has introduced the latest addition to its EcoDesign tube portfolio – a new lightweight plastic tube with reduced wall thickness comprising up to 30% less virgin material.

According to the company, the use of such lighter-weight packaging reduces both shipping costs and extended producer responsibility (EPR) fees.

The new solution is available in plastic tube diameters ranging from 30-50mm, and in four substrate varieties: polyethylene and recycled tubes, each with or without EVOH barrier. Chemicals Polyamide Recycling Hydrogen

The reduction of material usage is most apparent in the tube’s wall thickness, which has been reduced from 0.5 mm to 0.35 mm without, Neopac says, sacrificing “exemplary” haptics. Low profile closures are already in the pipeline with the aim of achieving maximum weight reduction in plastic tubes.

-What do we know about the Plastic Packaging Tax?

With just more than a year to go until the introduction of the government’s Plastic Packaging Tax, Martin Hyde, policy leader at environmental consultancy Comply Direct, looks at what we do and don’t know.

We are just over a year away from the introduction of the government’s Plastic Packaging Tax. Chemicals Polyamide Recycling Hydrogen

With significant financial and administrative implications for producers, it is imperative that businesses are able to identify their requirements and responsibilities under the tax so they can properly prepare for its implementation next year.

We know the tax will come into force in April 2022. How much it will cost is an area of little discussion; the treasury position is that the cost of £200 per tonne will apply to any ‘tax liable’ plastic packaging where 30% recycled content cannot be demonstrated.

-In 2050, Michelin tires will be 100% sustainable

By 2050, MICHELIN tires will be made entirely from renewable, recycled, biosourced or otherwise sustainable materials

Inspired by the VISION concept tire introduced in 2017, an airless, connected, rechargeable and entirely sustainable solution, the Michelin Group is committed to making its tires 100% sustainable by 2050.

Today, nearly 30%* of the components used in the manufacture of tires produced by the Michelin Group are already made from natural, recycled or otherwise sustainable raw materials. Chemicals Polyamide Recycling Hydrogen

A Michelin tire is a high-tech product comprising more than 200 ingredients. The main one is natural rubber, but the many ingredients also include synthetic rubber, metal, fibers and components that strengthen a tire’s structure, like carbon black, silica and plasticizers (resins, etc.). Incorporated in perfect proportions, these materials interact to deliver an optimal balance of performance, driveability and safety, while steadily reducing the tire’s environmental impact.

-China PTA futures hit one-year high

Purified terephthalic acid (PTA) futures on China’s Zhengzhou Commodity Exchange (ZCE) closed at a one-year high today on the back of rising feedstock paraxylene (PX) costs and possible maintenance shutdowns in March.

The main May-delivery (TA2105) contract has risen for three straight sessions to close at 4,718 yuan/t ($608/t) today, the highest since 21 February 2020.

Gains in feedstock PX prices are the main factor behind this week’s rise in PTA futures. PX prices on a cfr China basis have increased by more than $100/t – from $750/t to $860/t – since trading resumed after the lunar new year holidays on 18 February. This has helped squeeze PTA production margins in the Chinese domestic market to Yn300/t, down from Yn400/t in January to an uncomfortable level for most PTA producers. Chemicals Polyamide Recycling Hydrogen

The narrowing production margins have prompted some producers to consider shutting down for maintenance. Hengli Petrochemical and Xinfengming have indicated they may carry out turnarounds at their PTA production lines next month.

-OPRL extends partnerships for innovative, sustainable packaging

OPRL, the recycling labelling and recyclable packaging design not-for-profit, has opened a new membership category for organisations sharing its goals.

The inaugural members are the Bio-based & Biodegradable Industries Association (BBIA), the Foodservice Packaging Association (FPA), the Forest Stewardship Council(c) UK (FSC(c) UK), IOM3 and the Packaging Federation.

The aim of OPRL’s new Associate Membership scheme is to provide a framework for closer collaboration with other organisations, often with widely overlapping memberships, to provide mutual support, expertise and to promote each other’s activities in order to provide greater benefits to members. Chemicals Polyamide Recycling Hydrogen

-HDPE & PP MARKET IN EUROPE STATE OF PLAY – PRODUCTION, COLLECTION AND RECYCLING DATA

INTRODUCTION

This report, delivered by PRE, provides the latest data and trends regarding:

• The current state of the HDPE & PP market in Europe;

• Key changes impacting the market and the challenges faced by the supply chain; and

• What the future HDPE & PP recycling chain might look like.

PRE intends to update and re-publish this ‘State of the Market’ report every second year. Chemicals Polyamide Recycling Hydrogen

This report uses best available data sources to present data estimates, alongside results from a survey of market experts from the industry of HDPE and PP recyclers. PRE has also launched an internal survey of its members to check and improve on data estimates with figures collected directly from facilities, but in this case statistical representativeness will only be achieved in future updates to the report. The first year’s data presented here will provide a benchmark from which to analyse future developments and trends, including outlining remaining gaps in data to support full supply chain analysis. All data sources references in this report are listed in the Annex.

PRODUCTION AND CONSUMPTION

Net demand for HDPE was reported by Eurostat at 6.2 Mt, and net demand for PP at 10.5 Mt.1 Together, HDPE and PP account for almost a third of all converter demand in the EU28 for polymer resins.2

Europe produces almost enough to meet internal demand – 92% of net EU28 demand for HDPE can be met by EU28 production and

supply; for PP, the figure is 98%. Recyclate from post-consumer rigid product applications within the EU28 meets approximately 8% of demand for HDPE and 3% of demand for PP (12% of demand for HDPEand 5% of demand for PP when pre-consumer recyclate is included).

Chemicals Polyamide Recycling Hydrogen