Plastic PARecycling Oil Polyolefins 15-02-2021 - Arhive

Plastic PARecycling Oil Polyolefins

Petrochemical Naphtha PET PARecycling Trend

Crude Oil Prices Trend

-Itochu and Aquafil join forces to sell recycled nylon

The Japanese trading company Itochu and the Italian chemical firm Aquafil have entered a partnership to promote and expand the businesses of circular nylon production.

In 2011, Aquafil created the Econyl Regeneration System that turns recovered nylon waste such as fishing nets, carpets and post-industrial waste back to caprolactam (CPL), a crude raw material. Through its proprietary recycling technology, Aquafil claims to eliminate impurities completely and produce regenerated nylon having the same features as virgin quality materials.

Econyl is made completely from waste, which enables an up to 90 percent reduction in CO2 emissions compared to conventional nylon made from petroleum. Focusing on the fashion and carpeting industries, Econyl has been adopted by more than 2,000 brands around the world. In the fashion industry, it received “strong support” from major fashion brands including Burberry, Gucci and Prada.

Last year, Safilo announced the use of Econyl, being the first to introduce it in the eyewear industry. At the time, it said that the recycled nylon would be used for models in the Tommy Jeans collection, that had been recently launched by Tommy Hilfiger, one of the eyewear company’s licensed brands. Safilo planned to gradually use Econyl in other collections to reduce its carbon footprint.

-Toray well positioned for future growth in China

The Chinese market is one of Toray’s largest and most promising markets for future growth, said Kazuhiko Shuto, chairman and president of Toray Industries (China) Co.

From Uniqlo’s ultralight down jackets, home water purifiers and new-energy vehicles to Boeing 787 aircraft, Toray’s advanced materials and innovations are widely used.

Despite the impact of the coronavirus outbreak, Toray’s investment will continue in China thanks to the potential of the Chinese market and the country’s improving business and investment environment.

“Investment in China is developing toward high-end segments to meet people’s demands for comfortable lifestyle and safe environment,” Shuto said.

Toray’s success is rooted in its rich portfolio, covering fibers and textiles, resins and chemicals, films, carbon fiber composite materials, electronic and information materials, pharmaceuticals and medical products, water treatment and environmental sectors.

-US-China trade war continues to impact textile industry

The Joe Biden-led new US government is continuing with the Section 301 tariffs on finished apparel and textile imports from China. Tariffs were first imposed by the US in May 2019 to address intellectual property theft and other predatory trade practices by China. Since then, a number of tariffs and counter tariffs were imposed on import of goods.

However, due to the COVID-19 pandemic, the US government gave exclusions on some Chinese products, including textiles and apparel, which have now been extended till March 31, 2021.

Meanwhile, the Chinese government has reduced sliding tariffs on cotton cargoes imported under additional quotas. It has increased the number of products with lower than MFN tariffs and imported under temporary import tariffs from 859 earlier to 883 from January 1, 2021. The lower sliding tariffs would reduce the cost of importing cotton fibre into China, according to Fibre2Fashion’s market analysis tool TexPro.

-Sukano PLA masterbatches confirmed effective against SARS-Cov-2

The demand for a safe environment where surfaces do not play a possible role in transmitting a virus has significantly increased. Sukano high-performance Antiviral Masterbatch is designed to protect surfaces from acting as a transmitter.

Sukano PLA masterbatches confirmed effective against SARS-Cov-2

This is especially important in the healthcare area where disposables are increasingly sought to replace reusables due to their increased safety and reduced risk of contamination, while still aiming to reduce the environmental impact.

Biopolymers have become more and more relevant and today play a decisive role not only in packaging applications but also in medical uses. To further support safety and hygiene, Sukano has introduced an Antiviral Masterbatch for PLA applications to the market. This masterbatch helps to eliminate viruses and other microorganisms from surfaces.

-Endlessly Refreshing: Coca-Cola North America Rolls Out Bottles Made from 100% Recycled PET Plastic

Big news sometimes comes in smaller packages.

Coca-Cola Trademark brands (Coke, Diet Coke, Coke Zero Sugar, Coca-Cola Flavors) will debut a 13.2-oz. bottle made from 100% recycled PET (rPET) plastic this month in California, Florida and select states in the Northeast, with other sparkling beverage brands following this summer.

“Challenges around plastic packaging waste and recycling continue to be top of mind for our consumers, customers and our system,” said Alpa Sutaria, vice president and general manager, sustainability, North America Operating Unit. “Introducing 100% recycled PET bottles is a big proof point of how recycling can help create a circular economy.”

The new 13.2-oz. bottle – the first-ever Coca-Cola package made from 100% rPET in the United States – uses less plastic and offers a convenient, sippable portion size. “On-the-go consumers have been telling us they want an option like this, because it’s just the right amount for the ‘snacking’ occasion,” said Tammy Lee, brand manager, Coca-Cola Trademark. “We believe this innovation delivers the double benefit of convenience and sustainability.”

-Biorizon is working on a business plan for an application center for bio-aromatics

Biorizon Shared Research Center, located at the Green Chemistry Campus, is working on a business plan for an application center for bio-aromatics.

Aromatics are important building blocks for the chemical industry: as many as 40% of all chemicals are aromatic in nature. They add essential functionality to products such as plastics, resins and coatings, including scratch resistance and UV stability. Currently, these aromatics are petrochemical-based and this has a negative impact on the climate. Biorizon is developing bio-aromatics based on biomass waste streams.

Biorizon founders TNO and VITO together with the Green Chemistry Campus are now investigating how a Biorizon Application Center can best meet the needs of the industry and how Biorizon can optimally unlock and further develop the already present knowledge, experience and equipment in the field of bio-aromatics.

-Supply issues and virgin competition jostle resin prices

Recycled plastic sellers are facing cost pressures from cheap virgin material, and an expert says reclamation costs will not come down to close that pricing gap.

Tonya Randell, a program manager at plastics recycling research firm More Recycling, delved into how the virgin plastic market is impacting recycled plastic markets, and she offered insights on the market realities for key recovered resins.

Randell spoke during the recovered plastic portion of Recycling Markets 2021, a virtual presentation put on by the Northeast Recycling Council (NERC).

Markets vary by resin

Randell highlighted the differences in markets for each resin. “What we see is that not all plastics are recycled equally, and we don’t see the same challenges for every sector,” she said.

HDPE natural has been “a significant kind of workhorse within the last couple of years,” Randell said. The resin last month notched another record price. That growth, she added, is “tied really directly to the fact that there is a lessening supply of this material.” Milk jugs and dairy containers, which have been a large source of natural HDPE, are increasingly being replaced by other packaging types, Randell said.

-Researchers Unveil ‘Transformative’ Discovery for Chemical Recycling

Princeton researchers have found a new way to polymerize butadiene that, they say, has vast implications for fulfilling the promise of closed-loop recycling through depolymerization.

Finding viable, cost-effective solutions to chemical recycling of plastics is an ongoing effort not just among companies, but in academia, as well. Researchers at Princeton University have found a chemical recycling method that they described as “transformative” in an announcement on Jan. 25, 2021. Paul Chirik, the Edwards S. Sanford Professor of Chemistry at Princeton, and researchers in the Chirik Lab have discovered a potentially “game-changing new molecule” from a material known for over a century and used to make common products that has “vast implications for fulfilling” the promise of closed-loop recycling through depolymerization.

The Chirik Lab reported in Nature Chemistry that, during depolymerization, the molecule named (1,n’-divinyl)oligocyclobutane enchains in a repeating sequence of squares, a previously unrealized microstructure that enables the process to go backward, or depolymerize, under certain conditions. In other words, said the announcement, it can be “zipped up” to make a new polymer and the polymer can then be unzipped back to a pristine monomer for repeated use. “I honestly think this work is one of the most important things to ever come out of my lab,” Chirik commented in the announcement.

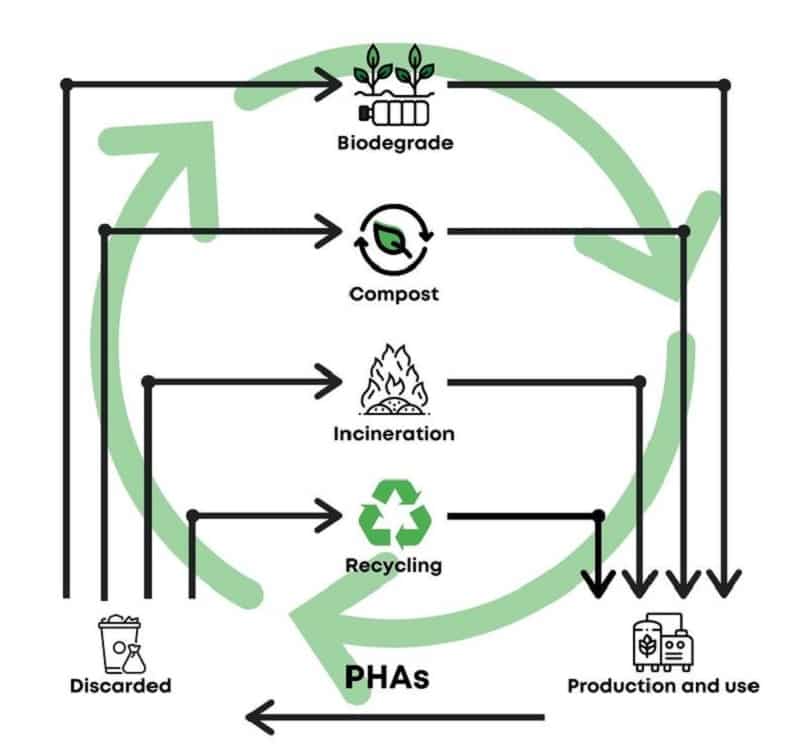

Milliken & Company’s Chemical Division has joined the Global Organization for PHA (GO!PHA) to help address the technical and market development challenges related to polyhydroxyalkanoate (PHA) biodegradable biopolymers. Milliken will bring to GO!PHA its expertise in polymer chemistry to help improve the processing, performance, aesthetics and other important attributes of PHA. The goal is to expand the application range of this family of materials into more packaging applications.

GO!PHA is a coalition of industry and academic stakeholders dedicated to advancing the development, commercialization and adoption of PHA polymers through advocacy and knowledge sharing. Milliken will collaborate with other GO!PHA members to prioritize technical issues and explore ways to solve them by adapting existing high-performance Milliken additives or developing new technologies.

-Technology to Eliminate Bacteria and Viruses on Fabric Used in Masks

Israeli start-up Sonovia has developed a technology to impregnate the fabric used in masks and other applications in order to protect the wearer from Covid-19 and other viruses.

This technology employs ultrasonic soundwaves to offer 98% particle filtration efficiency, 99.99% antibacterial efficacy—including antibiotic-resistant bacteria—and 99,89% virucidal efficacy. The process also has excellent durability against industrial laundries, according to Yuli Nofar, a Sonovia’s representative. She explained:

“Our technology was initially developed to fight hospital-acquired infections. This technology, which has been tested on Covid-19, eliminates all bacteria that land on the mask. The SonoMasks are reusable and can be worn for one year and have up to 55 washes.”

Antimicrobial Activities

Sonovia was founded in 2013 following over 10 years of research by Bar Ilan University Israel and a four-year, EU-funded research project looking into fighting hospital-acquired infections. Its patented technology uses ultrasonic soundwaves to physically infuse zinc oxide nanoparticles on to the fabric.

Plastic PARecycling Oil Polyolefins

Plastic PETRecycling Oil Polyolefins 13-02-2021