Petrochemical BioPolymers BioFilm 03-02-2021 - Arhive

Petrochemical BioPolymers BioFilm

Crude Oil Prices Trend

-Archroma and CleanKore join forces to promote sustainable, cost-effective indigo dyeing process

Reinach, Switzerland, and Westlake, 2 February 2021 – Archroma, a global leader in specialty chemicals towards sustainable solutions, today announced a strategic partnership with technology innovator CleanKore, aiming to advance sustainable dyeing processes throughout the denim supply chain.

The agreement will allow Archroma and CleanKore to promote the benefits of each other’s technologies.

This includes Archroma’s robust catalog of dyes and specialty chemicals along with CleanKore’s patented process of dyeing yarns at the denim mill that completely eliminates the need for potassium permanganate (PP) spray and laser booster to achieve the bright white abrasion effect in the garment finishing process.

Increasing complexity of automotive LED lighting designs creates demand for novel and easy to mold thermoplastics Petrochemical BioPolymers BioFilm

The trend toward developing complex, intricate automotive lighting designs using light-emitting diodes (LEDs) has created a need for high-performance thermoplastics with exceptional flow and easy mold release. Design elements such as part and function integration, wider, larger and thinner forward and rear lighting components, and critical aesthetics call for materials that can enable thin walls, aggressive styling with sharp draft angles and an impeccable appearance. SABIC’s portfolio of super high-flow LEXAN™ polycarbonate (PC) resins for automotive lighting bezels enables the industry to create complex geometries and integrate more features never before possible with ease of manufacturing.

LEDs Illuminate New Designs

As LEDs’ performance have improved and their power consumption and cost have dropped, they have become practical for use in multiple vehicle categories. In turn, broader adoption of LEDs has helped expand freedom in lighting design. Another outcome of increased LED use can be seen in expanded material options.

Hengyi Industries Sdn Bhd has selected Univation Technologies’ Unipol PE Process for its world-scale 600,000-tonne/year PE plant to be located in Palau Muara Besar, Brunei. The new PE plant will be integrated into a larger refinery and petrochemicals project centred on a 14-million-tonne/year (280,000 b/d) crude oil refinery that will include 11.2 million tonnes/year of downstream capacity producing ethylene, benzene, para-xylene, ethylene glycol (EG), purified terephthalic acid (PTA), polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET, polyester). The project will also include capacity to produce 6.33 million tonnes/year of fuels. Petrochemical BioPolymers BioFilm

Hengyi Industries says it elected to take advantage of the flexible product capability of the Unipol PE Technology with a full-density plant design to produce a broad range of HDPE and LLDPE products to satisfy large-volume product demand for flexible packaging films and various PE moulded articles.

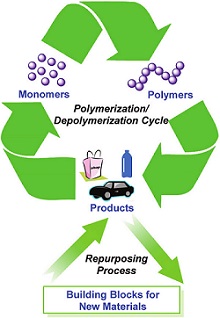

-Chemical recycling must not hinder mechanical recycling progress

Increasingly, chemical recycling appears to be the area of most interest in the world of recycling and sustainability.

Chemical recycling was a major topic at October’s EPCA (European Petrochemical Association) virtual event.

It was given its own virtual event through the PET Monomer Recycling Forum by Petcore Europe – the association representing the complete polyethylene terephthalate (PET) value chain across the continent.

Chemical recycling generates headlines in the world’s major business papers and can be seen featured in global brands’ and fast moving consumer goods’ (FMCG) sustainability strategies. Petrochemical BioPolymers BioFilm

Both ICIS and industry players believe commercial-scale chemical recycling (or ‘advanced’ or ‘molecular’ recycling depending on who you are talking to) is at least five to ten years away, but interest in recycling processes is growing at a rapid rate.

researchgate.net

Palsgaard A/S is driving the trend towards more natural ingredients and additives as industries strive for enhanced sustainability by increasing the use of renewables in their materials sourcing. The Danish pioneer in food emulsifiers has opened a new 10,000 tonnes pellet line that also expands the manufacturer’s production capacity for Einar® brand plant-based polymer additives. Petrochemical BioPolymers BioFilm

“We are seeing a fast-growing demand among consumers, brand owners, packaging designers and plastics manufacturers for more natural materials to reduce fossil depletion and waste,” says Ulrik Aunskjær, Global Industry Director Non-Food Business Development, Polymer Additives for Palsgaard. “Our expanded production capacity meets these requirements by boosting the availability of food-grade plant-based surfactants and modifiers for polymer manufacturers and compounders.”

-JVs, stronger polymers drive up LyondellBasell Q4 profits

Stronger polyolefins margins and contributions from new joint venture stakes drove LyondellBasell’s fourth-quarter earnings to the highest level in years, despite the impact of refining sector losses, the producer said on Friday.

The company reported its strongest fourth-quarter earnings before interest, taxes, depreciation and amortisation (EBITDA) since 2017 on the back of firmer polyethylene (PE) margins, contributions from joint ventures with Sasol and Liaoning Bora Enterprise drove profits. Petrochemical BioPolymers BioFilm

LyondellBasell invested $2bn for a 50% stake in the commodity chemical production assets at Sasol’s Beleaguered Lake Charles, Louisiana, project, and entered into a 50/50 joint venture with Bora for a polyolefins complex in China.

-Increasing demand for recycled plastics in Medical Industry after Pandemic outbreak

Polymers have always been an immense portion of health care sector. The pandemic is motivating plastics to new application heights.

Since the outset of the COVID‐19 pandemic, medical industries have been on the stride to develop useful and supple products that meet the demands of health care networks in uncertain times across the world.

Health care providers want flexible, effective and cost‐efficient solutions to patients’ needs. Petrochemical BioPolymers BioFilm

A big part of these developments includes advances in how plastics are manufactured, processed and selected for applications.

Technologies as far‐ranging as 3D and increasingly 4D printing are giving part makers and end‐users the flexibility they need for low‐run, economical custom device applications.

The growing use of properties‐rich thermoplastics like polyetheretherketone (PEEK) is leading to the substitution of high‐performance polymers for titanium and other conventional materials in implantables.

And chemical recycling is not only creating a stream of custom polymers from waste medical plastics but meeting the concerns of hospitals and patients for sustainable device manufacturing.

hortages of everything from hospital beds to surgical masks are seen in this Pandemic situation.

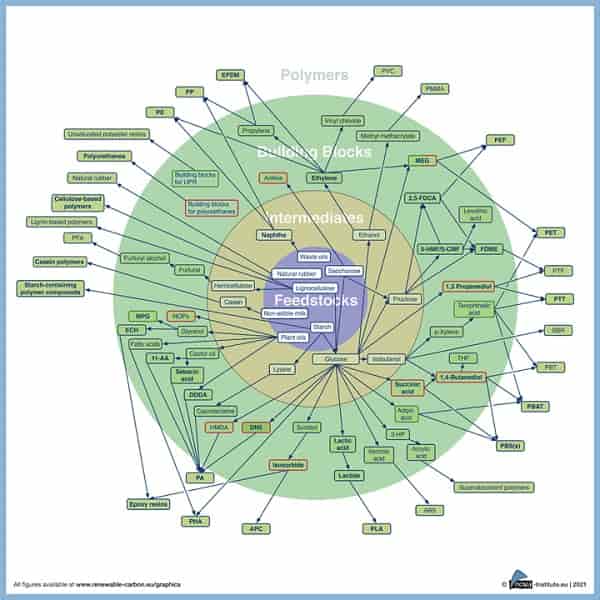

-Growth Rate of Bioplastics Higher than Overall Plastics Market Growth

nova-Institute reports that the for the first time, the growth rate of biobased polymers exceeds that of the overall plastics market growth.

A new market and trend report from German-based researcher nova-Institute characterizes the year 2020 as very promising for biobased polymers. Sold-out PLA in 2019 led to the installation of increased capacities, PE and PP made from biobased naphtha are breaking ground, and future expansion for biobased polyamides/nylons as well as for PBAT, PHAs and casein polymers is on the horizon. A lower production was only observed for biobased PET. Petrochemical BioPolymers BioFilm

“Bio-based Building Blocks and Polymers – Global Capacities, Production and Trends 2020–2025” from the international nova biopolymer expert group shows capacities and production data for all biobased polymers in the year 2020 and a forecast for 2025.

As we begin to dream of and conceive a post COVID -19 world, we realize that several trends developed during the pandemic will continue – namely clothing that provides comfort and reassurance, and that’s made with sustainable sources. Additionally, this clothing needs to be multi-functional in that it can cross the boundaries between home wear, activewear and outdoor wear. And, it must last overtime. Petrochemical BioPolymers BioFilm

As a solutions provider across the value chain from mill to brand to consumer, Hyosung consistently forecasts market trends to develop a comprehensive fiber offering to help its customers envision products that suit these trends. The company will present many its new sustainable and multi-function regen fibers at ISPO Munich Online February 1-5, 2021.

-Versatile ball tester developed for automotive interior applications

Testing service supplier Bertrandt says it has developed a standardized and validated testing system, incorporating mobile ball impact testing device, which enables customers to carry out independent testing of interior components.

The company notes that a trend toward lightweight vehicle construction is leading to the increased use of hybrid plastic technologies in the development of interior components. These require thorough testing and functional validation in a real vehicle environment.Petrochemical BioPolymers BioFilm

The ball impact test is used to test a component’s impact resistance. In conventional tests, a steel ball with a defined mass is dropped from a set height through a drop pipe onto a horizontal surface of the component being tested. In practice, however, some components are installed vertically or diagonally and it is therefore not possible to test them directly in the vehicle using a free-falling ball.

Petrochemical BioPolymers BioFilm

Petrochemical BioPolymers PETFilm 02-02-2021