Petrochemical BioPolymers HDPEPackaging 30-01-2021 - Arhive

Petrochemical BioPolymers HDPEPackaging

-Veolia expands plastic recycling operations to process 100 grades of plastic

Veolia has expanded its plastic recycling operations to process over 100 different grades of plastic from consumer, commercial and industrial sources.

By increasing the scale of recycling by 8,000 tonnes per year, and extending the scope of the recycling operations the company is supporting the target of reducing plastic leakage into the environment, promoting the UK to UK plastic circular economy, and passing these materials back into the supply chain for reuse.

Working from three dedicated sites in London, Essex and the Midlands the company can now provide a complete range of services from collection of raw feedstock direct from people’s homes or businesses, through all the recycling steps, and back to plastic pellets ready to be used to manufacture new plastic items.

Backing the operations is the support team that can ensure compliance with the complex legislation involved in the reprocessing of these materials, and Veolia’s own Sustainable Packaging Academy which was established last year.

-Japan’s Inpex mulls hydrogen business expansion

Japanese upstream firm Inpex plans to enhance its hydrogen business to achieve a 2050 net-zero carbon emissions goal by utilising carbon dioxide capture, utilisation and storage technology in its upstream projects.

Inpex targets to break down natural gas into hydrogen and carbon dioxide (CO2) to supply hydrogen as carbon-free energy. The company also aims to explore the use of CO2, including production of methane. Inpex considers shifting its core business to hydrogen from upstream development when its use becomes more common. The company is also considering providing LNG as a raw material of hydrogen instead as a fuel in the future. Petrochemical BioPolymers HDPEPackaging

It plans to examine the feasibility of carbon capture and storage at its Ichthys LNG terminal in Australia. The firm has been trialling a methanation plant manufacturing methane from hydrogen and CO2 at Japan’s northern prefecture Niigata since October 2019.

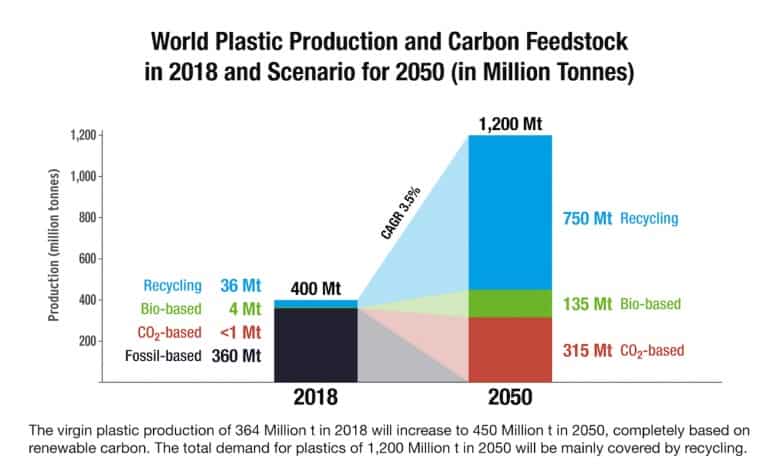

-Carbon dioxide on the rise in feedstock evolution

Nearly one million tonnes of production capacity is already installed for carbon dioxide-based polymers, illustrating how the plastics industry is responding to a growing trend for chemical feedstock.

According to nova-Institute, the potential and the actual production capacity for carbon dioxide-based polymers is much larger than commonly assumed and discussed. Production capacity already amounts to more than 850,000 tonnes a year, albeit focused on polycarbonates and polyols for polyurethanes, with an average weighted carbon dioxide-based carbon content of only 5.4 per cent.

400 million tonnes of polymers are produced globally each year, with 90 per cent of them created from fossil carbon. Petrochemical BioPolymers HDPEPackaging

-DIC/Jindal tie-up to target functional CPP films market in India

Japan’s DIC Corporation has for some time been exploring the possibility of an alliance with India’s Jindal Poly Films Limited, one of the world’s largest manufacturers of biaxially oriented polypropylene (BOPP) film, with the aim of helping to foster a market for functional cast polypropylene (CPP) film in India. Now, the two companies have reached a consensus to collaborate in this area.

India, like other countries, is experiencing a greater need for products with performance features that respond better to environmental concerns and sanitation issues. In the food packaging field, demand is increasing for films with performance features that meet such needs. Of particular note, demand for functional CPP film, which contributes to the realisation of reducing plastics, mono-material packaging, is expected to expand in the future. Petrochemical BioPolymers HDPEPackaging

-Südpack buys high-barrier film manufacturer LPF

Südpack is to acquire a high-barrier film manufacturer from the Clondalkin Group, as part of its long-term growth strategy.

Located in Grootegast, the Netherlands, LPF Flexible Packaging has been converting films for sensitive products since 1907. It has been part of Clondalkin since 2005, which is owned by private equity investor Egeria.

LPF produces printed and unprinted duplex and tri-plex packaging laminates, which provide product protection and prolonged shelf life for applications in the food, pharmaceutical and technical sectors. Petrochemical BioPolymers HDPEPackaging

“We value LPF’s high level of development and market competence and plan to establish the site in Grootegast as a Competence Centre for High Performance Laminates over the long term within the Südpack Group,” explained chief executive Erik Bouts.

-Dutch demonstration plant for chemical recycling

UK technology company Itero (London; www.itero-tech.com) has announced plans build a “commercial-scale” plant for chemical recycling with its own pyrolysis process in the Dutch chemical park Brightlands Chemelot Campus (Sittard-Geleen; www.brightlands.com).

The company said its patented technology is sustainable and converts polyolefins into oils, waxes and gases that can be used to make resins and petrochemical products while reducing emissions associated with the disposal of plastics through landfill and incineration.

Petrochemical BioPolymers HDPEPackaging

Due to the pandemic emergency, the final decision on the Delfzijl plant will take longer than expected. Petrochemical BioPolymers HDPEPackaging

Avantium takes some time to announce the final decision regarding the construction of the first plant for the production of 2,5-furandicarboxylic acid (FDCA) in Delfzijl, the Netherlands, an intermediate for the synthesis of polyethylene furanoate (PEF) , biobased polymer alternative to PET.

Due to the Covid-19 pandemic, negotiations with financial, commercial and technical partners have been delayed and the company will therefore take longer than expected to determine if all the conditions required to kick off the project will be met. A further update will be provided on March 24th on the occasion of the presentation of the 2020 results.

The project involves the launch of a demonstration plant with patented YXY technology for the synthesis of FDCA from sugars, capable of producing up to 5,000 tons per year, for an estimated cost of 150 million euros, largely (85 million) already covered from financing.

-Paraxylene producers in Asia set February contract prices at USD760-790 per tonne

Major Asian paraxylene producers have announced their material contract prices for February shipments at USD760-790 per tonne, market sources told ICIS .

Thus, South Korean SK Global Chemicals announced its contract price for paraxylene for February at USD770 per ton, CFR Asia, and Japan’s Idemistsu Kosan announced its price for material supplies next month at USD760 per ton, CFR Asia.

Meanwhile, Japan’s Eneos Corporation has nominated its February contract price for paraxylene at USD790 per tonne, CFR Asia, while India’s Reliance Industries has posted it at USD780 per tonne, CFR Asia. Petrochemical BioPolymers HDPEPackaging

Previously notedthat Asia failed to reach agreement on December contract prices for paraxylene. This is the twelfth time last year that agreement on contract prices for paraxylene in Asia has not been reached.

Paraxylene is a raw material for the synthesis of terephthalic acid – an intermediate product for the production of polyethylene terephthalate (PET).

-Interior trim supplier and plastics manufacturer form global alliance

Japanese automotive interior trim supplier Hayashi Telempu and Italian industrial plastics producer Adler Plastic are to create a Global Automotive Interior Alliance (GAIA), with the aim of further strengthening the existing partnership between the two groups. Petrochemical BioPolymers HDPEPackaging

The companies had already signed a technical cooperation agreement covering automotive interior and exterior business in 2017 and formed a JV focusing on development of interior parts specific to NEVs (New Energy Vehicles).

The new collaboration, they state, will push this cooperation further and create an alliance in the automotive interior trim, exterior and acoustic parts market, with a global network enabling seamless service and supply to automotive OEMs.

-Shintech Invests $1.3B to Increase Capacity at Plastics Plants

Plastics firm Shintech Louisiana LLC is planning to launch a $1.3 billion expansion project at its manufacturing and packaging facilities in Plaquemine and Addis in Louisiana, according to a release issued Tuesday by the office of Louisiana Gov. John Bel Edwards. The investment will be used to add capacity for PVC, chlor-alkali and vinyl chloride monomer at its Plaquemine plant and expand its PVC packaging and warehouse facility in Addis. Petrochemical BioPolymers HDPEPackaging

“Shintech continues to invest and increase its manufacturing presence in the North American market,” said Danny Cedotal, vice president of manufacturing for Shintech, in a statement. “We appreciate the company’s confidence in our local manufacturing team. The jobs and infrastructure the company has built in Plaquemine and Addis continue to create much-needed economic development in our communities.”

Petrochemical BioPolymers HDPEPackaging