PlasticRecycling BioPolymers PlasticAddittives 05-02-2021 - Arhive

PlasticRecycling BioPolymers PlasticAddittives

Crude Oil Prices Trend

-Nampak Plastics targets return to profitability

The Plastics division of rigid packaging converter Nampak is to continue consolidating sites this year as it attempts to improve the competitiveness of its business.

The South African company posted an impairment of R424 million ($28.4m) for the division in 2020 on the back of the global pandemic. After a strong start to last year, Nampak Plastics was on track to return to profitability when Covid-19 lockdown regulations led to an abrupt decline in demand for the smaller bottles in which its customers pack water, juice and carbonated soft drinks.

In April alone, sales declined by a third. For the year as a whole, revenue decreased and Nampak Plastics reported a small trading loss. However, this was a significant improvement from 2019’s loss as various restructuring initiatives – including reduced employee costs — bore fruit. The company also closed its Petpak Epping factory as well as its George and East London warehouses.

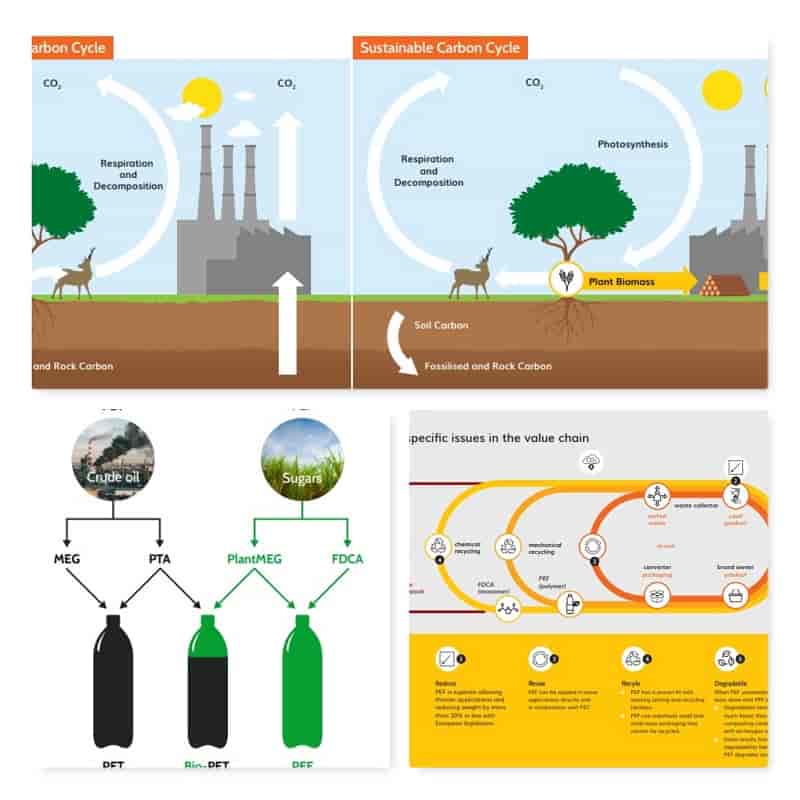

Avantium N.V., a leading technology company in renewable chemistry, publishes its Sustainability Plan ‘Chain Reaction 2030’, highlighting the company’s ambitious vision to achieve a fossil-free chemical industry by 2050.

In 2020, Avantium published its Sustainability Manifesto outlining a pathway for the company to take to tackle the global climate emergency. Chain Reaction 2030 is the evolution of this manifesto, a ten-year action plan the company can be measured against in this decade.

Chain Reaction 2030 commits Avantium to a series of goals and targets where it has the greatest impact on social and environmental issues. This includes accelerating its own technologies and operations to support the circular economy and driving responsible and sustainable business practice across the industry. The plan also includes the company’s actions to empower its own employees and to excite the next generation to accelerate the transition to a fossil-free world.

-Finnish UPM considers building biorefinery in Rotterdam

UPM moves forward with biofuels growth plans and starts the basic engineering phase of a next generation biorefinery. The potential biorefinery would have an annual capacity of 500,000 tonnes of high-quality renewable fuels including sustainable jet fuel. The products would significantly reduce carbon footprint in the road transport and aviation, as well as replace fossil raw materials with renewable alternatives in chemicals and bioplastics.

“The planned biorefinery would scale up UPM’s successful biofuels business to a new level. At the same time, it would further improve long term competitiveness and sustainability performance of UPM Biofuels by introducing several sustainable feedstocks and achieving uniquely high CO2 emission reduction compared to biofuels currently in the market,” says Jyrki Ovaska, Chief Technology Officer of UPM.

UPM’s solid wood biomass-based residues and side streams would play a substantial role in the feedstock pool. In addition, it would consist of sustainable liquid waste and residue raw materials. “UPM has an excellent position and expertise acquired over the decades in biomass sourcing both in Finland and Central Europe thanks to our large-scale operations in the pulp, paper, timber and plywood businesses. We are also developing and testing innovative carbon farming concepts.”

-German car sales drop 30% in January – source

New passenger car registrations in Germany fell more than 30% in January to around 170,000 vehicles, an industry source told Reuters on Wednesday.

Car dealerships have been hit by a second lockdown amid the coronavirus pandemic in Germany, with non-essential stores closed since mid-December, and by tax breaks for consumers running out at the end of 2020.

New car registrations in December had been up by almost 10%.

-Compact packaging line from GEA expands capacity for Irish brewery

For Carlow Brewing Company, GEA VIPOLL will install Ireland’s first Visitron ALL-IN-ONE line. Looking for a multifunctional filling system, the craft brewer chose GEA’s combined rinser-filler-seamer block, which offers brewers maximum production flexibility and reliability.

The ALL-IN-ONE rinses, fills, seals and seams cans, glass and even PET bottles with just one machine in the smallest possible space. Manufacturers can switch between bottle and can formats without tools in just 20 to 30 minutes.

The family-owned brewery produces the O’Hara’s craft beer brand range, Falling Apple cider plus a range of canned and bottled private labels for international customers.

To meet growing customer demand and interest in canned beer, Carlow Brewing decided to invest in a fundamentally new facility. Canning is a first for the brewery. However, no Irish contract packer could provide the required capacity.

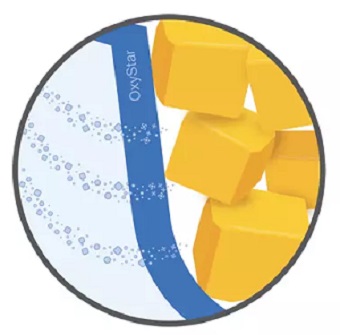

-Worlds first Nr.1 resin code recyclable PET barrier material

Placon continues to be a leader in sustainable, thermoform packaging innovation with their new patent pending recyclable oxygen barrier material called OxyStar™. When creating our custom food packaging, our number one challenge is figuring out how to help the food last longer. Direct oxygen contact with perishable foods has been a problem for food manufacturers since the beginning of time, but not anymore.

Introducing the world’s first recyclable PET barrier material, OxyStar. Most barrier solutions today are classified as a #7 recycle symbol that cannot be recycled. OxyStar PET barrier material has a #1 recycle symbol, allowing the package to be put back into the PET recycling stream to be used over again. Creating a package that gives your products a better way to stay fresher for longer and increases product shelf life while making a sustainable impact is how we make simply better packaging.

Placon’s OxyStar barrier material utilizes an active oxygen barrier that stops oxygen ingress through a free radical chain reaction within the packaging sidewalls. Throughout the shelf life of the OxyStar active agent, the oxygen ingress will be near zero. OxyStar is made using PET material, which allows it to be the first barrier material with the #1 recycle symbol. This is key to ensuring that we continue to support a close-loop recycling stream for PET plastics.

Varun Beverages Ltd, part of RJ Corp group, one of the largest franchises for PepsiCo Inc. globally, has installed Sidel’s Aseptic Combi Predis™ in its newly established plant in Punjab, India. This pivotal project aims to expand PET bottling capacity and provide production flexibility for the private label milk brand Cream Bell as well as Pepsi’s Tropicana juice range. By choosing the new aseptic dry preform sterilisation technology, RJ Corp is commercialising its liquid dairy products (LDP) in PET for the first time in India.

Since the early nineties, the privately owned Indian company RJ Corp has made itself a multinational powerhouse with thriving businesses in beverages, fast food restaurants, retail, ice cream, dairy products, healthcare and education. Through its operating company Varun Beverages Ltd., the group is one of the largest bottling partners for PepsiCo in the world, currently holding 36 plants on the Indian subcontinent and in Africa, and producing carbonated soft drinks, water and hot-fill juices as well as LDP.

-On the spot: Big Bottling Company invests in a powerful PET line from KHS

A young company in Nigeria with plans for growth has opted for KHS for its new PET line.

The Dortmund systems supplier has proved especially convincing with its local team that installed the system with practically no outside help.

With over 200 million inhabitants Nigeria is already by far the most heavily populated country in Africa.

In the next 30 years the United Nations reckon on this number doubling, meaning that by 2050 around 410 million people will live here.

After India and China, the country of Nigeria will then have the world’s third-largest population.

The supply of drinking water is inadequate: until a few years ago only one in two people had access to clean water.

The country’s infrastructure is also still in its infancy, so that Nigerians are continuing to have to resort to buying water in bottles – about 45 billion liters of it in 2019.

-Upax-Unity has launched the largest PET deep processing line in Russia

Upax-Unity (Perm, Upax-Unity) has launched Russia’s largest line for deep processing of polyethylene terephthalate (PET) and production of rigid packaging for food products, which has no analogues in Russia, according to a press release Administration of the Governor of the Perm Territory.

The new line allows the production of more than 50 types of food PET containers, packaging for the dairy and meat industries. It is noted that the created line covers the full production cycle: from sorting and deep processing of secondary raw materials to the production of finished products from recovered polymer. As a result, the company will be able to produce containers of various sizes and rigidity, shakers, disposable cups and other food containers. This plant allows you to process up to one thousand tons of recycled polyethylene terephthalate per month.

In December 2018, the Industrial Development Fund (IDF) and the Regional Industrial Development Fund of the Perm Territory provided the enterprise has a preferential loan under the Development Projects program in the amount of 520 million rubles. to launch a new production. At the same time, the total project budget amounted to RUB 1.5 billion. In the same month, Upax-Unity installed three thermoforming machines to release packaging.

-SIBUR plans to increase export of polymers this year

The largest Russian petrochemical company SIBUR plans to increase its export of polymers this year by commissioning new production facilities and expanding its product portfolio, Expert reports .

Sibur aims to become the world’s largest producer of base polymers, offering a wide range of advanced products. The company recently launched the country’s largest polymer plant, ZapSibNeftekhim. The production capacity of the new enterprise is a record 1.5 million tons of polyethylene and 0.5 million tons of polypropylene per year for the Russian market, a significant part of which will be exported.

SIBUR began to actively develop international trading about ten years ago in parallel with the development of a project for the construction of a new enterprise. Today, SIBUR’s export division, Sibur International, has four offices in China, an office in Vienna covering all European countries, and a renewed office in Istanbul, which works not only for Turkey, but also for the African Mediterranean, India, Latin America and other countries.

According to Andrey Frolov, Executive Director of Sibur International GmbH, in 2020 the company received about half of its revenue from export sales.

PlasticRecycling BioPolymers PlasticAddittives