PET packaging solutions

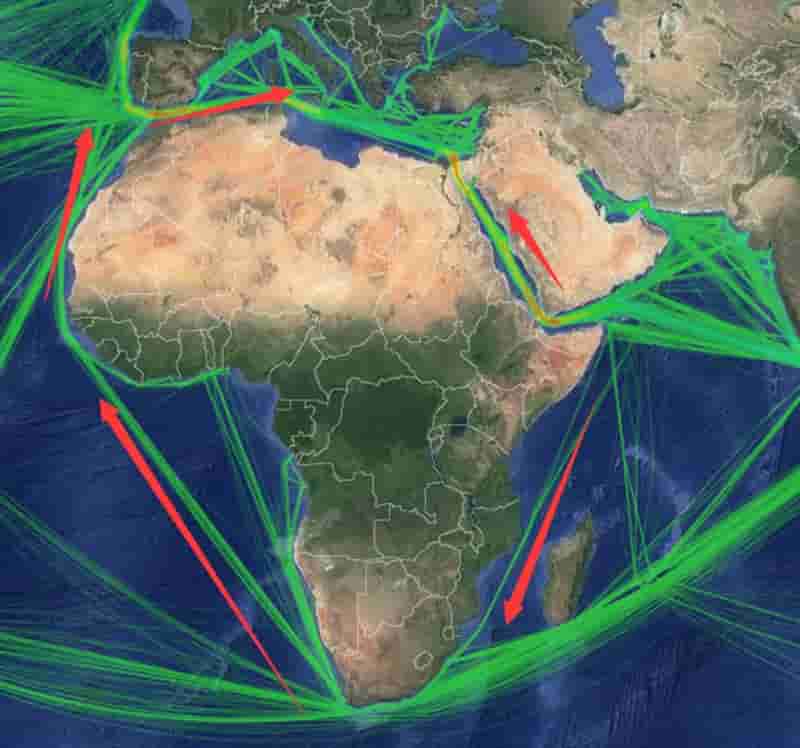

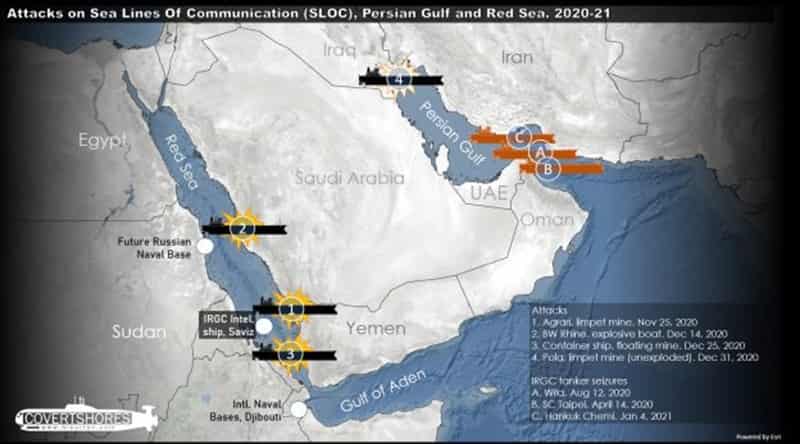

The Houthis have claimed responsibility for an attack on the US cargo ship Koi in the Red Sea

Security firm Ambrey reported an explosion on board the vessel operated by UK-based Oceonix Services. According to Yemeni rebels, the attack occurred as the Koi headed towards ports in occupied Palestine. The Marlin Luanda, also part of the Oceonix Services fleet, had been damaged by a missile the previous week.

Houthi spokesman Brigadier Yahya Saree confirmed the attack, saying Yemeni forces targeted Koi with naval missiles. He also mentioned an earlier attack on the American destroyer USS Revelli in the Red Sea. Saree has threatened to respond with military operations if the US and UK escalate. PET packaging solutions

Tensions grew further with US Central Command announcing it had shot down a ballistic missile and drones launched by the Houthis in the Gulf of Aden. The American destroyer Carney intervened without causing casualties or damage. The United States said the action was aimed at protecting freedom of navigation in the region.

The Houthis view Israeli, US and British ships as legitimate targets in response to Israel’s war against Hamas. Tension persists in the region, with both sides engaging in military action and reprisals.

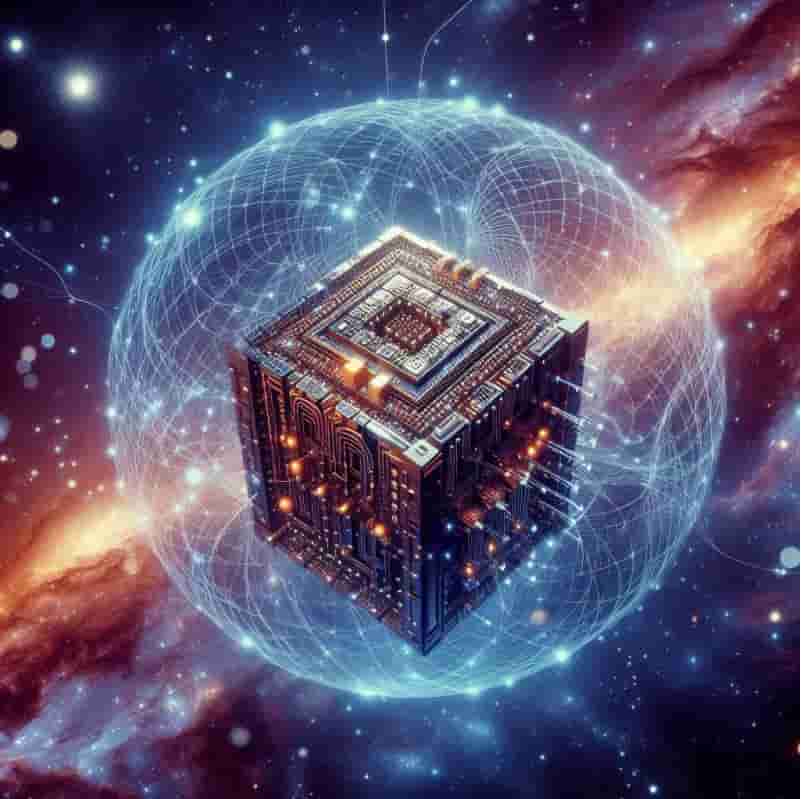

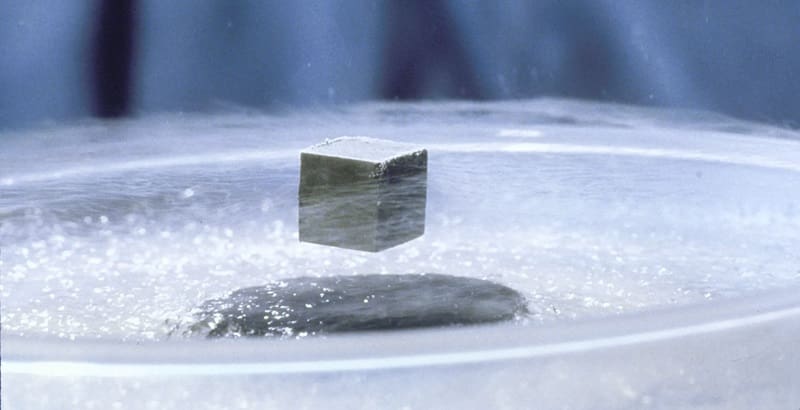

Why do quantum computers threaten global security?

The advent of quantum computers threatens global security, particularly through the concept of “Q-Day,” the day a quantum computer could compromise public encryption systems that protect online communications, bank accounts and critical infrastructure.

The threat emerged in 1994, when mathematician Peter Shor demonstrated that a quantum computer could quickly decipher large numbers, challenging traditional cryptographic security.

Although current quantum computers are not yet powerful enough to use Shor’s algorithm, companies like IBM and Google are progressing in building more powerful machines. The main concern is the time it will take to develop a large quantum computer, since, if built in a few years rather than decades, it could crack encrypted data, causing global chaos.

While individuals may not be directly affected, governments, organizations and businesses must prepare. PET packaging solutions

The concept of “store now, decrypt later” refers to the possibility of storing data until a sufficiently powerful quantum computer is available to decrypt it. Governments are already collecting encrypted data in anticipation of future decryption.

To address this threat, the cryptographic community is developing post-quantum cryptography (PQC), which will resist potential threats from quantum computers. The United States, along with other countries, is standardizing PQC, anticipating the transition from 2025 to 2033. Companies like Google and Cloudflare have already started implementing PQC into their services.

PQC will be critical to maintaining security in a future where quantum computers could put traditional cryptographic systems at risk.

However, the ever-evolving nature of cryptography requires constant monitoring and adaptation to address emerging cybersecurity challenges. PET packaging solutions

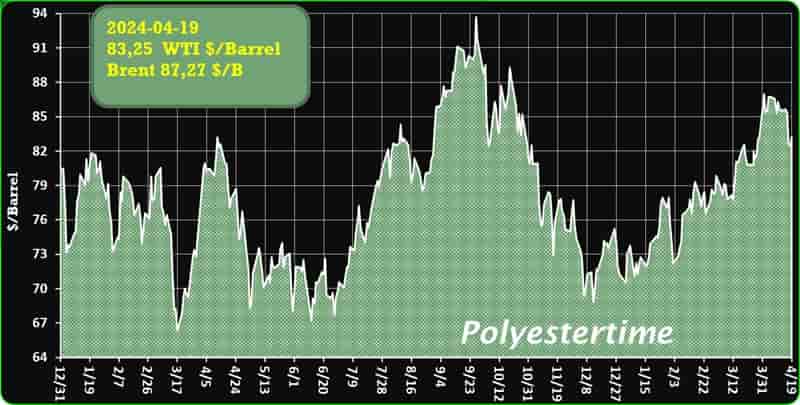

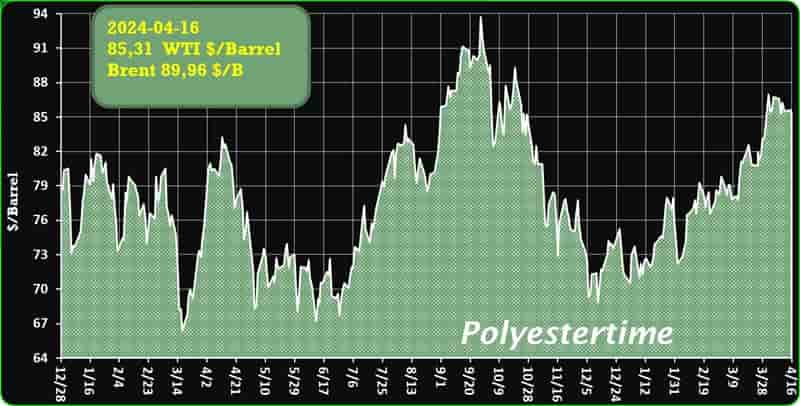

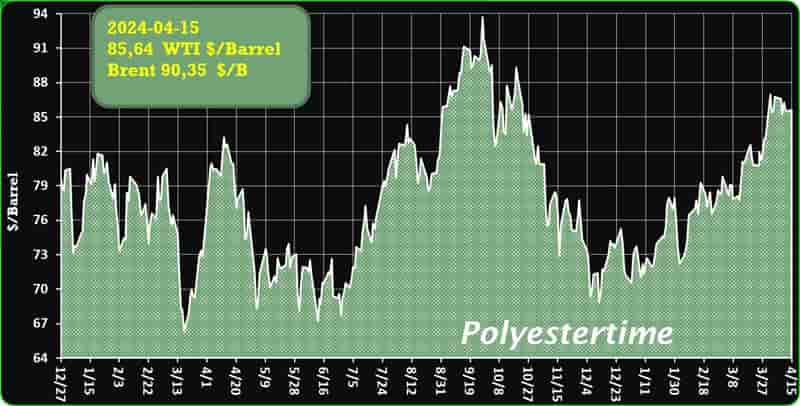

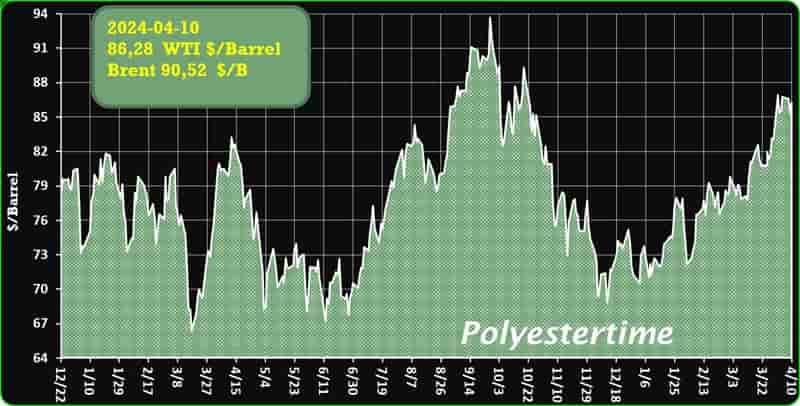

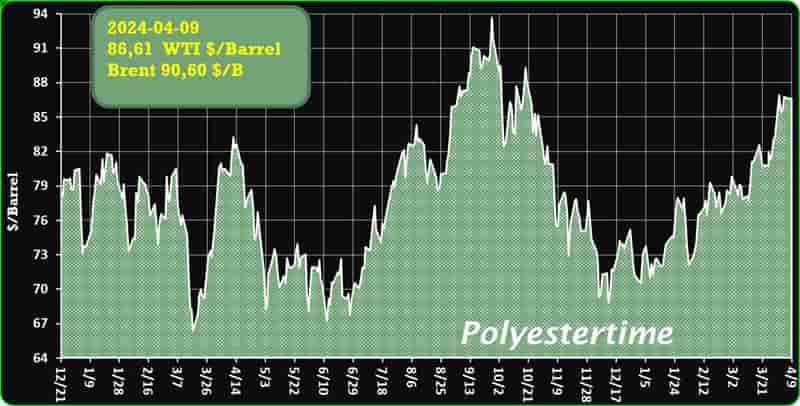

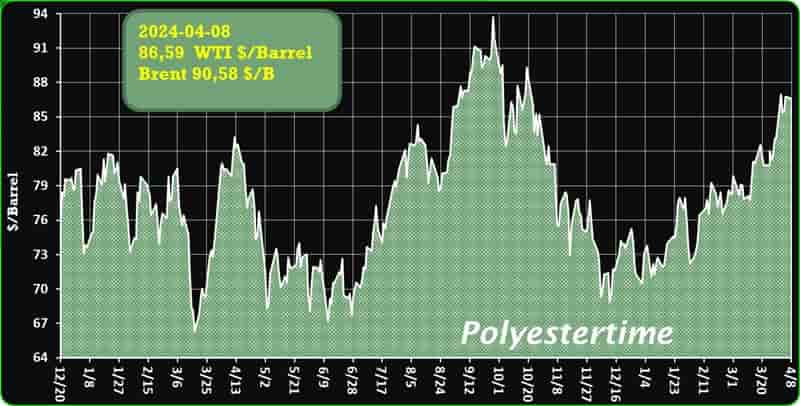

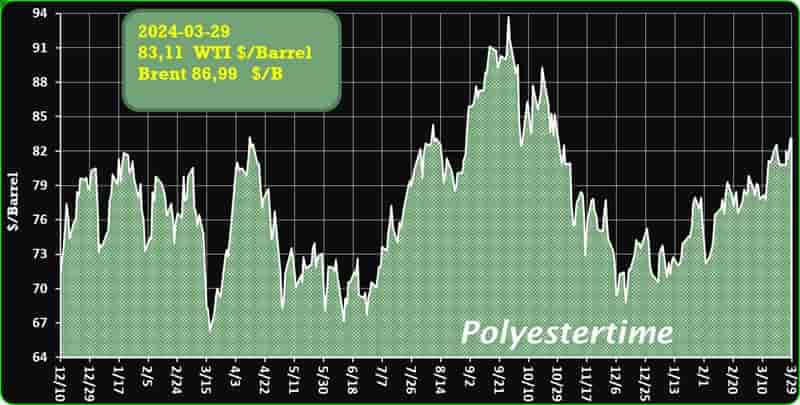

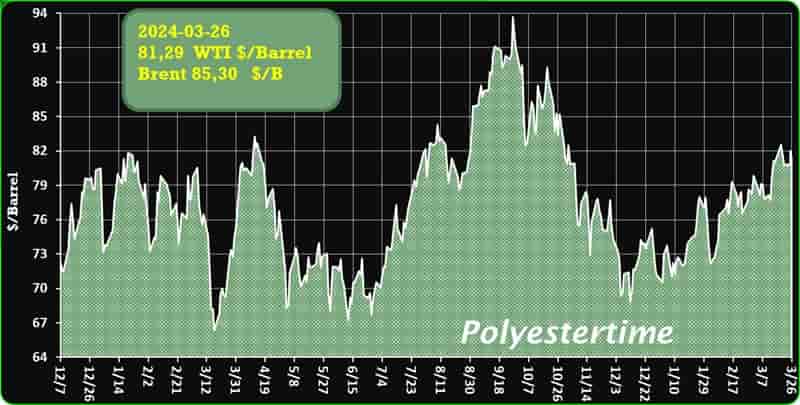

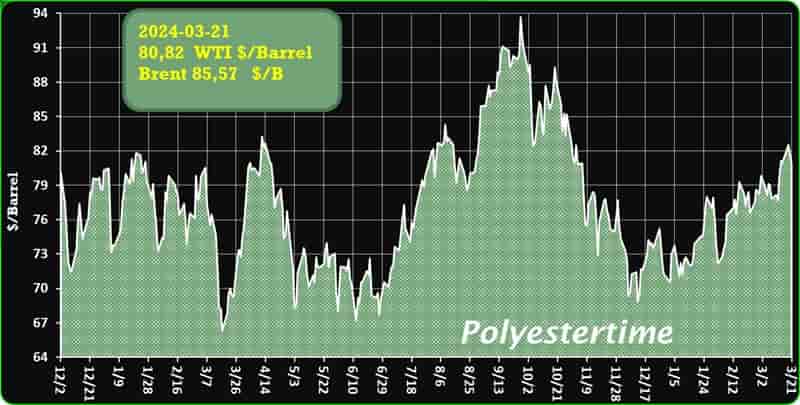

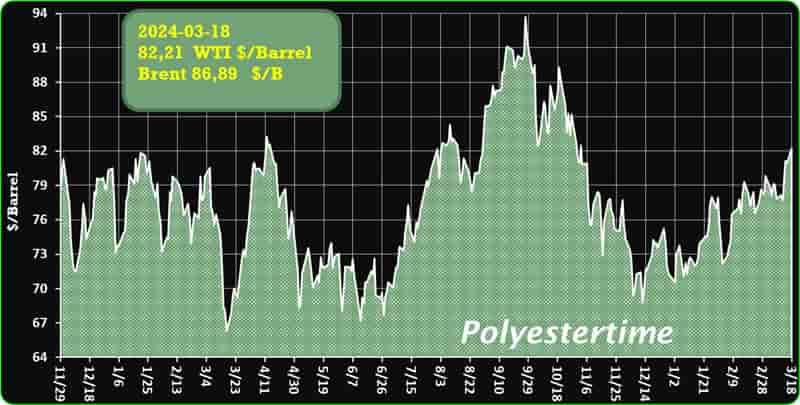

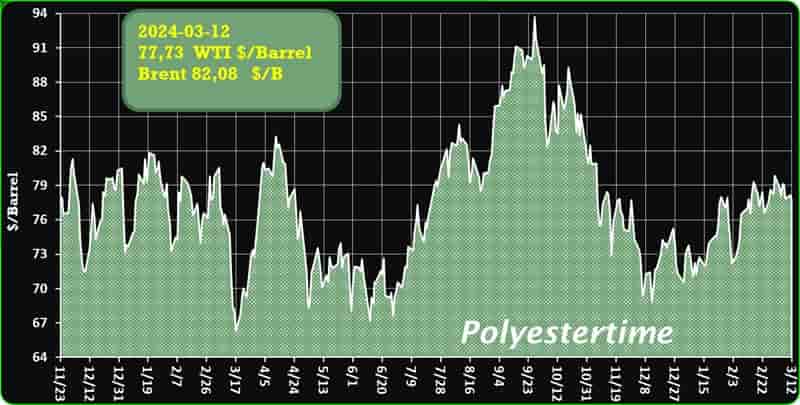

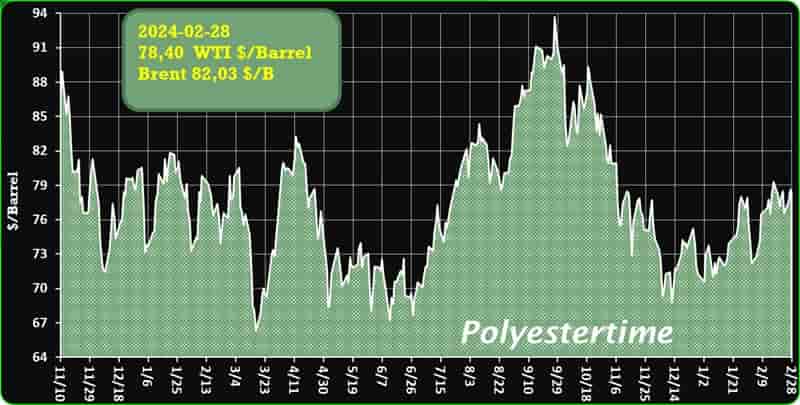

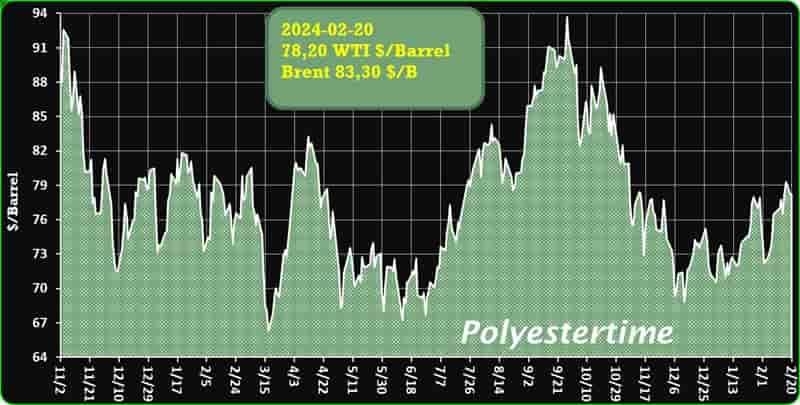

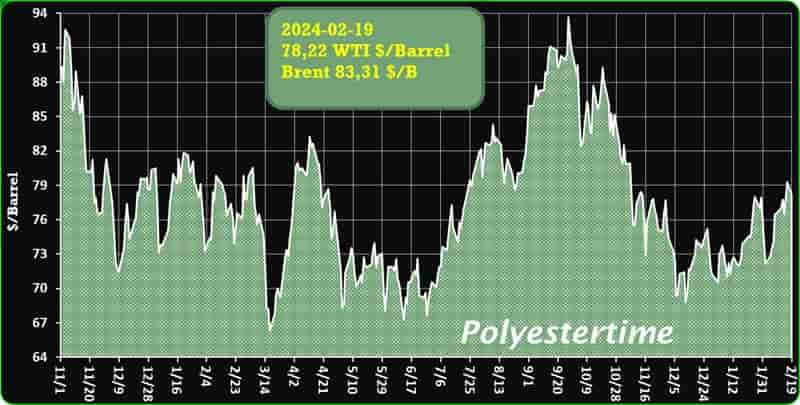

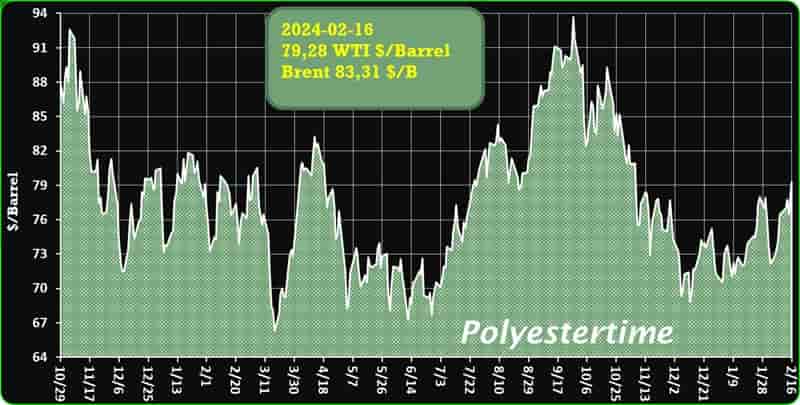

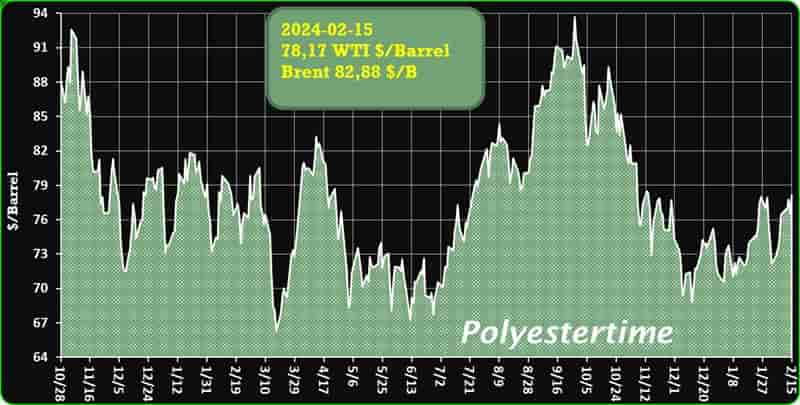

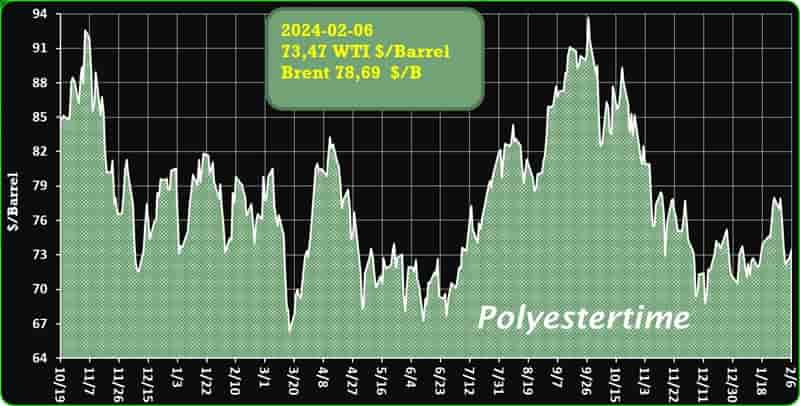

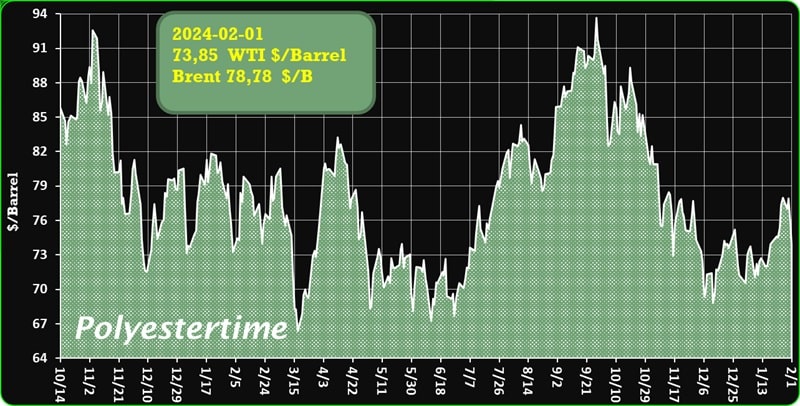

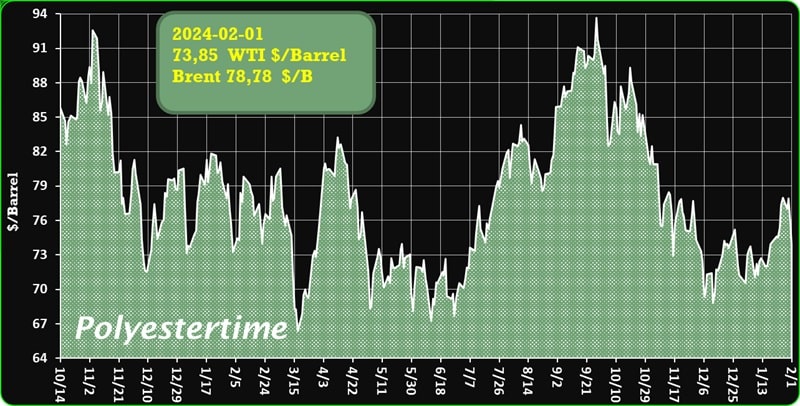

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

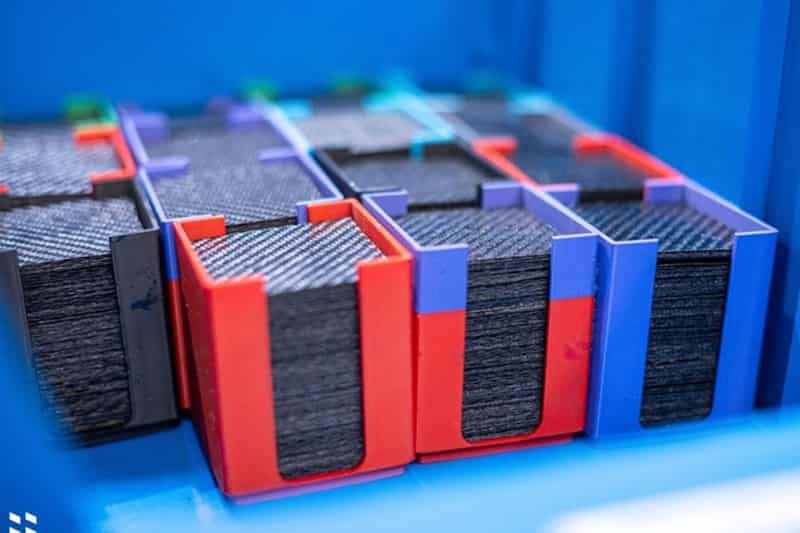

Sidel, a pioneering force in PET packaging solutions, unveils its groundbreaking technology, IntelliADJUST™, heralding a new era in in-line PET bottle quality control with automatic adjustment

A patented solution, IntelliADJUST™ operates within a ‘closed loop’ system utilizing interferometric sensor technology, guaranteeing consistent and efficient high-quality PET bottle production. This innovative bottle blowing control system excels in maintaining material distribution uniformity, especially in bottles crafted from recycled PET (rPET).

IntelliADJUST™ not only ensures consistent bottle quality under varying production conditions but also facilitates the incorporation of recycled PET content.

Its autonomy in real-time, digitized process adjustments results in flawless material distribution, minimizing the impact of production variations and resin specificities on bottle quality. PET packaging solutions

Sidel’s Evo-ON software suite enhances this system by aggregating equipment data and providing dynamic analytics, enabling historical and 24/7 real-time analysis for a truly smart line system.

Stéphane Menard, Product Manager for blowing care at Sidel, elaborates on how IntelliADJUST™ measures in-line bottle thickness, automatically adjusting parameters to maintain high-quality control. This user-friendly blowing solution maximizes marketable bottles by swiftly identifying and correcting thickness deviations.

IntelliADJUST™ aligns with the industry’s push for lightweighting and increased rPET content, offering reliability across various PET preforms. Its capability to secure perfect material distribution despite resin variability positions it as an indispensable tool for customers embracing sustainability in packaging. PET packaging solutions

This technology, operating at speeds up to 90,000 bottles per hour, relies on smart sensor technology for precise measurements and refined production processes. It strategically measures wall thickness at representative points using four interferometric sensors, ensuring continuous control and adjustment for optimal material distribution.

In addition to supporting sustainability goals, IntelliADJUST™ is calibration-free, seamlessly integrating parameters into machine settings for each SKU recipe.

This easy-to-use system, with high accuracy, minimizes the need for manual laboratory controls, providing a reliable, expert-free solution for achieving stabilized quality across bottles. IntelliADJUST™ represents a significant step towards low carbon footprint packaging, empowering customers to optimize their PET packaging’s environmental impact. PET packaging solutions

Saudi Aramco, the energy giant and cornerstone of Saudi Arabia’s economy, has halted its plan to increase oil production capacity to 13 million barrels per day (bpd)

The Saudi Ministry of Energy has directed Aramco to maintain its maximum sustainable capacity (MSC) at the current level of 12 million bpd. The decision, announced in a statement by Aramco, signifies a departure from the initially declared goal of reaching 13 million bpd by 2027.

This development follows Saudi Arabia’s commitment in October 2021 to achieve net zero carbon emissions by 2060, a move that garnered skepticism from environmental activists. Aramco’s profits, crucial to funding Crown Prince Mohammed bin Salman’s Vision 2030 reform program, are expected to support the kingdom’s transition to a post-oil era.

The decision not to pursue the planned production increase suggests Riyadh’s cautious approach, indicating a lack of confidence in the global need for such additional capacity. Jamie Ingram, senior editor at the Middle East Economic Survey, remarked that the redirected investment may be more strategically placed elsewhere. PET packaging solutions

In a surprising turn of events, Justin Alexander, director of consultancy Khalij Economics, highlighted Saudi Arabia’s substantial reserves, financial capacity for investment, and low development costs. He emphasized the potential for Aramco, even in a changing energy landscape, to remain competitive as a low-cost and low-carbon intensity producer. Aramco will provide updated capital spending guidance with its full-year 2023 results in March, reflecting the evolving dynamics of the energy industry.

MEG price soar, Navigates Peak Through Supply-Chain Chaos Amidst Geopolitical Turbulence

The price of Mono Ethylene Glycol (MEG) has experienced a rising trend in the global market in January 2024, due to high production costs, logistic charges, and chaotic stock management after the recent global supply disturbances. The US MEG market has seen an upsurge of more than 14% throughout January. On the other hand, the freezing cold in a major part of the USA has been a critical point in the swelling of MEG prices due to the shutdown of chemical manufacturing plants experiencing freezing cold during the timeframe. The freezing cold temperatures gripping the United States have ushered in a series of challenges for the country’s manufacturing sectors. Manufacturing companies like Nan YA Plastic Corporation and Sasol Chemical Company were forced to shut down production units due to freezing cold weather. PET packaging solutions

The closure of manufacturing plants disrupts the supply flow, leading to a shortage of goods. This disruption reverberates through the supply chain issues, affecting suppliers, distributors, and retailers. Under these market scenarios, inventory management has become hard to handle and strategize, which is likely to remain uncertain for further period. The MEG prices were observed to hovering around USD 450/MT FOB US Gulf (USA) post witnessing a steep incline (more than 14%).

Moreover, Asian countries are mirroring the same trend as the USA, with MEG prices soaring due to elevated production costs, shipping challenges, and increasing demand from PET manufacturing companies coupled with downstream effects. Stretched logistic freight charges, embracing the ongoing Red Sea conflict in the shipment route, have predominantly impacted trade between the United States and Asia. In January, China faced more than a 4% growth in MEG prices. PET packaging solutions

More…

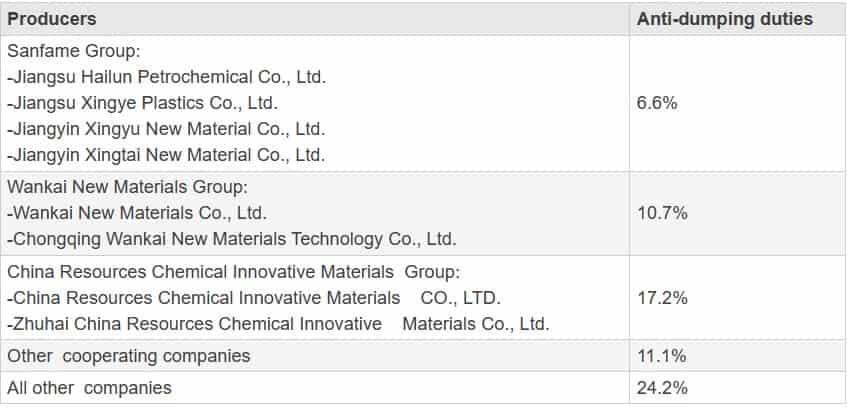

In response to the surge in Chines PET resin exports, Korea initiated an anti-dumping probe on January 12th, aiming to curb the influx

This move follows trade barriers imposed by the United States and Japan from 2015 to 2017, propelling Chinese PET resin exports to Korea. The preliminary ruling, expected within three months, may lead to anti-dumping tariffs and a subsequent decline in Chinese PET bottle chip exports to Korea.

Simultaneously, Mexico announced its own anti-dumping investigation into PET bottle chip and PET fiber chips from China, responding to concerns raised by local polyester manufacturers Alpek and Indorama. Focusing on tariff codes 3907.61.01 and 3907.69.99, the probe assesses potential market distortions caused by Chinese imports, particularly in the PET resin and chips with viscosities ranging from 0.60 to 0.88 deciliters per gram (dL/g). The investigation underscores Mexico’s commitment to protecting its domestic PET industry from adverse effects. PET packaging solutions

Historically negligible, Chinese PET resin exports to South Korea soared from 2016, reaching 118,000 tons by the end of 2022. Projections for 2023 estimate exports at 150,000 tons. Notable Chinese companies, including Hainan Yisheng Petrochemical and China Resources Chemical Materials Technology, face potential impacts from the anti-dumping measures.

Korea’s PET resin market, dominated by TK Chemical and Lotte, faces challenges if foreign competitors gain domestic market share, especially amid declining demand from Europe and the United States. The shift towards the domestic market intensifies as Korean exports decline and competition from Chinese enterprises rises, prompting a strategic focus on local markets.

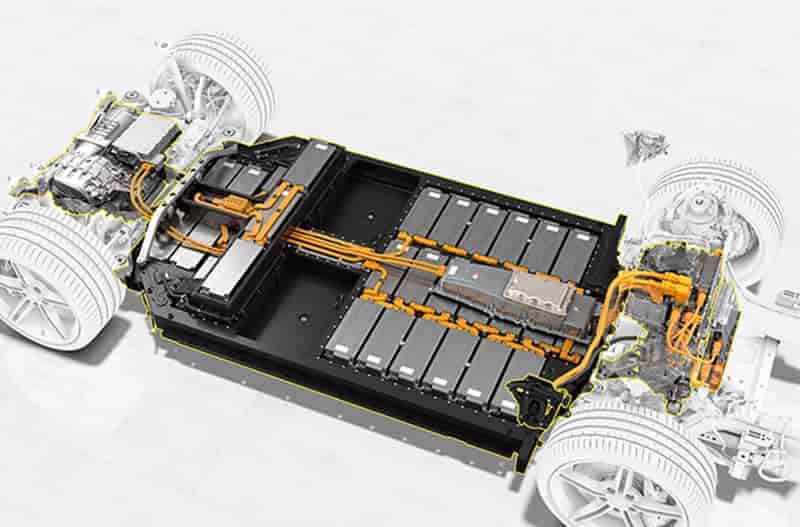

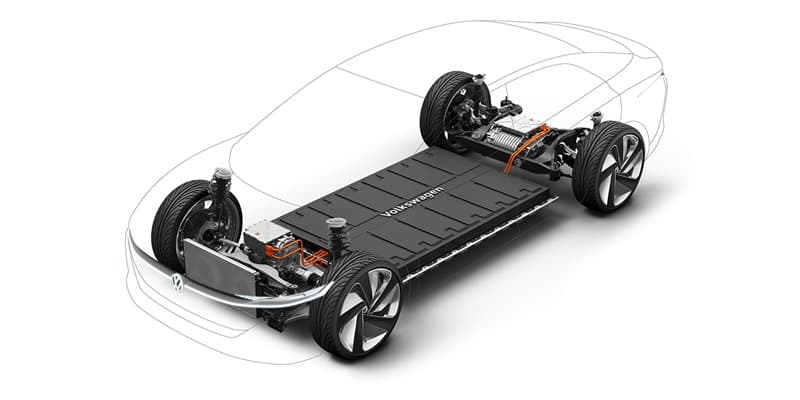

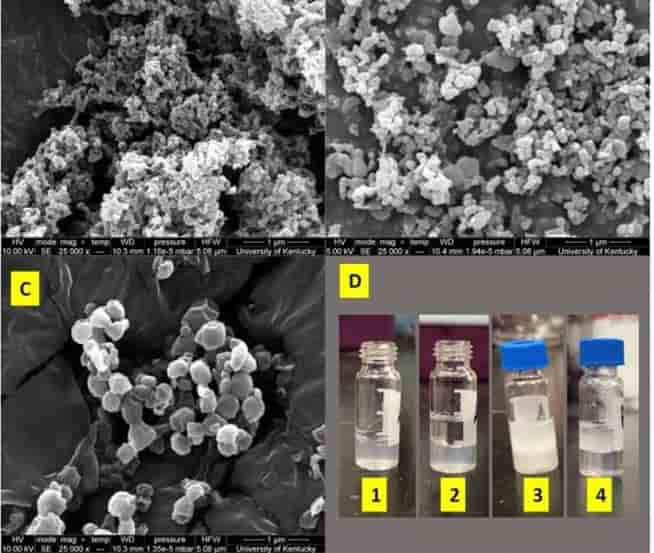

French Researchers (PROMES-CNRS Lab) Invent Solar Pyrolysis To Recycle Lithium Batteries

Research conducted at the PROMES-CNRS laboratory, under the leadership of Gilles Flamant, has recently validated the viability of employing a solar-powered pyro-metallurgical process for recycling valuable elements such as lithium, nickel, cobalt, and others from lithium-ion batteries. The PROMES-CNRS laboratory specializes in endeavors aimed at industrial decarbonization through the utilization of extremely high-temperature solar energy. PET packaging solutions

PROMES-CNRS lead Gilles Flamant asserts that with the anticipated surge in lithium-ion battery disposal over the coming decades, there is a pressing need for effective treatment methods, wherein solar thermal technology could significantly contribute to industrial decarbonization efforts.

For years and decades industries such as steel, cement, chemicals etc. have relied on fossil fuels, making fossil heat the established norm in these sectors. This poses a significant obstacle for concentrated solar power technology. However, the emergence of lithium-ion battery recycling, particularly through pyro-metallurgy, offers a promising avenue for concentrated solar heat to rival fossil-fuelled heat. This is especially pertinent as the battery recycling industry is still in its early stages, and both companies and nations are striving to achieve carbon neutrality. PET packaging solutions

Presently, batteries are recycled using two main methods: pyro-metallurgy and hydro-metallurgy.

Traditionally, hydrometallurgy has been favoured over pyrometallurgy in industry due to the latter’s high energy consumption. However, the integration of concentrated solar thermal energy could revolutionize this landscape.

The research team successfully harnessed high-temperature solar energy to generate a metal alloy comprising lithium, cobalt, nickel, and manganese (iron), as detailed in their paper titled “A Solar Pyro-Metallurgical Process for Li-ion Batteries Recycling: Proof of Concept,” published by PROMES.

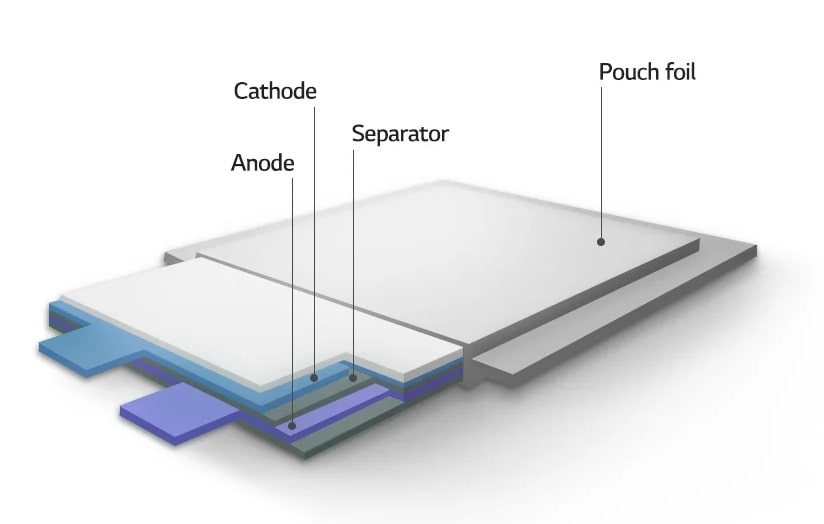

Lithium-ion batteries consist of key components including the anode, cathode (current collectors), separator, and electrolyte, containing crucial metals like lithium, cobalt, and nickel primarily in the cathode. PET packaging solutions

More…

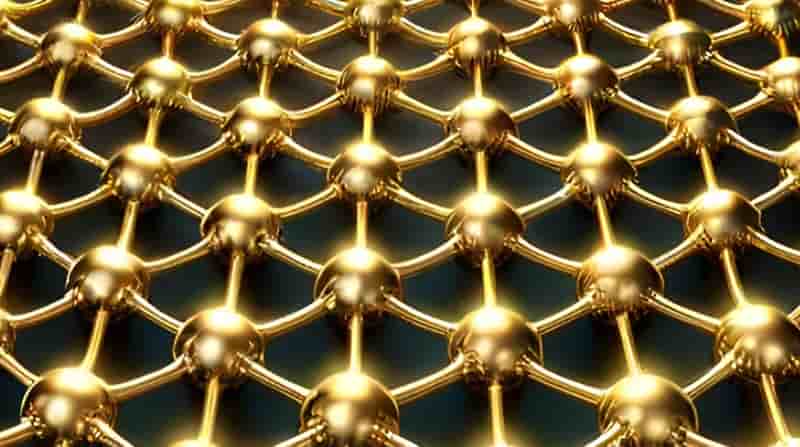

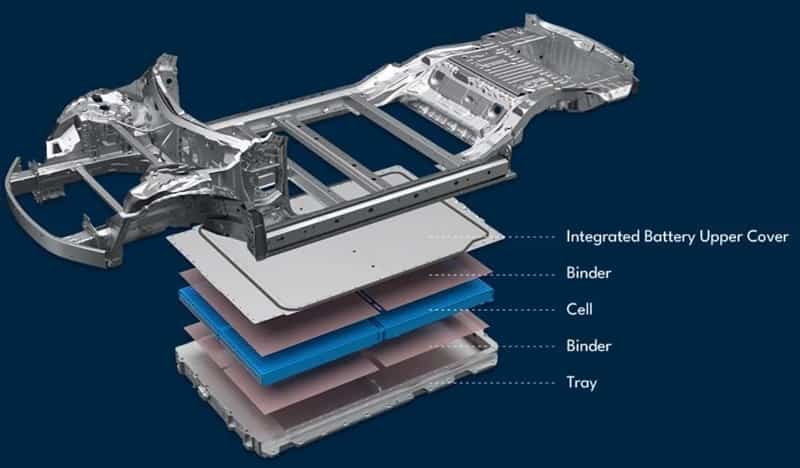

Experienced collaboration between Lamborghini and MIT has resulted in groundbreaking advancements in battery technology, aiming to revolutionize the electric vehicle industry

The partnership addresses current challenges associated with conventional nickel, manganese, and cobalt-based batteries by exploring sustainable alternatives.

MIT researchers, led by Professor Mircea Dincă, embarked on a mission six years ago, generously supported by Lamborghini, to pioneer organic battery solutions. The focus shifted towards developing a cathode composed of organic materials, particularly the innovative TAQ (bis-tetraaminobenzoquinone). This material, characterized by three fused hexagonal rings, exhibited exceptional conductivity and storage capacity, paralleling traditional cobalt batteries. PET packaging solutions

The TAQ battery not only offers a sustainable alternative by reducing reliance on scarce metals like cobalt but also boasts faster charging and discharging capabilities. Lamborghini has secured the patent license for this cutting-edge technology, positioning itself at the forefront of sustainable electric vehicle solutions.

Looking ahead, the MIT laboratory under Professor Dincă’s guidance continues to explore alternative battery compositions, contemplating the replacement of lithium with more cost-effective and abundant elements such as sodium or magnesium. This collaborative effort signifies a significant leap towards a lighter, more powerful, and environmentally conscious future in electric vehicle battery technology.

Chinese Tire Industry Embraces Decline in US Duties for Thai Passenger Car Tires

Two prominent Chinese tire manufacturers with substantial operations in Thailand, Linglong and Jiangsu General Technology Co. Ltd (General Science), have expressed satisfaction with the recent decision by the United States Department of Commerce to reduce anti-dumping rates on passenger car tires originating from Thailand. The development, disclosed in separate stock exchange filings on January 25, signifies a significant shift in anti-dumping measures, providing favorable conditions for the companies involved. PET packaging solutions

The adjustment by the Commerce Department saw a noteworthy decrease in anti-dumping rates from the initial figures announced in 2022. Specifically, the rates were lowered to 4.52% from the original 21.09% and 17.06%, marking a substantial reduction. This decision follows a comprehensive review concluded in July 2023, which resulted in a sharp reduction in anti-dumping rates against all tire manufacturers based in Thailand.

Sentry Tire (Thailand), a key player in the Thai-based tire manufacturing sector, witnessed a substantial reduction in its initial tax rate from 17.06% to a mere 1.24%. Similarly, Sumitomo Rubber (Thailand) experienced a decrease from 14.59% to 6.16%. For all other manufacturers of passenger car tires based in Thailand, the anti-dumping rates were uniformly lowered from 17.06% to 4.52%, as reported by both Linglong and General Science. PET packaging solutions

Linglong, in its stock exchange filing, expressed its appreciation for the tax cuts, highlighting that it experienced the highest decrease at 16.57%. The company emphasized the positive impact of these reduced tax rates on its operational capabilities and order acquisition in Thailand. Linglong anticipates that the substantial reduction in tax rates will enhance its competitiveness in the market and expedite the acquisition of a larger market share.

More…

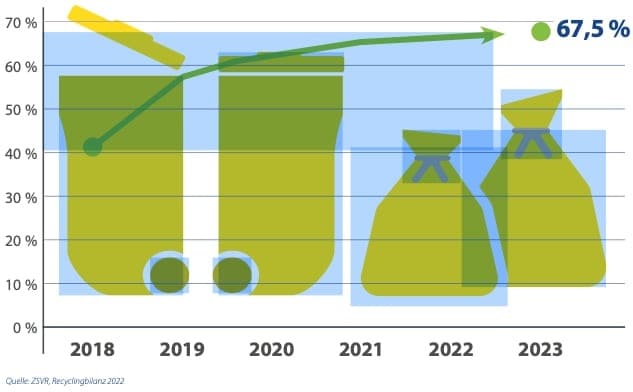

EV Cars Batteries – But then, was Mr. Akio Toyoda (Chairman of Toyota) right who always repeats that the solution is not the electric car? 31-01-2024

PET packaging solutions