Chemical-recycling – Sustainable-polyolefins 08-04-2022 - Arhive

Chemical-recycling – Sustainable-polyolefins

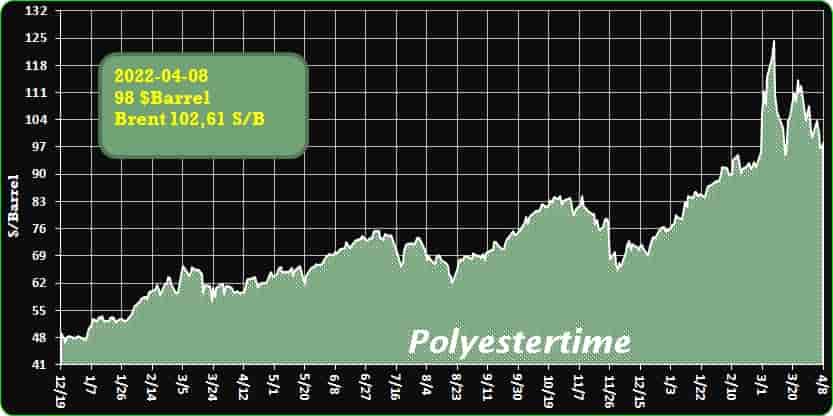

Crude Oil Prices Trend

NextChem, Maire Tecnimont’s energy transition technology company, has completed the construction of the first demonstration plant in Italy for the chemical recycling of PET and polyester from textiles, as part of the European Union’s DEMETO project. The plant is located in Chieti, in the Abruzzo Technology Park.

The depolymerization technology adopted, based on the reaction of alkaline hydrolysis with the use of microwaves, allows the plant to chemically recycle PET and polyester textile fiber waste and obtain pure monomers to produce new polymers.

The DEMETO project has been co-funded by the European Union under the Horizon 2020 program with NextChem as coordinator of a consortium of 14 partners, covering the entire value chain (NextChem, 3V Tech, SPINDOX UK, Technical University of Denmark, The European Outdoor Group, EuPC, The Fricke and Mallah GmbH, gr3n, H&M Group, NEOGROUP, RECUPRENDA, PETCIA, SUPSI, Synesis).

NextChem is the developer and co-licensor of the depolymerization technology, owned by the Swiss start-up gr3n, as well as designer and constructor of the plant. Various types of materials, including polyester-based textile fibers, will be tested in the plant, which is capable of recycling almost 100% of the incoming material, amounting to 1 MM kg/yr. Chemical-recycling – Sustainable-polyolefins

The project has been supported by an Industrial Advisory Board, which includes companies such as Unilever, Coca-Cola, Oviesse, Danone, Henkel and several others.

This innovative technology could contribute to the solution of some still-unresolved problems in textile waste recycling, such as mixed fibers. In Italy alone, tracked textile waste amounted to 157.7 Kt in 2019, of which 47% consisted of single and mixed synthetic fibers. In Italy 5.7% of unsorted waste is composed of textiles, with a total estimated at 663 Kta. In Europe, each inhabitant uses 26 kg of textile material each year and disposes of 11 kg, with a total production of textile waste estimated at about 5 MMt/y. Chemical-recycling – Sustainable-polyolefins

-Worley awarded feed contract for Trinseo’s new polystyrene recycling plant in Belgium

Worley (North Sydney, Australia) announced that it has been awarded a front-end engineering and design (FEED) services contract by Trinseo (Berwyn, Pa.) for its first-of-a-kind chemical recycling plant in Belgium. Chemical-recycling – Sustainable-polyolefins

Trinseo is a global materials company and manufacturer of plastics and latex binders. The plant will use gasification technology to depolymerize post-consumer polystyrene waste into pure styrene. It’s a first-of-its-kind project on an industrial scale.

Trinseo’s plant will process 15,000 tons of recycled polystyrene flakes every year. These will be transformed into high-quality recycled styrene and used for the production of new polystyrene and/or styrene derivatives, including acrylonitrile butadiene styrene (ABS) and styrene acrylonitrile (SAN).

ABS and SAN are thermoplastics polymers. They are durable and impact resistant, making them useful in the manufacture of car parts, medical devices, consumer electronics and more.

Worley completed the pre-FEED services for the project in 2021. TheFEED scope covers the engineering of the feedstock, storage, condensation and distillation areas, utilities and hot oil unit. It also includes the cost estimate for the project.

“Circularity in the chemical industry will be key if producers want to retain their license to operate in the coming years and decades,” said Geert Reyniers, Senior Director Process and Technology. “Our work today means we can help customers, like Trinseo, to implement first-of-a-kind technologies so they can realize their sustainability objectives.” Chemical-recycling – Sustainable-polyolefins

“Trinseo chose Worley to move forward with because of its recognized leadership in the industry,” said Francesca Reverberi, SVP and Chief Sustainability Officer at Trinseo.

–Worley awarded feed contract for Trinseo’s new polystyrene-recycling-plant-in-Belgium

–Mitsui-Chemicals to close TPA-plant in Japan

–Precision-pyrolysis: Controlled, heat-based-composites-recycling for higher-material-properties

–Evonik Invests in New-Rohacell-Production Facility

–ExxonMobil’s New PE-Resins Simplify Processing While Improving Performance

Chemical-recycling – Sustainable-polyolefins