Plastic BioPolymers DisposablePlastic 06-02-2021 - Arhive

Plastic BioPolymers DisposablePlastic

-Corbion to expand lactic acid production at Blair, Nebraska site

Corbion (Amsterdam, Netherlands) announced on Thursday that it will expand lactic acid production at its Blair, Nebraska, facility by 40% to meet growing demand for natural ingredients, said Chemweek.

The use of lactic acid and its derivatives as ingredients in foods and beverages for safe preservation and in home and personal care products for disinfection and hygiene has increased steadily in the Americas over the past five years, Corbion says. “Manufacturers of food, home, and personal care products worldwide are finding the efficacy, consumer-friendliness, and sustainability advantages offered by lactic acid-based solutions to be highly valuable in responding to multifaceted market pressures,” it adds.

Corbion also operates lactic acid production facilities in the Netherlands, Brazil, Spain, and Thailand, and early last year announced plans to build a new lactic acid plant at its existing site in Rayong Province, Thailand, to help meet global demand.

As per MRC, Total Corbion PLA, a 50/50 joint venture between Total and Corbion, announced the start-up of its 75,000 tonnes per year PLA (Poly Lactic Acid) bioplastics plant in Rayong, Thailand. The plant has successfully produced Luminy® PLA resins. This bioplastic provides a valuable contribution towards the circular economy being 100% renewable and biodegradable and offering multiple environmentally-friendly waste solutions.

-Bioplastics, Biodegradable Plastics, & Compostable Plastics: What’s the Difference?

The global bioplastic market is growing rapidly. Bioplastics, biodegradable plastics, and compostable plastics divert our demand for plastic and help lighten the load on our planet by, theoretically, breaking down in weeks rather than centuries. It’s an important step forward for single-use packaging, but we still encourage you to look for plastic-free options.

Let’s dig into the realities of biodegradable plastics. Despite high hopes for these alternatives to help build a circular economy, there seems to be a lot of confusion regarding how to dispose of them properly at their end of life. Do you know the difference between these bioplastics? Plastic BioPolymers DisposablePlastic

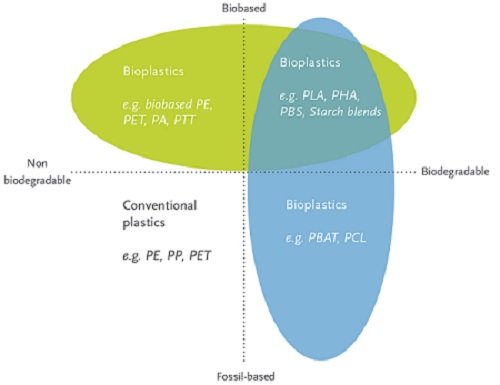

Bioplastics Cover a Wide Ground

A wide range of materials falls under the umbrella of bioplastics, which are commonly defined as “biobased, biodegradable, or both.”

It might surprise you to know that a bioplastic can be non-biodegradable or contain no bio-based materials. It can even be 100% fossil-based. To complicate matters, a bioplastic “can be any combination of being partially bio-based, fully bio-based, non-bio-based, biodegradable, compostable or non-biodegradable, so long as it is not both non-bio-based and non-biodegradable.”

Source :European Bioplastic

-RECITURF: turning fake lawn green

Artificial turf lawns have many advantages: for instance, they will be good for many hours of mud-free sporting activities and do not need to be watered.

However, when artificial turf reaches its end of life, which can come just five to ten years after it is laid, it is very difficult to recycle.

This is because it is made of different kinds of plastic that melt at different temperatures and have different viscosities. Therefore, an increasing amount of artificial turf waste is being sent to landfills, except for rubber which is used as a filler in these kinds of installations. Plastic BioPolymers DisposablePlastic

The RECITURF Project, led by AIMPLAS, the Plastics Technology Centre, and with the participation of the ACTECO and REALTURF companies, aims to give a boost to the circular economy in this sector. They want to use innovative waste processing methods to increase recycling and recovery rates. The project is funded by the Valencian Innovation Agency (AVI) and will focus on developing new recycling processes, including biological/enzymatic degradation and chemical recycling of the polyurethane backing. The different materials will be separated for subsequent mechanical recycling.

-Clariant signs catalysis research partnership with prestigious ETH Zurich university

- Research agreement to advance catalysis innovation and sustainable chemistry

- Clariant will provide a significant financial contribution for an initial period of 10 years

- ETH Zurich is one of the world’s leading universities, currently ranked sixth place globally Plastic BioPolymers DisposablePlastic

Muttenz, February 4, 2021 – Clariant, a focused, sustainable and innovative specialty chemical company, has signed a cooperation agreement with ETH Zurich to support research in catalysis and sustainable chemistry with a significant financial contribution over an initial period of ten years. The goal of the partnership is, firstly, to advance the understanding of catalyst properties – from nano- to macroscale – and their performance. Secondly, together with the ETH Foundation, Clariant will sponsor and collaborate in fundamental chemical research projects, promoting talented ETH scientists and students.

Hans Bohnen, member of Clariant’s Executive Committee, commented, “We are honored to announce our research agreement with the prestigious ETH Zurich. The partnership, like those with other academic institutions, underscores our commitment to fostering innovation and R&D to develop groundbreaking products and solutions that add value to people, industries, and the environment.”

-New compostable packaging doubles shelf life

Tipa and PerfoTec create compostable packaging proven to extend shelf life of fresh produce by up to two times

Israel-based compostable packaging producer Tipa and shelf-life extension specialist from the Netherlands, PerfoTec, have partnered to offer fully compostable packaging that extends the shelf-life of fresh produce.

The partnership comes as consumer demand for low-waste packaging continues to grow, and suppliers seek sustainable packaging solutions that don’t compromise produce quality. Plastic BioPolymers DisposablePlastic

The laser microperforated compostable film provides retailers and suppliers with packaging qualities that Tipa said will help reduce food waste, combat plastic pollution and cut carbon emissions.

Tipa and PerfoTec’s combined technologies have been found to double the expected shelf-life of fruit, vegetables and flowers.

Tipa’s compostable packaging performs like a conventional plastic but decomposes in compost back into the soil with no toxic residue, microplastics or other pollutants. Its packaging solutions can also fit with industry machinery and manufacturing practices.

PerfoTec’s said its patented high precision laser technology facilitates longer shelf-life by adapting the permeability of food packaging.

-ExxonMobil creates unit to commercialize carbon-reduction technology

ExxonMobil Corp has created a division to commercialize its technology that helps reduce carbon emissions, as the US oil major looks to step up efforts against climate change amid rising pressure from investors and activists, according to Hydrocarbonprocessing.

The move comes as Exxon looks to burnish its environmental credentials as it engages in a proxy fight with hedge fund Engine No. 1, which is attempting to appoint candidates on the oil company’s board and push toward a more renewables-focused future. Plastic BioPolymers DisposablePlastic

Exxon said its Low Carbon Solutions would initially focus on carbon capture and storage and directly compete with Occidental Petroleum Corp’s Oxy Low Carbon Ventures, which is looking to develop the largest ever facility to pull carbon dioxide out of the atmosphere.

The oil major said it would invest USD3 billion on lower emission solutions through 2025, by which time it plans to reduce the intensity of its oilfield greenhouse gas emissions by 15%-20% from 2016 levels.

-February contract price for phenol in Europe fell by EUR84 per tonne

The February contract price for phenol in Europe fell by EUR84 per tonne at both ends of the range following a decline in the contract price for benzene feedstock, which fell 12% this month, ICIS reported .

The February contract prices were agreed at EUR1 361-1 391 per tonne, FD NWE (North West Europe). Plastic BioPolymers DisposablePlastic

Numerous manufacturing problems at US phenol plants are expected to continue to restrict imports to Europe in the coming weeks.

Phenol demand is high as there has been an improvement in demand from the auto industry since the end of 2020, coupled with higher than usual demand from the construction sector during the winter.

Growth was also seen in the electronics and healthcare markets, supported by declining imports of Asian derivatives in recent months.

Phenol is the main raw material for bisphenol A (BPA) production, which in turn is used to produce polycarbonate (PC).

-Greenhouse gas emissions studies for four plastics recycling methods important first step

A report by sustainability consultancy Quantis, commissioned by the European Chemical Industry Council examines the greenhouse gas (GHG) emissions of chemical recycling and the potential of the process to close the plastics loop. The study, entitled “Chemical Recycling: Greenhouse gas emission reduction potential of an emerging waste management route”, uses both life cycle assessment (LCA) and systemic material flow analysis to assess the environmental benefits of chemical recycling, providing some insights into the potential reduction of GHG emissions compared with current end-of-life options such as incineration and landfilling.

Quantis’ analysis summarises and compares the findings on chemical recycling technologies from four recent and separate studies by Material Economics , Agora Energiewende in cooperation with Wuppertal Institut , CE Delft, and BASF.

Plastic BioPolymers DisposablePlastic

-Karpatneftekhim raised HDPE prices by USD90 per ton

The largest petrochemical plant in Ukraine – Karpatneftekhim (Kalush, Ivano-Frankivsk region) – has raised the prices of low-density polyethylene (HDPE) by USD90 per tonne from February 3 for supplies to the domestic market, according to the ICIS Price Review. MRC .

According to the company’s clients, the Ukrainian producer on Wednesday raised the prices of HDPE for supplies to the domestic market by USD90 per tonne compared to the previous week. For the end consumer, the price starts at USD1 270-1,280 per ton, excluding VAT, FCA. The increase in prices is primarily due to the growth of raw materials. Plastic BioPolymers DisposablePlastic

Also, high prices on foreign markets exert serious pressure on prices within the country. Thus, European producers raised their export prices in February by EUR 150-220 per tonne in comparison with January.

-February paraxylene contract price in Asia set at USD705 / t

Negotiators to agree on February contract prices for paraxylene in Asia have reached an agreement for the current month at USD705 per tonne after they failed to do so for 16 consecutive months, market sources told ICIS .

The contract price for paraxylene has been approved on CFR Asia terms.

Approval of the monthly contract price for the material is achieved when it is agreed by at least two suppliers and two buyers. Plastic BioPolymers DisposablePlastic

The Asian market for paraxylene contract prices was last reached in September 2019.

Paraxylene is one of the main raw materials for the production of polyethylene terephthalate (PET).

Plastic BioPolymers DisposablePlastic