Plastic Recycling BioPolymers 04-02-2021 - Arhive

Plastic Recycling BioPolymers

Crude Oil Prices Trend

-Leonardo and Solvay launch joint research lab for thermoplastic composites

The broader adoption of thermoplastic composites in aerospace – namely for primary structures – is requiring the development of new materials and new manufacturing processes so as to reach the needed higher performance and manufacturing efficiency

By creating the “Joint Research Virtual Lab”, Leonardo and Solvay decided to tackle this challenge by joining efforts and bringing to the table the complementary skills and expertise of the two Companies

The bulk of the activities will be carried out in Leonardo’s plant in Grottaglie (Taranto, Italy), and in Solvay’s Material Science and Application Center (MSAC) in Brussels

According to Roberto Cingolani, Leonardo’s Chief Technology & Innovation Officer: “This collaboration with Solvay is a significant step in research on advanced materials, which are part of the R&D programs to be developed by the Leonardo Labs. The research on advanced materials will enable improved performance and products’ security to boost a circular and efficient production system”

Nicolas Cudré-Mauroux, Solvay Chief Technology & Innovation Officer highlighted the importance of addressing the material development and its processing technologies with an holistic approach because “increasing the manufacturing speed is as important as achieving the required performance”. Solvay is committed to developing high performance lightweight materials key to a more sustainable aviation industry

Leonardo and Solvay announced the launch of a joint research lab dedicated to the development of novel composite materials and production processes critical for the future of the aerospace industry. This collaboration represents an important milestone in enabling a step-change in composite part manufacture and in reducing environmental impacts. Plastic Recycling BioPolymers

-INEOS Styrolution and Polystyvert establish joint development agreement

INEOS Styrolution and Polystyvert are collaborating to convert post-consumer polystyrene plastic into a new, high quality, polystyrene raw material resin.

Styrofoam recycling symbol PS 06, recycle arrow triangle, six type logo, Resin identification code, polystyrene. Ecology emblem, environment protection

Polystyvert uses a patented dissolution technology to process polystyrene waste into high quality recycled polystyrene.

The dissolution method of advanced recycling takes plastic waste in its solid form and dissolves it in a solvent. Once dissolved, the process can mechanically and chemically separate contaminants and additives, before finally separating the original polymer from the solvent. The end-product is then a cleaned polymer that may be used as new raw material resin again.Plastic Recycling BioPolymers

Polystyvert’s in-depth purification technology offers the ability to treat all types of feedstock, from industrial waste to post-consumer streams. The technology can eliminate a wide range of hard-to-remove contaminants such as pigments and brominated flame-retardants. Recycled polystyrene pellets can then be used to manufacture various categories of polystyrene products, including food-grade applications.

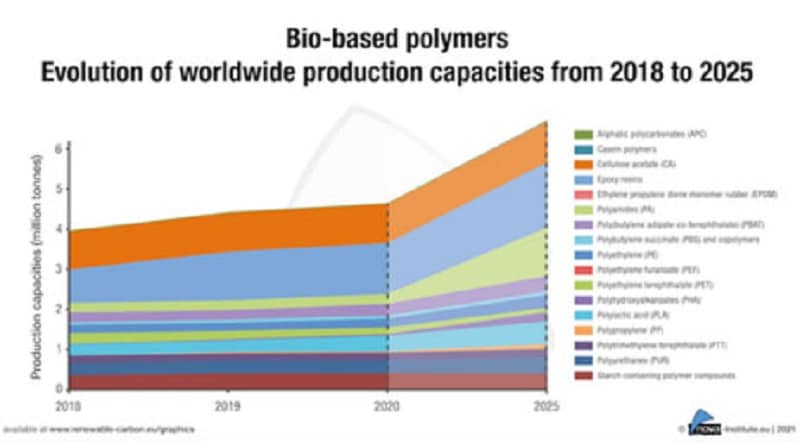

-Growth rate for biobased polymers exceeds overall polymer market growth

The year 2020 was a promising year for bio-based polymers: the demand for PLA in 2019 has led to the installation of increased capacities, PE and PP made from bio-based naphtha are breaking ground and there are future expansions on the horizon for bio-based polyamides as well as for PBAT, PHAs and casein polymers. A lower production is only observed for bio-based PET. Plastic Recycling BioPolymers

In 2020, the total production volume of bio-based polymers was 4.2 million tonnes, which is 1% of the total production volume of fossil-based polymers. For the first time in many years, the CAGR is, with 8%, significantly higher than the overall growth of polymers (3-4 %) – this is expected to continue until 2025.

Several global brands are already expanding their feedstock portfolio to include, next to fossil-based, sources of renewable carbon, CO2, recycling and especially biomass, increasing the demand for bio-based as well as biodegradable polymers. Nevertheless, at the same time, there is a lack of support from politics, which still only promotes biofuels and bioenergy.

-Asian chemical demand sentiment mixed post-Lunar New Year

Unlike previous years, post-Lunar New Year chemical markets in 2021 will be uniquely different in China – the world’s number-two economy – as well as in other parts of Asia where the holiday is celebrated.

This year will be adopting the playbook of the unprecedented 2020 as the pandemic continues to rage on, with the visceral difference of having vaccines in place and global inoculation is being rolled out at different pace and rate.

While China will soon celebrate the Lunar New Year (11-17 February), businesses and factories will resume operations earlier than expected after the period, as millions of Chinese migrant laborers in the cities were told to stay put given growing coronavirus cases in northern China that prompted lockdowns of selected cities and areas in January. Plastic Recycling BioPolymers

At issue, the extent of plastics demand recovery in Asia remains to be seen on prospects of businesses resuming earlier than past years, when factories shut for two to four weeks during the holiday in China.

-Major European project supporting hydrogen technologies about to launch

Call for expressions of interest issued for IPCEI on hydrogen

Today, the Federal Ministry for Economic Affairs and Energy and the Federal Ministry of Transport and Digital Infrastructure started a call for expressions of interest in funding for hydrogen technologies and systems. The call was published in the Federal Gazette. The two federal ministries, alongside the Federal Ministry for the Environment, Nature Conservation and Nuclear Safety and the Länder, are planning to provide funding for integrated green hydrogen projects along the entire value chain, starting from its production, to hydrogen infrastructure, and to its use in the industrial and mobility sectors. All in all, several billion euros is to be made available from the Federal Government’s 2020 stimulus package and by the Länder. Companies are invited to upload their project abstracts by 19 February 2021.

Said Federal Minister for Economic Affairs and Energy Peter Altmaier: “In Germany and Europe, we want to be world leaders on hydrogen technologies and launch a shared European project to give investments in this area the momentum required to achieve this. I’d like to call upon companies to decide to invest boldly in the future. Innovative hydrogen technologies will allow us to demonstrate that climate action and industrial policy are not mutually exclusive, but can be combined in a shared success story.” Plastic Recycling BioPolymers

A decade long collaboration between Swiss textile innovator HeiQ and Spanish premium synthetic fiber manufacturer Nylstar, has resulted in the innovation of a revolutionary new premium antiviral and antimicrobial textile with zero pollution sustainable benefits, Meryl® Skinlife Force powered by HeiQ Viroblock Permanent, winner of ISPO Textrends Award for the Best Product.

With the commencement of the pandemic, two leading textile innovators HeiQ and Nylstar pooled resources developed over a decade long collaboration to create a premium synthetic fiber that was sustainable, antimicrobial and durable, in short, the optimal fusion of innovative ingredient into sustainably made materials.

A record-breaking development speed of just six months resulted in the launch of HeiQ Viroblock Permanent, a new technology under the immensely successful HeiQ Viroblock technology platform. Plastic Recycling BioPolymers

The new technology is used exclusively on Meryl® Skinlife Force, an innovative hi-tech fabric that combines the silver-ion active principle antimicrobial properties developed by HeiQ and Nylstar’s hydrogen-based technology which allows the creation of yarns with a very strong molecular cohesion structure.

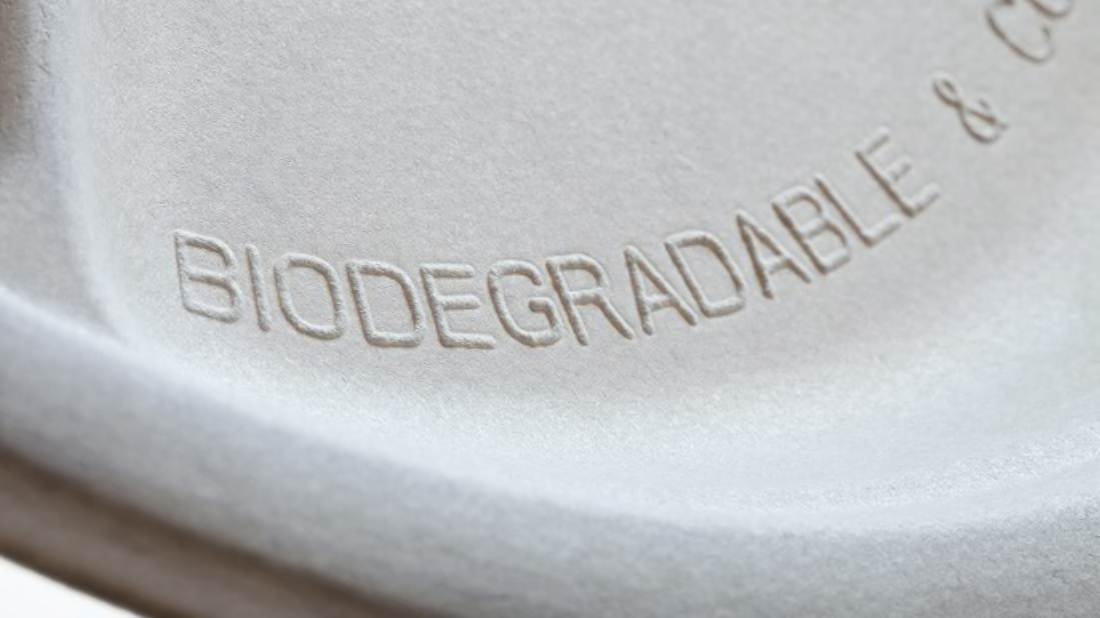

-Compostable vs. Biodegradable: What’s the Difference?

When considering whether something is likely to wind up spending years in a landfill, the terms compostable and biodegradable come up.

On the surface, the two seem interchangeable. Both imply materials—typically those used in packaging or in products like soap, bags, or cups—can be returned to the earth. Plastic Recycling BioPolymers

But there are actually a few key differences to keep in mind.

If something is biodegradable, it means it will eventually break down in the presence of bacteria, fungi, or other naturally occurring conditions in soil.

Typically, this means things derived from plants, animals, or natural minerals.

Even plastic, widely believed to be outside of this definition, is biodegradable, though biodegradable-resistant might be a better term.

It can take hundreds of years for plastic to succumb to the elements.

-Stepan announces the acquisition of the aromatic polyester polyol business of INVISTA

Stepan Company today announced that it has acquired the aromatic polyester polyol business of INVISTA and associated assets. Plastic Recycling BioPolymers

The transaction includes two manufacturers sites, one in Wilmington, NC (US) and the other in Vlissingen (The Netherlands), and intellectual property, customer relationships, inventory and working capital.

The acquired company has worldwide sales of approximately $ 100 million. This acquisition was financed with available cash and is expected to be accretive to Stepan’s EBITDA margins.

“We are excited to add the polyester polyol capabilities of INVISTA to Stepan.

This acquisition expands our manufacturing capacity in the United States and Europe, improves our business continuity capabilities for the market and supports the growth of our global rigid polyols business.

-Toyobo Film Solutions’ Teonex film used in new Mirai

Toyobo Film Solutions’ sealant based on its Teonex™ for fuel cells has been adopted for use in the latest model of the Toyota Mirai eco-car.

Teonex™ is a high-durability and heat-resistant polyethylene naphthalate (PEN) film and is increasingly being adopted for vehicle parts.

The new sealant is made by coating a unique adhesive to TeonexTM, along with precision processing. Plastic Recycling BioPolymers

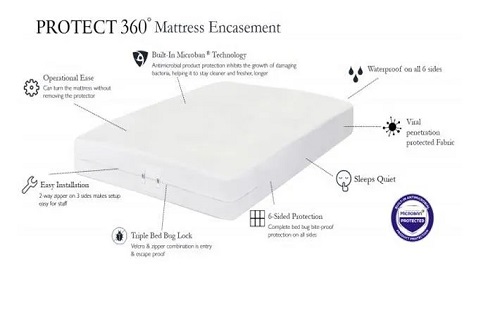

-Microban & Manchester Mills to make antimicrobial textiles

Microban and Manchester Mills have joined hands to make antimicrobial-treated textiles, Protect360, for the healthcare and hospitality industries.

Microban is a global specialist in antimicrobial technologies and odour control solutions. Manchester Mills is a leading textile manufacturer, with a powerful blend of manufacturing flexibility and expertise.

The Protect360 collection of products will be sold directly to customers, and through Manchester Mills and its distributor network in the US, Canada, the UK, and European Union. Plastic Recycling BioPolymers

Key offerings of the Protect360 product line include mattress encasements and pillow protectors that are treated with Microban antimicrobial product protection and inhibit the growth of product damaging bacteria.

PlasticRecycling BioPolymers CircularEconomy

Petrochemical BioPolymers BioFilm 03-02-2021