Solid-state batteries – Microplastics 16-05-2023 - Arhive

Solid-state batteries – Microplastics

-The future of the cell: powerful batteries are the central element of electric vehicles

The technology continues to evolve and is expected to make further progress when it comes to capacity, charging capacity, safety, and service life. Porsche is directly involved in current developments through the Cellforce Group and Group14 Technologies.

High energy content, high performance, long service life, maximum safety—all at the lowest possible cost: Batteries in electric vehicles have to meet many requirements, which the dominant lithium-ion technology is already succeeding at quite well. Further improvements can, however, be made to almost all of its parameters, and researchers and industry are currently working intensively on doing just that. At the same time, potential successors are already lining up. It is no coincidence that lithium-ion batteries dominate today’s market: Lithium atoms are particularly keen to emit one of their three electrons, and lithium is also the lightest metal. This makes the element a popular raw material for batteries. Solid-state batteries – Microplastics

“Pure lithium is the ideal active anode material in terms of energy density,” says Dr. Stefanie Edelberg, Specialist Engineer Battery Cell at Porsche Engineering. “For safety reasons, however, graphites are currently used primarily as active anode materials that can absorb lithium ions.” In addition, the charging capacity of the batteries is very high and their price is relatively low. Added to this is their long service life: “1,500 to 3,000 full charge cycles until a residual capacity of 80 percent is reached does not present a problem,” says Dr. Falko Schappacher, Commercial and Technical Director of MEET Battery Research Center at the University of Münster (WWU). Car battery service lives of up to one million kilometers are now being predicted.

Anode optimization

Because lithium-ion technology is a multi-component system, there are many ways to optimize it further. Take, for example, the anode: Graphite is currently used as an active anode material. Silicon is an interesting alternative to this because it offers a storage capacity that is ten times higher. “Silicon anodes would significantly increase the total capacity of the lithium-ion battery,” as Schappacher underscores. Edelberg also points out the advantages: “Silicon is of particular interest because it exhibits the second-highest storage capacity in terms of weight after lithium, which allows for cells with very high energy densities. What’s more, it is the second most common element in the earth’s crust.” Cells with a high fast-charging capability and which can be charged from five to 80 percent in less than 15 minutes are indeed feasible. Solid-state batteries – Microplastics

“However, when lithium is absorbed, the silicon particles expand by 300 percent, resulting in mechanical stress in the material and electrode,” says Schappacher. If this were to damage the electrode surfaces, the service life of the battery would also be impaired. “The biggest leverage in terms of energy density is attained by using pure silicon active material, but then you also have to contend with the worst downsides in terms of service life,” says Edelberg. Nevertheless, intensive work is being carried out on anodes with a very high proportion of silicon of up to 80 percent. This is the path that Cellforce (see box), for example, is following in conjunction with Porsche.

More nickel in the cathode

Intensive work is also underway on optimizing the active materials for the cathode. The important thing in this case is a combination of a large charging capacity and a high electrochemical potential of the material. At present, lithium-nickel-cobalt-manganese-oxide (NCM) in a ratio of 6:2:2—in terms of the parts nickel, cobalt, and manganese—is most frequently used in electromobility in Europe. Solid-state batteries – Microplastics

In the future, nickel’s share is likely to increase, while cobalt and manganese will be used to a lesser extent. The growing share accounted for by nickel promises higher charging capacities. Further optimization potential is offered by the separator, which consists of very thin (10 to 20- micrometer) films, mostly comprised of polyethylene or polypropylene. This separator costs space and weight. “The separator can indirectly contribute to the energy content of a battery cell,” says Edelberg. “The thinner it is, the more layers or coils on electrodes fit into a cell. This increases the cell capacity and the energy content of a battery cell.”

Compact solid-state batteries

Solid batteries, an area into which intensive research is being conducted, could need significantly less installation space than conventional lithium-ion batteries. They do not use an electrolyte solution, but a solid supporting electrolyte. “The plan for solid cells is that the classic separator will be completely replaced by a thin layer of solid electrolytes,” explains Edelberg. Solid-state batteries – Microplastics

“The solid electrolyte is then both electrolyte and separator in one.”

-Innovative e-bike technology: a nylon rear swing arm RadiciGroup and Acerbis have collaborated to create a groundbreaking product for electric two-wheelers that offers both reduced weight and advanced technical performance

This technology has been incorporated into select Fantic Trail and Enduro e-bike models.

The two Bergamo-based companies, RadiciGroup and Acerbis, have initiated an inventive project to produce design solutions that deliver high performance. They have developed a rear swing arm for electric bikes, which is made of nylon rather than aluminium, as a first of its kind in the e-bike market. This innovation enables the rear triangle to better absorb the stress caused by uneven terrain.

Fantic, an Italian manufacturer of motorbikes and electric bikes, is the first company to use this pioneering technology, which is the result of meticulous research and development. Fantic has decided to incorporate the new rear swing arm in several models of its Trail and Enduro lines that were unveiled at EICMA 2022 and are now available for purchase. Solid-state batteries – Microplastics

Claudio Ghilardi, CAE analyst of RadiciGroup High Performance Polymers Marketing and Technical Service, stated that as this component of the bike frame is structural, a polyamide 66-based specialty material reinforced with glass fibre has been selected to ensure that the part can withstand continuous high stress. This material also has properties that are less affected by moisture absorption. In addition, the material has an attractive appearance, is UV-stabilized, and is resistant to weathering.

The use of RadiciGroup’s compound in the nylon swing arm reduces its weight by 10% and eliminates the need for the painting process used for the corresponding metal component, resulting in improved environmental performance. RadiciGroup engineering polymers are solution-dyed, which means that the part is already colored during the extrusion process, resulting in an excellent surface finish.

The achievement of this result was made possible by the close collaboration of RadiciGroup, Acerbis, and Fantic in all phases of the project, from the part design to the material formulation, the creation of the mould, and the injection molding process, to the testing of the component mounted on an e-bike. Solid-state batteries – Microplastics

According to Guido Acerbis, CEO of Acerbis, this partnership among Italian companies represents a step towards a new way of thinking about production that will allow them to accelerate some production reshoring to Europe. By replacing a metal part with a nylon one and improving its function, the project has given them the opportunity to simplify and shorten the production time while increasing the volume of products brought to market in a short time.

-Indorama Ventures Reports Improved Quarterly Earnings; Focuses On Competitiveness Amid A Challenging Environment

Indorama Ventures Public Company Limited (IVL), a global sustainable chemical producer, today reported improved quarterly earnings as headwinds continue to ease from the previous quarter’s peaks, although still below normalized levels. The company continues to focus on enhancing its global competitiveness as the full benefit of China’s reopening spurs volumes through the year, and as volatile energy costs and the destocking trend by customers begin to normalize.

Indorama Ventures achieved Reported EBITDA of $301 million in 1Q23, an increase of 269% QoQ and a decline of 62% YoY. Sales volumes dropped 8% YoY amid the heavy destocking trend that is impacting the chemical industry globally, although volumes rose 5% QoQ as the pace of destocking begins to slow from the peak in 4Q22. With China reopening from pandemic lockdowns and economic activity increasing, there has been marginal improvement in benchmark spreads, albeit below historical levels. In Europe, the warmer-than-expected winter contributed to lower energy prices and alleviated the cost pressures faced last year. Solid-state batteries – Microplastics

Mr. Aloke Lohia, Group CEO of Indorama Ventures, said, “We are seeing early signs that the highly unusual headwinds that are impacting our industry are starting to ease from their highs, although it will take some time to normalize. We continue to maintain a sharp focus on enhancing our competitiveness, including acting on sites that are marginally profitable, especially in Europe. In Asia, we are introducing more innovative products to improve our businesses’ global competitiveness, and we are strengthening leadership across our three business segments to deliver shareholders returns. Project Olympus, our ongoing cost transformation program, will continue to drive efficiencies in 2023.”

-In a victory for Europe, Northvolt, the Swedish battery maker, announced on Friday (12 May) its plans to invest several billion euros in building an electric vehicle battery facility in Germany, beating the United States in the competition

The plant, which is set to commence operations in 2026, will have a production capacity of 60 gigawatt hours, which is sufficient to power approximately one million electric vehicles every year. Although the precise investment and funding amounts are not finalized, two sources familiar with the matter claim that Northvolt could spend around €3-5 billion on the facility and receive approximately half a billion euros in German subsidies. German Economy Minister Robert Habeck lauded the project, stating that it would create thousands of green-tech jobs, making it one of the most critical flagship projects of the energy and transport transition. Solid-state batteries – Microplastics

Northvolt, in collaboration with Volkswagen, is among the few European players leading the way for the continent’s home-grown battery sector. However, Asian players will own a large portion of the planned capacity in Europe. The new battery facility is the first project to receive subsidies under the EU’s Temporary Crisis and Transition Framework (TCTF), aimed at supporting green industrial initiatives and countering the subsidies offered by the US’s Inflation Reduction Act (IRA). The EU’s TCTF allows countries to match foreign subsidies under specific conditions, allowing them to provide the same amount to firms as third countries for specific projects. The German government intends to supplement these subsidies with state funding under the EU’s scheme of “Important Projects of Common European Interest.”

The plant, located in Heide, will create 3,000 direct jobs and thousands more in the surrounding industry and service sector. Additionally, the battery facility will receive state funding as part of the EU’s “Important Projects of Common European Interest” program. Although Northvolt had previously put its final investment decision for the plant in northern Germany on hold, citing higher subsidies and lower production costs in North America, the company’s decision to build in Germany does not preclude the possibility of constructing another plant in North America. The plant’s approval clears a significant administrative hurdle, and its completion will be critical to the growth of Europe’s electric vehicle market. Solid-state batteries – Microplastics

-Microplastics seeping into wastewater through recycling facilities, says study

New research has found that a ‘state-of-the-art’ plastic recycling facility in the UK could be releasing up to 75 billion microplastics per cubic meter of wastewater annually.

New research suggests that plastic recycling facilities could be releasing wastewater packed with billions of tiny plastic particles, contributing to the pollution of waterways and endangering human health.

A team of international scientists sampled water inside a new recycling facility at an undisclosed location in the UK They suggest that the facility could be releasing up to 75 billion microplastics — tiny plastic pieces less than 5 millimetres, or 3/16 of an inch, in length — per cubic meter of wastewater per year.

That’s about 6 per cent of the plastic that entered the facility to be recycled. However, the researchers only considered microplastics as small as 1.6 microns (μm), which means these numbers are likely to be an underestimate, they say.

The researchers tested the wastewater before the facility installed a water filtration system, as well as after the filtration system was installed. They found that while the system filtered out about 90 per cent of the microplastics larger than 10 μm, it didn’t remove the pieces smaller than 10 μm. Solid-state batteries – Microplastics

The study, which was recently published in the Journal of Hazardous Materials Advances, suggests the recycling plant discharged up to 2,933 metric tons of microplastics each year prior to the water filtration system, and up to 1,366 metric tons of microplastics each year after the system was in place.

“Given the size of these microplastic particles, the environmental repercussions and risk of ingestion by all manners of invertebrates, biota and humans is worrying.”

“We wouldn’t have done this study if we hadn’t thought there was any pollution in the water, but it was just shocking numbers,” study lead author Erina Brown, a researcher at the University of Strathclyde in Scotland, tells Mongabay. “Over 80 per cent of the particles that we found were under 10 microns, which have been shown to be really harmful, both to humans and so many different organisms — from large organisms down to tiny zooplankton.” Solid-state batteries – Microplastics

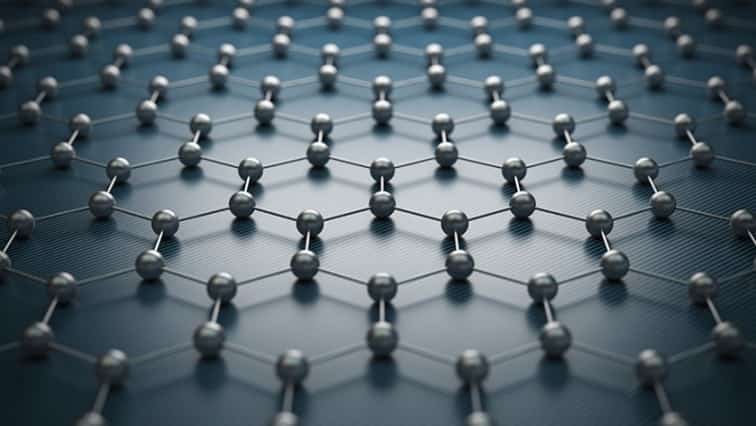

-Gerdau Graphene has introduced two novel graphene additives, NanoDUR and NanoLAV, specially designed for the coatings and paints sector

The company, which specializes in developing advanced graphene-enhanced materials for industrial purposes, utilizes graphene nanoplatelets in the production of these cutting-edge additives. The new products are formulated with Gerdau Graphene’s G2D technology and deliver unprecedented performance improvements for water-based paints and coatings, without altering pH levels. Furthermore, they decrease or eliminate the requirement for some traditional manufacturing inputs, additives, and processes, which can lessen production costs and enhance sustainability by reducing environmental impact.

According to Alexandre de Toledo Corrêa, CEO of Gerdau Graphene, the utilization of carbon nanomaterials like graphene in commercially available additives makes it possible to upgrade product performance, reduce manufacturing costs, and improve sustainability simultaneously. NanoDUR and NanoLAV are the latest additions to Gerdau Graphene’s growing portfolio of graphene additives and are expected to help coatings manufacturers leapfrog their competitors across the value chain. Solid-state batteries – Microplastics

NanoDUR, a water-based graphene additive, enhances paint and coating durability on low- and high-traffic surfaces, demonstrating excellent dispersion. The use of NanoDUR leads to painted surfaces with remarkable wear and tear resistance, weathering, and resistance to other external factors that can lead to degradation over time, while still maintaining physical and chemical properties such as adhesion, color, and resistance to chipping, flaking, cracking, fading, and peeling. NanoLAV, a graphene additive specifically formulated for water-based architectural paints, increases washability and moisture-resistance, making it an ideal choice for applications where hygiene is essential, such as hospitals, schools, and kitchens.

Gerdau Graphene’s portfolio of graphene additives includes products for a wide range of industrial materials and applications. Poly-G, a collection of graphene-enhanced thermoplastic masterbatches for the plastics sector, is among the company’s latest offerings. Solid-state batteries – Microplastics

Poly-G dramatically enhances the durability and sustainability of plastic packaging films, profiles, and sheets made by extrusion processes. Gerdau Graphene is collaborating with Sumitomo Corporation to import and distribute Poly-G in Japan.

Graphene is a one to 10 atom-thick sheet of densely compacted carbon, recognized as the strongest material on Earth. Since its discovery in 2004, its extraordinary chemical, physical, electrical, thermal, and mechanical properties have fascinated the world and led to its inventors being awarded the Nobel Prize in chemistry.

-The 62nd edition of the Dornbirn Global Fibre Congress (GFC) is scheduled to occur from September 13 to 15, 2023 at the Kulturhaus located in Dornbirn, Austria

The Dornbirn GFC 2023 has broadened its scope significantly, offering an expanded selection of 120 presentations in multiple halls.

Distinguished international speakers from both industry and research fields will unveil the latest advancements in the fiber and textile sectors across four platforms. A distinctive culinary experience and exceptional hospitality await visitors attending this year’s Dornbirn GFC. Solid-state batteries – Microplastics

An early bird ticket is currently available at a discounted price until May 31, 2023. The participant ticket will grant admission to all 120 expert lectures, the exhibition area, the 3rd Innovation Days, and the customary gala evening on the opening day, complete with a buffet and fashion show. The congress ticket also comprises a premium lunch on the first and second day, refreshments such as fruits, coffee, and cake during breaks, as confirmed by the event’s organizers in a press release.

The Dornbirn GFC organizing team has imbued the spirit of Innovation Days to offer superior quality to both participants and attendees. The 3rd Innovation Days will be given a more extensive platform as part of the Dornbirn GFC. FashionForGood and PriceWaterhouseCoopers (PWC) have collaborated to provide a larger stage to the 25 participants of the 3rd Innovation Days. The young companies will pitch their innovative concepts during the opening morning, with over 500 experts following each presentation. The Contact Point, the heart of the Innovation Days, will be situated in the vast foyer of the event location, connecting the professional audience with the Innovation Days participants. FashionForGood, a renowned company with vast experience in the fashion industry, will support these budding entrepreneurs throughout the congress and explore new possibilities. Solid-state batteries – Microplastics

A unique series of lectures will ensue from the collaboration on the topic of sustainability between RWTH Aachen University and European industry partners. The block of lectures will commence with the Swiss company TEXAID Textilverwertungs presenting on the topic of “Sustainability in the textile industry: the conversion of recycled materials into yarn by spinning mills.” Other prominent industry players will take the stage to showcase their innovations in this critical field and future direction.