AI in Packaging

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

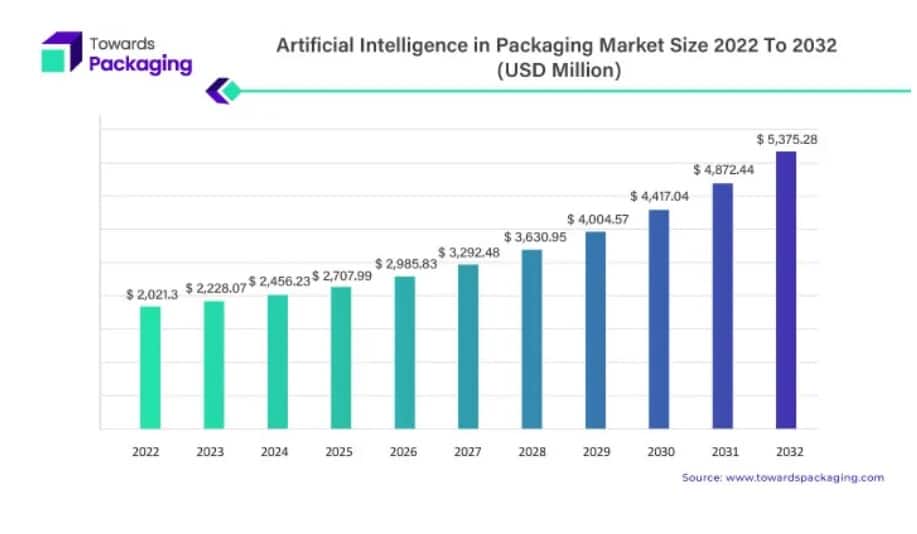

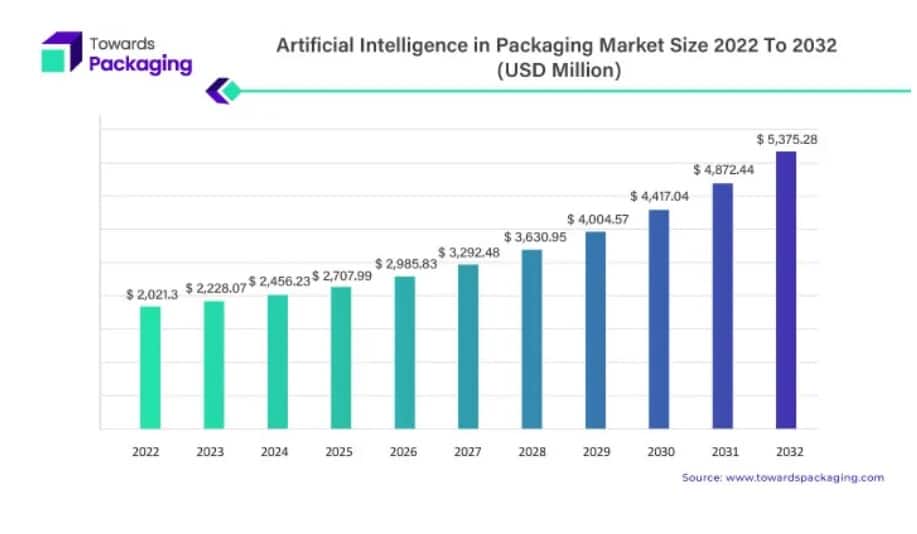

Artificial Intelligence in the Packaging Industry: A Revolution from 2023 to 2032

The packaging industry stands at the forefront of a revolution, driven by the incredible potential of artificial intelligence (AI). In this transformative journey from 2023 to 2032, AI is set to redefine packaging design, manufacturing, sustainability, and even recycling. This article explores the dynamic landscape of AI in packaging, shedding light on its profound impacts and future prospects.

AI-Powered Packaging Design

Traditionally reliant on human imagination, packaging design now embraces AI algorithms for unparalleled creativity and precision. AI analyzes vast data sets, including consumer preferences, market trends, and brand guidelines, enabling designers to craft unique and captivating packaging. AI in Packaging

Simulations help visualize the packaging’s appearance in different environments, saving time and resources while ensuring it resonates with the target audience.

Manufacturing Excellence with AI

AI’s influence extends to manufacturing, where intelligent systems equipped with computer vision swiftly detect flaws in packaging materials, minimizing waste and product recalls. Furthermore, AI optimizes packaging arrangements, maximizing material usage and reducing excess, resulting in cost savings and enhanced sustainability.

Sustainable Packaging through AI

More…

LyondellBasell announced its acquisition of a 25% equity stake in the Cyclyx joint venture, a partnership between Agilyx and ExxonMobil

Cyclyx, formed in December 2020, focuses on advancing plastic waste recycling with the ambitious goal of increasing the recyclability of plastics from 10% to 90%.

The addition of LyondellBasell to this collaboration is poised to significantly accelerate innovation and the development of essential infrastructure for a nationwide circular economy for plastics. AI in Packaging

Cyclyx International aims to create an innovative supply chain through its mission brand, working in tandem with industry partners to drive advancements in plastic recyclability. The joint venture’s strategic vision aligns with LyondellBasell’s commitment to sustainable practices, emphasizing the importance of robust supply chains to enhance access to circular and renewable feedstocks.

Yvonne van der Laan, LyondellBasell’s Executive Vice President of Circular and Low Carbon Solutions, expressed the significance of investing in plastic waste value chain experts like Cyclyx. This collaboration is instrumental in establishing the necessary scale of recycled material and infrastructure, particularly for LyondellBasell’s planned integrated Circular and Low Carbon Solutions Hub in the Houston area. AI in Packaging

Joseph Vaillancourt, CEO of Cyclyx, welcomed LyondellBasell to the ownership structure, emphasizing their shared vision for a more sustainable future. The inclusion of LyondellBasell is seen as a strategic move, given their global leadership and commitment to advancing sustainability goals in plastic circularity. The joint efforts of Agilyx, ExxonMobil, and LyondellBasell are expected to contribute significantly to the realization of a circular economy, addressing the challenges posed by plastic waste.

Non-toxic plasticisers for use in elastomers and thermoplastics

Bio-based plasticizers from Central Germany

The Fraunhofer Institute for Microstructure of Materials and Systems IMWS is working with partners to develop a marketable, completely bio-based and non-toxic plasticizer for use in elastomers and thermoplastics. Using rapeseed oil as a starting product, more sustainable solutions for tires and packaging should become possible. The project partners also want to design a corresponding pilot plant in central Germany as part of the “Biocerine” project. AI in Packaging

Plasticizers are used to make plastics more flexible and pliable during the manufacturing process and/or during subsequent use. However, common industrially produced plasticizers such as phthalates are viewed critically because some of them can be potentially harmful to health and/or pollute the environment.

“Such plasticizers are not only frequently used in traditional plastics, but also in biopolymers, whose environmental compatibility they then impair. For this reason, alternatives are being sought worldwide that offer at least comparable quality at affordable prices and can ideally be produced from renewable raw materials,” says Dr. Patrick Hirsch, Group Leader “Sustainable Materials and Processes”, who is leading the project at the Fraunhofer IMWS. AI in Packaging

This is precisely the solution the partners want to find within the project, which is being funded by the Federal Ministry of Education and Research as part of the “WIR! – Change through Innovation in the Region” program. The consortium is relying on the expertise and opportunities already available in Central Germany. In addition to the Fraunhofer IMWS, GLACONCHEMIE GmbH and Polymer Service GmbH from Merseburg are also involved, while Folienwerk Wolfen, Expinos GmbH and Reifenwerk Heidenau GmbH will test the product samples created in the research project as associated partners.

More…

Global PBT Resin Market 2024-2030 is Booming Around the world with Upcoming years

PBT Resin Market [2024-2030] research report is a comprehensive information that consolidates data and analysis gathered from diverse sources. Its primary purpose is to provide industry with a comprehensive understanding of the present market dynamics, including trends specific to their industry and insights into competitors’ activities within different applications like (Electrical & Electronics, Automobile Industry, Mechanical Equipment, Other Products) and Type (Injection Grade PBT, Extrusion Grade PBT). Armed with these valuable insights, organizations can make well-informed decisions and formulate successful growth strategies. AI in Packaging

Polybutylene Terephthalate (PBT) is semi-crystalline, white or off-white polyester similar in both composition and properties to polyethyleneterephthalate (PET). It is a thermoplastic engineering polymer that is used as an insulator in the electrical, electronics, automobile, Mechanical Equipment and precision instruments industries. Compared to PET (polyethylene terephthalate), PBT has slightly lower strength and rigidity, slightly better impact resistance, and a slightly lower glass transition temperature.

In this report, the volume of PBT is calculated by PBT neat resin, excluding PBT modified resin and PBT Compounds. AI in Packaging

The global PBT Resin market was valued at USD 4162.7 million in 2022 and is anticipated to reach USD 5382 million by 2029, witnessing a CAGR of 3.7 percent during the forecast period 2023-2029. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes.

PBT is present in everyday life and is common in electrical, electronic and automotive components. PBT resin and PBT compound are the two types of products that are used in various applications.

More…

China to Achieve Circular Economy in EV Batteries Before Europe and the US, According to Researchers

The University of Münster researchers project that China will outpace Europe and the US in achieving a circular economy for electric vehicle (EV) batteries AI in Packaging

Their analysis, detailed in Resources Conservation and Recycling, envisions China meeting its primary lithium demand for EVs through recycling by 2059, well ahead of Europe and the US, expected to achieve this milestone after 2070.

Examining crucial battery materials like lithium, cobalt, and nickel, the study predicts China reaching cobalt recycling by 2045, Europe by 2052, and the US by 2056. For nickel, China is expected to achieve recycling by 2046, with Europe and the US following suit in 2058 and 2064, respectively. AI in Packaging

Utilizing dynamic material flow analysis and considering factors like market forecasts, battery production, and sales, the researchers emphasize the uncertain timeline for achieving “complete circularity” – a balance between material supply and demand.

They also suggest that a faster pace of electrification, coupled with reduced battery sizes and decreased use of second-life batteries, could expedite circularity realization.

However, the predictions underscore the importance of monitoring industry trends to adapt to evolving circumstances in the electric vehicle battery and recycling sectors.

From useless plastic waste to valuable oil

Researchers and business people have developed a new technology that can make oil from plastic waste that cannot be recycled. This oil can be used to make new plastic and other oil-based products. The technology was recently used in a new commercial facility in West Zealand, Denmark. AI in Packaging

Do you ever wonder how much (or how little) of the plastic waste (packaging, containers, and milk cartons) you put in your recycling bin is actually recycled? The garbage truck transports it to a waste management facility for sorting and recycling. The ‘good’ plastic is recycled, and the rest—which is either too dirty, mixed, or damaged for recycling—is incinerated.

In Denmark alone, around 370,000 tons of plastic waste is incinerated every year. According to the Danish Ministry of the Environment, plastic waste incineration makes up a significant portion of Denmark’s fossil-fuel carbon emissions. In other words, there is a huge green potential in developing new methods for recycling even more plastic waste than we do now. AI in Packaging

If we can also reduce the amount of non-renewable plastic waste, we can reduce the need for the non-renewable raw materials needed for plastic production—oil and natural gas.

A group of DTU researchers have therefore investigated new possibilities for recycling our plastic waste in collaboration with Roskilde University and a number of industry partners. Their research project, RePlastic, has shown that valuable oil can be produced from otherwise useless plastic waste through pyrolysis. AI in Packaging

“I’m surprised at the great potential of pyrolysis technology for the most impure and mixed plastic fractions. This process can handle the plastic we have no other uses for. This enables us to bring end-of-life plastic back into the cycle and make it useful again,” says Anders Egede Daugaard, Associate Professor at DTU Chemical Engineering and head of the RePlastic project. AI in Packaging

Plastic is not just plastic

More…

Polyethylene waste could be a thing of the past

undamental research has developed a way of using polyethylene waste (PE) as a feedstock and converted it into valuable chemicals, via light-driven photocatalysis.

The University of Adelaide’s Professor Shizhang Qiao, Chair of Nanotechnology, and Director, Centre for Materials in Energy and Catalysis, at the School of Chemical Engineering, led the team which published their findings in the journal Science Advances.

“We have upcycled polyethylene plastic waste into ethylene and propionic acid with high selectivity using atomically dispersed metal catalysts,” said Professor Qiao.

“An oxidation-coupled room-temperature photocatalysis method was used to convert the waste into valuable products with high selectivity. AI in Packaging

“Nearly 99 per cent of the liquid product is propionic acid, alleviating the problems associated with complex products that then require separation.

“Renewable solar energy was used rather than industrial processes that consume fossil fuel and emit greenhouse gases.

“This waste-to-value strategy is primarily implemented with four components, including plastic waste, water, sunlight and non-toxic photocatalysts that harness solar energy and boost the reaction. A typical photocatalyst is titanium dioxide with isolated palladium atoms on its surface.”

Most of the plastics used today end up being discarded and accumulated in landfills. PE is the most widely used plastic in the world. Daily food packaging, shopping bags and reagent bottles are all made from PE. AI in Packaging

It is also the largest proportion of all plastic waste and primarily ends up in landfills, posing a threat to global environment and ecology.

“Plastic waste is an untapped resource that can be recycled and processed into new plastics and other commercial products,” said Professor Qiao.

More…

PET Bottles -Goodbye to oil? OPEC puts the veto : greenhouse gas emissions isn’t so important! – In contrast to the global trend of phasing out petrol cars, Australia appears to be an outlier, exhibiting a persistent dependence on fossil fuel vehicles, according to recent data 11-12-2023

AI in Packaging