BGPET Hydrogen Batteries but recycling batteries is convenient and environmentally friendly? Artificial turf recycling outstanding results Is hydrogen becoming less important? 03-07-2023 - Arhive

BGPET Hydrogen Batteries

-BGPET Nylon still low prices

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-RadiciGroup overcomes difficulties and strengthens its position in 2022 and beyond

Bergamo, 30 June 2023 – RadiciGroup, global leader in the chemical and textile sector, today announced positive results for its 2022 financial statements despite a complex geopolitical and economic context. The Group confirms its investment strategy, allocating 70 million euros for 2023, in order to improve competitiveness and enhance human capital. BGPET Hydrogen Batteries

During 2022, RadiciGroup recorded a slight growth compared to the previous year, reaching a turnover of 1,543 million euros. This result was achieved thanks to the activities of its more than 30 production and commercial sites distributed in Europe, Asia and America. EBITDA reached 157 million euros, while the net profit for the year was 80 million euros. BGPET Hydrogen Batteries

Mr. Angelo Radici Charman of RadiciGroup

Angelo Radici, Chairman of RadiciGroup, commented on the results, stating: “We are moderately satisfied with the results achieved in 2022. Despite the unforeseen and management difficulties we faced during the year, we managed to achieve positive results. The increase in costs of energy and raw materials, combined with the outbreak of war in Ukraine and the unavailability of some raw materials, has created an extremely challenging situation, especially in the chemical sector.However, thanks to our internationalization strategy and the presence in the High Performance Polymers area, we managed to balance these difficulties and maintain a strong position.”

Mr. Maurizio Radici, Vicepresident of RadiciGroup

Maurizio Radici, Vice President of RadiciGroup, underlined the importance of investments in the current context: “Despite the uncertainties that characterize the global economy in 2023, we have decided to continue investing to strengthen our global presence and increase competitiveness in markets in growth. BGPET Hydrogen Batteries

We recently inaugurated a new production site in China, which will allow us to double production capacity to meet market growth expectations. Furthermore, we continue to invest in environmental sustainability, reducing CO2 emissions and adopting sustainable processes and solutions. ”

Mr. Alessandro Manzoni, CFO of RadiciGroup

Alessandro Manzoni, CFO of RadiciGroup, underlined the solid financial management of the Group: “Our careful asset management has allowed us to maintain a stable net financial position despite the significant investments and the increase in raw material costs. This financial solidity gives us allows us to face the challenges of the global markets in which we operate.” BGPET Hydrogen Batteries

Despite the difficulties and uncertainty of the international context, RadiciGroup is committed to continuing along the path of innovation, competitiveness and sustainability, confirming its leadership in the chemical and textile sector. BGPET Hydrogen Batteries

Mr. Paolo Radici shareholder of RadiciGroup with his brothers Mr. Angelo and Mr. Maurizio

-Hydrogen paused to contemplate its position. It was deemed too costly and lacked environmental friendliness

Hydrogen reflected on its disadvantages, acknowledging its high price tag and its failure to meet green standards. It seemed to be one of the biggest infatuations in the world of sustainable energy, as highlighted by the International Energy Agency (IEA) in 2019. This infatuation, often observed during critical energy transitions, is characterized by soaring expectations followed by disappointment with the technology.

According to a recent study by Ambrosetti, the numbers speak for themselves: by 2050, hydrogen has the potential to reduce CO2 emissions by 28%, generate a value of production between 890 and 1,500 billion euros, and create 320,000 to 540,000 new jobs. Despite these promising prospects, only 13 hydrogen projects have been implemented in Italy. So, what are the reasons behind this limited progress? BGPET Hydrogen Batteries

The costs involved, particularly electrolysis expenses, and the complexity of establishing a supply chain, including the creation of specialized infrastructure and uncertainty regarding blending with existing natural gas infrastructure, are significant challenges. Moreover, when hydrogen production claims to be green by utilizing renewable sources with virtual markets (guarantees of origin), it doesn’t necessarily mean it is carbon-free. Francesco Gulli, associate professor of energy economics and environmental economics at Bocconi University and deputy director of the Institute of Energy and Environmental Economics and Policy, explains this complex aspect. BGPET Hydrogen Batteries

Gulli emphasizes that drawing energy from the centralized electricity grid to produce hydrogen, when the electricity generation park is not yet fully decarbonized, renders hydrogen not clean, even with guarantees of origin from carbon-free renewable sources. Therefore, until the electricity generation park becomes completely decarbonized, hydrogen supply cannot be considered truly green. BGPET Hydrogen Batteries

The exception to this rule lies in hydrogen valleys, where renewable plants exclusively dedicated to hydrogen production are established without direct connection to the centralized electricity grid. However, doubts remain about the viability and justification of such projects.

This explains the significant delay in the development of hydrogen technology, which was anticipated to be one of the most ambitious experiments under the National Recovery and Resilience Plan (Pnrr) but has only received 35 proposals, accounting for half of the allocated funds. BGPET Hydrogen Batteries

Nonetheless, companies like Iren, Eni, Enel, Hera, and Snam are actively exploring hydrogen technology. However, the industry is still in the testing phase, with Snam, led by Stefano Venier, introducing hydrogen into Italian gas pipelines and storage facilities. Their aim is to blend 20% hydrogen with natural gas in a “hybrid” mix. This project progresses in stages to ensure all technical requirements are met. It’s important to note that Snam acts as a transporter rather than a producer of hydrogen. Through projects like the South2 Corridor, Snam is facilitating the development of a strategic hydrogen corridor involving more than 20 companies and targeting Italy, Germany, and Austria. This project has recently been a topic of discussion between Prime Minister Meloni and Chancellor Scholz and is expected to have future advancements. BGPET Hydrogen Batteries

Despite the goodwill of involved parties, the sector is still largely in a testing phase, and establishing a complete value chain remains challenging, as desired by the Ambrosetti think tank. Valerio De Molli, Managing Partner & CEO of The European House Ambrosetti, emphasizes the need for a long-term policy vision that combines industrial objectives with sustainability goals, based on the principle of technological neutrality. Effective governance, collaborating with Italian institutions, is crucial for implementing, monitoring, and updating the national hydrogen strategy. BGPET Hydrogen Batteries

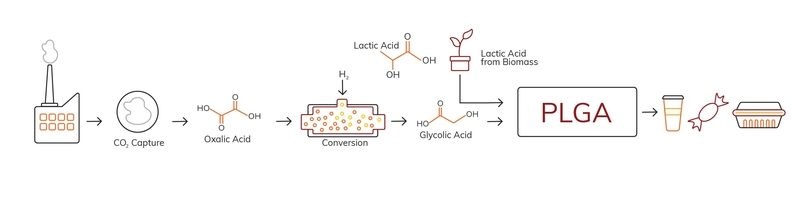

-Avantium, a leading renewable chemistry company headquartered in Amsterdam, has partnered with SCG Chemicals, an integrated petrochemical innovations company based in Thailand, to advance the development of CO2-based polymers

The primary objective of this collaboration is to bring these innovative polymers to the pilot phase.

The partnership will leverage Avantium’s groundbreaking Volta Technology platform, which utilizes electrochemistry to convert CO2 into valuable products and chemical building blocks, including glycolic acid. BGPET Hydrogen Batteries

By combining glycolic acid with lactic acid, Avantium has successfully produced a carbon-negative polyester called polylactic-co-glycolic acid (PLGA). This remarkable material boasts exceptional oxygen and moisture barrier properties, as well as impressive mechanical strength. Furthermore, PLGA is recyclable, home compostable, and marine degradable, making it an environmentally friendly choice.

Since the beginning of 2023, Avantium and SCGC have been collaborating on the development of PLGA. Avantium has created various samples of PLGA, which were evaluated at SCGC’s Norner AS facility. BGPET Hydrogen Batteries

The positive results from this evaluation led to the establishment of a Joint Development Agreement between the two companies. The agreement aims to further explore the potential of PLGA and subsequently scale up the production of glycolic acid monomer and PLGA polyester over the next two years. The goal is to establish a pilot plant with a capacity of approximately 10 tonnes per annum.

Dr. Suracha Udomsak, Chief Innovation Officer and Executive Vice President at SCGC, expressed their admiration for the sustainability and performance characteristics of PLGA after assessing the samples. BGPET Hydrogen Batteries

He stated, “We look forward to working together with Avantium in the years to come.” Tom van Aken, CEO at Avantium, added that this partnership would enable them to advance PLGA, a highly promising carbon-negative plastic, towards commercialization. He also expressed openness to welcoming other strategic and complementary partners to participate in this collaboration.

Overall, the Avantium and SCGC partnership signifies a significant step forward in the development and application of CO2-based polymers, particularly PLGA. Their joint efforts will not only contribute to the advancement of sustainable materials but also pave the way for the next phase of commercialization.

-FormaTurf opens first artificial turf recycling plant in Germany

Two years ago, Sport Group, a leading global supplier of sport surfaces, and its subsidiary Polytan, the leading installer of artificial grass in Germany, announced plans to build a recycling plant that would be able to recycle almost all the different types of artificial turf systems installed to date, instead of only pitches installed by Polytan.

The plant would be operated by FormaTurf, a new company established by Sport Group for this purpose. BGPET Hydrogen Batteries

Now, after two years of construction, FormaTurf announced last week that the new plant has been officially opened. The festive opening event took place in Essen and was attended by among others, the mayor of Essen, Thomas Kufen, and the head of the department for the Circular Economy, Cornelius Laaser. Sport Group Holding was represented by Christoph von Nitzsch (CEO) and Dr. Klaus Hauschulte (COO).

The new plant spans an area of 20,000 square meters In terms of capacity, FormaTurf plans to process 200 large pitches per year. BGPET Hydrogen Batteries

The technology used by FormaTurf enables almost 100 percent of a discarded artificial turf pitch – turf carpet, sand and rubber granulate – to be separated and recycled. Mechanical and chemical recycling is used to process the waste materials into secondary raw materials. Sand accounts for around 70% of the weight of an artificial surface, so as much sand and infill as possible needs to be separated from the turf backing and filaments during the initial stage. BGPET Hydrogen Batteries

The turf backing, including filaments, is shredded into millimetre-sized pieces and mixed with the separated infill material, a patented process called ‘aptrusion’ that allows for a sand content of up to 75%.

The FormaTurf facility is the first recycling plant dedicated to recycling artificial pitches in Germany, the company emphasised. And with FormaTurf now in operation, Sport Group is the only company in the industry to cover the entire artificial turf value chain – from research, development and production to installation, maintenance and recycling by FormaTurf, thus effectively closing the loop. BGPET Hydrogen Batteries

-NOVA Chemicals and Plastic Energy Launch Feasibility Study on Advanced Recycling Plant to Further Canadian Circularity Aspirations

- Facility would be constructed in the Sarnia, Ontario, region

- If constructed, would be largest facility of its kind in Canada to date

- Investment would build on already CAD 2 billion injected into Province of Ontario

NOVA Chemicals Corporation (“NOVA Chemicals”) and Plastic Energy have entered into an agreement to explore the feasibility of developing a pyrolysis-driven advanced recycling facility in the Sarnia, Ontario, region. If constructed, the facility would be the largest of its kind in Canada with a potential initial capacity of 66kt per annum.

“Post-use plastics offer tremendous value to furthering the circular economy, and our teams at NOVA Chemicals work daily to innovate new and collaborative ways to extend the lifecycle of our products and plastic packaging,” said Greg DeKunder, VP, NOVA Circular Solutions. “This agreement with Plastic Energy is a prime example of two companies working together to create timely, effective, and sustainable solutions that will help us make progress towards our 2030 recycled plastics ambitions, while diverting hard-to-recycle segments of plastic waste away from landfills.” BGPET Hydrogen Batteries

Plastic Energy is one of the world’s leading advanced recycling technology companies through use of its patented TAC™ process to treat post-consumer plastic waste. Recycled polyethylene manufactured using Plastic Energy-produced feedstock, called TACOIL™, has identical properties to virgin polyethylene and can be used in food contact and high-performance applications, helping manufacturers and packagers achieve their recycled content goals. Plastic Energy has two commercial recycling plants in Spain that have been in operation for seven years, alongside new projects in Europe and Asia.

“We are pleased to sign this agreement with NOVA Chemicals to explore the scope for our first advanced recycling project in Canada,” said Carlos Monreal, Founder and CEO of Plastic Energy. BGPET Hydrogen Batteries

“Advanced recycling will continue to be important for the North American market by providing a solution for incorporating recycled content into food-grade packaging. Together with NOVA Chemicals, we aim to reduce the amount of plastic waste ending up in landfills, incineration, or as leakage into the environment, which is important for the circular economy in Canada.” BGPET Hydrogen Batteries

NOVA Chemicals recently announced its aspiration to reach 30 per cent recycled content as a share of its total polyethylene sales by 2030 in its Roadmap to Sustainability Leadership, including its commitment to build a state of the art mechanical recycling business and continue exploring world-leading and proven advanced recycling technologies. If built, this new facility would see NOVA Chemicals build on its already CAD 2 billion investment into Ontario to inject additional new technology, jobs, and long-term viability into the local and Canadian economies. BGPET Hydrogen Batteries

-BASF to establish a co-located battery materials and recycling center

BASF celebrated the opening of Europe’s first co-located center of battery material production and battery recycling in Schwarzheide, Germany, said the company.

The inauguration of a state-of-the-art production facility for high-performance cathode active materials and the unveiling ceremony for a battery recycling plant for the production of black mass represent important steps toward closing the loop for the European battery value chain – from the collection of used batteries and the recovery of mineral raw materials to their use in the production of new battery materials. Major step in Europe to participate in the rapidly growing global battery market. BGPET Hydrogen Batteries

Battery materials are at the heart of lithium-ion batteries as they significantly determine their performance and therefore play a crucial role in the transformation of mobility.

“Despite all challenges we are currently facing in Europe, is a reason for all of us to be optimistic. BGPET Hydrogen Batteries

The state-of the art cathode active materials plant and the recycling plant for black mass production underline that we at BASF believe in the future of the chemical industry in Europe and in Germany and invest in innovative products and services for our customers in our home market,” said Dr. Martin Brudermuller, Chairman of the Board of Executive Directors of BASF SE. “With our two investments we significantly contribute to the reduction of the CO2 footprint of batteries and close the loop for sustainable mobility.”