BICO fibers – solid-state batteries 26-05-2023 - Arhive

BICO fibers – solid-state batteries Plastic recycling – solar Panels

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-Xi says no to Putin: I’m doing the new gas pipeline with Turkmenistan

Friendship is unquestionable, close, and has a common enemy: what remains of the awakened US-led global order. Immediately after the G7 meeting in Japan, in which it was decided to help Ukraine even more and contain China, Xi Jinping received Russian Prime Minister Mikhail Mishustin in Beijing, and the two promised each other “firm and on issues of fundamental interest”, i.e. economy, security and military development. One thing Putin is certainly very keen on is finding new outlets for his gas industry, which has almost completely lost its most profitable market, Europe. The obvious alternative is to increase deliveries to China (it must be said, however, that Turkey is also proving to be an excellent customer).

War Ukraine Russia, today’s news live

Putin has therefore been wanting to close a new supply contract with Xi Jinping for a long time. The gas pipeline in the pipeline is called Power of Siberia 2, 6700 kilometers long, capable of carrying 50 billion cubic meters of gas every year from Russia to China, passing through Mongolia.BICO fibers – solid-state batteries Plastic recycling – solar Panels

The Russian government has announced several times that almost all parameters have been agreed and that Gazprom is ready to go. The completion works of the structure – says the Russian government – should last five years. The only thing missing is the contract. But the Chinese friend hesitates, he calculates for him. Putin waits. And in the meantime Gazprom is falling apart: it is the Russians themselves who have announced that this year their gas exports through pipelines could be halved.

Between January and March, Russian oil and gas revenues fell 45% compared to the same period last year. The Russian deficit is starting to rise: this year the Kremlin had forecast a deficit of around 2% of GDP, but the accounts already don’t add up. Several analysts now expect a deficit of between 6 and 8 trillion rubles, between 4 and 5% of GDP, high numbers by Russian standards.

So the agreement for Siberia 2 is vital, and it is very probable that the signing of the green light will come sooner or later. Not now though: Chinese officials inform Reuters news agency that Xi Jinping has given priority to a new connection with Turkmenistan, 30 billion cubic meters a year, this despite Turkmen gas, adds Reuters, costs China 30% more than the Russian one. According to Reuters sources, feasibility studies on the project – which is called “Linea D” – began last week. “This means Line D is being prepared,” the source said. Last year, China imported 35 billion cubic meters of gas from Turkmenistan, against 16 billion from Russia through the Power of Siberia. “Central Asian gas pipelines are seen by China as a key investment,” said a Chinese official familiar with the plans of CNPC, the state-owned energy giant. But the strategy is quite clear, and you don’t need an analyst to understand it. China diversifies sources, puts them in competition with each other, minimizes risks and extracts favorable conditions. As mentioned, the signing of Siberia 2 will come sooner or later. But Putin still has to wait, or simply offer his Chinese friend even more advantageous prices. BICO fibers – solid-state batteries Plastic recycling – solar Panels

-Beaulieu Fibres International, a supplier of polyolefin and BICO fibers, has revealed its latest environmentally friendly solutions for the hygiene and industrial sectors

The company’s focus is on resource conservation and reducing carbon footprints.

One of their innovations is the Meralux BICO Trilobal fiber, which offers several advantages. These unique polypropylene/polyethylene fibers have a distinct cross-section shape that allows for a reduced weight compared to traditional round BICO PP/PE fibers, while maintaining the same fiber coverage. This design enables savings of up to 54% in fiber usage and a remarkable 57% reduction in carbon footprint. Additionally, Meralux BICO Trilobal fibers enhance opacity, bulkiness, and liquid management, leading to improved dryness in nonwoven fabrics for hygiene applications. Moreover, these fibers are designed for recycling, thanks to the use of polyolefin polymers.

Beaulieu is also dedicated to achieving 100% recyclable industrial applications and has introduced UltraBond, a bonding staple fiber that significantly reduces the ecological footprint of 100% polyolefin nonwoven products. Unlike traditional methods that involve latex or chemical binders, UltraBond utilizes thermal bonding, a completely dry process that eliminates the need for water. This results in reduced production and energy costs, as well as a lower carbon footprint. BICO fibers – solid-state batteries

The company’s commitment to sustainable practices extends to its Rewind event carpet, a 100% polypropylene needlepunched flooring solution. Compared to traditional event carpet, Rewind consumes 85% less energy, requires 100% less water, and generates 55% less CO₂ during production. Plastic recycling – solar Panels

As of March 2023, all three of Beaulieu’s manufacturing sites offer bio circular products. The Belgian and Italian plants have obtained ISCC Plus certifications, affirming their ability to develop sustainable fiber solutions with a negative carbon footprint. Beaulieu Fibres International aims to provide performance fibers that align with the circular economy and possess sustainability-related properties. The company believes in collaboration and leveraging its research and development capabilities to assist nonwoven producers in achieving their sustainability targets and product performance goals. Maria Teresa Tomaselli, General Manager of Beaulieu Fibres International, emphasizes their dedication to delivering fit-for-purpose fibers that prioritize the environment and support a circular economy.

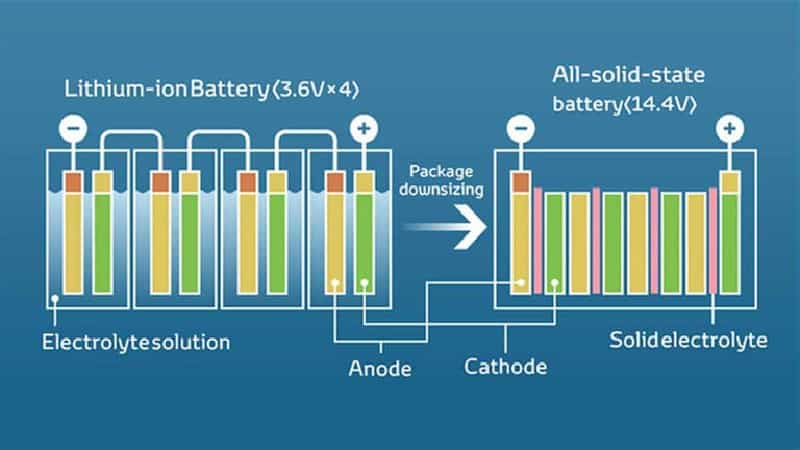

-Significant progress has been made in the field of solid-state batteries, with China’s Ganfeng leading the way in high-volume production

While previous attempts to mass-produce solid-state batteries have been unsuccessful, Ganfeng has successfully established a production line capable of manufacturing these advanced energy storage devices. With an annual capacity of 4 GWh, Ganfeng’s solid-state batteries are now being produced on a large scale.

The first-generation solid-state battery developed by Ganfeng boasts an energy density of 260 Wh/kg. Although this is not a record-breaking figure, as other companies like CATL are set to release batteries with higher energy densities by the end of 2023, Ganfeng’s achievement is still commendable.

Notably, NIO, in collaboration with WeLion and with support from companies like Xiaomi and Huawei, has already introduced a semi-solid state battery with a density of 360 Wh/kg and a capacity of 150 kWh. However, Ganfeng remains at the forefront of solid-state battery production. BICO fibers – solid-state batteries

Not content with their current accomplishments, Ganfeng is actively working on the development of a second-generation solid-state battery. This next iteration promises even greater performance, with an energy density of 400 GWh. The company has achieved this impressive improvement by utilizing a newly developed lithium metal anode. Furthermore, this advanced battery meets the rigorous safety requirements of the automotive industry, making it a viable option for electric vehicles. Plastic recycling – solar Panels

Ganfeng’s second-generation solid-state battery is expected to enter production by the end of the year, marking another significant milestone for the company. As they continue to refine their battery technology and expand their production capabilities, Ganfeng aims to further revolutionize the energy storage industry and contribute to the widespread adoption of electric vehicles and other clean energy applications.

-Greenpeace asserts that recycling exacerbates the issue of toxic chemicals in plastics. The organization is urging negotiators of a global plastics agreement to prioritize reduction

In their recently released report, titled “Forever Toxic,” Greenpeace consolidates peer-reviewed studies from various countries to establish claims about the impact of chemicals found in plastics, particularly recycled plastics, on human health and the environment.

This release follows a Greenpeace report from seven months ago, which alleged that no plastics in the United States meet the definition of “recyclable.” Although the earlier study received significant attention from mainstream media, its methodology was criticized by Plastics Recycling Update.

According to a Greenpeace press release, the toxicity report references studies that collectively conclude that recycling amplifies the toxicity of plastics. It suggests that the forthcoming global plastics agreement negotiations in Paris should focus on implementing caps and phased reductions in plastic production, as well as regulating chemical additives.

The study highlights that plastics contain over 13,000 chemicals, with more than 3,200 of them known to be hazardous to human health. Additionally, many other chemicals present in plastics have not been assessed and may also be toxic. BICO fibers – solid-state batteries

Responding to the study, the American Chemistry Council (ACC) emphasizes the benefits that plastics bring to society. Joshua Baca, Vice President of Plastics at the ACC, states, “If Greenpeace had its way, modern life would be dramatically different.” He argues that people worldwide, particularly in developing countries, would have limited access to clean drinking water, safe food supplies, sanitary medical and personal care products, and renewable energy.

The Greenpeace report outlines three primary ways in which recycled plastics accumulate potentially hazardous chemicals: direct contamination (when the virgin plastic being recycled already contained the chemical), leaching, and heating during the recycling process. For instance, recycling plastics containing brominated flame retardants can result in the formation of brominated dioxins, while a stabilizer used in plastic recycling can degrade into a highly toxic substance found in recycled plastics. Sorting challenges and the presence of certain packaging components in sorted materials can also contribute to toxicity in recycled plastic. Plastic recycling – solar Panels

Although single-use food and beverage packaging typically does not contain brominated flame retardants, the report argues that such chemicals can enter the recycling stream and end up in the resin. Therese Karlsson, a science advisor with the International Pollutants Elimination Network (IPEN), states in the press release that “plastics are made with toxic chemicals, and these chemicals don’t simply go away when plastics are recycled.” Karlsson emphasizes that genuine solutions to the plastics crisis necessitate global controls on chemicals in plastics, along with significant reductions in plastic production.

Greenpeace calls on stakeholders participating in the Intergovernmental Negotiating Committee on Plastic Pollution, scheduled to convene in Paris later this week, to expedite refill- and reuse-based systems that eliminate plastic. The organization also advocates for a cap on plastic production, coupled with reduced production and a fair transition for workers in the plastics industry.

Greenpeace suggests that remaining plastic stockpiles should be managed using non-combustion technologies. They recommend implementing extended producer responsibility on a broader scale. The agreement should include stricter regulations for recycling facilities, transparency regarding the chemicals present in plastics, and an incentive for companies to eliminate all toxic additives and chemicals from their plastic products.

Joshua Baca from the ACC contests some of these proposed strategies. He asserts that the recommendations in the Greenpeace report would disrupt global supply chains, impede sustainable development, and substitute plastics with materials that have a significantly higher carbon footprint in critical applications.

-Braskem´s owner Novonor says won’t hold talks with ADNOC, Apollo

Braskem, the largest petrochemical company in Latin America, and owner of an ethylene-polyethylene complex in Mexico, as well as the leading polypropylene producer in North America with five plants in the U.S., has declined a joint offer from the Abu Dhabi state oil company ADNOC and the Apollo fund, according to Reuters

The offer, made in May, was not considered by Braskem’s owners, Novonor, or the top officials from Petrobras, as stated in a letter sent by Braskem’s financial director, Pedro Texeira de Freitas, to the Brazilian stock authorities on May 16, 2023.

The letter, which was written in response to an article published in the Brazilian newspaper Folha de Sao Paulo titled “Braskem controllers disapprove offer from Arabs,” clarified that the offer of 47 Brazilian reais (approximately $9.40) per share would not result in that amount being paid to shareholders. In reality, shareholders would likely receive only around 20 reais per share. BICO fibers – solid-state batteries

The main shareholders of Braskem, Novonor (formerly Odebrech) with a stake of just over 50%, and Petrobras with 38%, have chosen not to engage in negotiations and sit at the negotiation table due to the perceived insufficiency of the offer. The letter emphasized that Novonor had not received any proposals from potentially interested parties that would significantly advance the discussions being held with banks holding stakes.

Despite Braskem’s management reaching out to Novonor for information regarding any potential sale decision, they received a written response stating the majority owner’s intention to abstain from talks. Plastic recycling – solar Panels

It is worth mentioning that Eni and ADNOC have announced plans to explore collaborative opportunities in various areas, including renewable energy, blue and green hydrogen, carbon dioxide capture and storage (CCS), greenhouse gas and methane gas emissions reduction, energy efficiency, routine gas flaring reduction, and the Global Methane Pledge. This cooperation aims to support global energy security and facilitate a sustainable energy transition. Furthermore, both companies will assess potential areas of cooperation to promote sustainable development and foster a culture of sustainability within the energy industry and its stakeholders. BICO fibers – solid-state batteries

-Solarge, in collaboration with chemical company Sabic, has launched a groundbreaking innovation in the form of new lightweight solar panels

These panels not only boast full circularity but also offer a carbon footprint reduction of over 25% compared to traditional panels.

The unveiling of the new panels took place at Solarge’s recently inaugurated production facility in Weert, the Netherlands, on May 22. The event witnessed the presence of industry leaders, including representatives from Sabic and Solarge, as well as esteemed guests like Rob Jetten, the Dutch Minister for Climate & Energy, and Kadri Simson, the European Commissioner for Energy. Lada Kurelec, the General Manager of PP & E4PS at Sabic, emphasized the company’s commitment to collaboration and innovation in support of sustainability and the energy transition. Kurelec expressed enthusiasm for the partnership and its potential in driving sustainability and working towards carbon neutrality.

Sabic played a pivotal role in the development of these low-carbon footprint solar panels in close collaboration with Solarge. Unlike traditional glass panels, the new panels are made from Sabic PP compounds, which offer expanded application possibilities. This feature is especially advantageous for buildings with roofs that cannot bear the weight of numerous glass PV panels. BICO fibers – solid-state batteries

By substituting Sabic’s PP Compounds, the panels achieve a weight reduction of more than 50% in addition to the 25% reduction in carbon footprint. Furthermore, after 25 years of use, the panels can be recycled and reused within the PV production chain, making them an attractive option for commercial and industrial building segments seeking lighter and more energy-efficient alternatives. Plastic recycling – solar Panels

Jan Vesseur, CEO of Solarge, expressed his satisfaction with the new production line, which enables the realization of the most sustainable solar panels on a large scale. Vesseur emphasized the critical role of Sabic’s collaboration in the development of this groundbreaking product and commended their exemplary execution.

The initial concept and patent for these PV panels were developed by Sabic and Solarge. Sabic engineered a range of polypropylene materials to ensure that the lightweight solar panels meet all performance requirements. Subsequently, Sabic collaborated with Solarge in further application development, testing, installation, and supported the industrial scale-up of the product for market entry. BICO fibers – solid-state batteries

The Sabic PP compounds used in these panels will be manufactured at Sabic’s polypropylene compounding site in Genk, Belgium. As a pilot, the company has already installed 50 of these new PV panels on the roof, with a full-scale roof installation of nearly 5,000 panels scheduled for completion in 2023. This significant deployment marks a significant step towards accelerating the energy transition in the most sustainable manner possible. Plastic recycling – solar Panels

-Chevron Phillips Chemical has partnered with Circulate Capital, a financier promoting a circular economy for plastics in emerging nations, to inaugurate a $65 million endeavor aimed at combating plastic pollution in Latin America and the Caribbean, as stated by the corporation

CPChem is among a consortium of investors pledging their support for this initiative, which will initially focus on Brazil, Chile, Colombia, and Mexico, with plans to expand throughout the region.

The objective is to expand the recycling supply network, tackle climate change, and enhance the economies of the impacted countries, according to the investors.

“We have identified promising prospects throughout Latin America that, if expanded, could reverse the plastic waste predicament in the region,” remarked Rob Kaplan, CEO and founder of Circulate Capital. Plastic recycling – solar Panels

“By implementing the lessons and exemplary practices garnered from our years of work in South and Southeast Asia, we are confident that we can foster scalable solutions in Latin America’s thriving markets to establish a circular approach.

Our corporate partners will also play a pivotal and strategic role in facilitating collaboration between top-tier recyclers and global supply chains.” BICO fibers – solid-state batteries

Alongside CPChem, IDB Lab, Builders Vision, Danone, Dow, Mondelez International, and Unilever are participating in this venture. Plastic recycling – solar Panels

According to the United Nations, the burgeoning economies in Latin America and the Caribbean have outpaced the development of their waste management and recycling infrastructure, presenting an opportunity to fortify the recycling value chain across the region.

Credit : Chevron Phillips Chemical

-When electric car batteries are either not holding enough charge or have been damaged in an accident, they’re not done with by any means

Currently, only a small number of electric and hybrid vehicles are old enough for to become End of Life Vehicles (ELVs), but the amount of accident-damaged EVs has been growing. Hybrid cars, with their smaller batteries, have also been around much longer.

Firstly, let’s deal with the traditional battery which every car uses to start and which powers its accessories. Usually, the vehicle recycler removes it and passes it to a battery recycler where it’s dismantled into its various parts, such as lead, silver, plastic and acid. The valuable parts can be extracted for re-use, while the lead is melted down, very easily recycled and acid neutralised.

The EV battery is another matter. Each car uses a pack consisting of 2,000-plus individual lithium-ion cells working together in modules. Other valuable elements are nickel, manganese and cobalt. They reach the end of their vehicle life when there is no longer an acceptable charging capacity.

This can be after well over 100,000 miles and eight to ten years, which is usually the warranty period. Volkswagen, for example, guarantees a minimum battery capacity of 70% – regardless of charging behaviour for eight years or 100,000 miles.

Car manufacturers are legally obliged to keep control of how their EV batteries are treated at the end of their life in a car. Under current EU rules, all waste from all types of battery should be collected free of charge for end-users, regardless of their nature, chemical composition, condition, brand or origin. In the UK battery producers must also pay for waste battery collection, treatment, recycling and disposal.

Ecobat is the world’s largest recycler of batteries with facilities in the UK, mainland Europe and North America. It built its business on recycling the traditional lead-acid batteries and now works with many major manufacturers on processing end of life and second-life EV batteries. It also collects those tubes of tiny used batteries you see in supermarkets.

The volumes of EV batteries are still relatively small. Since opening in 2021, Ecobat’s UK diagnostic and disassembly centre in Darlaston has processed over 5,000 Batteries and performance graded more than 10,000 Modules, but it expects this to steadily grow.

The battery takeaway

Where an EV battery is not re-sold by a dismantler, or if a dealership needs to have one taken away, Ecobat Solutions collects the battery from the vehicle dismantler using specialist boxes loaded onto trucks which protect against ‘thermal runaway’ where a damaged battery can catch fire. They are treated with the same care – if not more – as a tank of petrol. Normally, batteries must be transported at a maximum 30% charge except when they are waste.

Ecobat has dedicated units on-site where high-voltage critical batteries can be stored then examined safely and remotely – called quarantining. Battery modules are examined for faults or damage and can be discharged to safe levels for storage or further transportation. Neatly, this excess energy helps part -power car charging points in front of the building. Each battery is graded for future re-use.

The metal casing, connectors, cables and raw material like steel, aluminium and plastics are taken away for recycling. The cooling system is removed and this leaves the many individual lithium-ion cells which are either cylindrical or multiple flat plates in individual modules. These can be re-built into modules or batteries and re-certified for a new use.

The second life of EV batteries

The most common form of second use is repurposing for an energy storage system in a domestic or industrial setting or a solar farm. A battery that’s done, say 10 years in an EV and is at 70 or 80% state of health can go into an energy storage system as it will no longer being subject to being charged up multiple times and ask to perform under sudden heavy loads. A kind of being put out to pasture.

Many carmakers have set up specific uses for the old batteries from their EVs. In 2011, Nissan’s Leaf was one of the very first mass-produced EVs. In Namie, Japan, a dedicated factory (4R Energy) takes back batteries and grades them.

Sometimes, the battery components are as good as new; they get an ‘A’ grade and can be reused in new high-performance battery units for a new EV. With a ‘B’ grade, the batteries are powerful enough for industrial machinery like forklifts and large stationary energy storage. In a home or commercial building, for example, they can capture surplus electricity generated during the daytime by solar panels and then power the building during the night.

The ‘C’ grade batteries can be used in units that supply backup power when the electric grid fails, say at grocery stores that must have their refrigerators and lights running even during a power outage. The 4R Energy engineers estimate the recovered batteries have a life span of about 10 to 15 years.

In 2022 Jaguar Land Rover partnered with Pramac to develop a portable zero-emission energy storage unit powered by second-life Jaguar I-Pace batteries from prototype and engineering test vehicles. Charged from solar panels, the unit is a self-contained solution that consists of a battery system linked to a bi-directional converter and the associated control management systems.

The top system has a capacity of up to 125kWh – more than enough, JLR claims, to fully charge an EV, or to power a regular family home for a week. The units are available for commercial hire and fitted with Type 2 charging connections.

On a larger scale former EV batteries could be used to power manufacturing plants and streets. Eventually the factories that produce the batteries could be powered using the repurposed batteries.

When an EV battery isn’t viable for being re-used, there is little chance it will be sent to landfill. The cells are put through a first stage recycling process, essentially crushing, sifting and filtration. Once any non-metal material is extracted the remains are called ‘black mass’ but contain lithium, nickel, manganese, cobalt, all valuable metals.

Until now, black mass, in simple terms, ended up in a blast furnace but should be able to be separated in future. For example, in Germany Volkswagen opened its first plant for recycling used electric car batteries in 2021 and it aims to create a closed material cycle that will not only reduce the Volkswagen Group’s primary demand for raw materials in the long term but can also significantly reduce the carbon footprint of the batteries.