Bio-based polyamide – Plastics waste 20-05-2023 - Arhive

Bio-based polyamide – Plastics waste Gigafactory – eco-friendly packaging

-Biopolymers are polymers that are derived from natural sources such as plants, animals, and microorganisms

They are distinct from synthetic polymers, which are derived from petroleum-based sources. Biopolymers have gained significant attention in recent years due to their potential as sustainable alternatives to traditional plastics and other materials. Here are some common types of biopolymers and their uses:

- Starch-based biopolymers: Starch is a polysaccharide found in various plants. It can be modified and processed to create biodegradable and renewable biopolymers. Starch-based biopolymers are used for packaging materials, disposable cutlery, and agricultural films.

- PLA (Polylactic Acid): PLA is a biodegradable and compostable thermoplastic aliphatic polyester derived from renewable resources such as cornstarch or sugarcane. It is commonly used in food packaging, disposable tableware, medical implants, and 3D printing. Bio-based polyamide – Plastics waste

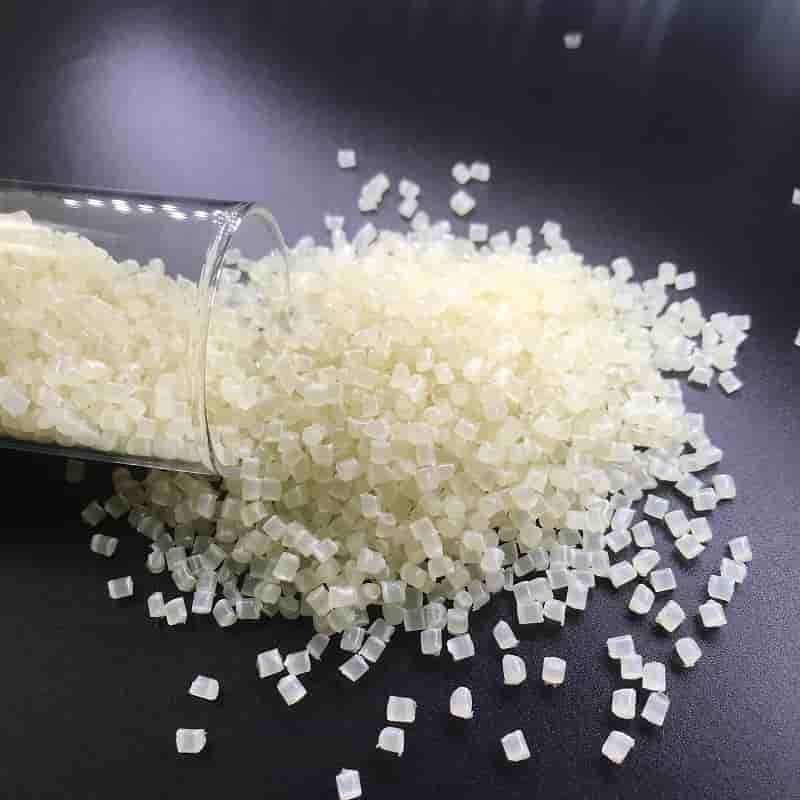

- PHA (Polyhydroxyalkanoates): PHAs are a group of biodegradable polymers produced by microorganisms through fermentation of renewable feedstocks. They have properties similar to conventional plastics and can be used in packaging, agricultural films, medical devices, and consumer goods.

- PCL (Polycaprolactone): PCL is a biodegradable polyester derived from petroleum or renewable resources. Gigafactory – eco-friendly packaging

- It has a low melting point and is often used in drug delivery systems, tissue engineering, and 3D printing applications.

- Chitosan: Chitosan is derived from the shells of crustaceans such as shrimp and crabs. It has excellent biocompatibility and antimicrobial properties, making it useful in wound dressings, drug delivery systems, and tissue engineering scaffolds.

- Protein-based biopolymers: Proteins such as collagen, gelatin, and silk are used as biopolymers in various applications. Collagen and gelatin find applications in biomedical engineering, wound healing, and drug delivery, while silk is used in textiles, sutures, and tissue engineering. Bio-based polyamide – Plastics waste

- Cellulose-based biopolymers: Cellulose is the most abundant biopolymer on Earth and is derived from plant sources. It is used in a wide range of applications such as paper, textiles, food packaging, and medical products.

These are just a few examples of biopolymers and their uses. The field of biopolymer research is rapidly expanding, and scientists are constantly exploring new sources and applications for these sustainable materials. Gigafactory – eco-friendly packaging

PHA Pellets

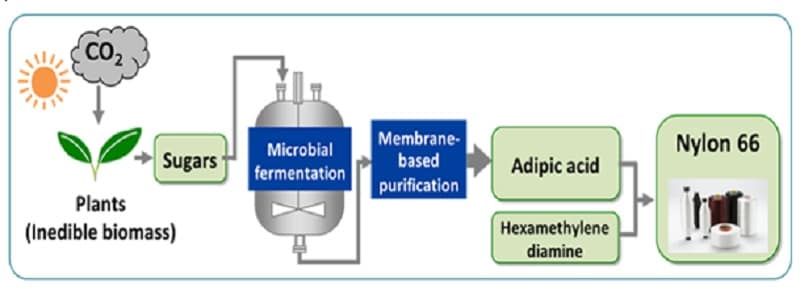

-Bio-based polyamide feedstocks refer to raw materials derived from renewable resources that can be used to produce polyamide (nylon) polymers

Traditional polyamides, such as nylon 6 and nylon 6,6, are primarily made from petrochemical-based feedstocks. However, with growing concerns about sustainability and environmental impact, there is an increasing interest in developing bio-based alternatives.

Some common bio-based feedstocks used for polyamide production include:

- Plant-Based Feedstocks: Certain plants or plant-derived materials can serve as feedstocks for bio-based polyamide production. Examples include:

- Castor Oil: Castor oil, obtained from the castor bean plant (Ricinus communis), can be used as a precursor to produce bio-based polyamides like nylon 11.

- Vegetable Oils: Various vegetable oils, such as soybean oil, can be chemically modified to create polyamide precursors for bio-based nylon production. Bio-based polyamide – Plastics waste

- Biochemical Feedstocks: Certain bio-based chemicals can be synthesized from renewable resources and used as intermediates in the production of bio-based polyamides. These feedstocks may undergo further processing to yield the desired polyamide polymers. Examples include:

- Bio-Succinic Acid: Succinic acid, produced through fermentation of biomass feedstocks, can be used to synthesize bio-based polyamide precursors like polyamide 5,10. Gigafactory – eco-friendly packaging

- Bio-Adipic Acid: Adipic acid, an essential component in the production of nylon 6,6, can be derived from bio-based sources such as glucose or plant sugars.

- Animal-Based Feedstocks: Some bio-based polyamides can also be produced from animal-derived materials. One notable example is:

- Chitosan: Chitosan, derived from the shells of crustaceans like shrimp and crab, can be chemically modified to create bio-based polyamide materials. Bio-based polyamide – Plastics waste

It’s worth noting that the availability and commercial viability of bio-based polyamide feedstocks can vary depending on factors such as cost, scalability, and regional availability of the feedstock sources. Ongoing research and development efforts aim to expand the range of bio-based feedstocks and improve the overall sustainability of polyamide production. Gigafactory – eco-friendly packaging

Toray : From sugar to bio-based PA 66

-UN targets 80% reduction in plastics pollution

Ahead of the second round of global plastics treaty talks in Paris later this month, the United Nations Environment Programme on May 16 released a road map that said a well-crafted agreement could reduce plastics pollution by 80 percent by 2040.

UNEP, which is coordinating the treaty negotiations, called for first eliminating “problematic and unnecessary” plastics and then adopting policies like container deposits, producer responsibility and more reusable packaging, along with better recycling systems and “careful” replacement of items like plastic wrappers, sachets and takeaway items.

UNEP Executive Director Inger Andersen told an online news conference that the report finds that plastic pollution costs the world several hundred billion dollars a year, including from climate impacts of plastics manufacturing, air and water pollution and exposure to hazardous chemicals. Bio-based polyamide – Plastics waste

She said the report, “Turning Off the Tap,” also suggests steps to help make recycled materials more cost competitive compared with virgin plastics.

“As long as virgin plastic is cheaper than recycled, then that becomes an economic dimension that will make us, as a global society, lean back on virgin,” she said.

The report looks at levies on virgin materials, which Andersen admits might be a non-starter in some counties, as well as extended producer responsibility programs and container deposits. Gigafactory – eco-friendly packaging

The U.N. report found that the largest gains could be made toward the 80 percent reduction from policy options like reusables, EPR and bottle deposits. It estimated they could account for a 30 percent drop.

As well, it said building more profitable recycling systems, including removing subsidies for fossil fuels and enforcing design guidelines for recyclability, could account for another 20 percent drop. Bio-based polyamide – Plastics waste

It estimated those steps could boost the share of economically recyclable plastics from 21 percent to 50 percent.

As well, UNEP estimated that replacing products like plastic wrappers, sachets and takeaway items with alternatives, including paper and compostable packaging, could deliver an additional 17 percent reduction.

Andersen said countries will set their own policies but she hoped the UNEP report can help steer the treaty talks. The second of five negotiating rounds begins May 29 in Paris, with 2,500 diplomats and observers from 170 countries gathering for five days.

“Governments can deliver a strong deal to end plastic pollution,” she said. “Businesses [can] ensure innovation and commitment to move away from virgin plastics, starting immediately.

“International financial institutions and other large investors need to move significant investments towards solid waste management and collection systems,” Andersen said. “Creative chemical engineers must take a hard look at product design and weed out harmful chemicals and plastics.” Bio-based polyamide – Plastics waste

-62nd #Dornbirn-GFC 13 – 15 September 2023

Dornbirn, Austria

Tim Biemelt et al, Indorama Ventures/Trevira GmbH, Guben (GER)

Smart Textiles are on the rise. Annual growth rates of their market volumes amount up to 30%.

To access this market, new ways of linking electronics and textiles need to be found. Innovative, flexible textile-based conductors are consistently challenged to combine electrical conductivity, mechanical robustness, textile flexibility and the lowest possible cost.

dvanced additives can help to open previously unattainable features, while at the same time paving the way from laboratory scale to industry.

Graphene and its relatives (GRM) are considered to be novel wonder materials, whose excellent electronic, mechanical and thermal properties have the potential to replace commonly used materials in various fields. Bio-based polyamide – Plastics waste

In this context, there are also many examples in which GRMs have been investigated for their usage in conductive polymer compounds. Gigafactory – eco-friendly packaging

However, when these conductive compounds are spun into synthetic fibers, either the conductivity is lost or the resulting yarns lack tenacity.

Trevira GmbH has now developed a method of melt spinning conductive core-shell yarns that overcome just this obstacle and are both electrically conductive and have high tenacity.

Fabrics made from this material can be used in a wide variety of applications such as antistatic, sensory, heating, electromagnetic shielding or medical equipment.

Trevira GmbH is an innovative European manufacturer of polyethylene terephthalate granulates, fibers and filament yarns.

It is the only company in Europe that covers the entire value chain from monomers to finished yarn and ready-to-use fibers. Trevira is a subsidiary of Indorama and part of IVL Lifestyle Europe.

-Investment in eco-friendly packaging continues to surge

Aquapak study suggests PE utilization likely to decrease

A recent report, titled ‘Transforming Packaging for a Sustainable Future in Europe,’ unveiled yesterday at the Rethinking Materials Innovation and Investment Summit in London, reveals that the material choices made by the European packaging sector are undergoing rapid changes.

The study was commissioned by Aquapak, the company behind Hydropol, an environmentally friendly, water-soluble polymer derived from PVOH suitable for various packaging applications, including coated or laminated bags and pouches.

To dispose of these items, consumers can place them in their regular paper waste.

The Hydropol layer is designed to dissolve during the paper repulping process and subsequently biodegrades in the wastewater system or can be transformed into clean energy if the facility employs an AD system. Bio-based polyamide – Plastics waste

Based on a survey conducted by research firm Pure Profile in March 2023 among 150 sustainability and packaging experts from the UK, Italy, and Germany, the findings indicate that 62% anticipate their companies to increase investment in sustainable packaging materials over the next five years, with an additional 23% expecting a substantial increase in budgets. Gigafactory – eco-friendly packaging

Within the next five years, the adoption of composite solutions incorporating paper and plastic, innovative polymers, and paper is projected to rise, while the use of polyethylene is set to decline.

The majority of respondents (83%) expressed their intention to expand the utilization of composite solutions across their product portfolios, while 72% plan to utilize more paper in the next five years.

Additionally, 69% and 65% foresee an increased use of novel polymers, such as PVOH and bioplastics, respectively, in their packaging materials.

These trends remain consistent over a ten-year timeframe. However, sustainability must be accompanied by crucial attributes such as product protection.

The survey participants indicated that barrier properties, shelf-life extension, and user-friendly functionality outweighed the importance of recyclability.

According to Mark Lapping, the CEO of Aquapak, the report demonstrates that the European packaging industry is transitioning towards more sustainable materials as it focuses on the circular economy. Bio-based polyamide – Plastics waste

“Nevertheless, it is evident that packaging’s primary function remains paramount, with product protection and functionality taking precedence. Gigafactory – eco-friendly packaging

The encouraging news is that there are now advanced barrier film technologies available, offering both performance and environmental responsibility on a large scale,” he stated.

-Tesla expands Giga Shanghai (and will produce pouch cells)

The House moves to expand its largest production plant and install a small line dedicated to bag cells

The largest Tesla plant in the world gets even bigger… bigger! Let’s talk about Giga Shanghai, the flagship of Elon Musk and associates, which is preparing for a production expansion plan. In fact, for months there has been talk of enlarging the plant, but now the House is officially moving.

The proof is reported by Reuters and put in black and white in a request for authorization that the manufacturer has asked the local authorities. According to leaked information, the goal is to produce 1.75 million engines a year, up from 1.25 million today. But not only.

Space for pouch cells Gigafactory – eco-friendly packaging

Tesla would also have requested permission to install a small production line dedicated to pouch cells (also called “bag”), with a capacity of approximately 20,000 Ampere-hours (Ah) per year, equivalent to the power of a Model battery pack Y.

Production at Tesla Giga Shanghai

An absolute novelty for the manufacturer, who had never used this technology until now. The differences? In pouch cells, the battery components are contained in a flexible metal pouch, rather than a rigid cylinder.

Goal: 20 million Tesla

And, again, the House would be creating new facilities to recycle chemicals and treat wastewater from the Gigafactory. However, there are no official comments from the manufacturer.

In any case, it seems that Tesla is laying other foundations to reach the production targets: 2 million electric cars in 2023 and 20 million in 2030. The starting point is the 1.3 million deliveries in 2022, also the result of the 726,000 cars baked in Shanghai. But now he puts his foot on the accelerator.

-China will be present at the meeting alongside the republics of the “Stans,” but Russia will be absent for the first time in many years, signaling a shift in the regional power dynamics

Stefan Hedlund, an expert on Russia and professor at Uppsala University, emphasizes this significant development in the upcoming China-Central Asia summit scheduled for Thursday 18 and Friday 19 May.

While the leaders of the world’s seven largest industrialized economies convene in Hiroshima, the presidents of the five Central Asian republics (Kazakhstan, Kyrgyzstan, Tajikistan, Uzbekistan, and Turkmenistan) will gather in Xi’an, China.

Beijing views this event as a pivotal step towards forging a community with a shared destiny. Bio-based polyamide – Plastics waste

China’s primary investment undertaking now centers around the “middle ground” or the Trans-Caspian International Transport Route.

This initiative enables the transportation of goods without traversing Russian territory.

The “Northern Corridor” had long served as the preferred route for container shipping, but the imposition of Western sanctions on Russia has disrupted traffic along this pathway.

The Chinese Foreign Ministry spokesperson heralds this meeting as the dawn of a new era in collaboration between the two sides. The summit will culminate in the signing of an undisclosed “significant political document.” Gigafactory – eco-friendly packaging

What remains undeniable is Russia’s conspicuous absence, as China endeavors to assume the role of the region’s dominant power. In 2013, Chinese President Xi Jinping unveiled the new Silk Road in Astana, the capital of Kazakhstan, a comprehensive infrastructure investment plan encompassing the entire Eurasian continent.

The Ukrainian conflict and Russia’s waning international influence have amplified the opportunities that the region presents to China.

Hedlund sees this development as the demise of Russia’s position as the region’s linchpin, a vision Vladimir Putin espoused during the APEC meeting in Vladivostok in 2012.

At that time, Putin aimed to invigorate the Russian economy with Chinese investment. However, Hedlund now describes the Russian economy as a wreck adrift at sea, with China offering no assistance. Bio-based polyamide – Plastics waste

Russia’s role as the guarantor of security in Central Asia has been eroding, particularly since the onset of the Ukrainian war.

Yet, experts note that China is not yet prepared to assume this responsibility, as its primary focus lies in exploiting the region’s trade opportunities.

For the European Union, the area is of particular interest due to the efficacy of the imposed sanctions on Russia.

Traffic between Central Asia and Moscow has nearly doubled in 2022, leading the EU to suspect that the five republics are exporting European goods affected by the sanctions, thereby assisting the Kremlin in circumventing them.

Consequently, the EU includes these republics and China in its efforts to target companies that evade sanctions and denounce the Russian invasion. Bio-based polyamide – Plastics waste