Biodegradable-films – Polyamide 27-09-2022 - Arhive

Crude Oil Prices Trend

-First Chemical Recycling Program for Synthetic Turf Launched in US

Netherlands-based TenCate Grass partners with Cyclyx and ExxonMobil to chemically recycle artificial grass into feedstock for new plastic products

TenCate Grass, a manufacturer, distributor and installer of synthetic turf based in the Netherlands, will partner with Cyclyx International and ExxonMobil to establish what it says is the first program in the United States to chemically recycle artificial grass.

The goal is to help solve the long-time problem of how to efficiently and effectively recycle synthetic turf into feedstock that can be used to create new turf and other plastic products.

“This process of plastic recycling results in high-quality polyethylene pellets that will be used as feedstock for new products,” Joe Fields, President and CEO of TenCate Grass Americas, told PlasticsToday. “All prior turf recycling efforts have been downcycling turf, burning it to turn it into fuel or lower-grade recycled materials with limited uses.”

Known as TenCate Turf Recycling Solutions, the program will process 50 aged turf fields from high schools and college campuses and ship them to a Southern California facility where they will be shredded.

The shredded turf will be transported to Texas, where Cyclyx International will further pre-process the feedstock before sending it to ExxonMobil’s Baytown advanced chemical recycling facility. With ExxonMobil’s proprietary Exxtend technology, the turf will be broken down into raw materials that can be used to make new products that are similar in quality and performance to those made from virgin raw materials.

ExxonMobil’s advanced chemical recycling technology improves the circularity of plastics while delivering lower relative greenhouse-gas (GHG) emissions compared with processing the same amount of fossil-based feedstocks, the company said.

“Our current recycling partnership with ExxonMobil and Cyclyx is designed to handle fields made of primarily polyethythene,” Fields told PlasticsToday, “and well over 90% of all installed synthetic turf fields nationwide fall into that category.”

ExxonMobil’s advanced recycling facility in Baytown has processed more than 11 million pounds of plastic waste, as of June 2022, the company said. It is expanding to a large-scale advanced recycling facility at the site. At startup later this year, it will be among North America’s largest advanced plastics recycling facilities, with the capacity to recycle 66 million pounds of plastic waste per year. Beyond Baytown, the company said plans are underway for up to one billion pounds of advanced recycling capacity annually by the end of 2026 across multiple sites globally.

“Our advanced recycling technology has already processed millions of pounds of otherwise difficult-to-recycle plastics, like food packaging and artificial turf, that are generally not recycled today,” said Dave Andrew, Vice President of New Market Development at ExxonMobil. “With our scalable technology and collaborations like this one alongside TenCate Grass and Cyclyx, we are helping to meet the growing demand for circular products.”

The program with ExxonMobil and Cyclyx builds on TenCate’s efforts to recycle synthetic turf. In its home base of the Netherlands, TenCate recycles its end-of-life turf into Ecocept, an elastic layer for sports fields. Third parties also use the agglomerated material to manufacture new products.

“We are committed to leading the industry and moving sustainability forward in a meaningful way,” Fields said. “We understand the issue of end-of-life synthetic turf, and we have taken it upon ourselves to find a true solution for the entire industry. Our goal is to keep turf out of landfills and put back to use.”

After this initial phase is complete, TenCate said it plans to expand the initiative across the United States. In North America alone, the total value of installed synthetic turf systems is estimated at $2.7 billion in 2020, according to the Synthetic Turf Council. This translates into approximately 265 million square feet of installed turf.

-UBC researcher develops plastic alternative from forest waste

Dr. Feng Jiang breaks down wood fibres in a chemical solution to create a translucent, strong and water-resistant film.

UBC researcher Dr. Feng Jiang has spent years concerned about how plastic is contributing to the ecological crisis the world faces, and contemplating solutions.

Jiang, an assistant professor at UBC’s Faculty of Forestry and the Canada research chair in sustainable functional biomaterials, uses wood fibres collected from forest waste. He breaks down the wood fibres in a solution of cold sodium hydroxide, and from that he can make a product that is translucent, strong and water-resistant film.

The durable film can break down in the environment within three weeks, he said.

“After harvesting and after making wood products like lumber, there’s still a lot of residual waste,” he told Postmedia Friday.

“So we wanted to see how we can turn those residuals into something valuable, into something that can be more sustainable and biodegradable to replace the plastic.”

Other researchers have also developed biodegradable films to replace plastic but the UBC project — funded by the office of the chief forester at B.C.’s Ministry of Forests — is the first to use small amounts of energy and chemicals in the manufacture.

He said the film can be made into coffee or snack bags, or pouches for cereal or protective wrap such as envelopes.

“There are so many uses for this in the market and for commercial products,” he said. “Some plastics take up to a million years to decompose, but this can break down in the environment in a very short time.”

-Sudden decline in CPL spot before Risun starts up

fter the middle of September, that is, in the week starting Sep 19, CPL RMB spot price suddenly fell rapidly continuously from last 12,600-12,700yuan/mt last week to 12,000yuan/mt in just 3 working days. Such a rapid decline is out of the expectations of both upstream and downstream.

The core factor is still attributed to the commissioning plan of Risun’s phase II plant in Cangzhou, Hebei. The new CPL plant of Risun Hebei is designed with a single set of 300,000 tons capacity, and equipped with coal gasification, ammonia, hydrogen peroxide and production of other major raw and auxiliary materials, and its startup will strengthen the cost competitiveness of the original phase I in Cangzhou.

Added with 300kt/year capacity in Heze Shandong (Dongming Risun), Risun Group’s total CPL capacity is rising to 750kt/year, becoming the largest Chinese CPL producer. As its upstream cyclohexanone plant has been started up, the new CPL plant is expected to yield product this week. Out of concern about the impact of new capacity, the overall mood of CPL and nylon 6 market is pessimistic.

Another reason for this round of decline is intensive presales of CPL suppliers before the National Day holiday (Oct 1-7, 2022). In fact, for the time being, CPL suppliers’ inventory is relatively limited, and there is no similar burden like in June and July. But the general idea of the sellers is to take orders before the National Day holiday in order to avoid the accumulation of stocks after the holiday. But the combination of weak demand, new capacity starting up, and restart plans of other producers including Juhua and Eversun, has made the sellers’ behavior very consistent, to sell stocks in advances. This urgent selling behavior causes a rapid decline in CPL prices.

In fact, pre-holiday stocking is also a necessary choice for downstream polymer plants. A part of the downstream buyers have expected the price to fall somewhat and then replenish moderately from the lower rates. But since CPL spot has been staying relatively firm in the week of (Sep 12-16) when buyers bargained evidently, while it suddenly fell by 600yuan/mt in 3 trading days, buyers are also too puzzled to purchase. Buyers who originally prepare to restock have retreated to sidelines instead.

Given the actual supply and demand pattern of CPL, it is still recommended for polymer plants to restock appropriately at low levels, and there is no need to be overly pessimistic.

-Toray : Price hike for polyamide yarn, airbag fabrics

Toray Industries, Inc., announced today that it intends to lift the prices of nylon 66 yarn and fabric for automotive airbags by up to 35% for shipments from October 1 this year.

This move is because prices have remained high for nylon 66 polymer, a principal material in automotive airbag yarns and fabrics. This is amid rising demand from a global economic recovery and surging crude oil prices stemming from supply concerns as a result of the Russian invasion of Ukraine. Another factor is that the company expects the cost of producing yarn and fabrics to keep climbing owing to further price hikes that started last year for such inputs as secondary materials, fuel, and transportation.

The U.S. dollar’s sharp appreciation since April this year has driven procurement costs higher for Toray’s airbag business, with the impacts of exchange rate fluctuations from the yen’s depreciation exacerbating the situation by affecting export prices to Japanese market.

It was against this backdrop that Toray is undertaking a project under Project AP-G 2022, its medium-term management program, to bolster its total cost competitiveness by slashing expenses and streamlining fixed and variable spending.

The company has nonetheless found its savings initiatives unable to offset higher current cost increases. It accordingly has to raise prices to maintain consistent quality and develop and commercialize products that deliver even higher value.

-Kazakh government supports construction of gas processing plant at Kashagan

Kazakh Prime Minister Alikhan Smailov met with, Eni’s Natural Resources Chief Operating Officer Guido Brusco and Director Upstream Luca Vignati, Kazinform cites primeminister.kz.

During the meeting, Smailov noted that the Kazakh government commends the company’s contribution to the development of oil and gas sector of Kazakhstan and is committed to the further strengthening of long-term cooperation.

He added that the government supports the Consortium’s plans to build a gas processing plant at Kashagan with a capacity of 1bn cubic meters with QazaqGaz.

In his turn, Guido Brusco confirmed the company’s long-term work plan in the country.

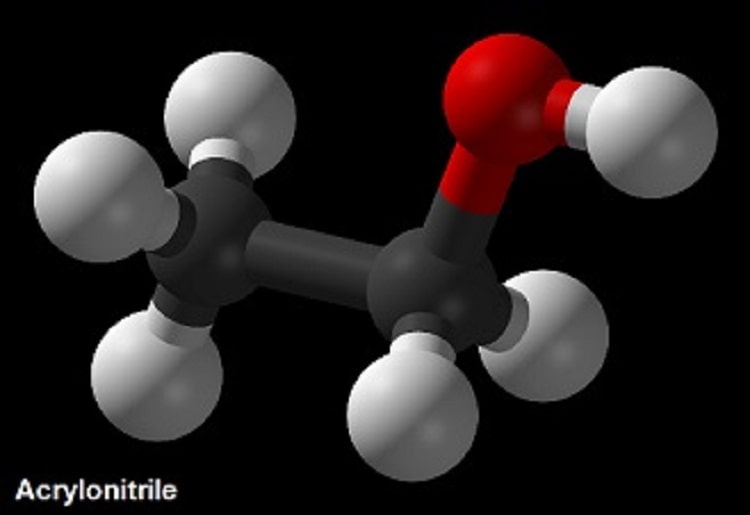

In September, ACN market prices finally embraced an upward trend, up from 9,100yuan/mt in the early of the month to 9,800yuan/mt on Sep 23. Such an increase, which may seem tiny in previous years, had become hard-to-find these days when the ACN is over supplied. However, after the gentle price rise last week, the top range of the traded price tended to be clear. According to traders, offers higher than 10,000yuan/mt are hard to be accepted, and there’s few room for further price rises despite the unsmooth delivery of good.

View from the ACN plants, the price rise in Sep was largely owing to the production cut and shutdown for maintenance of various ACN units, such as the alternative operation of PetroChina Jilin’s ACN unit, the production cut of Shanghai Secco and Jiangsu Sierbang, and the delayed restart of Tianchen Qixiang and Shandong Koruhr. As a result, the operating rate was at around 70%. By now, the average annual operating rate was only 80% compared to the 88% last year. Per unit profit and the operating rate of ACN plants were negatively correlated so far.

As for the costs, propylene prices also saw rebounded signs in September. This, coupled with increased liquid ammonia costs due to agricultural demand rise, had caused amounted cost pressure for ACN. Take the current propylene offers of 7,400yuan/mt in Shandong as an example, then the theoretical cost of ACN is around 9,700yuan/mt. As such, the current ACN market prices which prevail at 9,700-9,900yuan/mt offer little profit room for plants, thus the prices are less likely to drop in short term.

The emergency ofplastic pollution it represents a growing problem that needs to be addressed as soon as possible. A study published in the journal takes an important step to counter the need for plastics Science of the Total Environment, led by scientists from the University of California San Diego and the Scripps Institution of Oceanography. The team, led by Stephen Mayfield, Michael Burkart and Robert Pomeroy, came up with the biodegradable materials that could replace the conventional use of plastics and fight pollution.

Plastic is now ubiquitous on the planet and reaches marine depths, food supplies and living organisms. In marine ecosystems, plastic residues can migrate to central areas and form swirls of waste, which compromise the well-being of the ocean environment and increase pollution levels. One example is the Big Pacific Garbage Patch, which covers an area of over 1.6 million square kilometers. According to current estimates, in just one year or so eight billion kilograms of plastic reach the ocean and in 2025 these values are expected to increase considerably. The US research team has devised a plastic-like substance that biodegrades in the ocean in less than a month. The team worked with polyurethane foams capable of degrade in compost. The location of the pier allowed scientists to perform tests and experiments in the natural ecosystem near the coastwhere the accumulation of pollutants is more likely.

Scholars have identified a mix of fungi and bacteria which colonizes the foam and the breaks down in the starting chemicals, which can be consumed by the microorganisms themselves. These forms of marine life, the scientists point out, occur naturally in the marine ecosystem. “We have demonstrated the possibility of making plastic products capable of dissolve into the ocean in just four weeks, ”says Stephen Mayfield, one of the scientists leading the team. “When organisms settle on the foams we see the formation of a kind of microbial coral reef. It was really interesting. Environmental problems must be addressed and it will be necessary to design eco-sustainable and effective strategies to combat pollution. We hope our work can offer one viable solution to reduce the need for plastic and polluting products “.

-Live Demos at K 2022 Highlight Recyclate, Processing Equipment, and Additives

Collaboration will demonstrate elements of HDPE and PP recycling.

At the upcoming K 2022, HDPE and PP from PreZero will be recycled in a live demonstration using additives from Baerlocher and Milliken and equipment by Erema.

Regranulation will be completed using an Erema Intarema TVEplus extrusion system. HDPE regrind will be upgraded with Baerlocher’s Baeropol T-blend to improve mechanical properties and processing performance. PP regrind will be upgraded with Hyperform HPN from Milliken, which improves processing stability fo the material while reducing cycle time.

PreZero is a recycling and recovery company owned by the Shwarz retail group. The company and its partners will aim to demonstrate that high product quality is possible starting with recycled materials.

The HDPE process demonstration will take place on October 19 and 23, at 10 AM. The PP demonstration will take place on October 21 at 3:30 PM.