Biodegradable plastics – New Public-Private Partnerships Look to AI and Enzymes to Break Down Plastic and Textile Waste 12-10-2023

Biodegradable plastics

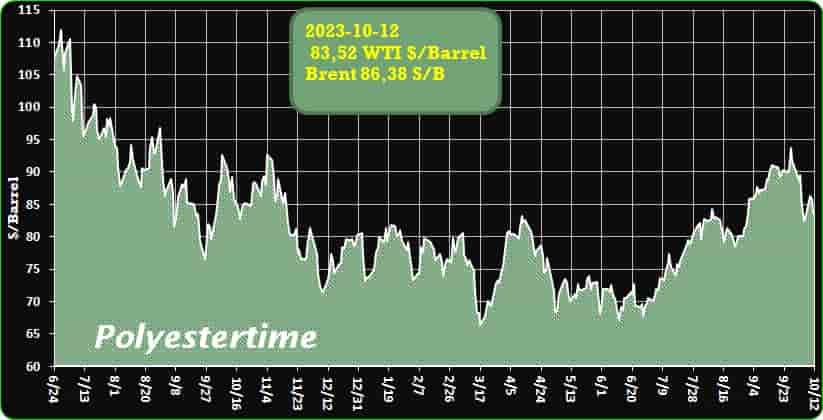

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

France becomes first country to implement Digimarc’s plastics recycling platform

France, selected by the HolyGrail initiative leadership team, will become the first country-wide implementation of Digimarc Recycle. Digimarc Recycle allows brand owners to digitize products and packaging, enabling a direct communication channel with consumers. When the digitized item is scanned with a Smartphone, consumers can see recycling instructions and sustainability content of the item.

Digimarc says that this marks a milestone in combatting plastic pollution and that the implementation of Digimarc Recycle is a testament to the hard work and collaboration of stakeholders who want to unlock the circular economy for plastics, address fast-approaching legislation, and create a more sustainable world. Biodegradable plastics

By linking covert digital watermarks (used to identify plastic packaging to any desired level of granularity deterministically) with an extensible cloud-based repository of product attributes (such as brand, SKU, product variant, packaging composition, food/non-food/cosmetics use, etc.), Digimarc Recycle helps drive a step change in the quality and quantity of recyclate. This improvement also unlocks new end markets for post-consumer recyclate that do not exist today. Moreover, the information used to drive this sortation in facilities provides product-specific and location-based disposal instructions via a brand-owned direct-to-consumer digital communication channel accessed via on-pack watermarks or QR codes. Biodegradable plastics

“Digimarc applauds the vision and action of the France team and its pioneering member organizations, including P&G, L’Oreal, Henkel, Veolia, CITEO, and Pellenc ST,” said Riley McCormack, Digimarc president and CEO. “Moreover, we are committed to working alongside this group to expand the rollout to other facility operators, brands, and retailers in France, because when the only thing that stands in the way of progress is inertia, true leadership is defined by those who take action.”

In addition to providing the information necessary to power advanced sortation at recycling facilities, Digimarc Recycle captures and provides a view of the post-purchase product journey benefiting stakeholders across the value chain. Biodegradable plastics

Among these benefits, governments can gain insights into the size, scope, and content of their waste stream; producer responsibility organizations (PROs) can design and implement more meaningful and more accurate extended producer responsibility (EPR) schemes; facility operators can unlock operational efficiencies and insights; and brand owners and retailers can access data to power design-for-recyclability improvements, packaging-usage reductions, consumer behaviour insights, and overall functional gains.

Study stirs controversy over the benefits of biodegradable plastics

Research that suggests the breakdown products of compostable plastic bags could be toxic has been criticised by the bioplastics industry

Controversy has been sparked by a study that appears to show that when they break down, compostable plastic bags release more toxins into the environment than conventional plastic bags do. Biodegradable plastics

European Bioplastics, which represents companies that produce various types of biodegradable plastics, has branded the research “scientifically questionable” and suggested that it does not replicate how plastics degrade in the real world.

The dispute highlights concerns over biodegradable plastics. To some, they are the answer to the world’s acute problem of plastic waste, but to others these materials are a distraction from what they see as the true answer – simply using less plastic.

What did the study find?

Carried out by scientists in Spain and released in the Journal of Hazardous Materials, the study involved testing the breakdown products of various types of plastic bag on zebrafish cells grown in the laboratory. Biodegradable plastics

The researchers looked at compostable bags, which are a type of biodegradable plastic bag designed to break down under specific conditions, and compared them to conventional plastic bags.

It found that extracts of compostable bags decreased the viability of the cells, an effect that was made stronger if the bag had been exposed to ultraviolet light or had been composted.

However, similar remains from conventional plastic bags did not have the same toxic effect on the cells.

“These findings highlight the importance of investigating the effects of degradation mechanisms such as sunlight and composting on the toxicity of bioplastics,” the researchers wrote in the Journal of Hazardous Materials. Biodegradable plastics

“It is also crucial to investigate the composition of newly developed formulations for bioplastics, as they may be more harmful than conventional ones.”

What criticism has been levelled at the study?

To extract chemicals from the plastics before they were tested on the zebrafish cells, the scientists used methanol, a type of alcohol.

In a statement issued this week, European Bioplastics said that there was no evidence in the study that the methanol did not change the chemical structure of the samples. As a result, the study, they suggested, may not reflect how these plastics behave in the real world. Biodegradable plastics

Claims made by the Institute of Environmental Assessment and Water Research, one of the organisations behind the study, “are not supported by the scientific evidence”, according to European Bioplastics.

Lummus’ Green Circle Announces Agreement for Advanced Plastic Recycling Technology with Dongyang Environment Group

plastics circularity

Lummus Technology, a global provider of process technologies and value-driven energy solutions, has announced an agreement with Dongyang Environment Group to deploy Lummus’ advanced plastics recycling technology in South Korea. The plant will be located in Seosan, Chungcheongnam-do, Korea, and will be operated by Dongyang Environment’s subsidiary, Seohae Green Chemical. Biodegradable plastics

“We are pleased to announce this agreement with Dongyang Environment, one of South Korea’s leading providers of energy and environmental services,” said Greg Shumake, Vice President and Managing Director of Green Circle. “This is a significant step forward in our commitment to the circular economy and to deploying advanced plastics recycling technology in South Korea and other key markets around the world.”

Lummus’ Green Circle business unit will provide to Dongyang Environment its advanced plastic recycling technology, which effectively converts plastic waste into high-value chemicals and feedstocks, creating circularity. This technology is a proven, reliable and economic solution to address the global plastic waste problem, offering additional environmental benefits such as a lower carbon footprint and the elimination of char production. Biodegradable plastics

“Dongyang’s resource recycling and energy conversion expertise and Lummus’ world-class technology will create strong synergies,” said Byung Jin Song, the head of Dongyang Environment R&D center. “Additionally, Dongyang will strengthen its position in the chemical recycling industry, offering more sustainable products and increased value to our customers.”

Green Circle concentrates and expands Lummus Technology’s capabilities to capture new opportunities in the energy transition and circular economy.

Green Circle is a leader in providing economically and technically sound solutions to process solid wastes containing plastics; process various renewable bio-based feedstocks to value-added chemicals, polymers and fuels; decarbonize refinery and petrochemicals assets; expand production of blue hydrogen and biofuels; and treat industrial wastewater.

New Public-Private Partnerships Look to AI and Enzymes to Break Down Plastic and Textile Waste

Protein Evolution, Inc. Partners with U.S. Department of Energy’s Agile BioFoundry, Advanced Biofuels and Bioproducts Process Development Unit, and the Joint BioEnergy Institute to Decarbonize the Chemicals Industry Biodegradable plastics

Protein Evolution, Inc., a biological recycling company focused on decarbonizing plastic production, announced today that it is partnering with the U.S. Department of Energy’s (DOE’s) Agile BioFoundry (ABF), Advanced Biofuels and Bioproducts Process Development Unit (ABPDU), and the Joint BioEnergy Institute (JBEI), a DOE Bioenergy Research Center, both led by Lawrence Berkeley National Laboratory, on two separate projects.

The first project will leverage the team’s collective advancements in artificial intelligence to create enzymes that break down plastic and textile waste, and the second will streamline the methods for manufacturing these enzymes at scale. JBEI, ABF and ABPDU are part of Berkeley Lab’s BioManufactory – a collaborative group of programs that partner with industry to provide expertise and support as companies develop, optimize, and scale-up their bio-based projects. Biodegradable plastics

“Our innovative process uses AI to design novel enzymes to transform various types of polyester waste back into the building blocks of new polyester,” said Maren Wehrs, Director of Bioprocess Development of Protein Evolution. “These partnerships provide access to cutting-edge research, infrastructure, and a wealth of domain expertise that will help us accelerate sustainable waste management and the global transition to a lower-carbon, circular economy.”

Protein Evolution’s innovative technology is the first in the U.S. to use enzymes as a catalyst to successfully produce new polyethylene terephthalate (PET) from polyester textile waste. The PET resulting from Protein Evolution’s process is indistinguishable from the petroleum-derived virgin alternative, but with a far lower carbon footprint, and it is suitable for both textile and packaging grade applications.

The company is actively scaling its commercial capacity to take in greater quantities and more diverse types of plastic waste as feedstock to facilitate the production of low-carbon polyester. Biodegradable plastics

Partnering to Decarbonize the Chemicals Industry

Protein Evolution’s partnerships with JBEI, ABF and ABPDU share the overarching goal to reduce emissions from petroleum-based plastic production and the landfilling and incineration of plastic waste.

“Identifying and cost-effectively producing highly catalytic enzymes to transform waste into new products has the potential to significantly reduce industry’s reliance on petroleum,” said Jay Konieczka, Chief Technology Officer at Protein Evolution. “At scale, our technology will divert millions of waste products from landfills and the environment, helping to reduce pollution, conserve natural resources, and contribute to a more sustainable and cleaner future.” Biodegradable plastics

Breakthrough study in post-consumer polypropylene packaging – Characterising contamination levels

Having just read UNEP’s recent Global Plastics Treaty draft policy, it is interesting to note their suggested approaches per country to the areas NextLoopp and Nextek have been focusing on. Reviewing and upgrading how we manage and maximise recycled plastic contents, through to reviewing product design for sustainability and enhancing waste management is our mission.

As such closing the loop on post-consumer food-grade polypropylene (PP) packaging is very much in-step with our commitment to save CO2e by extending the lifecycle of plastic. The reason for this is that, from a climate change perspective, 1.6 tonne/1.8 ton of CO2e could be saved if we were to use food-grade recycled PP versus using virgin PP resin.

Polypropylene accounts for more than 20 percent of global plastics production with food packaging being this prolific polymer’s primary product. In fact, some 55 percent of PP rigid packaging (1 Mt) is food-contact, equivalent to around 10 percent of total PP demand. Biodegradable plastics

According to Plastics Recyclers’ latest report the net demand for PP in Europe is 10.5 Mt., yet PP recyclate from post-consumer rigid product applications only meets 3 percent of this demand.

This is the driving force behind NextLoopp’s continued science-based exploration to close the loop on post-consumer food-grade PP

Achieving this has required addressing each and every roadblock along the way and deep-diving into the specific sorting and decontamination requirements for the recycling processes for PP. This has led to our most recent investigations to determine the residual contamination levels of post-consumer PP packaging, which up until now, have not been characterised. Biodegradable plastics

The lack of data showing the misuse rate within PP feedstocks has meant there was no reliable way of defining the residual levels that could potentially migrate into food as well as understanding which molecules to target via decontamination processes.

Nextek’s study aimed to identify substances that might cause samples to be outliers from the expected input stream which could represent challenges to the final safety of the recycled plastics. Key was to check whether the substances observed could potentially be genotoxic. This is a critical criterion for EFSA safety evaluations given that the substance could be derived from the mis-selection of an item of non-food PP packaging, which is not necessarily a case of misuse. Biodegradable plastics

Although, being olefinic, PP has very similar properties to HDPE, the packaging format of PP reduces the chances of it being in a consumer-misuse scenario. A large proportion of PET packaging is relatively durable, with a tight closure, making it a container of choice when used for the storage of hazardous materials.

Likewise, HDPE packaging is also in bottle form with a closure, meaning it, too, may be used in such a scenario.

PP food containers, on the other hand, are less likely to come in bottle form and much more likely to be pots, tubs, or trays with limited closure capability.

OMV Europe PE margin down year on year

OMV’s polyethylene (PE) indicator margin for Europe stood at €308/tonne in Q3 2023 versus €312/tonne in Q3 2022 and €320/tonne in Q2 2023, said the Austrian oil, gas and petrochemical group. Biodegradable plastics

For the polypropylene (PP) indicator margin for Europe, the figures were €330/tonne, €357/tonne and €372/tonne, respectively.

For the propylene indicator margin for Europe, the figures were €330/tonne, €574/tonne and €459/tonne, respectively.

For the ethylene indicator margin for Europe, the figures were €455/tonne, €614/tonne and €567/tonne, respectively.

Also in the trading statement, the company put its European refining margin indicator (based on Brent crude) for the third quarter at $14.05/bbl compared with $14.38/bbl in the third quarter a year ago and $7.59 cents/barrel in the second quarter of this year.

Three new partners targeting recycled plastic packaging join the Canada Plastics Pact

Most recently, the CPP released its five-year roadmap (2023 to 2027) for advancing flexible plastic packaging in Canada. Biodegradable plastics

The Canada Plastics Pact (CPP) has welcomed Omnia Packaging Inc., BASF Canada, and NSF to its expanding network of more than 95 partners in the third quarter of 2023.

Omnia Packaging Inc. joins as a signatory partner

Omnia Packaging Inc., a Canadian subsidiary of Sunino Group, is a food packager specializing in injection plastic production producing exclusively recyclable polypropylene (PP) plastic packaging. They are committed to collaborating with other PP producers in Canada to increase recycling efforts.

NSF joins as an implementation partner

NSF is a public health and safety organization that helps companies responsibly manage their corporate, facility, product, and supply chain materials with customized solutions. They are committed to assisting CPP partners to operate more responsibly through better materials management. Biodegradable plastics

BASF Canada joins as a knowledge partner

BASF is focused on advancing sustainability and driving a circular economy by taking actions like designing materials for circularity, developing solutions that improve or enable recycling, and establishing product-specific recycling loops. They are committed to sharing professional, technical, and commercial systems knowledge to support CPP’s advancement on its roadmap and collaborate on programming, standards, policies, and solutions to further plastics circularity.

“We are excited to welcome these new stakeholders to the pact, each contributing unique perspectives to the plastics value chain,” said Cher Mereweather, managing director at the CPP. “Our collective commitment to advancing solutions to achieving a circular economy for plastics is strengthened by their involvement.” Biodegradable plastics

Since the CPP launched in January 2021, various initiatives have been underway to address the opportunities and challenges to enacting systems change, such as forming nine working groups that bring together the key stakeholders to tackle the pressing issues around plastic waste and pollution.

The CPP’s guidance documents, driven by the collective expertise of its working groups, are a tool for supporting stakeholders to implement circular economy principles in their operations, by sharing knowledge and solutions. Most recently, the CPP released its five-year roadmap (2023 to 2027) for advancing flexible plastic packaging in Canada. It’s designed for stakeholders across Canada, including manufacturers, producers and brand owners, retailers, stewardship agencies, recyclers, and governments, to work together on clear and practical objectives. Biodegradable plastics

Biodegradable plastics