Bionylon66 -Chroma adds compostability to improve recycling of complex parts 14-05-2024

Bionylon66

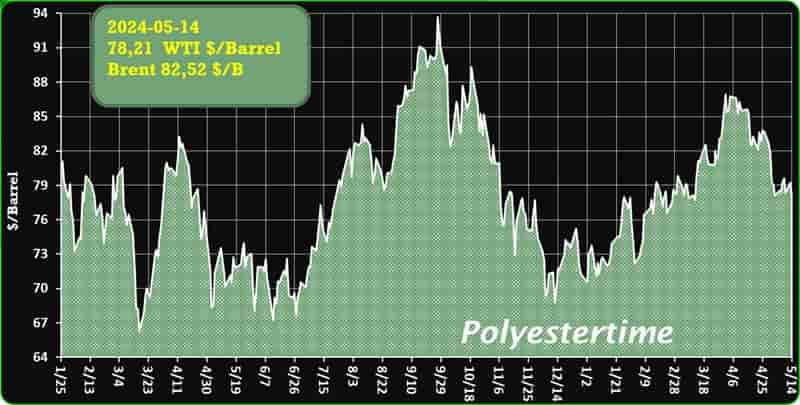

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Bionylon6.6

Fulgar, an Italian company specializing in synthetic fibers, has obtained the Recycled Claim Standard (RCS) certification from Textile Exchange for its Q-Cycle yarn

This certification, endorsed by a significant non-profit organization focused on sustainable practices in the textile industry, emphasizes recycling’s role in sustainable production and consumption. It aims to reduce the use of virgin raw materials, water, and energy.

Q-Cycle is crafted from polyamide 6.6, utilizing pyrolysis oil derived from end-of-life tires, aligning with mass balance principles. Despite being a recycled product, this yarn retains the desirable properties of virgin polyamide 6.6, such as lightness, strength, and durability. It is versatile across various textile applications, easily integrates with other yarns, and is sustainable. Bionylon66

Additionally, Q-Cycle has secured the ISCC PLUS certification, ensuring global sustainability, traceability, and mass balance across its production. It also adheres to the Oeko-Tex STD Class I STD 100 Appendix 6 standards and features an LCA (Life Cycle Assessment) that evaluates its environmental impact within the supply chain.

The RCS certification includes a third-party verified environmental declaration that confirms the use of recycled materials and the traceability of these materials throughout the production process, from manufacturing to final product labeling. This standard corresponds to the ISO 14021, defining recycled content criteria. Bionylon66

A recent study, “100 Years Lifetime of Plastic Pipes,” suggests that plastic pipes could last over a century

The research, led by Austria’s Polymer Competence Center and backed by the European Plastic Pipes and Fittings Association (TEPPFA), reviewed existing studies to estimate these materials’ durability. TEPPFA’s Ludo Debever highlights that following EN and ISO standards in design, production, and installation is key to longevity. This finding offers assurance to those investing in plastic pipe systems for utilities, suggesting a lifespan of at least 100 years. Bionylon66

The study examined polyethylene, polypropylene, and unplasticized polyvinyl chloride pipes, commonly used for water, gas, and waste systems, considering both smooth and structured types. It accounted for typical operational conditions, such as temperatures below 20°C and adherence to current EN, ISO, and ASTM standards, while excluding pipes used for industrial, underfloor heating, or made from recycled materials.

Results, derived from pipe examinations up to 50 years old and scientific literature, showed few failures, mainly due to non-compliant manufacturing or installation. TEPPFA’s report underscores the pipes’ dependability, projecting a service life well beyond 100 years under normal conditions. Bionylon66

The full report is accessible via TEPPFA’s website.

Nextchem has partnered with Johnson Matthey (JM) for the global marketing of their Circular Methanol technology package, a sustainable technology initiative, as announced on May 13 in Rome by Maire Tecnimont’s subsidiary, Nextchem

Operating under its MyRechemical division, which specializes in waste-to-chemical technologies, Nextchem utilizes its unique waste-to-syngas technology to support this collaboration.

The partnership, built on a July 2021 cooperation agreement, integrates MyRechemical’s waste conversion technology with JM’s syngas-methanol production capabilities. This integration facilitates the joint marketing of the technology alongside the Circular Methanol brand owned by MyRechemical. Bionylon66

This new agreement grants JM the right to use the Circular Methanol brand, enhancing the market presence of this combined technological offering. Both companies aim to lead in the sustainable technology sector, leveraging their respective expertise in chemical processing and environmental sustainability to commercialize this innovative technology globally.

Dairen joins The LYCRA Company & Qore to develop renewable LYCRA fibre

- The LYCRA Company partners with Dairen Chemical Corporation to produce low-impact bio-PTMEG from QIRA, enabling the creation of renewable LYCRA fiber.

- DCC’s innovative process reduces carbon footprint, earning them The LYCRA Company’s Green Partner Award.

- This collaboration signifies a shift towards sustainable production in the apparel industry.

The LYCRA Company, a global leader in developing innovative, sustainable solutions for the apparel and personal care industries, has announced that it has signed a letter of intent with Dairen Chemical Corporation (DCC) to convert QIRA—a brand of BDO (1,4-butanediol)—into low-impact PTMEG, the main ingredient in patented bio-derived LYCRA fiber. Dairen will be the first company in the world to mass produce this low-impact bio-PTMEG at scale. Bionylon66

In September 2022, The LYCRA Company and Qore announced they were joining forces to enable the production of bio-derived LYCRA fiber made with QIRA. Now, DCC joins this distinctive collaboration, converting QIRA into bio-PTMEG. This unique PTMEG will make up the renewable portion of LYCRA fiber, accounting for 70% of the fiber’s content. It is being made exclusively for The LYCRA Company to its stringent specifications. With its low-impact allyl alcohol process, DCC has pioneered a technology that creates the lowest-impact PTMEG available, which is cleaner and has a lower carbon footprint than product produced with natural gas or coal. Bionylon66

Honeywell has introduced a new naphtha to ethane and propane (NEP) technology, which promises to revolutionize the production of light olefins like ethylene and propylene by enhancing energy efficiency and reducing carbon emissions

This innovative process allows for the conversion of naphtha and/or LPG into ethane and propane, which are subsequently utilized as feedstocks in ethylene and propylene production. These chemicals are vital in the manufacture of various products including plastics, chemicals, and fibers.

The NEP technology not only supports the transition to cleaner energy but also aligns with Honeywell’s strategic focus on addressing global megatrends. Bionylon66

By optimizing the production process, the technology facilitates a significant reduction in the production of lower-value byproducts, traditionally associated with mixed-feed steam cracking units. This optimized method enables a net cash margin improvement ranging from 15% to 50%. Bionylon66

Moreover, adopting NEP technology in olefin production complexes can reduce CO2 intensity by 5% to 50% per metric ton of product, compared to traditional methods. This enhancement is part of Honeywell’s broader initiative within its Integrated Olefin Suite technology portfolio, marking a pioneering advancement in the industry.

Matt Spalding, vice president and general manager at Honeywell Energy and Sustainability Solutions in MENA, emphasized that this technology not only meets the high demand for ethylene and propylene but also helps in reducing carbon emissions, addressing both competitive pressures and raw material acquisition challenges in the global petrochemical industry.Bionylon66

Is Recycling Plastic Even Worth It?

As a country, we’re decent about some of our recycling. We successfully process about two-thirds of our aluminum and paper and about one-third of our glass back into new products.

But when it comes to the more than 200 pounds of plastic waste each of us generates per year, we only put about 15 percent of it into recycle bins. And only about five percent actually gets recycled. Bionylon66

“Recycling of paper, cardboard, metal and glass is definitely worth it,” says Judith Enck, president of Beyond Plastics and a former regional administrator for the Environmental Protection Agency (EPA). “But the plastics waste stream is very complex and is not easy to recycle.”

So when presented with packaging choices, it’s best to veer away from plastic. (Spoiler alert: Aluminum is the best.) But ditching plastic altogether isn’t practical. So here’s how to make better choices with the plastic we do use to help get more of it recycled.

Chroma adds compostability to improve recycling of complex parts

“Most consumers are not going to take the time to rip apart the paper and the plastic component,” James Walsh, vice president of technology at Chroma Color, told Plastics News at NPE2024.

PHAs are a group of bio-based and biodegradable polyesters made by bacterial fermentation.

Bionylon66