Bioplastics Hydrogen Enzyme 03-10-2022 - Arhive

-PET-bottle-chips – Petrochemicals

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

Sinopec to delist from London on November 1, citing low ADS trading volume and administrative burden

Chinese video-sharing services provider Bilibili’s primary listing status on Hong Kong stock exchange is effective from Monday

China Petroleum & Chemical Corp (Sinopec) said on Monday that it plans to delist from London Stock Exchange, with market observers saying that other mainland Chinese companies could exit overseas markets amid rising political and economic risks.

The move comes just a month after Sinopec filed an application to delist from the New York Stock Exchange.

The world’s largest oil refiner said in an exchange filing that the delisting of its American depositary shares (ADS) will take effect on November 1. The company said the decision to delist was based on several comprehensive considerations and that the board had approved the plan.

Separately, Chinese video-sharing services provider Bilibili said that its primary listing status on the Hong Kong stock exchange’s main board from a secondary listing was effective from Monday. That makes the Shanghai-headquartered firm a dual-primary listed company on both the Hong Kong stock exchange and Nasdaq.

Sinopec said that it took the decision to delist because of the small volume of the underlying H shares relative to its outstanding ADSs, minimal trading volume of its ADSs on the LSE in contrast to its global total, and the administrative burden of maintaining the listing.

The move came as the UK economy is facing headwinds from a slumping British pound, which hit a record low last week.

“The company noticed that the London market is not big, trading volume is small, there are also various foreign regulations that could cause uncertainties, as well as political risks no matter in the US or UK, ” said Alvin Cheung, associate director at Prudential Brokerage in Hong Kong. “So staying overseas no longer offers it any benefits [that it wanted originally].”

More Chinese companies, especially the large-caps with a greater presence in domestic markets, are likely to re-examine their options to dodge offshore risks, Cheung added.

A team of Texas A&M AgriLife Research scientists has developed a system that uses carbon dioxide, CO2, to produce biodegradable plastics, or bioplastics, that could replace the nondegradable plastics used today. The research addresses two challenges: the accumulation of nondegradable plastics and the remediation of greenhouse gas emissions.

Published Sept. 28 in Chem, the research was a collaboration of Susie Dai, Ph.D., associate professor in the Texas A&M Department of Plant Pathology and Microbiology, and Joshua Yuan, Ph.D., formerly with the Texas A&M Department of Plant Pathology and Microbiology as chair for synthetic biology and renewable products and now Lopata professor and chair in the Washington University in St. Louis Department of Energy, Environmental and Chemical Engineering.

The research was made possible by the John ’90 and Sally ’92 Hood Fund for Sustainability and Renewable Products, Texas A&M AgriLife and Texas A&M University.

Creating bioplastics

Dai said today’s petroleum-based plastics do not degrade easily and create a massive issue in the ecosystems and, ultimately,

To address these issues, the Texas A&M College of Agriculture and Life Sciences researchers and their teams worked for almost two years to develop an integrated system that uses CO2 as a feedstock for bacteria to grow in a nutrient solution and produce bioplastics. Peng Zhang, Ph.D., postdoctoral research associate, and Kainan Chen, doctoral student, both in the Texas A&M Department of Plant Pathology and Microbiology, contributed to the work. The Texas A&M University System has filed a patent application for the integrated system.

“Carbon dioxide has been used in concert with bacteria to produce many chemicals, including bioplastics, but this design produces a highly efficient, smooth flow through our carbon dioxide-to-bioplastics pipeline,” Dai said.

∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼

-Germany’s GDP estimate revised to –0.4% in 2023: Report

Projection for Germany’s gross domestic product (GDP) has been lowered from 3.1 per cent to –0.4 per cent, according to a recent report. For the current year, the spring forecast is almost halved. The revision mainly reflects the extent of the energy crisis. For example, the combined economic output in 2022 and 2023 should be €160 billion lower than it had been expected in the spring.

The gas markets crisis has severely impacted the German economy, according to the Joint Economic Forecast 2/2022. Soaring gas prices are drastically increasing energy costs, leading to a massive reduction of the purchasing power.

Despite a decline in the second half of the year, gross domestic product is expected to expand by 1.4 per cent in 2022. For the coming year, the institutes expect a contraction by 0.4 per cent, followed by an increase of 1.9 per cent in 2024.

The main reason for the deterioration in the economic outlook is the reduced gas export from Russia, which has eliminated a significant part of the gas supply and increased the risk that the remaining supply and storage volumes will not be sufficient to meet the demand during the coming winter, adds the report.

Against this background gas prices have skyrocketed in the summer. Businesses have already started to cut back their gas consumption noticeably. Even though the institutes do not expect any gas shortages under normal weather conditions over the winter, the supply situation remains extremely tight. Although the situation is expected to ease somewhat over the medium term, gas prices are likely to remain well above pre-crisis levels. This will mean a permanent loss of prosperity for Germany.

“The Russian attack on Ukraine and the resulting crisis on the energy markets are leading to a noticeable slump in the German economy,” said Torsten Schmidt, head of economic research at RWI – Leibniz Institute for Economic Research and spokesman for the Joint Economic Forecast Project Group. “The high energy and food prices, which are likely to rise further in the coming year, are causing significant losses in purchasing power. Both low-income households and businesses are therefore dependent on further support from policymakers. In the case of businesses, however, care must be taken to avoid permanent subsidies. At least the labour market is showing signs of stability; due to the shortage of personnel in many sectors, no increase in unemployment is expected despite the economic crisis.”

∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼

The LYCRA Company, a global leader in developing innovative fiber and technology solutions for the textile and apparel industry, today announced it has entered into an agreement with Qore® to enable the world’s first large-scale commercial production of bio-derived spandex using QIRA®, the next generation 1,4-butanediol (BDO), as one of its main ingredients. This will result in 70% of the LYCRA® fiber content being derived from annually renewable feedstock.

This change could potentially reduce the carbon footprint of LYCRA® fiber by up to 44%* versus equivalent product made from fossil-based resources, while maintaining the same high-quality performance parameters of traditional LYCRA® fiber.

QIRA® will be produced at Cargill’s biotechnology campus and corn refining operation in Eddyville, Iowa. The facility, which is currently being built, will commence operations in 2024. The first renewable LYCRA® fiber made with QIRA® will be produced at The LYCRA Company’s Tuas, Singapore manufacturing site in 2024. The LYCRA Company is currently seeking commitments with brand and retail customers who are pursuing bio-derived solutions for their apparel.

We are proud to partner with The LYCRA Company on bringing this sustainable material solution to the market. This collaboration demonstrates that QIRA® directly replaces conventional BDO and thus significantly improves the fiber’s sustainability profile,” said Jon Veldhouse, CEO of Qore®. “QIRA® is an innovative platform chemical that can be used in various applications across industries.”

The first generation of renewable LYCRA® fiber made with QIRA® will use feedstock from field corn grown by Iowa farmers and will enable a significant reduction in CO2 footprint. In addition to replacing a finite resource with an annually renewable one, another benefit for mills, brands and retailers is that there is no change in fiber performance, eliminating the need for any re-engineering of fabrics, patterns, or processes. Equivalent performance was demonstrated in 2014 when the world’s first bio-derived spandex was launched under the LYCRA® brand. The LYCRA Company has since been granted a patent for the process used to make renewable elastane from bio-derived BDO.

-Hyosung Succeeds in Developing the Liner Material of Hydrogen Vehicle Fuel Tanks Using Nylon

Hyosung TNC successes in development and utilization of nylon as a Liner material for hydrogen fuel tanks for the first time in Korea

Lighter material than metal and conventional plastic materials, and excellent hydrogen leakage cut-off effect

The perfect substitution in the monopoly market of foreign companies and secure the technology to lead the hydrogen market

A core material that will complete the value chain from hydrogen production to storage and utilization

Chairman Cho Hyun-Joon, “We will contribute to the future energy industry with our best textile and material technology.”

Nylon has evolved into the core material of the hydrogen energy industry.

Hyosung TNC announced that it has succeeded in developing and using nylon for the liner material of hydrogen vehicle fuel tanks with its own technology, the first of its kind for a Korean company.

A liner is a core component required to store hydrogen in the fuel tank’s internal container and prevent leakage.

Hyosung TNC’s nylon material is superior to conventional metal and high-density polyethylene (HDPE) liner materials in terms of lightweight, gas barrier, and impact resistance.

▶Superior light and safe than metal… Excellent impact resistance against temperature fluctuation

The nylon liner material developed by Hyosung TNC is 70% lighter than metal and 50% lighter than HDPE and the gas barrier property that prevents leakage of hydrogen gas is also 30% higher than metal and 50% higher than HDPE.

Metal liner is heavy and has a high risk of brittleness when exposed to hydrogen for a long period of time, whereas nylon liner has low hydrogen absorption and air permeability, so there is no risk of brittleness.

HDPE liners are used as high-pressure containers at 400bar levels, but cannot withstand the 700bar pressure required by typical hydrogen electric vehicles.

In addition, the hydrogen container liner must be able to withstand rapidly changing temperature fluctuation caused by frequent charging and discharging of hydrogen and the nylon liner has excellent impact resistance against to it from -40 to 85 degrees Celsius.

▶Expected the import effect of 270 billion won annually by 2030

The success of this development is significant in that it has laid the foundation for Hyosung TNC to enter the nylon liner market, which has been monopolized by foreign companies, for the first time as a domestic company.

According to H2 Research, a research institute specializing in the hydrogen market, the global hydrogen vehicle market will grow in earnest, including restrictions on the operation of internal combustion engine trucks in major urban areas in Europe from 2025 is expected to expand to 1.05 million units.

Therefore, the import substitution effect of the nylon material liner market is expected to grow to about 270 billion won annually in 2030.

In addition, with the expansion of various hydrogen mobility markets such as hydrogen electric vehicles, drones, trams, ships, and UAM (urban air mobility), nylon is expected to gain more attention as a liner material for hydrogen containers.

▶The complete of Hydrogen Value Chain in Production, Distribution, Storage and Utilization

The nylon liner is expected to contribute to the completion of Hyosung’s hydrogen value chain.

Hyosung has built a hydrogen value chain through No. 1 supplier of hydrogen charging stations in Korea, construction of liquefied hydrogen plants and liquefied hydrogen filling stations that will change the map of the hydrogen economy, production of carbon fiber, which is essential for fuel tanks for hydrogen vehicles, etc.

The success of this development is significant because Hyosung has secured the technological capabilities to lead the global market not only in the production and distribution of hydrogen but also in the storage and utilization fields.

-EU countries agree power demand reduction targets, new levies to tackle energy crisis

EU ministers on Friday (30 September) agreed on new emergency measures to tackle the energy crisis, including a mandatory target to reduce electricity consumption by 5% at peak hours and two new revenue-creating levies to help protect consumers.

The measures, proposed by the European Commission on 14 September, aim at shielding consumers by seizing the extraordinarily profits made by some energy firms and using those to support households or help them invest in green technologies.

“Our citizens and businesses are eagerly waiting for the EU to come up with concrete proposals on how to take on currently extremely high energy prices,” said Jozef Sikela, the industry and trade minister from the Czech Republic, which currently holds the EU’s rotating Council presidency.

“The agreement reached today will bring relief to European citizens and companies. Member states will flatten the curve of electricity demand during peak hours, which will have a direct positive effect on prices. Member states will redistribute surplus profits from the energy sector to those who are struggling to pay their bills,” he said in a statement outlining the main elements of the deal.

EU countries agreed the proposals in around two weeks, after several meetings to hash out the details. In the end, they agreed on the three measures, but included more flexibility for member states to implement them.

“The Czech presidency has worked extremely hard in order to provide as much flexibility to all member states as possible. And I have to underline, without limiting the ambition and help that households and businesses need now,” Sikela said as he arrived for the meeting.

For instance, EU countries now have more wiggle room to meet the 10% voluntary reduction target for electricity consumption. And Malta and Cyprus are exempted from the 5% mandatory demand reduction target for peak consumption hours.

Meanwhile, EU countries have also pushed for more freedom in implementing the two revenue measures. These include a revenue cap of €180 per megawatt hour on cheap electricity and a “solidarity contribution” on revenues made by oil and gas companies.

While Brussels had proposed an EU-wide, uniform approach in the levies, EU countries pushed for more lenience. This includes allowing countries to “set a specific cap” on the market revenues obtained from the sale of electricity produced from hard coal.

Governments will also be able to set a higher revenue limit for producers with investment and operating costs “higher than the Union-wide cap” and exempt their chosen “supplier of last resort” from the the mandatory electricity demand reduction target at peak times.

Renewable energy industry nervous

The agreement leaves the door open for EU countries to keep existing national price caps on electricity or set new caps and taxes on energy companies at the national level.

∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼

-AI-Engineered Plastic-Eating Enzyme Could Be the Solution to Plastic Pollution

The world is dealing with a major plastic pollution crisis. The recent discovery of a plastic-eating enzyme at UT Austin could be a much-needed game changer to address it.

Research suggests that the world is generating twice as much plastic as it did two decades ago, with the majority of it either getting incinerated or ending up in landfills or dispersed in the environment, especially in oceans.

According to the Global Plastics Outlook report published by the Organisation for Economic Co-operation and Development (OECD), only 9% of plastic is successfully recycled while 22% of plastic is mismanaged.

Because plastic is not naturally biodegradable, teams of researchers and scientists are always devoting time and resources to finding new innovative ways to address the growing problem of global plastic pollution.

Researchers at the University of Texas (UT) at Austin used a new machine learning (ML) algorithm to create a new variant of enzymes that could potentially degrade plastic.

Understanding the Global Plastic Waste Crisis

The United Nations Environment Programme (UNEP) estimates that around 7 billion tons of plastic produced between 1950 and 2017 became plastic waste that was either dumped or ended up in landfills. Plastic waste can negatively impact the environment and its natural processes, contribute to climate change, and affect millions of people’s livelihoods and the world’s food production capabilities. Chlorinated plastic can spread harmful chemicals if not properly disposed of or degraded, harming the surrounding soil, groundwater, and ecosystems.

Increased amounts of plastic pollution can also impact the health and well-being of humans. Researchers believe that children are exposed to microplastics and their smaller counterparts – called nanoplastics – more often than adults. The latter can also face adverse health effects due to microplastics, including DNA damage and inflammation. If inflammation becomes chronic, adults might need medical intervention to receive proper care.

It is well known that plastic can also harm the environment and the vulnerable animal populations living in affected areas. With the growing amount of plastic polluting natural lands and waterways across the world, it is crucial to adopt new technologies and develop alternative packaging to solve the root causes of pollution.

Researchers Develop a Novel Plastic-Eating Enzyme

Hal Alper is a lead researcher of the engineering biology team in the McKetta Department of Chemical Engineering at UT at Austin. He is also a professor and fellow of the Les and Sherri Stuewer Professorship in Chemical Engineering at UT.

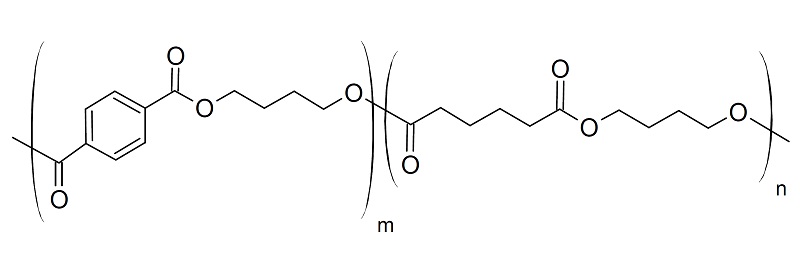

Alper and his team of engineers and scientists created a variant of an enzyme called hydrolase using an ML algorithm. The enzyme is capable of breaking down PET (polyethylene terephthalate), one of the most common plastics used today, into its component molecules.

-CPL price difficult to fall in Oct

We have talked about a mentality-caused decline in CPL in last insight “Sudden decline in CPL spot before Risun starts up”. The panic mood was soon cleared afterwards, and prices have narrowly rebounded. Looking forward into October 2022, how will caprolactam market develop?

Based on the operation schedules of CPL plant after the National Day holiday, there is not much pressure on CPL market.

Oct CPL supply to rise, while merchant spot supply to be steady to lower

As shown in the figure above, CPL plant operating rate will be slightly higher after the holidays. But from the perspective of the direct influence on spot market, the fact may be the other way around.

First of all, although the restarted capacity of Eversun Technology is quite large, but its output of CPL is mainly absorbed directly by Zhongjin’s nylon 6 production, and the amount for merchant sales is extremely limited. Thus, Eversun’s restart will have little impact on CPL spot market.

Second, current CPL spot supply is still concentrated in East China and North China, most importantly in Shandong and Shanxi provinces. In Shanxi, Lanhua and Lubao’s turnaround plans have been confirmed. So there will be a supply shrinkage in October. In Shandong, although Hualu Hengsheng, Luxi and Lunan are running at full capacity, their supporting nylon 6 polymer production will be put into production gradually. Polymerization in The new capacity of nylon 6 polymer in October is conservatively expected to reach about 100kt/year.

- CPL merchant supply reduction: Excluding the factor of Lubao, it is expected that CPL merchant supply (in capacity) in North China will be reduced by about 240,000kt/year (140 + 100). In addition, due to recent compressed CPL processing fee, Shenma has cut production again, and the influenced capacity is estimated at about 50kt/year. The actual merchant supply of CPL (in capacity) is expected to reduce by nearly 300kt/year.

∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼

-Biodegradable PBAT capacity in China more than tripled

With a worldwide “Plastic Limit” and “Plastic Ban” campaign in the past 2 years, the biodegradable material PBAT has been developing rapidly, especially in China. The capacity of the new biodegradable plastic material has almost triple in the past 2 years.

By September 2022, the total PBAT capacity in China has been expanded to 936kt/year, up 136% from the capacity by the end of 2021, and up 280% from that by the end of 2020. The new capacities scheduled in the last quarter of 2022 are still huge.

Despite of the fast developing capacity, PBAT plant operating rate, or the utilization of the capacity has lingered low. The annual average operating rate of PBAT plant in 2021 was 30.05%, and the average O/R in Jan-Sep 2022 was 31.13%. In Aug 2022, the run rate has dropped to only around 10%.

Such low utilization indicates a relatively low consumption for the materials.

Despite of a series of “Plastic Limit Order”, and “Plastic Ban”, consumption of the newly developed biodegradable plastics is still low, when compared to traditional plastic materials including polypropylene (PP), polyethylene (PE) and polyesters (PET). The price gap between PBAT and the traditional plastics is well above 11,000yuan/mt for the time being. That is to say, there will hardly be active purchase under market mechanism, and PBAT consumption is mainly depending on policy restrictions.

CCFGroup has published “China’s biodegradable plastic PBAT market study” for two consecutive years of 2020 and 2021, and has updated the bi-weekly report of “Bio-degradable plastic PBAT market weekly”..

The Bio-degradable plastic PBAT market weekly report is updating real-time prices, and plant operation and weekly market review of the raw materials of PBAT (PTA, BDO and adipic acid). And it also include the prices and market reviews for PBAT and other relative plastic-grade polymers (PP, PE, and PET chip).

The report also gives PBAT comprehensive raw material cost and the nominal cash flow based on the direct esterification process for your reference, for customers’ better understanding of current PBAT production margin.