Bottle-PCR – Green-Hydrogen 11-10-2022 - Arhive

Bottle-PCR – Green-Hydrogen

Crude Oil Prices Trend

-Report: Prioritise mechanical recycling to meet climate goals

But CRE’s John Sewell says meeting new targets will be hard without chemical recycling

Using pyrolysis-based chemical recycling to meet plastic recycled-content targets could emit up nine times the greenhouse gases compared with traditional mechanical recycling, according to a new study from the environmental group Zero Waste Europe.

The Sept. 27 study looked specifically at 2030 recycled-content targets under consideration by the European Commission and how they would help meet climate targets under the Paris Agreement to limit global warming to an increase of 1.5° C.

Drawing on data from research done for the commission by the consulting firm Eunomia, ZWE said that greenhouse gas emissions from recycling plastics using pyrolysis are nine times higher than those from mechanical recycling, and it said that “mechanical recycling must be prioritized over pyrolysis wherever possible.”

The environmental group launched the study in a Sept. 27 webinar, where it invited plastics industry groups to participate and comment.

The managing director of Chemical Recycling Europe, John Sewell, said the results did not surprise him, but he argued that his association’s technologies will play a role in handling hard-to-process plastic waste that can’t be handled by mechanical processes.

“Is anyone really surprised that mechanical recycling has a lower GHG than chemical? I’m certainly not,” he said. “As an industry, we are totally supporting the hierarchy of waste — that is, if it can be mechanically recycled, then it should [be]. We support that as an industry.”

But Sewell, the secretary-general of the Brussels-based group, said “there exists a hell of a lot of plastic waste out there that is not mechanically recycled today.”

“We see that there’s an opportunity for us to fit and work together,” he said.

The ZWE study comes as the European Commission is revising its Packaging and Packaging Waste Directive. The study looked at the impact of recycled-content targets of 30 percent and 40 percent.

The environmental group wants any new EC directive to be more explicit about limits on chemical recycling.

“Without adequate regulations, efforts to strengthen mechanical recycling will be severely hampered,” the study said.

ZWE said the EC should specifically prioritise mechanical recycling and consider the climate impact of different recycling technologies when it sets targets for recycled content, as well as focusing on design for recycling and other steps to boost mechanical recycling.

“The revision of the PPWD should serve as a lever to make the packaging sector more circular and be in line with European climate commitments,” said Lauriane Veillard, ZWE’s chemical recycling and plastic-to-fuel policy officer. “If we are serious about achieving [a] net-zero emission economy, mechanical recycling must be preferred over pyrolysis.”

But Sewell said it could prove difficult to meet any new targets without chemical recycling.

He suggested it’s not possible to “wave a magic wand” and have mechanical recycling solve problems processing complex mixtures of plastic waste.

As well, he said that chemical recycling technologies can produce cleaner streams of recycled plastics that could go take food packaging plastic waste and reuse it more easily back into new food-contact plastic.

“Would you not agree with me that you don’t want to wave a magic wand and say that mechanical recycling can solve all these problems,” Sewell said.

The study’s author, Johannes Betz with the Oeko-Institut, an environmental research organisation in Freiburg, Germany, told the webinar audience that the study did not compare the climate impact of chemical recycling against virgin plastics production or incineration.

But he suggested it would compare favourably.

“Of course, there are some benefits of chemical recycling compared to new plastics,” Betz said. “And there’s also a benefit of chemical recycling vs. incineration.

“We should use chemical recycling up to a certain point, but this point has to be very, very, very small as chemical recycling has not as much benefit as mechanical recycling,” Betz said.

Another panelist, Fanny Rateau, a program manager with the Environmental Coalition on Standards, noted that the study found the biggest overall GHG benefit from a reduction in overall single-use packaging, of 20 percent, combined with enhancements to mechanical recycling.

“What is most important for packaging is to eliminate unnecessary packaging and transition from single-use to reusable plastic packaging,” she said. “What’s important is to prioritise mechanical recycling.”

-Ceresana examines the global market for bioplastics

According to the latest edition of the Ceresana report on bioplastics, the global market for “green” polymers will continue to grow dynamically: analysts expect bioplastics sales to rise to around USD 9.7 billion by 2031.

Climate protection, independence from crude oil and natural gas, environmentally friendly products and new opportunities for agriculture – bioplastics are associated with great hopes. Nevertheless, there is also a great deal of confusion surrounding these materials, as there is currently no generally recognised definition of bioplastics and no uniform labelling. The current Ceresana study looks at two material groups that can overlap but do not always have to be identical: biodegradable plastics on the one hand, which can be decomposed by micro-organisms in the wild or at least composted in industrial plants; on the other hand, biobased plastics, which are produced from renewable raw materials. Some bioplastics meet both conditions: PHA from sugar and TPS from starch, for instance, are bio-based and biodegradable. However, there are also plastics made from biogenic raw materials that are not compostable, for example PEF from fructose or bio-polyethylene based on sugar cane. In contrast, some petrochemical plastics, i.e., plastics produced from crude oil or natural gas, can be biodegradable, such as PCL, PBAT or PBS.

Green polymers for the Circular Economy

Plastics and packaging play a major role in the “Circular Economy Action Plan” published by the European Union as part of its “Green Deal” to overcome the throwaway society and reduce waste. The EU Commission is working on a new policy framework on bio-based, bio-degradable and compostable plastics. This should clearly define what is meant by bio-plastics and how they are to be disposed of. The project is rendered more complicated by the fact that biomass components are also increasingly being added to fossil plastics in order to reduce their carbon footprint. So far, it has not been defined at what proportion of renewable raw materials a “bio-attributed” or “mass-balanced” polymer blend may be marketed as a bio-plastic. Plastics obtained with the help of genetically modified organisms are also controversial. In any case, the EU Commission wants to avoid greenwashing: bio-based plastics should only be used if they offer “genuine ecological advantages” over fossil plastics and do not compete with food production, for example.

Highest Growth Rate for PLA and Starch

Biodegradable plastics, for example polylactic acids (PLA) and starch polymers, reached a market share of 65% of the total bioplastics market in 2021. For this product group, Ceresana expects further volume growth of 10.4% per year until 2031. For bio-based plastics that are not bio-degradable, such as polyethylene, PET or PA, growth is expected to be lower at 7.5% per year. Ceresana’s latest market report analyses how the use of bio-plastics is developing in the various sales markets. The most important application area in 2021 was the packaging industry: 58% of all bio-plastics were processed in this area. Ceresana expects the highest growth rate in the “bags and sacks” segment.

Current Market Data on Bio-plastics

Chapter 1 of Ceresana’s new study provides a comprehensive analysis of the global market for bio-plastics – including forecasts up to 2031: the development of demand, revenue and production is presented for each region.

In chapter 2, the 8 most important sales countries for bio-plastics are considered individually: Germany, France, the United Kingdom, Italy, Spain, the USA, China, and Japan. The following are presented in each case: demand and revenue, demand for each application area, and product type.

-Energy-Efficient Bottle Blowing with PCR

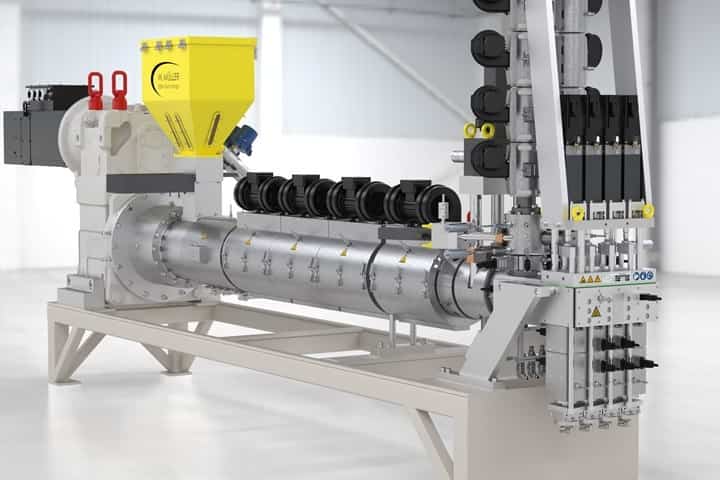

At K 2022 this month, W. Müller is presenting a system for PCR processing in a three-layer coextrusion, using an energy-saving barrel-heating system.

In line with the show’s emphasis on sustainability and the circular economy, W. Müller will be highlighting its experience with processing post-consumer recycle (PCR) at K 2022 this month in Düsseldorf. The company will present a ReCo3 system designed specifically for processing PCR in the core of a three-layer coextrusion sandwiched between thin layers of virgin resin.

An interesting feature of this system is a energy-saving barrel heating/cooling system supplied by Austrian heating specialist Keller, Ihne & Tesch (also exhibiting at K). The system uses standard air-cooling fans plus special heating tapes made of aluminum instead of the usual ceramic. The metal tapes are said to be more stable, and to distribute heat energy more quickly. This modified heating/cooling combination saves around 2000 W in this application, according to W. Müller, and the energy is distributed over the entire area, but the unit does not get hot on the outside, enhancing worker safety.

-Nexam Chemical takes first major order from South Korea

Nasdaq First North-listed Nexam Chemical – which invents, develops, produces and sells additives to the plastics industry worldwide – takes the largest order to date in the South Korean market, said the company.

The order applies to the Reactive Recycling area for recycled PET to a value of approximately SEK 1 million. Nexam Chemical has previously announced that the company has a new agent in Seoul, which has successfully started to develop the market with a focus on reactive recycling. Reactive Recycling, is a product series from Nexam Chemical that can significantly improve the properties of plastics in the recycling process.

“Nexam has the chemical expertise to recycle plastic without destroying the original properties. Therefore, this is an area of ??the future for us. With this order, we go from delivering sample volumes to an order to be used on a larger industrial scale, which is a confirmation of how well our recycling products work,” says Johan Arvidsson, CEO of Nexam Chemical and continues: “This time we are also doing business in a new part of the world. It strengthens our vision of what we can achieve in the rapidly growing plastic recycling market”.

Nexam Chemical develops technology and products that make it possible to significantly improve the production process and properties of most types of plastics in a cost-effective manner and with retained production technology. The improved properties include strength, toughness, temperature and chemical resistance as well as service life.

-Pyrum set to commission expansion at flagship tire recycling plant

ELT pyrolysis company receives official operating licence for the project in Dillingen

Dillingen, Germany – German waste tire pyrolysis company Pyrum Innovations AG is set to commission two further recycling lines at its flagship processing plant in Dillingen, having received all official state approval for the project.

In a statement 5 Oct, the company said lines 2 & 3 of the plant were ready for start-up in three months, noting that the approvals were “a major milestone” demonstrating “the licencability of Pyrum’s series production plants.”

The approvals will also mean that restrictions are not expected to apply to Pyrum’s future plants, the company added.

“We are very satisfied to have received the final operating license so early,” said CEO Pascal Klein.

The approval, he said, will be important for the company’s ambitious rollout plans, which include its Revalit joint venture in Straubing and the planned major scale-up with Unitank.

Pyrum is currently expanding its industrial plant in Dillingen by adding two more production lines to a total of three pyrolysis reactors and the associated systems, such as a shredder and a pelleting system.

The official approvals cover the operation of the plant with two new reactors and a throughput of around 2 tonnes of end-of-life tires (ELTs) per hour.

The project will also add a storage capacity of 160,000 litres of oil and 500 tonnes of old tires, as well as a shredder plant with a capacity of up to 6 tonnes of ELTs per hour.

-RECOUP annual conference hears from industry experts on sustainability

Plastics recycling charity RECOUP has recently held its annual conference for the plastics recycling and resources sector.

Speakers form various organisations including Nestle, Innovate UK and WWF presented at the conference, which also featured the launch of reports and projects, including:

A Best Practice Guide for UK Plastics Recycling Communications Best Practice Guide for UK Plastics Recycling Communications – RECOUP Recycling

Recyclability by Design 2023 and case studies highlighting the importance of recyclability basic principles, material substitution concerns and work in the area of bacon and meat packaging. www.recoup.org/design

ESA Quality Standard for Recycled Plastics with support from the British Plastics Federation, Recycling Association and RECOUP, to define a quality standard for post-consumer recycling.

Sara Banning, innovation lead from Innovate UK – UKRI, told a panel about the importance of data to be used for accountability, the need for clear government signals and policies for reuse and prevention targets, a mindset shift towards circular economy and the common theme of the day, collaboration.

Hayley Lloyd-House, head of corporate affairs and sustainability at Nestlé Waters (UK), highlighted the positive joint work with RECOUP and drew attention to the ‘The 5 -pillar strategy’ aimed to Reduce, Re-use, & Refill, Redesign and Rethink behaviours.

She was part of a panel that debated the lack of consistency in kerbside plastics collections and communications as well as UK recycling capacity. With mixed messaging and ‘wish’ recycling causing contamination and a call for the harmonisation of labelling.

Paula Chin, senior policy advisor – consumption at WWF, said it was important that the sector use the “right material, in the right place and with the right approach”.

Rowan Byrne, marine plastics global lead at the major consultancy Mott MacDonald commented on the issue of plastics in the natural environment particularly rivers and oceans, insisting ‘to manage something you have to measure it’: “The challenge with plastics in the environment is the issue gets bigger as plastics get smaller. Just because you can’t see it doesn’t mean it isn’t there.”

∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼

-Air Products to Invest in N.Y. green liquid hydrogen production plant

Air Products and Chemicals Inc. said Thursday that it plans to invest about $500 million to build, own and operate a 35 metric ton a day facility to produce green liquid hydrogen at a new site in Massena, N.Y., as well as liquid hydrogen distribution and dispensing operations, said the company.

The company said the commercial operation of the facility is targeted to begin in 2026-2027.

In support of this project, in July, the New York Power Authority board approved 94 megawatts of low-cost St. Lawrence hydroelectric power to Air Products for its investment and the creation of 90 jobs in New York state.

Air Products said it is also investigating the feasibility of establishing a hydrogen fueling station network in the U.S. northeast region, including the ability to serve Air Products’ truck fleet. Air Products has announced plans to convert its global fleet of roughly 2,000 trucks to hydrogen fuel-cell zero-emission vehicles.

The low-carbon intensity liquid hydrogen product from the facility is expected to be sold to the mobility market in New York state, as well as other potential northeast industrial markets. If all the hydrogen is used for the heavy-duty truck market, future climate benefits over the project’s lifetime would include avoiding more than six million tons of carbon dioxide, which is equivalent to the emissions from over 600 million gallons of diesel used in heavy-duty trucks, the company said.

-Versalis announces new branding in alignment with sustainable objectives

San Donato Milanese (MI), 3rd October 2022 – Versalis has revised its logo to represent the company’s strategy as an industry leader, in alignment with Eni’s identity, in its offering of decarbonised products.

Through innovation, the company aims to develop technologies within the circular economy and chemistry from renewable sources, as well as specialising its product portfolio.

Versalis’ portfolio specialisation is focused on the development of markets and products for energy transition and sustainable mobility. As part of the circular economy, Versalis is committed to the mechanical and chemical recycling of plastic waste and chemistry from renewables, and the continuous development of new markets and applications for these by- products.

The new logo draws inspiration from the unique values and characteristics of a company which is capable of embracing the continuous evolution of the chemical industry. The main feature is still the six-legged dog, Eni’s symbol, rendered in Versalis’ colours which reflect the company’s sustainable mission.

∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼