Bottles-to-fabric – Teesside welcomes Mura Technology’s first HydroPRS plant 30-10-2023

Bottles-to-fabric

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Petrochemicals r-Polyester – Artificial Intelligence and the Call for Safety: A Global Initiative

Teesside welcomes Mura Technology’s first HydroPRS plant

The UK’s first plant that uses supercritical water to transform plastic into hydrocarbons has been opened by Mura Technology in Teesside.

The HydroPRS process converts plastics into valuable feedstock materials that can be used by Mura’s customers, who will start receiving deliveries in early 2024.

The plant has an annual capacity of 20,000 tons of recycled liquid hydrocarbons, which can be increased to 60,000 tons. Bottles-to-fabric

The company claims that the process can recycle postconsumer plastics such as films and trays, offering a sustainable solution for these materials.

The HydroPRS process also cuts carbon emissions by 80% by preventing plastics from being burned. Steve Hahon, Mura Technology CEO, says: “Our HydroPRS process is creating a new opportunity for plastic waste, generating value and keeping both plastic and carbon in a circular economy.

The technology complements existing mechanical recycling to make sure no plastics are deemed ‘unrecyclable’ and need to be incinerated or landfilled.” Bottles-to-fabric

Mura has received funding from various companies in the plastic industry, such as KBR, Dow, CPChem, LG Chem and igus GmbH, as well as from UK Research & Innovation’s Smart Sustainable Plastic Packaging Challenge and the government’s Future Fund.

LyondellBasell acquires 25% of Cyclyx

It joins Agilyx and ExxonMobil in the joint venture

“Investing in plastic waste value chain experts such as Cyclyx, together with Agilyx and ExxonMobil, helps create the robust supply chains we all need to increase access to circular and renewable feedstocks,” said Yvonne van der Laan, LyondellBasell executive vice president, circular and low carbon solutions. “This collaboration unlocks the necessary scale of recycled material and infrastructure for our planned integrated Circular and Low Carbon Solutions Hub in the Houston area and aligns with our purpose of creating solutions for everyday sustainable living.” Bottles-to-fabric

Cyclyx draws on over 1500 post-use plastic chemical characterisations to assesses each source of waste plastic to understand its chemical profile. It then uses artificial intelligence and big data to sort those profiles into the various mechanical and chemical recycling pathways that the plastics can be used for. Finally, the company aggregates and pre-processes the products according to costumers’ needs.

This factory in Tiruppur turns used PET bottles into fabric and garments

Sulochana Cotton Spinning Mills in Chitambalam ventured into recycling in 2010, and aims to achieve carbon neutrality by 2027 and says it has also aligned with nine of the 17 sustainable development goals

A 150-acre facility at Chitambalam, about an hour’s drive from Coimbatore, has over 10,000 trees, 1,000 birding nests, solar energy panels, bio gasifiers, and plastic-free zones. Tiruppur-based Sulochana Cotton Spinning Mills buys 4,000 tonnes of used polyethylene terephthalate (PET) bottles a month and coverts them into polyester fibre, yarn, cloth, and garments on this campus. Bottles-to-fabric

Even as global apparel brands commit to Environmental, Social and Governance (ESG) targets, textile factories, such as Sulochana, in Tamil Nadu, a textile powerhouse, are showing the way in sustainable and circular fashion. The company, which won the State government’s Green Champion Award for 2021, ventured into PET bottle recycling in 2010 and currently buys used PET bottles from waste aggregators in Tamil Nadu, Kerala, Puducherry, and parts of Karnataka.

The bottles land at its gates at Chitambalam in three colours – white, green, and brown. The labels on the bottles are removed and sent to cement factories to be used as fuel. The plastic caps and rings are converted into pellets that go into the making of planters, car bumpers, etc. The bottles are washed multiple times and broken into flakes. Colour master batches are added to the flakes to make coloured polyester fibre or yarn. “We do not use water, salt, or chemicals to dye the fibre. The (PET) recycled fibre saves on both cost and time,” says the company’s CEO, G.D. Gopalakrishnan. Bottles-to-fabric

The recycled fibre waste also has its applications in the manufacture of conveyor belts, automobile mats, etc.

A scuba diving jacket made by Sulochana has 96% recycled polyester filament, avoids 47 kg of carbon dioxide (CO2) emission, saves 46 litres of water, and has 40 g of diverted waste. Similarly, yoga wear made by the company has 96% recycled polyester filament, avoids 32 kg of CO2 emission, saves 31 litres of water, and has 27 g of diverted waste.

Vietnam’s fibre exports foresee positive signals

Latest statistics from the General Department of Customs showed that, by the end of the third quarter of 2023, fibre exports earned 3.2 billion USD with more than 1.3 million tonnes of goods exported abroad, up 9.3% in volume but decreasing 13.8% in value compared to the same period last year. Bottles-to-fabric

Increase in quantity

Regarding the market, in September, fibre exports to China reached 77,459 tonnes worth more than 203 million USD, down 18.8% in volume and down nearly 20% compared to August 2023.

Overall, in the first nine months of the year, Vietnam exported 647,862 tonnes of fibre to the Chinese market and earned more than 1.71 billion USD, up 18.1% in volume but down 2.1% in value over the same period last year. The export price reached 2,652 USD per tonne, down 17.1% compared to the same period in 2022.

The Republic of Korea (RoK) is the second-largest export market of Vietnamese fibre. In September, fibre exports to the RoK reached 10,898 tonnes with a value of more than 30 million USD, an increase of 0.6% in volume and an increase of 2.8% in value compared to August 2023. Bottles-to-fabricOverall, in the first nine months of the year, fibre exports to this market reached 101,880 tonnes and earned more than 284 million USD, down 5.78% in volume and 24.2% in value compared to the same period in 2022. The average export price reached 2,788 USD per tonne, down 19.65% over the same period in 2022.

The US market ranked third. In the first nine months of 2023, Vietnam exported 75,483 tonnes of fibre to the US with a value of more than 108 million USD, down 13.8% in volume and 29.4% in value over the same period. The average export price reached 1,443 USD per tonne, down 17.5% over the same period in 2022 and less than half the export price to China or the RoK. Bottles-to-fabricMore…

Innovation in plastics packaging – driving the transition to a circular economy

This month, the UK government introduced an extension of the ban on single-use plastics to include polystyrene foods and drinks containers. In the two years since our last article series on targeting plastic waste, a lot has changed both in terms of legislation and the development of plastic-free alternatives. Bottles-to-fabric

In this article we consider how effective these changes have been in tackling plastic packaging waste, key areas of innovation, and how innovators can protect the new materials and processes that are being developed.

The current landscape

In 2021, packaging was the largest application in the world plastics market. In a bid to tackle this and reduce the use of virgin plastics, the UK government has implemented new legislation that will give UK organisations that import or supply packaging extended producer responsibility (EPR). This requires producers to pay the full cost of dealing with the waste they produce, with businesses needing to collect data on how the packaging is used and ensure packaging is recycled where possible. This legislation is an environmental policy which follows the introduction of the plastic packaging tax in 2022 on the manufacture or importation of plastic packaging components that contain less than 30% recycled plastic. Bottles-to-fabric

The UK government has also launched a range of funding schemes to incentivise development into sustainable plastic packaging, such as grant schemes from the UK Research and Innovation’s Engineering and Physical Sciences Research Council and Biotechnology and Biological Sciences Research Council. On top of this, the UK government recently announced a further £3.2 million investment in the UKRI’s Smart Sustainable Plastic Packaging (SSPP) challenge. With a budget of £60 million for spending from 2019 to 2025, the SSPP has received the largest investment in sustainable packaging initiatives to date. Interestingly, nearly 50% of this funding is directed at mechanical recycling projects, with 30% of the funding being split between refill/re-use, chemical recycling schemes and prevention and reduction projects.

Governmental drive has been reinforced by consumers with 8 in 10 consumers in the UK supporting a ban on single-use plastics. A recent report from Trivium Packaging and Euromonitor International showed that of nearly 10,000 respondents, 82% of respondents would be willing to pay more for sustainable packaging, while 63% of consumers are now less likely to buy products with environmentally harmful packaging.

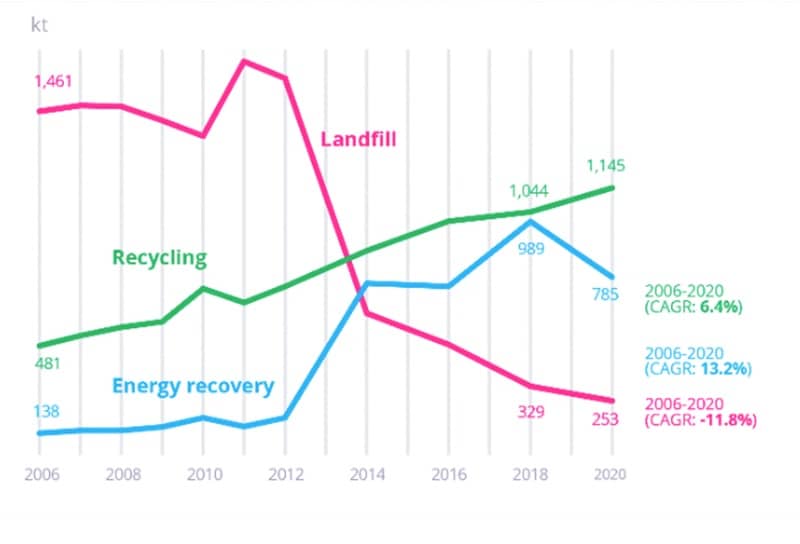

These regulatory, financial, and consumer-backed incentives seem to be working. Since 2006, recycling and energy recovery have overtaken landfill as the largest waste treatment options. Bottles-to-fabric

Bottles-to-fabric