Chemical recycling – Pyrowave introduces nanopurification technology for plastics 15-11-2023

Chemical recycling

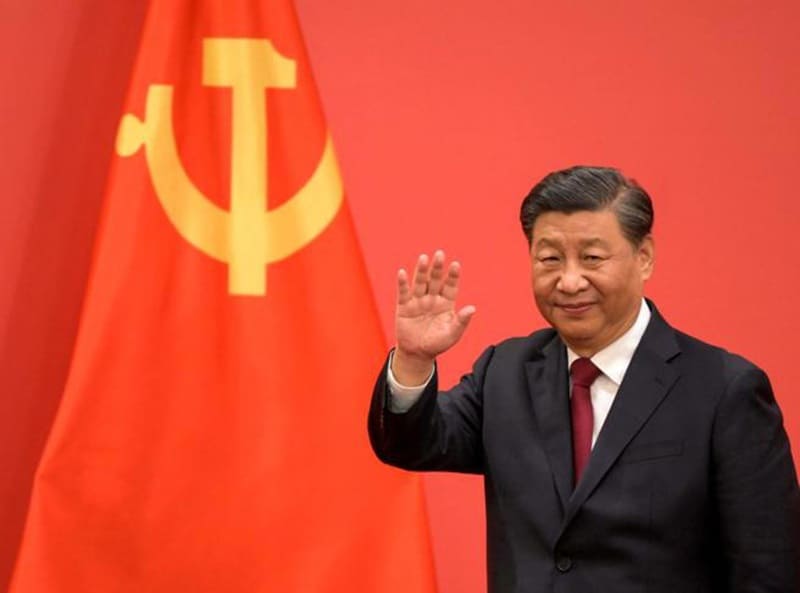

The Chinese brick is crumbling

As of the first 10 months of 2023, the foundations of China’s real estate sector are visibly cracking, with a 6.8% year-on-year decline in property sales, adding to the preceding 7.5% downturn observed from January to September. This data, emanating from the National Statistics Office, serves as a glaring indicator of the deep-seated crisis gripping the Chinese real estate market. Concurrently, investments in the construction sector have hit the brakes, experiencing a notable 9.3% decrease following the 9.1% contraction in the preceding January-September period. Chemical recycling

A closer look at specific metrics reveals a concerning trend. New construction initiations, measured in square footage, have plummeted by 23.2% on an annual basis, mirroring the 23.4% slump witnessed in the first nine months of the year. Additionally, the funds amassed by real estate developers have seen a precipitous 11% decline, building upon the 13.5% contraction recorded in the initial nine months of the year.

These alarming figures find resonance within the broader context of investments in fixed assets, which, contrary to expectations, have only grown by a modest 2.9% in the first 10 months of the year. Chemical recycling

The total, amounting to 41,940 billion yuan (equivalent to nearly 5,830 billion dollars), falls short of anticipated growth, which was pegged at 3.1%. This downturn in real estate activity is emblematic of the economic turbulence faced by China, exacerbated by the crises befalling major players in the industry such as Evergrande and Country Garden. These industry giants, grappling with insurmountable debt and teetering on the brink of collapse, are contributing significantly to the erosion of the dragon’s economic prowess. The reverberations of this downturn extend beyond the realm of real estate, casting a shadow on China’s overall economic landscape.

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Pyrowave introduces nanopurification technology for plastics

A short-loop chemical recycling process to remove toxic additives and contaminants in plastics

According to Pyrowave, its nanopurification technology operates at the molecular level to remove contaminants from polymers with perfect control on purified resins, offering a plastic waste pre-treatment to purify the resins that can be used in advanced recycling methods, or directly into final applications. The technology debottlenecks the access to plastic feedstock, by standardising the material upstream to be compliant with most advanced recycling process, including its own microwave depolymerization process.

Pyrowave has successfully demonstrated the technology by decontaminating polymers and supplying high-quality recycled plastics to industries requiring strict compliance, including food-contact applications.

Cosmo First results expect worst to be behind

Cosmo First declared its financial results for the quarter ended June 2023 on 10 August. The results for the quarter would have been better by Rs 20-crore but for the non-repetitive inventory loss arising from the sharp drop in prices of raw materials towards the quarter end. Chemical recycling

During the quarter, the BOPP demand has started picking up and the demand-supply balance should get restored in the coming quarter(s). In the case of BOPET, where the supply is far in excess of demand, it will take many more quarters for the supply-demand gap to bridge. Margins are therefore likely to remain under pressure with little downside risk.

The export markets showed signs of improvement with better specialty sales. Cosmo with over two third of its revenue coming from BOPP speciality films could withstand the margin pressure better than the industry. Chemical recycling

“We continue to build our specialty films portfolio by adding speciality polyester films, including shrink labels and sun shield films which would further strengthen our overall margins and also the ability to withstand margin pressures if any in the future,” the company said.

The company’s Petcare vertical Zigly continues to grow rapidly and clocked monthly revenue (GMV) with a run rate revenue of Rs 3-crore on the back of expanding retail footprints, innovative sales promotion, and increasing online presence. The acquisition of Petsy, an online venture in the Petcare space, is complete and would further accelerate the growth of the Petcare vertical. Chemical recycling

The speciality chemical subsidiary is set to launch newer adhesives in H2, FY24.

Pankaj Poddar, Group CEO, Cosmo First, said “The company is working on multiple growth drivers including speciality BOPET films, sun shield film, rigid packaging, specialty chemicals, petcare, etc.

The joint ventures intend to issue a final investment decision in 2023, with construction beginning that year

Production is production to commence in late 2025 or early 2026. Between the two facilities, over 125 new jobs would be created if the project moves forward.

“With the establishment of this JV, LG Chem will not only procure production capacities for highly pure lactic acid needed for commercial-scale PLA production, but will also be able to apply biomaterials in the development of various high-value-added products. Based on eco-friendly materials, which is an axis for new growth engines, we will respond to the rapidly changing market and customers, while becoming a market leader, ” said Hak Cheol Shin, CEO of LG Chem, in a statement. Chemical recycling

Chemical recycling