CO2-Based-Polyester – rPET 19-01-2023 - Arhive

CO2-Based-Polyester – rPET

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-The Fed sends Asia into the red and sends oil tumbling. Historical deficit in Japan

Asia in the red, Thursday 19 January after the weak closure of Wall Street. At 7:15 am Italian the Nikkei drops 1.5%, Hong Kong has just passed above parity, Shanghai travels at +0.2%, the Asia Dow index is down by 0.65%.

Gold rose by 0.25% to 1,911 dollars per ounce, American WTI oil dropped 1.5% to 78.3 dollars a barrel. The euro changes hands at 1.0796, the yen, after Wednesday’s slide, recovers 0.76% to 127.94, while the yield on the 10-year US T bond sees the yield fall to 3.325% from 3.375%. Wall Street futures are now in the red by an average of 0.15%.

Disappointing US data released yesterday fueled recession fears as investors continue to assess the monetary policy outlook. The latest data showed U.S. retail sales fell more-than-expected in December, while producer prices fell to their lowest level since April 2020, stoking concerns about a potential slowdown.

Meanwhile, St. Louis Fed Chairman James Bullard said rates are not yet tight and could climb as high as 5.5% by the end of the year.

In Asia, investors are weighing data on Japan which posted another trade deficit in December, while Australia’s unemployment rate remained stable at 3.5% for the same month. CO2-Based-Polyester – rPET

Japan has the largest trade gap in 7 years

Japan’s trade deficit widened to 1,448.5 trillion yen in December 2022 from 603.1 trillion a year earlier, marking the 17th consecutive month of a gap that represents the longest stretch since 2015.

For the full year of 2022, the trade deficit widened to $19,971.3 billion, the highest amount since 1979, driven by a jump in imports amid high commodity prices and a plunging yen.

Imports from Japan extend the double-digit increase

Imports into Japan rose 20.6% year-on-year to 10,235.7 trillion yen in December 2022 versus market consensus of 22.4% and after a 30.3% jump in November.

It was the 20th consecutive month of double-digit growth, but the slowest pace since April 2021 amid buoyant domestic demand and high commodity prices. Purchases of mineral fuels increased by 44.1%, supported by oil (41.4%) and LNG (36.8%), those of electric cars instead gained 8.5%, led by semiconductors (16 .8%).

Oil falls on fears of recession, inventories rise

WTI crude futures fell below $79 a barrel on Thursday, extending losses from the previous session after disappointing US data fueled recession fears, while US crude inventories rise by surprise .

The latest data indicated that US retail sales fell more-than-expected in December, while producer prices fell the most since April 2020, stoking concerns about a potential slowdown. CO2-Based-Polyester – rPET

Data from the American Petroleum Institute also showed that US crude inventories rose by 7.6 million barrels last week, defying expectations of a 1.8 million barrel decline.

Meanwhile, the International Energy Agency wrote in its latest forecast that global consumption will hit a record daily average this year, led by a recovery in demand in major crude importer China, although it signaled a large surplus in the first quarter.

Saudi Aramco went on to say it was optimistic on oil consumption as China recovers and air travel rebounds.

The Fed sends Asia into the red and sends oil tumbling. Historical deficit in Japan

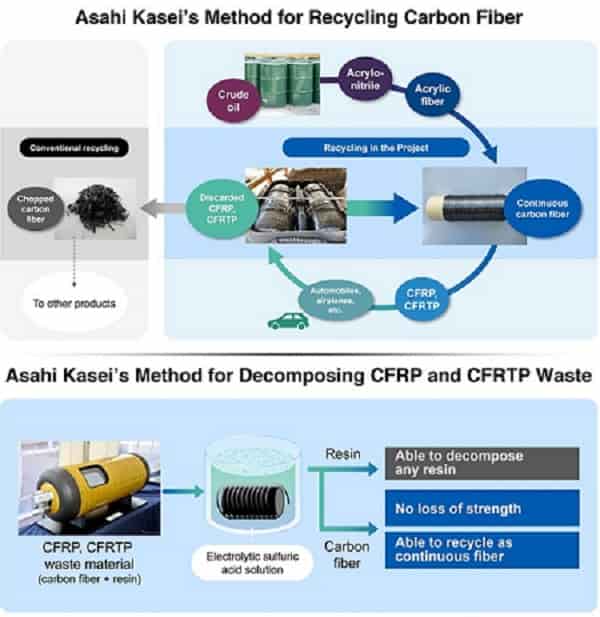

-Asahi Kasei Collaborates on Development of High-Quality Recycled Carbon Fiber

Working with academic partners, Asahi Kasei has developed new technology for recycling carbon fiber plastic compounds.

A new technology for recycling carbon fiber plastic compounds has been developed by Asahi Kasei together with the National Institute of Technology at Kitakyushu College and Tokyo University of Science. Carbon fiber reinforced plastics (CFRP) are highly attractive for various industries in demanding application fields due to their unique balance of rigidity, mechanical strength and light weight – also compared with conventional glass fiber reinforced plastics. However, CFRPs are expensive and challenging from a recycling perspective, as it is difficult to extract the carbon fibers from the resin after usage.

In collaboration with its academic partners, Asahi Kasei has developed a recycling method that allows carbon fibers to be extracted from CFRP or carbon fiber reinforced thermoplastics (CFRTP) used in automobiles. CO2-Based-Polyester – rPET

This reportedly results in high-quality, inexpensive continuous carbon fiber that can be recycled perpetually, contributing to circular economy. Unlike carbon fiber that is chopped up during the recycling process, Asahi Kasei’s method allows carbon fiber to be extracted from a plastic compound seamlessly, resulting in continuous strands of carbon fiber that can be reapplied in exactly the same manner while retaining properties identical to the original substance.

According to the company, the conventional technologies for recycling carbon fibers by chopping and re-applying them results in a product with lower quality and less durability, insufficient for high-performance applications. To address this issue, Asahi Kasei developed an “electrolyzed sulfuric acid solution method” that allows the carbon fiber to retain its original strength and continuous nature while fully decomposing the resin the carbon fiber is embedded in. This allows for its continued use in high-performance applications and presents an inexpensive, circular solution to the end-of-life dilemma of carbon fiber plastic compounds.

As such, carbon fiber compounds present in vehicles for weight reduction can be easily and inexpensively be broken down at end-of-vehicle-life and reapplied to new vehicles in the future. In addition, Asahi Kasei is developing a carbon fiber reinforced thermoplastic unidirectional tape (CFRTP-UD tape) that utilizes both recycled continuous carbon fiber and the company’s Leona nylon resin.CO2-Based-Polyester – rPET

Boasting a higher strength than metal, this CFRTP-UD tape can be applied to automobile frames and bodies, further enabling the recycling of end-of-vehicle-life parts into different, new automobile parts. This is said to present a solution to the long-term challenge that carbon fiber usage for vehicles has posed on the industry and is expected to economically benefit and strengthen carbon fiber’s usage within the automobile industry on a global scale. Moving forward, Asahi Kasei will perform demonstrations and develop the business, aiming for practical application around 2030.

-Fairbrics Raises €22 M to Bring to Market its CO2-Based Polyester Fiber and Reduce the Textile Industry’s Carbon Footprint

- A €17 M grant is awarded by the European Union to the Company, through a Technology Upscaling Project bringing together 13 partners from 7 countries throughout Europe.

- Partners to the Project will contribute an additional €5 M.

- The combined funds will be used to build a pilot line within the next 2 years and a demo plant within the next 4 years.

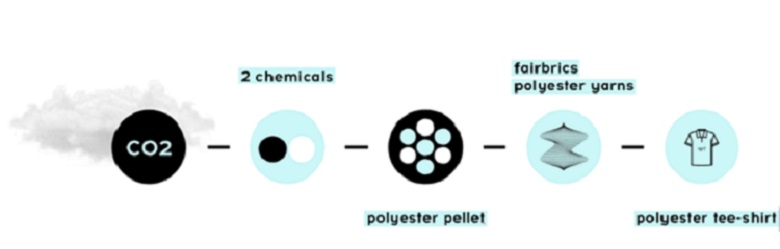

Faibrics, a sustainable chemical company developing a technology that converts CO2 emissions into high value polyester through a circular manufacturing approach, announced today it has raised €17 M from the European Union’s Horizon 2020 Research & Innovation Program and 5 M€ from Partners to the Technology Upscaling Project, representing a total amount of €22 M to bring its innovative solution to market.

The EU’s grant was awarded to a consortium coordinated by Fairbrics that brings together 13 partners from 7 countries throughout Europe, ranging from upstream and process development experts (i.e. engineering design, CO2 capture, chemical reuse, electrolyzer) to final product specialists (i.e. Faurecia for automotive, Les Tissages de Charlieu for textile). To prompt societal impact, the Project also includes a strong educational component and, together with academic partners, it will develop learning and training resources on CO2 valorization for young professionals, university students and lifelong learners.CO2-Based-Polyester – rPET

The combined funds will be used to upscale Fairbrics’ technology, first in a pilot line of 100 kg/day by 2024 and later, by 2026, in a 1 ton/day demo plant. The primary aim is to fight climate change and accelerate energy intensive industries’ decarbonation by replacing fossil-based polyester with CO2-based polyester, using a circular approach that recycles CO2 waste fumes from chemical plants into high value textile products. Fairbrics targets sectors employing polyester as a main material: clothing but also sports equipment, automotive and packaging.

“By using CO2 emissions instead of fossil resources to manufacture polyester, Fairbrics addresses one of the greatest global challenge, climate change caused greenhouse gas (GHG) emission. This funding comes as a strong recognition of the work Fairbrics has accomplished so far, the quality of the consortium we brought together, and the extraordinary potential of our technology to provide highly polluting industries like textile with an alternate environment-friendly and economically viable solution,” said Benoît Illy, Cofounder and CEO of Fairbrics. CO2-Based-Polyester – rPET

Today, polyester accounts for 60% of all textiles produced worldwide and a third of the fashion industry’s GHG emission. By replacing fossil fuel sources by CO2-based sources, Fairbrics provides a sustainable and scalable solution to energy intensive industries. Fairbrics will initially address the fashion industry and has already secured strategic partnerships with major brands such as H&M, On-Running and Aigle. It intends to progressively diversify its technology platform with solutions addressing other sectors such as sports equipment, packaging and automotive.

About Fairbrics

Fairbrics is sustainable chemical company founded in 2019 and based in Paris (France). It has developed a disruptive patented technology platform that converts CO2 emissions into high value polyester fibers, providing energy intensive industries with environment-friendly and economically viable solutions. Fairbrics’ mission is to fight climate change by developing circular manufacturing process. Its technology has been demonstrated at lab-scale. Fairbrics has successfully secured partnerships with major fashion brands such as H&M, On-Running and Aigle. Next to clothing, the company intends to progressively deploy its technology to address other industries that employ polyester as their main material such as automotive and packaging. Fairbrics won several national and international innovation awards: Citeo Circular Challenge, French Tech Green20, I-Nov, Cleantech Open France, H&M Foundation’s Global Challenge Award. For more information: www.fairbrics.co

-EU’s international trade deficit in goods reaches €20.7 bn in Nov ’22

European Union (EU) recorded €20.7 billion deficit in trade in goods with the rest of the world in November 2022, compared with minus €10.7 billion in November 2021, according to Eurostat. The first estimate for extra-EU exports of goods in November 2022 was €237.3 billion, up by 17.7 per cent compared with November 2021 (€201.6 billion).

EU’s imports from the rest of the world stood at €258 billion, up by 21.5 per cent compared with November 2021 (€212.3 billion). CO2-Based-Polyester – rPET

The first estimate for euro area’s exports of goods to the rest of the world in November 2022 was €264.7 billion, an increase of 17.2 per cent year-on-year (€225.9 billion). Imports from the rest of the world stood at €276.3 billion, a rise of 20.2 per cent compared with November 2021 (€229.8 billion). As a result, the euro area recorded a €11.7 billion deficit in trade in goods with the rest of the world in November 2022, compared with a deficit of €3.9 billion in the corresponding period of the previous year. Intra-euro area trade rose to €241.5 billion in November 2022, up by 16.8 per cent compared with November 2021, as per Eurostat.

In January to November 2022, extra-EU exports of goods rose to €2 352.8 billion (an increase of 18.7 per cent compared with January-November 2021), and imports rose to €2 771.1 billion (an increase of 44.8 per cent compared with January-November 2021). As a result, the EU recorded a deficit of €418.4 billion, compared with a surplus of €69.5 billion in January-November 2021. Intra-EU trade rose to €3 889.3 billion in January-November 2022, up by 23.8 per cent year-on-year (YoY).

In January to November 2022, euro area exports of goods to the rest of the world rose to €2 638.4 billion (an increase of 18.9 per cent YoY), and imports rose to €2 943.4 billion (an increase of 40.5 per cent compared with January-November 2021). As a result, the euro area recorded a deficit of €305.1 billion, compared with a surplus of €125 billion in January-November 2021. Intra-euro area trade rose to €2 506.7 billion in January-November 2022, up by 25.5 per cent YoY. CO2-Based-Polyester – rPET

In November 2022, compared with November 2021, all the member states registered increases in extra-EU exports except Estonia (minus 13.2 per cent), and Cyprus (minus 10.6 per cent). The highest increases were registered in Slovenia (61.1 per cent), Bulgaria (53.4 per cent), and Malta (50.6 per cent).

With regard to the extra-EU imports, all member states registered increases, except Estonia (minus 14.9 per cent), Cyprus (minus 13.8 per cent), and Latvia (minus 2.1 per cent) who registered a decrease. The highest increases were observed in Hungary (74 per cent) and Greece (40.9 per cent).

-The Recognition Of The Mass Balance Chain Of Custody Is Key To Accelerating Chemical Recycling And Meeting The EU’s Climate And Circularity Targets

The EU’s Single-Use Plastics Directive and the proposal for a revised Packaging and Packaging Waste Regulation set out recycling targets for used packaging in order to reduce packaging waste and promote the use of recycled content in new packaging. In particular, the European Commission’s proposal for the Packaging and Packaging Waste Regulation stipulates that at least 50% of all plastic waste in the EU be recycled by 2025.

The EU chemical industry supports a broad EU action to tackle waste and accelerate recycling. Where recycled content targets are concerned, chemical recycling technologies developed by the industry are a viable option to curb plastic waste and can complement mechanical recycling. CO2-Based-Polyester – rPET

For the chemical recycling rates to accelerate in the EU, industry needs to invest more in chemical recycling facilities. For the investments to take off, clarity about the use of a mass balance chain of custody method to calculate the recycled content of plastics in products is required. Unfortunately, the current Commission proposal does not provide enough clarity on the use of this method which can hamper further progress of chemical recycling.

Why is Mass Balance important?

The mass balance methodology is needed to allow for a smooth and rapid transition to leverage recycled feedstocks in existing infrastructure, together with the virgin fossil sourced feedstock. As the two different feedstocks cannot be physically separated once they are co-fed into the complex large-scale installations, the mass balance methodology is required to accurately calculate and verify the amount of recycled content allocated to products.

It is important to be able to leverage existing infrastructure to allow co-feeding of the recycled feedstock, replacing part of the fossil-sourced feedstock. It would be counterproductive to build an entirely new stand-alone infrastructure for producing plastics solely from recycled waste.

Mass balance is a well-known “chain of custody” model, as defined in ISO standard 22095, already used in other sectors, such as biofuels, fairtrade cacao and coffee. It tracks a specific characteristic, in this case recycled materials co-processed with virgin materials in existing assets, and guarantees that the recycled content is appropriately allocated to products. Mass balance will help ensure that recycled feedstock progressively replaces more and more fossil-based virgin materials in the production of plastics and a broad range of chemicals and products in Europe. CO2-Based-Polyester – rPET

As explained by Annick Meerschman, Cefic Innovation Director:

“84% of all plastics produced annually in the EU does not find its way back into new products . Substantial amounts of plastic are still landfilled, incinerated or exported. In this context, innovation and complementary recycling technologies and business models are needed to transition from a linear economy towards a sustainable circular economy. This need calls for rapid scale-up of both mechanical and chemical recycling technologies.”

Since one of the main barriers to scale-up chemical recycling technologies is uncertainty about the method for calculating the recycled content of plastics,

“we need EU rules to support chemical recycling as a complementary solution to mechanical recycling, to pull investments into this technology and help the EU meet targets for more recycled content. We also need a clear mass balance method as a key enabler of this process, if we want to meet EU’s climate and circularity targets in time”, continued Meerschman. CO2-Based-Polyester – rPET

-ESG Shows Ways from Pollution to Solution to Recycled Plastic Companies: Astra ESG Solutions

The growing spotlight on the environmental, social and governance (ESG) framework has prompted the recycled plastic industry players to foster their sustainability portfolio. Stakeholders are positioning themselves to connect brands with environmentally friendly plastic. In essence, recycling companies are gearing up to minimize waste and seek innovative ways to combat carbon emissions. Amidst the global push to eradicate pollution, packaging has garnered huge headlines. UNEP notes that global plastic production is pegged at 400 million tons per year. Besides, merely 9% of this is recycled and 12% is incinerated. Accordingly, in March 2022, the U.N. member states endorsed a resolution to beat plastic pollution and create an international legally binding agreement by 2024. Sustainable and affordable options for recycled products have gained ground, furthering the need for ESG frameworks globally. CO2-Based-Polyester – rPET

Public policy could be instrumental in overcoming plastic packaging pollution. The ubiquitous nature of plastic has put pressure on regulators and investors to find solutions for pollution across sectors, including retail, manufacturing, industrial, and electronics. According to Greenpeace, supermarkets in the U.K. emit 800,000 tons of plastic packaging per year, while the government is committed to ensuring all plastic packaging is reusable, recyclable or compostable by 2025. Meanwhile, in May 2022, legislators in New York proposed two bills to enhance plastic recycling rates. It would need producers to eliminate toxic chemicals from packaging, minimize packaging and pay for recycling and disposal costs.

Veolia Bolsters Environmental Profile to Navigate Growth Potentials

Concerted efforts from manufacturers and suppliers to combat pollution have led to the demand for recycled products and services. The shifting trend toward recycled products is expected to foster the environmental profile. Companies upgrading technologies to reduce environmental impacts could be the new normal. Veolia asserted in its Integrated Report 2021-2022 that around 476 thousand metric tons of plastic were recycled in its transformation plants in 2021. The company has acquired a host of end technologies to recycle plastic and equipment for biological, material and energy processing. It expects around 610,000 metric tons of recycled plastic to leave its processing plants by 2023.

With China and countries from Europe and North American Free Trade Agreement (NAFTA) witnessing a surge in plastic production, stakeholders are poised to boost their efforts to eliminate waste from the environment. CO2-Based-Polyester – rPET

Leading players are likely to use polyethylene (HDPE or LDPE)—in packaging or construction—and polypropylene (PP)—in household appliances, furniture, automotive and construction. In October 2022, Veolia rolled out PlastiLoop which will help customers source recycled plastics with a host of polymers. The France-based company has been offering high-performance ready-to-use recycled resins, including HDPE, PP, PET, LDPE and PS.

PureCycle Emphasizes Social Performance

Well-established players are positioning themselves to connect brands with sustainable and high-quality products and complement social responsibilities. Recycling technology companies are prioritizing workplace safety, diversity and training & development, recruiting & hiring, discipline, compensation & benefits. To illustrate, PureCycle has a Diversity & Inclusion Policy in place to foster non-discrimination, equal employment opportunity and diversity and inclusion, among others. The company alluded to a low turnover as low as 7.5% in 2021. It has also put forth risk management systems and formed policies to help reduce possible accidents, such as team member and visitor safety protocols, a code of business conduct and ethics, guidelines for management systems and operational excellence policy. CO2-Based-Polyester – rPET

Moreover, the company is slated to establish a recruiting and employee engagement program to reinforce a resilient workforce.

Investors, manufacturers and other stakeholders have underscored the importance of workers’ safety. Prominently Shell inferred that over 100,000 employees and contractors completed compulsory training on the Life-Saving Rules that came into effect from January 2022. It is also committed to its Shell Supplier Principles and expects contractors and suppliers to offer a dedicated whistle-blowing mechanism where grievances pertaining to labor and human rights, Health, Safety, Security, Environment (HSSE) & Social Performance (SP) and business integrity are recorded anonymously.

Dow Invests in Corporate Governance Structure

Stakeholders have depicted profound inclination to enhance governance, accountability and transparency. In doing so, industry players are likely to maintain a board with diverse backgrounds, design compensation programs and ensure a culture of integrity. According to Dow’s 2021 ESG report, 5 new members of its board have been women or U.S. ethnic minorities in the last 3 years.

It has also set comprehensive ESG disclosures in line with GHG Protocol, GRI, TCFD, WEF and SASB. In its 2021 report, the company alluded to meeting the 2017 commitment to fully implement the TCFD recommendation. CO2-Based-Polyester – rPET

Get more insights about how key industry participants like REMONDIS SE & Co. KG, Biffa, Stericycle, Republic Services, Inc., WM Intellectual Property Holdings, LLC, and Veolia are identifying, analyzing, and mitigating ESG risks and ensuring compliance

All board committees—audit committee; compensation and leadership development committee; corporate governance committee and Environment, Health, Safety & Technology (EHS&T) Committee— comprise independent directors. The board and its committees underscored ESG transparency and accountability with the first integrated ESG report in 2021. Furthermore, the company noted in its second annual ESG report released in June 2022 that it took a giant stride with enhanced carbon emissions reporting and climate risk disclosures and greenhouse gas intensity metrics.

Corporate governance, with the focus on recycling technologies, has become the mainstay for board members and stakeholders to remain ahead of the curve. In the last two years, Dow has reportedly infused around USD 50 million into recycling infrastructure, impact funds and major technologies to transform waste into solutions. Moreover, in June 2022, it revealed a slew of partnerships in plastics recycling, including the collaboration with Mura Technology. It will help eliminate plastic pollution with the construction of advanced recycling facilities. Mura’s first plant using the technology could begin in 2023 in England.

Is your business one of participants to the Global Recycled Plastic Industry? Contact us for focused consultation around ESG Investing, and help you build sustainable business practices.

At a time when environmental, social and governance frameworks could propel customer-centric, innovative and sustainable, stakeholders could inject funds into organic and inorganic strategies. CO2-Based-Polyester – rPET

For instance, in January 2022, SCG Chemicals announced a collaboration with Shell to introduce eco-friendly lubricant bottles. The packaging reportedly recycles household plastic waste complying with ESG and the UN Sustainable Development Goals. Grand View Research anticipates the global recycled plastic market to depict around 4.8% CAGR by 2030. Industry leaders are expected to underpin their efforts to minimize GHG emissions, prevent plastic waste and provide recycled plastic products.

Key Benefits of the Recycled Plastic Industry ESG Thematic Report

- Developing a comprehensive understanding of macro-economic, Policies & Regulations and innovations affecting the Recycled Plastic space, globally

- Key insights into environmental developments and ESG issues affecting the theme

- Identifying ESG risks and opportunities to business among leading players in the Recycled Plastic

- Obtaining a clear and relevant understanding of company actions, progress, and impact and find opportunities for investment into the sector

Browse more ESG Thematic Reports from the Materials Sector, published by Astra – ESG Solutions

About Astra – ESG Solutions By Grand View Research

Astra is the Environmental, Social, and Governance (ESG) arm of Grand View Research Inc. – a global market research publishing & management consulting firm.

Astra offers comprehensive ESG thematic assessment & scores across diverse impact & socially responsible investment topics, including both public and private companies along with intuitive dashboards. CO2-Based-Polyester – rPET

Our ESG solutions are powered by robust fundamental & alternative information. Astra specializes in consulting services that equip corporates and the investment community with the in-depth ESG research and actionable insight they need to support their bottom lines and their values. We have supported our clients across diverse ESG consulting projects & advisory services, including climate strategies & assessment, ESG benchmarking, stakeholder engagement programs, active ownership, developing ESG investment strategies, ESG data services, build corporate sustainability reports. Astra team includes a pool of industry experts and ESG enthusiasts who possess extensive end-end ESG research and consulting experience at a global level.

For more ESG Thematic reports, please visit Astra ESG Solutions, powered by Grand View Research

Need expert consultation around identifying, analyzing and creating a plan to mitigate ESG risks related to your business? Share your concerns and queries, we can help!

Contact:

Michelle

Sales Specialist, USA

Astra ESG Solutions – Powered by Grand View Research, Inc.

Phone: 1-415-349-0058

Toll Free: 1-888-202-9519

Web: https://astra.grandviewresearch.com/

Email: astra.esg@grandviewesearch.com

LinkedIn: https://www.linkedin.com/company/astra-esg-solutions/

SOURCE Astra ESG Solutions

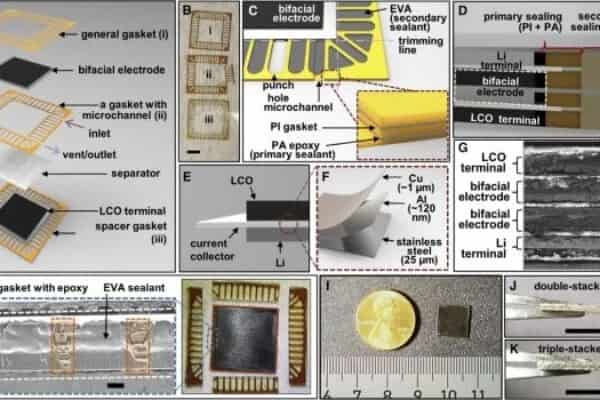

-Packaging boost for high voltage microbattery

Researchers at the University of Illinois Urbana-Champaign have created a high-voltage 9V lithium microbattery with a unique packaging design.

The battery is hermetically sealed to prevent exposure to ambient air in single-, double-, and triple-stacked configurations with high operating voltages, high power densities, and energy densities. CO2-Based-Polyester – rPET

“We need powerful tiny batteries to unlock the full potential of microscale devices, by improving the electrode architectures and coming up with innovative battery designs,” said Paul Braun, Material Science and Engineering Professor at the University.

The problem, say the researchers, is that as batteries become smaller, the packaging dominates the battery volume and mass while the electrode area becomes smaller. This results in drastic reductions in energy and power of the battery.

The researchers developed novel packaging technology that used the positive and negative terminal current collectors as part of the packaging itself rather than a separate entity. This allowed for the compact volume (= 0.165 cm3) and low package mass fraction (10.2%) of the batteries. In addition, they vertically stacked the electrode cells in series (so the voltage of each cell adds), which enabled the high operating voltage of the battery.

Another way they improved the microbatteries was by using very dense electrodes, which offers energy density. Normal electrodes are almost 40% by volume occupied by polymers and carbon additives (not active materials). The researchers have grown electrodes by an intermediate temperature direct electrodeposition technique that are fully dense and without polymer and carbon additives. CO2-Based-Polyester – rPET

These fully dense electrodes offer more volumetric energy density than their commercial counterparts. The microbatteries were fabricated using the dense electroplated DirectPlate LiCoO2 electrodes manufactured by Xerion Advanced Battery Corporation (XABC, Dayton, Ohio), a company that spun out of Braun’s research.

“To date,” says Arghya Patra, graduate student, MatSE, MRL, and co-first author of a paper on the research, “electrode architectures and cell designs at the micro-nano scale have been limited to power dense designs that came at the cost of porosity and volumetric energy density. Our work has been successful to create a microscale energy source that exhibits both high power density and volumetric energy density.”

An important application space of these microbatteries, say the researchers, includes powering insect-size microrobots to obtain valuable information during natural disasters, search and rescue missions, and in hazardous environments where direct human access is impossible.

“The high voltage is important for reducing the electronic payload that a microrobot needs to carry,” says co-author James Pikul (Assistant Professor, Department of Mechanical Engineering and Applied Mechanics, University of Pennsylvania). “9 V can directly power motors and reduce the energy loss associated with boosting the voltage to the hundreds or thousands of volts needed from some actuators.

This means that these batteries enable system level improvements beyond their energy density enhancement so that the small robots can travel farther or send more critical information to human operators.” CO2-Based-Polyester – rPET

Dr. Sungbong Kim (Postdoc, MatSE, current assistant professor at Korea Military Academy, co-first author) adds, “Our work bridges the knowledge gap at the intersection of materials chemistry, unique materials manufacturing requirements for energy dense planar microbattery configurations, and applied nano-microelectronics that require a high-voltage, on-board type power source to drive microactuators and micromotors.”

Their current microbattery design, say the researchers, is well-suited for high-energy, high-power, high-voltage, single-discharge applications. Their next step is to translate the design to all solid-state microbattery platforms, batteries that would inherently be safer and more energy dense than liquid-cell counterparts.

Serially integrated high-voltage and high power miniature batteries

-Plastic recycling in Poland

According to a recent study conducted on 120 companies in the sector, the market would be undersized compared to its potential.

According to a study conducted by the Polish magazine Plastics Review, the plastics recycling turnover in the country is estimated at 613 million euros, a low value which suggests good growth opportunities for the future, considering the importance of plastics in the Polish economy. CO2-Based-Polyester – rPET

Just think that the sales of recycled plastics grew by almost 50% in 2021 compared to the previous year.

About 150 recycling companies operate in the country, with an average turnover estimated in 2021 at 220 thousand euros a year.

Overall, around 400 thousand tons of plastic waste were recycled in the country. “There is a great future for plastics recycling in Poland – says Waldemar Sobanski, editor-in-chief of Plastics Review -.

The inflow of capital will contribute to the rapid implementation of modern technologies, which should lead to rapid business development. notice, plastic recycling is one of the most attractive investment directions for the Polish economy in the coming years”.

The study published by the Polish magazine was conducted on the financial results of over 120 plastics recyclers active in Poland, on the basis of which a ranking of the top 77 companies in the sector was compiled.

CO2-Based-Polyester – rPET