CO2 capture – Composites continue to face challenges in Europe, marked by a notable downturn last year despite global expansion 25-03-2024

CO2 capture

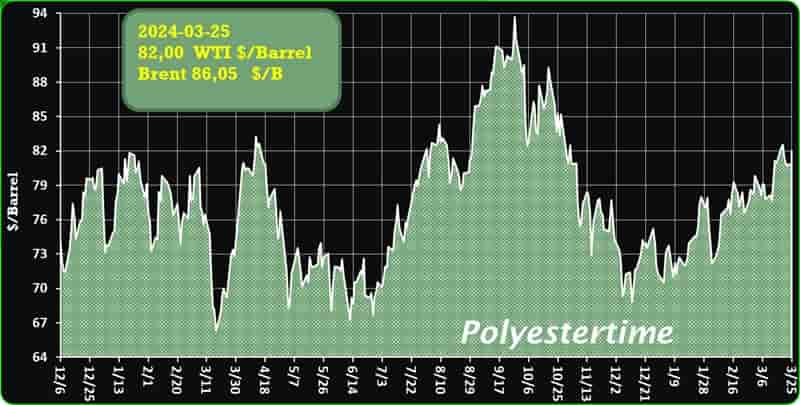

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Nylon price trend – Eastman proudly announces the successful initiation of on-spec production and revenue generation at its new molecular recycling facility in Kingsport, Tennessee

Composites continue to face challenges in Europe, marked by a notable downturn last year despite global expansion

As per a recent AVK association report, 2023 witnessed a significant 8% decline in the production of polymer matrix fibre-reinforced and composite materials in Europe, in stark contrast to the 5% global market growth.

This downward trajectory, which commenced in 2018, is influenced by uncertainties and macroeconomic factors such as escalating raw material and energy expenses.

Despite a rebound in the automotive sector, a major consumer of these materials, it has yet to reach pre-pandemic levels. CO2 capture

Additionally, the crisis in the European construction and large infrastructure sector has contributed to the production contraction.

Globally, the composites market expanded to 13 million tons last year, up from 12.3 million tons the year prior.

In Europe, however, production dwindled from 2.78 to 2.56 million tonnes, reflecting an 8% decrease following a 6% decline in 2022.

Thermosets accounted for 1,073,000 tonnes, down from the previous year’s 1,138,000 tonnes, comprising 43% of Europe’s composite production. CO2 capture

Currently, European production constitutes approximately 20% of the global output, with America and Asia holding 30% and 50% respectively.

The automotive sector remains the largest consumer of composites, followed by electrical/electronic and construction and infrastructure industries. For more comprehensive market data, please refer to the report.

CarpeCarbon, an Italian initiative aiming to capture CO2, stands apart in the quest to curb climate change

The latest IPCC report underscores the urgency of reducing atmospheric CO2 to limit global warming to +1.5°C. CarpeCarbon, headquartered in Turin, is pioneering Italy’s first direct carbon capture plant, driven by the conviction that solely halting emissions is insufficient.

Traditional Direct Air Capture (DAC) technologies face hurdles akin to electric cars, namely, energy-intensive operations and reliance on critical minerals, rendering them unsustainable. In contrast, CarpeCarbon adopts an innovative approach emphasizing scalability and energy efficiency. CO2 capture

By leveraging renewable energy and eschewing harmful chemicals, CarpeCarbon significantly reduces costs and environmental impact.

Moreover, the company ensures supply chain resilience by sidestepping critical raw materials. Their method involves filtering air to trap CO2 emitted from fossil fuel combustion, resulting in negative emissions.

CarpeCarbon’s uniqueness has garnered recognition, securing funding exceeding 1.7 million euros from Tech4Planet initiative, Cdp Venture Capital, 360 Capital, and other backers. This financial boost will aid in establishing Italy’s first DAC system.

Additionally, CarpeCarbon explores diverse industrial applications for captured CO2, aligning with UN SDG 12 for a circular economy. CO2 capture

CEO Giuliano Antoniciello envisions a future where their plant operates off-grid, decoupling CO2 removal from energy production. This approach, distinct from Carbon Capture and Storage (CCS), enables capturing existing atmospheric CO2, not just new emissions.

As global emissions soar, CarpeCarbon emerges as a beacon of hope, poised to address climate challenges. With 2024 potentially marking a pivotal year for the startup, the world anticipates their contributions to a sustainable future.