Electric vehicles

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Thyssenkrupp Uhde has secured a basic engineering package and front-end engineering design package for the establishment of a biopolymer plant on the Arabian Peninsula, said Hydrocarbonprocessing.

The plant is intended to produce an industrial large-scale volume of polylactic acid polymer, utilizing lactic acid from corn as the primary feedstock. While polymer specialist Uhde Inventa-Fischer will perform the BEP for the PLA production based on its proprietary state-of-the-art technology, its sister company thyssenkrupp Uhde India will perform the FEED which covers the complete production complex including associated offsite and utilities.

The design of the biopolymer plant focuses on stringently optimized feedstock utilization during all stages: from starch conversion to lactic acid production, and finally polylactic acid production. Electric vehicles

An integral aspect of this project is the plant’s ability to sustainably produce a range of PLA grades, addressing the diverse requirements of various industries such as packaging, textiles, and hygiene supplies.

“Replacing fossil feedstocks with renewable ones can minimize the ecological impact of entire value chains,” stated Dr. Cord Landsmann, CEO thyssenkrupp Uhde. “This project is another proof that we can significantly contribute to a more sustainable production of much-needed materials for global key industries.”

Harald Kroll, CEO Gulf Biopolymers Industries: “We are proud to announce the establishment of the first large biopolymer plant in the MENA region. This project is a milestone for the reduction of fossil-based plastics and advancing the adoption of environmentally friendly PLA polymers.”Electric vehicles

More…

Toyota, new battery and fuel cell electric vehicles

At the Kenshiki 2023 event by Toyota Motor Europe, a cadre of global and European executives took center stage to unveil the automotive giant’s cutting-edge electrified products and technologies.

Chief Branding Officer and Head of Design at Toyota Motor Corporation, Simon Humphries, divulged a series of concept models poised to shape the next era of battery electric vehicles (BEVs) under the banners of Lexus and Toyota.

The key highlight was the introduction of a revolutionary modular design architecture, integrating gigacast chassis, component minimization, and the innovative Arena operating system.Electric vehicles

Humphries emphasized that this design framework not only facilitates enhanced design freedom but also elevates the overall user experience.

Toyota’s commitment to sustainability was underscored by the announcement of their goal to achieve complete carbon neutrality in Europe by 2040. In tandem, they aim to attain SBTi Scope 1 and 2 emissions neutrality in European operations and production facilities by 2030.

With a focus on Scope 3 emissions, Toyota sets ambitious targets, including a 100% reduction in CO2 emissions from new vehicle sales by 2035 and complete carbon neutrality across the value chain and logistics by 2040. The company is already making strides in this direction by incorporating hydrogen fuel cell electric heavy-duty trucks on crucial logistics routes. Electric vehicles

Toyota’s vision extends beyond battery electric vehicles, encompassing a robust hydrogen strategy. The Mirai and the new Crown spearhead their passenger car segment, while TME’s Hydrogen Factory Europe integrates fuel cell technology into a diverse array of commercial vehicles, including heavy goods vehicles, buses, coaches, boats, and pickups. The unveiling of the hydrogen fuel cell Hilux prototype at Kenshiki exemplifies this commitment.

In a nod to the future, Toyota plans to refine hydrogen technology further with the launch of its third generation fuel cell systems in 2026.

The Toyota Professional light commercial vehicle range is expanded with the addition of the Proace Max, a large van available in multiple configurations, offering customers versatility. Like its counterparts, the Proace Max is available with a battery electric powertrain, boasting an impressive range of 420 km (WLTP) and providing access to zero-emission zones.Electric vehicles

Completing the Toyota Professional fleet is the Hilux, a stalwart in Toyota’s commercial lineup, set to receive a boost with the introduction of a 48-volt hybrid system in the coming year.

This hybrid system promises increased power and torque, coupled with a 10% improvement in efficiency, solidifying Toyota’s commitment to innovation across its entire commercial vehicle spectrum.

Innovative bio-based aromatics pave the way for 100% sustainable aviation fuel

Iain Gilmore, Senior Manager, Catalyst Technologies, Johnson Matthey, and David Kettner, President and General Counsel of Virent, shed light on a groundbreaking development. This advancement, a collaborative effort between Johnson Matthey and Virent, the inventor of the technology, introduces bio-based aromatics as a key component in a 100% sustainable aviation fuel (SAF) that is cleaner-burning, more efficient, and compatible with existing aviation fleets and infrastructure. Electric vehicles

The aviation industry is actively seeking solutions to curb emissions, and SAF emerges as a leading option. However, the effectiveness of SAF varies, with many available forms only permitting limited emission reductions due to blending constraints.

The term ‘SAF’ can be misleading, as it is applied to many synthetic fuels with a carbon intensity below a certain threshold in relation to conventional jet fuel, as defined by various policies and international agreements. This results in a range of fuel blends that sit under the SAF umbrella, which contain varying proportions of synthetic components, most of which are not 100% SAF.

Presently, SAF is typically blended with varying percentages of conventional jet fuel, producing varying qualities of fuel to meet the criteria of international standards, specifically to ensure it contains aromatics in the range of 8-25%. Aromatics are an important component of the fuel as, among other benefits, they enhance lubricity, lower freeze point, and interact with polymer seals in the engines and fuelling systems to help prevent fuel leakage. Electric vehicles

Traditional jet fuel naturally contains aromatics but many bio-based fuels, such as Hydroprocessed Esters and Fatty Acids (HEFA) and Fischer Tropsch (FT) products, do not. This restricts their use to a maximum blend of 50% with conventional jet fuel, which, in turn, limits emission reductions and falls short of meeting international aviation emission targets for 2030 and 2050.

More…

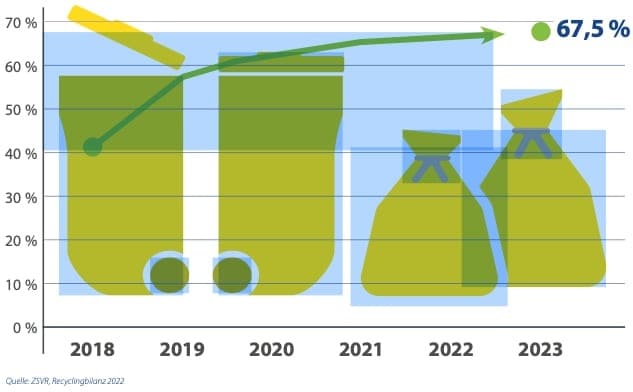

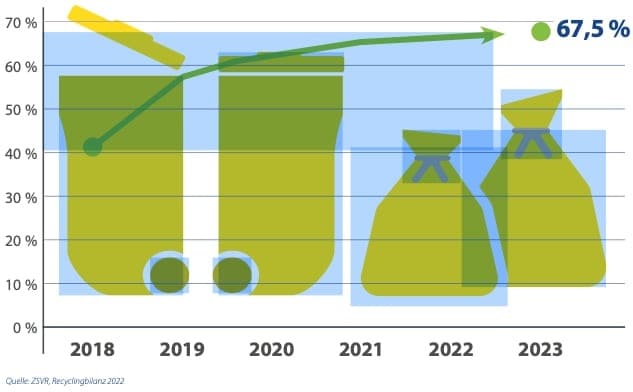

Germany’s plastic recycling rate breaks records in 2022

The recycling of plastic packaging is on the rise in Germany, experiencing a remarkable 20% increase in just four years, reaching 67.5% of the total introduced to the market in 2022. According to the industry association IK Industrievereinigung Kunststoffverpackungen, the recycling of plastic packaging in Germany reached 67.5% of the total introduced to the market last year, amounting to 1.54 million tons (a slight decrease compared to the previous year)Electric vehicles

The data, provided by German authorities (Central Packaging Registry ZSVR and Federal Environment Agency UBA), surpasses the 2022 target of 63% set by the packaging law enacted in 2019 and represents an unprecedented achievement. In the last four years alone, since the regulations came into effect, the recycling rate has surged by twenty percentage points.

Isabell Schmidt, the director of IK, emphasizes, “The growing recycling of plastic packaging is a great success. Now it is important to further solidify this positive development and shield it from undesired trends. Reducing plastic in the direction of composite packaging does not contribute to achieving the goal. Recyclability and material savings must be a priority in packaging design. We cannot tolerate false arguments and greenwashing.”Electric vehicles

According to the association of plastic packaging manufacturers, ZSVR and UBA have repeatedly criticized the significant increase in composite paper-based packaging entering the market, as they are more challenging to recycle. IK asserts that almost half of the recyclable packaging with less than 90% recyclability is of a composite nature.

“Discriminatory goals for plastic, as envisaged by the European packaging regulation, as well as exceptions to recycled content quotas, could further reinforce the trend towards composite packaging, even if not explicitly intended.”

Enabled by foam forming technology, VTT’s formable cellulose-based webs with 30% extensibility were used to make rigid packages using an industrial product packaging line. This opens up the manufacturing of a wide range of sustainable packaging solutions.

In a pilot-scale study to find alternative raw materials for rigid plastic packages, VTT Technical Research Centre of Finland has obtained unprecedented maximum limits of its highly extensible formable cellulose-based webs used for rigid packaging applications. The results enable the manufacturing of a wide range of sustainable 3D packaging solutions that were previously unattainable.Electric vehicles

Typical commercial boards have between 3–6% extensibility (geometrical mean) and best commercial formable boards have 10–18% extensibility. By utilising foam forming technology, VTT has now obtained up to 30% extensibility. This enables brand owners to use rigid, cardboard-like packaging to serve consumers looking to buy more sustainable products. This material improvement enables e.g. food brands producing cold cuts to increase cardboard-like package size from 75 grams up to 200-250 grams. By adjusting the tray forming process and tray dimensions even larger cardboard-like packages can be produced.

“Polypropylene film is one of the world’s most used polymers – its extensibility is up to 300%. Our invention now offers a viable, sustainable alternative on the market,” says Jarmo Kouko, Research Team Leader at VTT. Electric vehicles

“There’s been a lot of great academic research around the world on how to eliminate plastics, but the challenge is that those seldom go beyond research. So, we’re extremely excited and proud of the results we’ve produced in our pilot-scale study, which clearly shows the commercial potential of our rigid cellulose-based packaging. packaging give suppliers a sustainable and affordable alternative to single-use plastic.

More…

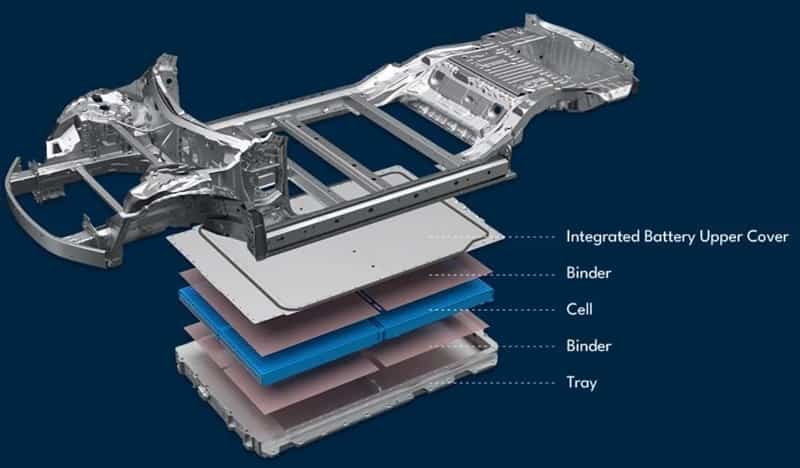

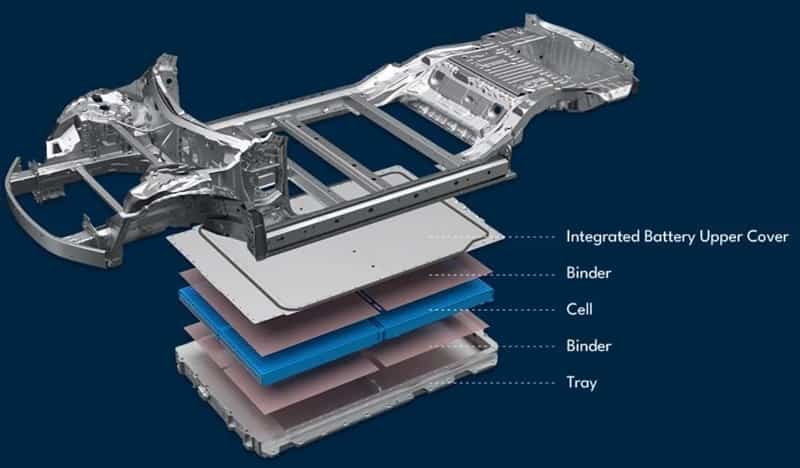

Evolution of Battery Architecture: From Modules to Cell-to-Body Integration

Electric vehicles (EVs) have undergone a remarkable transformation in battery technology, moving from modular designs to cell-to-body integration. This concept involves embedding cells directly into the vehicle’s frame, unlike conventional gasoline-powered vehicles that depend on fuel tank size for capacity. EVs’ energy storage is determined by both physical dimensions and factors affecting energy density. Electric vehicles

The development of electric vehicle battery architecture can be traced from the traditional modular structures to the cutting-edge cell-to-body integration.

The chemistry of the cells and their internal architecture are two key factors that influence the energy density of EV batteries. This discussion focuses on the latter, exploring the evolution from established modular designs to the innovative realm of cell-to-body integration.

Lithium-ion batteries adopted a conventional structure with cells, modules, and battery packs. Modular designs, while enabling battery control and temperature management, introduced inactive elements, reducing energy storage efficiency.

The modular approach allowed automakers to adjust battery capacity by adding or removing modules. Electric vehicles

In a recent shift, automakers have adopted the cell-to-pack paradigm, eliminating the intermediate modules. This design integrates individual cells directly into the external casing, increasing energy storage capacity within the same external dimensions. However, these cell-to-pack batteries remain separate components attached to the vehicle’s chassis during manufacturing.

Leading the future, manufacturers like BYD, with its Seal sedan, have introduced a revolutionary structural design – cell-to-body integration. This approach incorporates cell housing directly into the lower part of the vehicle’s frame, eliminating the need for a separate element attached to the chassis. While not increasing the percentage of active material within the battery, similar to the cell-to-pack approach, this innovation simplifies components, minimizes external housing requirements, and enhances the structural integrity and overall efficiency of electric vehicles. The battery becomes an essential part of the vehicle platform, marking a paradigm shift in the electrification of the automotive industry. Electric vehicles

Argentina’s new bioethanol quotas may swamp demand

Argentine bioethanol supply quotas may outstrip demand over the coming years.

The outgoing federal energy department recently awarded 413,100m3/y of new supply quotas of bioethanol for blending with gasoline, known as E12. These will swell the 1.12Mm3/y (million cubic meters per year) in place.

The new facilities or plant expansions that will produce the additional ethanol are due to enter service in 2026 and could require capex of around US$500mn based on current exchange rates. Electric vehicles

But in 2026, the total annual E12 quota of 1.53Mm3/y will outstrip projected demand from refiners of 1.18Mm3, local bioenergy and rail transport consultant Claudio Molina told BNamericas. A mismatch is also projected for 2024-25.

“They’ve awarded more quotas than there is demand,” said Molina, adding that the process lacked transparency and would have future implications.

Molina said: “They’re going to have to arbitrate over a process so that, in a proportional manner, each sells less than the quota they have, because sufficient demand isn’t there. It’s like opening a can of worms.” Electric vehicles

By law, 12% of the finished gasoline blend must be ethanol made from corn or sugarcane.

Outgoing economy minister and former presidential candidate Sergio Massa had planned to raise the proportion to 15%, which would have absorbed the additional output. The increase was opposed by refiners and auto manufacturers, the latter citing the engine-calibration challenges associated with changing the blend. Massa had even pledged a hike to 25% if he had won the presidency.

More…

Biodegradable polymer – Toyota ‘not giving up’ on hydrogen but also ramps up production of battery electric cars 06-12-2023

Electric vehicles