STF Group of Germany and Zimmer America Recycling Solutions announce the sale of a complete STF PET Bottle Recycling Plant in Hilo, Hawaii. The equipment will be installed at Malama One Recycling LLC, Waiakea Water, a supplier of sustainably sourced and packaged premium volcanic water.

The line has an initial capacity of 1.5 metric tons/hour output of flakes. It incorporates a modular design where the output can be increased to 2.5 metric tons/hour in the future.

In addition to PET, HDPE and PP are also recovered to be sold into the recycled material markets. Engineering plastics

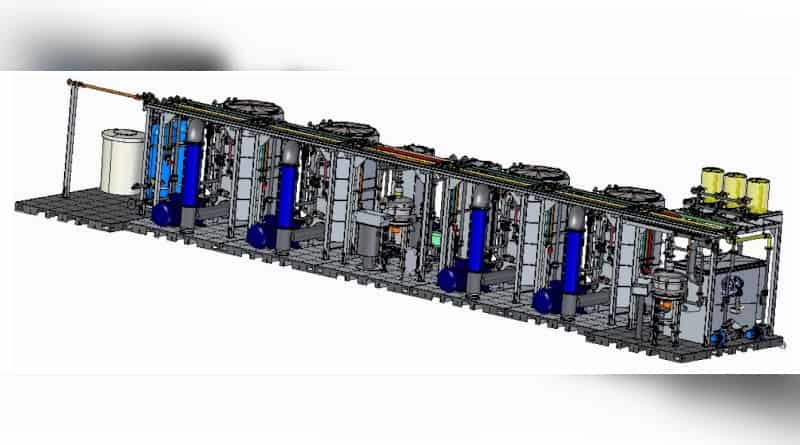

The line consists of machinery and equipment manufactured by STF Group in Germany. The sorting line includes Material Feeding and Conveying Systems, Bale Braker, Dosing Screws, Magnetic Over-Belt Metal Separator, Manual Sorting Station, Label Scraper, and Star Screen. The line also features wide Tomra AutoSort optical bottle sorters with two parallel streams.

The washing equipment includes STF Wet Grinder with Friction Cleaner and Circulation System, Air Stream Separation, Hot-Washers, Sink/Float Separation Stage with Stirring and Separating Containers, Post-Washers, Tomra Flake Sorting, Filling Stations for PET, PO and Labels as well as a Water Treatment System with Decanter, Neutralization Tank and Dosing Station. Engineering plastics

Emerging industries attract foreign investment

Volkswagen Anhui’s MEB plant in Hefei, capital of East China’s Anhui province, is buzzing with activity as more than 1,000 robots engage in the production of new energy vehicles.

Next to the production plant, two supplier parks have been set up, with 18 partners already moving in.

In just two and a half years, Volkswagen has built a new hub in Hefei, covering the complete value chain from research and development to manufacturing, sales and service of NEVs. Engineering plastics

“We are specifically utilizing new technologies and the outstanding infrastructure of Anhui,” said Erwin Gabardi, CEO of Volkswagen Anhui. “We will also benefit from this innovative strength.”

Volkswagen is among several global companies that have consistently increased investments in China’s emerging industries.

As China promotes industrial innovation with technological innovation, more high-quality, high-end, and technologically innovative industries are becoming the new magnet for foreign investment.

Data from the Ministry of Commerce show that the actual use of foreign investment in manufacturing rose 1.9 percent year-on-year to 283.44 billion yuan ($39.84 billion) during the first 10 months, with that in high-tech manufacturing logging an increase of 9.5 percent. Engineering plastics

ngineering plastics

Compostable fishing nets: An end to Ghost Nets in the oceans?

Ghost nets lost from fishing boats become deadly traps for marine wildlife, persisting for centuries. Now a South African/Swedish joint venture aims at ending the problem with compostable fishing nets.

Fishing nets lost at sea are a major source of plastic pollution in the ocean. These so-called “ghost nets” drift globally, ensnaring and killing fish, dolphins, seals, birds, and sea turtles. They can last up to 600 years, releasing microplastics as they slowly degrade.

Now South African initiative Catchgreen, is developing a solution. By creating nets and other gear from compostable Biodolomer, a net lost at sea would degrade into biomass within a few years. They also have a higher density so they will sink to the bottom of the ocean where they cause less harm and are subject to microbes that speed up decomposing. Engineering plastics

– Biodolomer nets will not only reduce ghost fishing,” says Emma Algotsson, project lead at Catchgreen and CEO of Kompost-It. “It will reduce the amount of micro plastics in the ocean. And old nets can be disposed of at industrial composting facilities and turned into biomass.

Biodolomer was invented by packaging material legend Åke Rosén who has been instrumental in developing many materials for Tetra Pak and has over 65 patents to his name. Engineering plastics

Plastic waste – whose responsibility?

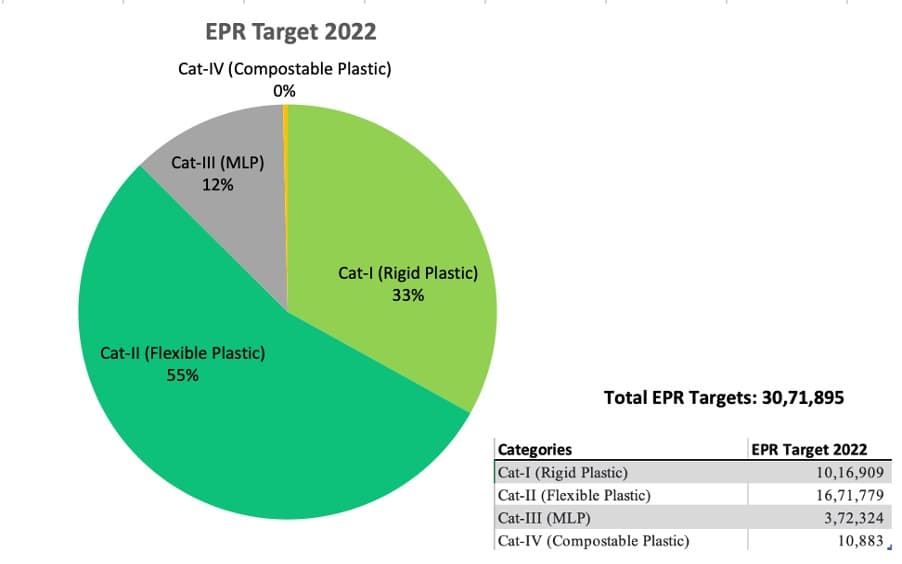

India has opted for the EPR route

In India, the problem of plastic waste is being tackled by an Extended Producer Responsibility system. Under the present EPR system, the Central Pollution Control Board (CPCB) has mandated recyclers to report their plastic packaging recycling data and generate EPR credits for the same. Engineering plastics

It is a policy approach under the Solid Waste Management Rules of 2016, which makes producers responsible for the end-of-life disposal of their products. This means that manufacturers, brand owners, and importers are legally obligated to manage the collection and disposal of their products in an environmentally sound manner. The goal of EPR is to encourage producers to design products that are more environmentally friendly and to take responsibility for the entire life cycle of their products, including their disposal.

OQ’s latest polymer innovations

Headquartered in Oman, OQ stands out for its diverse expertise as an energy transition enabler across various markets. Excelling in polypropylene (PP) and polyethylene (PE), catering to both flexible and rigid packaging solutions, OQ has announced two major product launches designed to solve industry challenges and provide key sustainability benefits.

First is the OQ Luban polypropylene impact copolymer portfolio, introducing Luban EP 2340L, EP 2340P, and EP 2348R, which underwent initial proving in 2022 and are set for a full launch in Q4 2023. These grades, along with the upcoming Luban EP 2348S and EP 2348T are scheduled for launch in the same quarter. These products provide solutions covering a broad range of applications, including thin-walled packaging, appliances, automotive parts, and consumer goods, industrial, containers, crates, batteries, and beyond. Engineering plastics

Alongside this, OQ is also launching Luban LL8446.21 – a new LLDPE Rotomoulding solution. Designed to enable safe, clean, and reliable storage and transportation of water and other liquids, it has multiple applications, including water tanks, chemical containers, pallets, traffic barriers, air conditioning enclosures and refuse bins.

OQ will showcase all its latest polymer portfolio innovations at Arabplast 2023 in Hall 4/C110

Taking Pressure from Supply Shift, The US and Mexico Propylene Prices Surge in December

In the second week of December 2023, the U.S. Propylene market experienced a significant price surge of 8.5%, driven by pivotal shifts in commercial crude oil inventories, a crucial feedstock for Propylene production. The latest U.S. Energy Information Administration (EIA) weekly petroleum status report revealed a notable 4.3-million-barrel decrease in inventories, excluding the Strategic Petroleum Reserve (SPR), between December 1 and December 8. Engineering plastics

This decline directly influenced Propylene prices, reaching the week-ending December 15. U.S. crude oil stocks, excluding the SPR, declined to 440.8 million barrels on December 8, down from 445.0 million barrels on December 1, significantly lower than the December 9, 2022, figure of 424.1 million barrels. SPR crude oil remained steady at 351.9 million barrels on both December 8 and December 1, compared to 382.3 million barrels on December 9, 2022. The broader U.S. petroleum market experienced a 10.0-million-barrel week-on-week decrease and a 2.2% downturn, with total petroleum stocks reported at 1.611 billion barrels on December 8.

Meanwhile, in the Mexican market, Propylene prices observed an 8.4% increase, influenced by expensive Propylene imports from overseas, particularly the USA, where prices rose by 8.5%. Despite this, the Propylene Refinery Grade price remained stable at USD 281 per metric ton. Engineering plastics