Fibre Extrusion Technology – Europe could miss targets due to low plastic recyclate demand, report warns 02-02-2024

Fibre Extrusion Technology

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Europe could miss targets due to low plastic recyclate demand, report warns

According to Plastics Recyclers Europe, the total European installed plastics recycling capacity saw a 7% decline in growth rate year-on-year and reached 12.5 million tonnes in 2022 – potentially putting Europe at risk of missing legislative targets.

Its latest report examines 850 different recycling sites across Europe, many of them small, with an average capacity of 15,000 tonnes. Plastics Recyclers Europe states that the plastics recycling sector consists of over 30,000 workers and generates a turnover of €10.4 billion. Fibre Extrusion Technology

The decrease in growth rate from 17% to 10% year-on-year is attributed to heavy market disruptions that the European market has been facing since 2020.

“Progress is indispensable for ensuring the viability of the plastics recycling industry,” said Ton Emans, president at Plastics Recyclers Europe. “While the commitment from recyclers remains strong, our sector has faced unprecedented challenges, first with the halt of activities during the COVID-19 outbreak, followed by the energy crisis in 2022.

“Most recently, in 2023, the concerningly low demand for recyclates hit the sector, resulting from low prices for virgin plastics due to reduced industrial production in the EU and cheap imports of recycled plastic from outside the EU. Fibre Extrusion Technology

Moving forward, enforcement of legislative measures will be essential in ensuring the progress can be continued.”

This report is Plastics Recyclers Europe’s first to distinguish between polyethylene and polypropylene, which were previously combined into a single figure.

Arkema, a pioneering force in specialty materials, is at the forefront of innovation with the introduction of the groundbreaking Foranext® Gaseous Thermal Barrier (GTB) line

This revolutionary material is specifically designed to enhance the safety of electric vehicle (EV) batteries by preventing the propagation of thermal runaway, a key factor in battery fires.

The Foranext® GTB represents a paradigm shift in EV battery safety, addressing the critical need for preventive measures at the origin of battery fires. As the industry strives to advance EV technology, Arkema’s commitment to safety is evident in this first-of-its-kind solution. Fibre Extrusion Technology

In parallel, Arkema achieves a significant milestone in the decarbonization of its acrylic production chain. The company proudly announces the attainment of ISCC+ certification for its acrylic acid and ester production facility in Taixing, Jiangsu Province, China. This certification underscores Arkema’s dedication to sustainability and environmental responsibility.

Arkema continues to play a pivotal role in shaping the future of materials and technologies, demonstrating a commitment to safety, innovation, and sustainability across its diverse portfolio. With a track record of leadership in specialty materials, Arkema stands as a driving force in the ongoing evolution of industries towards a safer and more sustainable future. Fibre Extrusion Technology

Heather Tomas, Vice President Polymers Americas at TotalEnergies, proudly announces a groundbreaking achievement as the company successfully produces chemically recycled plastics in the United States

This milestone, realized at the La Porte, Texas polypropylene plant, marks a significant stride towards TotalEnergies’ commitment to meet the increasing global demand for innovative and sustainable plastics. The feedstock, sourced from New Hope Energy’s chemical recycling facility in Tyler, Texas, utilized a patented pyrolysis technology developed in collaboration with Lummus Technology to process mixed plastic waste.

TotalEnergies signed a noteworthy feedstock agreement with New Hope, securing 100,000 tonnes of recycled plastics annually for processing at the La Porte plant. The conversion of New Hope’s feedstock into monomers took place at BASF’s and TotalEnergies’ Petrochemicals (BTP) facility in Port Arthur, Texas. Despite facing a temporary closure due to a fire in September of the previous year, the facility, operating one of the world’s largest steam crackers, resumed operations. Fibre Extrusion Technology

TotalEnergies’ La Porte plant is poised to manufacture ISCC+ certified polymers, catering to diverse applications, including food-grade packaging. This achievement follows TotalEnergies’ successful initiatives in Europe and aligns with their ambitious goal to produce one million tons of circular polymers annually by 2030. Heather Tomas emphasizes this accomplishment as a pivotal step forward in realizing the company’s commitment to sustainability and meeting the evolving needs of the global market.

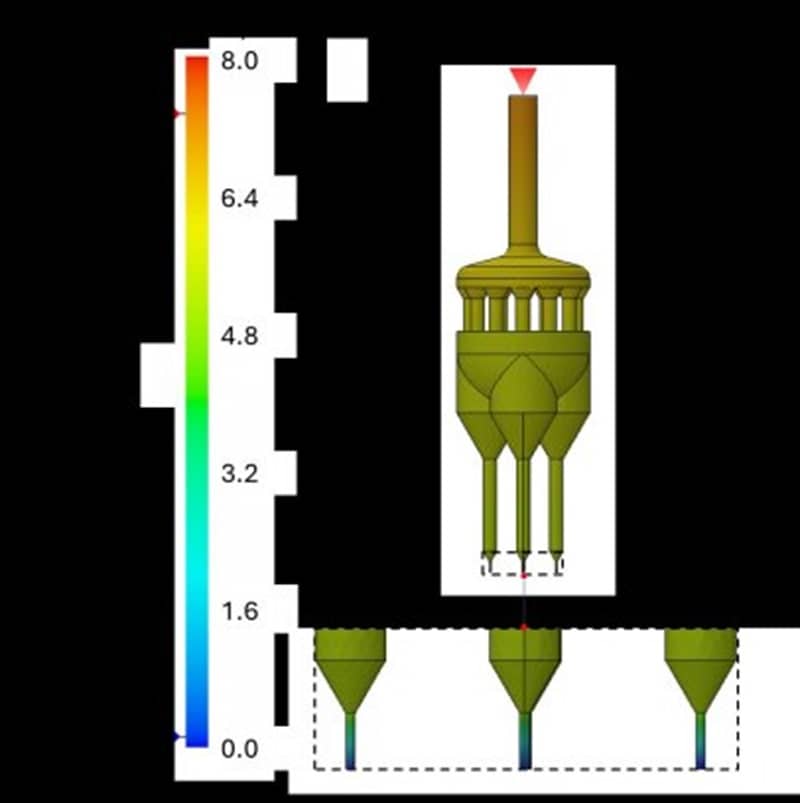

CFD project for improved extrusion

BYD, a major player in the electric car market, has ignited a price war by slashing prices in Germany, a move soon to extend across Europe

This aggressive strategy serves as a direct challenge to industry leader Tesla and other renowned brands. The German electric car market, already in flux due to an early end to government incentives, witnessed a rapid slowdown in domestic demand for new cars. In response, BYD opted for a bold approach, reducing prices by 5% to 15%, intensifying the ongoing rivalry with Tesla. Fibre Extrusion Technology

The battleground expands beyond China, with BYD aiming to conquer European territory. The price cuts on electric vehicles not only signify a tactical response to dwindling state incentives but also a strategic move to fortify BYD’s market presence in Germany and beyond. Despite ambitious expansion plans, BYD’s current sales volumes remain relatively modest, facing stiff competition from European and American counterparts.

BYD’s aggressive pricing strategy includes a 15% reduction for the Atto 3, making it available in Germany at €37,990 for the Comfort trim and €39,990 for the Design edition. With a more modest cut of approximately 8% for the Dolphin and a 5% reduction for the Seal, BYD aims to influence the adoption of electric mobility, presenting consumers with more affordable options. Fibre Extrusion Technology

As BYD seeks to enhance its market share, the impact of these price reductions on electric car registrations, especially in comparison to Tesla, remains to be seen. The electric car landscape is not only characterized by a price war but also reflects important strategic and cultural differences, creating an intriguing dynamic in the rapidly evolving industry.

Coca-Cola is embarking on an innovative environmental initiative with its first UK trial of “label-less” packaging for Sprite and Sprite Zero on-the-go bottles

In a limited trial starting this January, labels on single 500ml bottles will be temporarily removed and replaced with an embossed logo on the front, while laser-engraved product and nutritional information will be featured on the back. This move aims to simplify the recycling process by eliminating the need to separate labels during recycling and reducing overall packaging material usage. Fibre Extrusion Technology

The label-less design will be available for purchase at eight Tesco Express Stores in Brighton and Hove, Bristol, London, and Manchester from January to March 2024. Despite the removal of labels, the clear 100% recycled PET bottles will retain the iconic green and transparent attached caps, distinguishing between regular Sprite and Sprite Zero.

This initiative aligns with Coca-Cola’s ongoing commitment to sustainability, demonstrated through various design changes in recent years. These include transitioning Sprite bottles from green to clear plastic for easier recycling, implementing attached caps to reduce littering, and investing in lightweight bottle designs and streamlined external packaging to minimize environmental impact. As Coca-Cola continues to explore innovative solutions, the label-less trial showcases its dedication to environmentally conscious packaging practices. Fibre Extrusion Technology

Fibre Extrusion Technology