Green hydrogen – Bio Plastic 16-03-2023 - Arhive

Green hydrogen – Bio Plastic

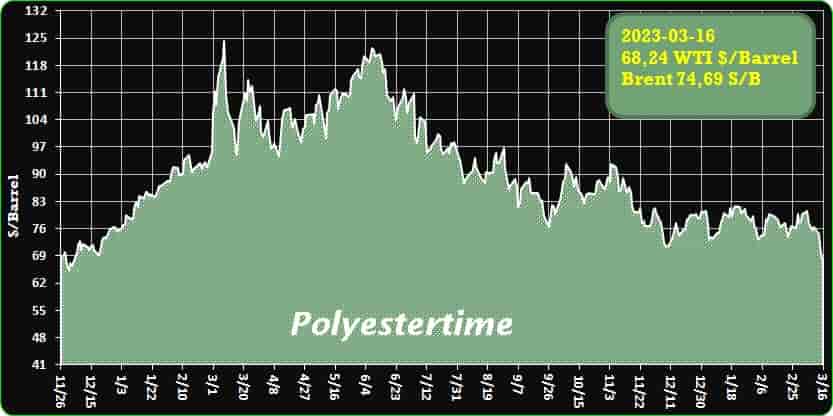

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-Unigel and thyssenkrupp nucera sign Memorandum of Understanding to increase production capacity of green hydrogen plant

Unigel and thyssenkrupp nucera sign Memorandum of Understanding to increase production capacity of green hydrogen plant

Thyssenkrupp nucera and Unigel have signed a Memorandum of Understanding (MoU) to increase the capacity of the green hydrogen plant that Unigel is developing in Bahia, Brazil, from 60 MW to 240 MW of water electrolysis, said the company.

The signing ceremony was held in Belo Horizonte, during the visit of the German Federal Minister for Economic Affairs and Climate Action, Dr. Robert Habeck. This is a key step for both companies continue their good collaboration to accelerate the green transformation through the development of the green hydrogen economy worldwide.

Unigel’s facility will be the first industrial-scale green hydrogen plant in Brazil. It is planned to be delivered at the end of the year. Green hydrogen – Bio Plastic

In the first phase, the plant will have a total water electrolysis capacity of 60 MW with thyssenkrupp nucera standard electrolyzers and an initial production capacity of 10,000 tons/year of green hydrogen and 60,000 tons/year of green ammonia. Unigel is one of the largest chemical companies in Latin America and the largest producer of nitrogen fertilizers in Brazil. The new plant will be an important stimulus for the development of the entire region.

“Unigel’s green hydrogen plant will be the first on an industrial scale in Brazil. We continue to negotiate strategic partnerships to enable the new phases of the project”, said Roberto Noronha Santos, CEO of Unigel. The green hydrogen and green ammonia will be offered to customers seeking to decarbonize their production chains such as the steel industry, oil refineries and ammonia producers.

Green ammonia will also be used in Unigel’s value chain, as it is a raw material for the production of fertilizers and acrylics. Green hydrogen – Bio Plastic

-What are salt batteries

Salt batteries, also known as salt accumulators, are devices that store energy: the goal, so to speak, is the same as lithium batteries, but the internal chemical composition changes. This type of accumulator is called “salt” due to the very high presence of sodium chloride (32%): sodium is an element of the periodic table which, compared to the lithium of canonical batteries, is easier to find and is also recyclable, even if it has a

However, all that glitters is not gold: as we mentioned at the beginning, not only are salt batteries more expensive than lithium ones, but they also have a strong nickel component (20%), by far the element most present after sodium and followed to a lesser extent by ceramics, iron, copper and various elements. Salt batteries

Nickel, compared to sodium, is more difficult to find and requires special precautions in the context of disposal so as not to impact nature. Green hydrogen – Bio Plastic

Composition and operation

But how are salt batteries specifically made? Forgive us for the brief technical parenthesis, it is necessary to better understand this technology.

Each cell in the charged state sees a positive electrode of copper and nickel chloride (cathode) and a negative one of liquid sodium (anode): separating the two electrodes is a ceramic tube called beta-aluminate ceramic electrolyte. The contact between the latter and the positive electrode is ensured by a molten secondary electrolyte. We won’t go into too many details, however know that the operation is based on reaching high temperatures to melt a specific element, in this case sodium (97.8°C): essentially, salt batteries work with a range between 270°C and 350°C.

-Newly Developed Transparent Bio Plastic as an Alternative to Aluminium for Aerosols

VELOX GmbH and its long-term partner SK Chemicals Co. Ltd. are presenting an innovation for plastic packaging applications such as aerosol containers as well as cosmetic and hot fill bottles.

ECOZEN HF® is a newly developed bio-copolyester range that is perfectly suitable for aluminum, glass and PET replacement wherever heat and pressure resistance combined with transparency is required. First customers have already started sampling the grades.

“ECOZEN HF® has similar processing requirements to PET and can be used in the same injection-stretch blow moulding (ISBM) process. However, the new grades by SK Chemicals perform perfectly in areas where PET can sometimes fail, such as in high temperature and high pressure applications”, explains François Minec, General Manager at VELOX. “For example, PET is sometimes used to produce aerosol bottles. These bottles can often fail due to high residual stress and the low temperature resistance of PET, especially in the summer months when possible leakage is the result. ECOZEN HF® offers an ideal alternative here.” Green hydrogen – Bio Plastic

Besides remarkable resistance to pressure, stress-cracking and high temperatures, ECOZEN HF® is characterised by excellent transparency and easy processing. As a glass replacement, e.g. for food packaging, it not only helps to reduce weight and transportation costs but can also be used to produce hot-fill containers without the need for an expensive PET heat-setting process or the need for crystallising the bottle or jar neck. Similarly, as an aluminum substitute in the cosmetics packaging industry, ECOZEN HF® combines high pressure-resistance with design flexibility and transparency. In addition, Ecozen HF® is totally miscible with PET in the recycling stream.

-Safripol announces bottle-to-bottle product

The annual Safripol Sustainability Conference is being held at the Sandown Hilton from 15-16 March 2023. Thought leaders, captains of industry, and EEHs (Everyday Environmental Heroes) will discuss ‘circularity’ and climate impact within the theme ‘Let’s plastic responsibly’.

It seems that Safripol has already put some words into action. Safripol CEO, Nico Van Niekerk says “To support a local plastic circular economy, we have launched our recycled polymer portfolio, and are excited to bring to market our first rPET product Aspirer, with post-consumer resin in FY 2023”. Green hydrogen – Bio Plastic

The new product is a gamechanger for South African recycling, bringing Safripol closer to achieving the sustainability goals they set themselves to reach by 2025. It is a giant leap forward in the creation of a true local plastic circular economy.

The product offers between 15% and 25% rPET polymer resin for the manufacture of plastic packaging, especially plastic bottles, as a one-bag solution for Safripol customers. The South African Waste Act stipulates that 12% must be used, so this solution helps Safripol and manufacturers go beyond compliance.

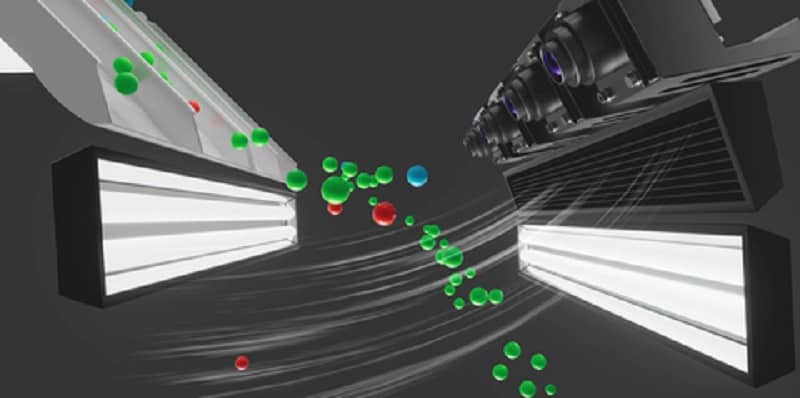

-Quectel showcases industrial smart color sorter solution with edge intelligence at Embedded World 2023

Quectel Wireless Solutions, a global IoT solutions provider, today announces how its latest smart module with machine compute and edge intelligence capabilities is revolutionizing the color sorter industry with higher efficiency and accuracy. Employing Quectel’s high performance SG560D smart module, the solution improves the color sorting of industrial materials that can be transformed via a visual identification system, through a combination of machine vision and edge intelligence capabilities, and automatically sort objects based on color and shapes accordingly. Green hydrogen – Bio Plastic

The advanced color sorter application, aimed at the industrial materials management industry, utilizes the Quectel SG560D smart module based on the Qualcomm QCS6490 chipset, and additional integrated hardware including cameras, lamps, and air guns. The solution is able to detect, recognize, and sort a broad array of textures, colors and materials including food materials such as rice, wheat, corn, soybean, seeds, nuts, salt, plastic objects such as plastic pieces, plastic granules, plastic bottle cap flake as well as minerals like quartz stone, quartz sand, pearls, marble, and others.

“As a global leader, Quectel is committed to serving our customers across all industries with the latest innovative technologies. We are proud to drive innovations in large industrial verticals such as color sorting where machine vision, edge computing and next-generation robotics applications can transform entire industries with faster time-to-market, increase productivity and produce significant cost-savings,” said Norbert Muhrer, President and CSO, Quectel Wireless Solutions. Green hydrogen – Bio Plastic

With advanced visual identification system, the smart color sorter solution can manage color sorting of high-volume objects with four cameras working simultaneously to stream video, with an accuracy of less than 1/200000 error rate. Additionally, it can help reduce operating and labor expense significantly.

-FIMIC develops filtration technology for PET recycling

FIMIC has installed two units (RAS-type filters) on PET recycling lines to work with more contaminated PET waste streams, i.e., not coming from hot-washed bottle flakes only, such as for example PET lumps from petrochemical waste or from strapping production, waste fibers as well as PET straps. In these cases, the contamination of the input material was higher than the typical “ppm” contaminations used for food grade applications, reaching levels as high as 5%. The benefits and the advantages of a continuous scraping filtration are ‘significant’, according to FIMIC. Green hydrogen – Bio Plastic

Dedicated to different end applications, these filter units are working with performance and great quality results in both cases: as a pre-filter in the first project (applied filtration is 150 or 120 micron on laser screen) and as the only filtration step in the second one (applied filtration is 80 micron on laser screen). The respective output performances are 2.000 kg/h and 700 kg/h, at very different and sometimes inconsistent iV levels.

At the same time, FIMIC says it has increased the amount of units installed for the recycling of soft PVC Most recently, FIMIC has been testing an alternative solution to be applied to hard PVC.

According to the company, PolyEthyleneTerephthalate (PET) is one of the most recyclable plastics, widely used world-wide in many different applications. Light, strong, durable and safe, PET offers a number of advantages being almost uniquely among plastics. Because of PET’s incredible performance and recyclability it is one of the most sustainable packaging materials. It is in fact approved as safe for use in direct food contact all over EU, as well as many other Countries, both in virgin or recycled form. Its uses vary from food, beverage, pharmaceutical and medical sectors, clothing, automotives, outperforming other plastic packaging. 70% of carbonated soft drinks, fruit juices, dilutable drinks and bottled water are made of PET. Green hydrogen – Bio Plastic

-Green Claims: clarity is needed to empower consumers and industry to make sustainable choices

Suntory Beverage & Food Europe (SBFE) believes in the power of clear and accurate communications to consumers to drive more sustainable purchasing behaviours and better-informed choices. For over a century, Suntory has focused on driving positive impacts in communities worldwide, and SBFE continues this heritage in the EU. Our iconic brands, including Schweppes, Orangina and Oasis, offer a range of refreshment choices that bring joy and satisfaction to Europeans across the continent.

Michelle Norman is the Director of Sustainability and External Affairs at Suntory Beverage & Food Europe. Green hydrogen – Bio Plastic

It is in SBFE’s interests to provide meaningful and accurate information to consumers and investors on the environmental performance of our products and our production. EU legislation on substantiating environmental claims should outline a clear regulatory framework that supports industry in delivering on objectives while avoiding unnecessary restrictions on our ability to market sustainable solutions to consumers.

Our commitment to sustainability is long-lasting and drives our commercial strategy

SBFE makes continuous investments in the transition to more sustainable products. Our Growing for Good[1] company values support a global strategy with local impact that empowers our business to act for positive change. SBFE is committed to delivering on the objectives of the European Green Deal and on the UN Sustainable Development Goals[2]. This is evidenced in our robust voluntary commitments to achieve:

100% recyclable packaging by designing for circularity, and a minimum of 50% recycled plastic in our bottles by 2025; Green hydrogen – Bio Plastic

100% sustainable plastic bottles by 2030;

A 50% reduction in scope 1 and 2, and 30% reduction in scope 3 greenhouse gas emissions by 2030;

A 50% reduction in food waste from production by 2030;

A 20% reduction in water use by 2030, and;

Net-zero emissions across our business by 2050 or sooner.

Green hydrogen – Bio Plastic