Hydrogen – Circular-Economy 01-11-2022 - Arhive

Hydrogen – Circular-Economy

Crude Oil Prices Trend

-Starlinger: New PET bottle-to-bottle recycling line reduces production costs

According to Starling, the new machine concept of Starlinger’s Recostar PET art saves about 21 % production costs. The machine was presented for the first time at K 2022.

The newly conceived PET bottle-to-bottle recycling system, Recostar PET art scores not only with 25 % less energy consumption compared to the previous model, it also requires 46 % less maintenance time, has a 21 % smaller machine footprint, and a production output increase of 15 %. In total, bottle-to-bottle recyclers can save about 21 % in production cost with the new system.

-The fine art of PET bottle-to-bottle recycling at K 2022

Music, culture, and art of the highest level: That’s what Austria is all about. Starlinger is perpetuating this tradition with its business unit Starlinger recycling technology, using its decades of accumulated knowledge of plastics technology and mechanical engineering to create cutting-edge technology.

At K 2022, Starlinger recycling technology will showcase the recoSTAR PET art, the company’s latest plant model in the field of PET recycling.

In addition to Starlinger’s established technology solutions such as excellent decontamination performance for food contact applications and impeccable rPET pellet quality, the new plant is characterized by particularly low energy consumption and considerably simplified maintenance processes. Hydrogen – Circular-Economy

For 35 years now, Starlinger recycling technology has been involved in processing plastic waste so that it can be used as an alternative resource to virgin materials. Starlinger recycling plants are used the world over to recycle used plastics from a wide variety of sectors, thus counteracting the problem of waste and scarcity of resources. Ideally, closed packaging cycles are created – as is the case with PET beverage bottles.

“What happens in the PET bottle-to-bottle recycling process to turn a used mineral water bottle back into a new mineral water bottle can be called high art,” says Paul Niedl, Commercial Director at Starlinger recycling technology. “It is a composition, a synthesis of experience combined with the latest scientific knowledge and high technological standards. Our new recoSTAR PET art embodies 20 years of experience in the field of PET food contact recycling. In addition, technical improvements have been made to make the plant easier to maintain and even more energy-efficient – in times like these, this is an important issue, especially in Europe. But we don’t want to give too much away in advance – at K 2022 and our Dynamic Days in Schwerin, interested parties can learn about the recoSTAR PET art and all its technological innovations in great detail.”

The pre-drying unit and the extruder of the new recoSTAR PET art will be on display at the Starlinger recycling technology stand in Hall 9, and the SSP reactor at the Starlinger stand in Hall 16. The company will also be showcasing machine solutions from the fields of polyester fibre/filament recycling and recycling of post-consumer polyolefins, including odour reduction technology.

Starlinger Dynamic Days in Schwerin – spotlight on PET and post-consumer plastics recycling

On 26 and 27 October 2022, while the K trade fair is taking place, Starlinger recycling technology will also be holding its “Dynamic Days” in-house exhibition at its Schwerin site in Germany, where the new recoSTAR PET art and a recoSTAR dynamic recycling plant will be in operation. Hydrogen – Circular-Economy

Interested customers will have the option of travelling from Düsseldorf to Schwerin via Rostock and back again on their chosen day by means of a charter flight and bus transfers. Further information: https://dynamicdays2022.com

-Are you scared of the plastic boogeyman?

It’s no secret that plastics recycling is booming. Just ask the 225 000 visitors and 33 500 exhibitors at the Kshow in Düsseldorf, Germany, over the last two weeks. So what did I spy walking the halls?

The venue was buzzing with energy. Robotic arms were not just sorting scrap, they were playing chess on a giant suspended board, playing drums and DJ-ing to catch the attention of passers-by.

Smart sorting solutions and integrated systems were surveyed while sipping a cold beer and eating a salted pretzel with bratwurst. The mood was relaxed yet a curiosity and eagerness clung to the air. For plastics recyclers across the world, this was the time and the place to showcase what they’ve been working on ever since the pandemic hit. Especially since a new report by Greenpeace slams plastic recycling as a ‘dead end’.

No pressure, then.

An interesting fact is that the global recycled plastics market was worth almost US$ 28 billion last year. This is projected to exceed US$ 43.5 billion by 2026. Quite a leap in five years, no?

Liquid gold?

‘It’s incredible to see how much has changed in just a few years!’ says Andreas Jäger, global sales manager at Steinert. ‘Chemical recycling was but a blip on the radar at the 2019 edition of the K-Show. Now look around. Chemical recycling is everywhere.’

Market data backs up this observation. UK-based research firm IDTechEx forecasts that pyrolysis and depolymerisation plants will recycle over 20 million tonnes of plastic scrap per year by 2033. For anyone curious to learn more on the topic, be sure to check out an upcoming webinar.

Amongst the innovators exhibiting at the Kshow was Carboliq. The German start-up converts mixed and heavily contaminated plastics into a ‘high quality liquid resource’, which it believes is an important milestone towards the end of waste.

Carboliq relies on a one-stage process to liquefy solid hydrocarbons under atmospheric pressure and process temperatures below 400°C.

‘Our process is suitable for multi-layer film as well, which represents a big waste volume these days,’ says project manager Florian Hanser. ‘There must be an answer for all plastics,’ he argues. ‘It’s great that there are bottle-to-bottle plants but not all product types are so easily returned to the loop.’

On the other hand, chemical recycler Recycling Technologies has gone under this September. The UK company, which had been fine-tuning its patented technology since 2012, was not able to acquire additional funding to take its process to the next level. Company founder Adrian Griffiths hopes interested parties will step forward to preserve the recycler’s intellectual property. Hydrogen – Circular-Economy

Room for everyone

Jäger is quick to add that, as a solutions provider, Steinert does not ‘pick sides’ and believe there is room for everyone in the industry. ‘We look at it from a practical perspective; all recyclers need sorting equipment, no matter what they do with their scrap in the end. Who are we to judge them?’

While some count mechanical recycling as ‘the only real recycling’, Jäger argues there is no single right way to do it. ‘It all depends on the situation, the material quality, the total carbon footprint. Ultimately, it has to make sense, it has to be feasible.’

The idea that chemical recyclers are being cast as the bad guys makes him laugh. ‘Technology is not the enemy. Well, you could say the consumer is.

-Hydrogen heating campaign launches to promote benefits for UK homes

A hydrogen heating campaign is underway as the UK energy sector

A hydrogen heating campaign has launched to raise awareness of the benefits heating homes with hydrogen could have.

100% hydrogen boilers are not yet available in the UK but a hydrogen-ready boiler can run with a hydrogen mix of 20%. And one benefit of opting for hydrogen heating is that transferring to hydrogen gas in the future is expected to be easy for those with a hydrogen-ready boiler because it can convert to hydrogen without the need for an entirely new heating system. Hydrogen – Circular-Economy

‘Hello Hydrogen’ is a new campaign from leading names in the UK energy industry including Worcester Bosch and Cadent Gas, which is also highlighting how hydrogen boilers could lower carbon emissions from homes, by 20 million tonnes a year, after switching from natural gas.

Angela Needle, campaign director of Hello Hydrogen, said: “As people start to turn on their heating again, we think now is the perfect time to begin the conversation about how we will all heat our homes in the future

“We want households to know that there will be numerous ways to warm up their radiators or cook their dinner and hydrogen could be the right choice for them.”

The campaign is also urging the government to restate its commitment to embracing hydrogen heating in homes and to help make it a viable choice for UK households.

-Circular Economy – Once waste, turned into valuable raw material

OMV is not just a reliable partner for energy supply in Austria. We are already researching tomorrow’s solutions today and invest in innovative recycling projects such as the patented ReOil process. We strive to contribute to recycling the majority of plastic waste in Austria as valuable raw materials and lowering CO2 emissions.

What does the new OMV recycle?

We recycle a material that’s indispensable to our everyday lives and is too valuable to simply throw away: plastic. We turn waste into raw material for producing new high-quality plastics using innovative recycling processes. This is circular economy.

How does the new OMV recycle?

Mechanically and chemically. Mechanical recycling is mainly handled by Borealis, which has been part of the new OMV since 2020 and has already been running two large recycling plants of its own in Austria and Germany since 2016 and 2018 respectively. Here, plastics are sorted, shredded, cleaned and recycled into new plastic. However, the new OMV is focused on chemical recycling. With an innovative process developed in Vienna, plastic that would normally be incinerated is turned back into crude oil. The oil is then processed for producing new plastics. Hydrogen – Circular-Economy

What’s so special about the OMV patented recycling process?

With the standard mechanical recycling process, only unmixed plastic waste can be recycled and reprocessed into plastics. Thanks to our chemical recycling process, the plastic waste can be converted into synthetic oil in an intermediate stop – and is thus the starting product for the production of virgin plastics for demanding applications.

What can the new OMV’s chemical recycling process achieve?

The goal of the new OMV is to recycle the majority of Austria’s plastic waste, conserving resources and reducing CO2. To achieve this, the new OMV is making huge investments: of the 3 billion euros earmarked for the Schwechat site by 2025, around a third will go to new energies and projects that establish a circular economy – like our chemical recycling process.

-Latest advances in sodium-ion battery research

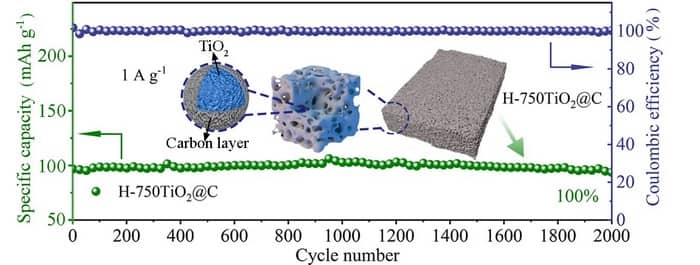

Qingdao University researchers have synthesized high-performance titanium dioxide-based anode materials with excellent cycling stability, while German scientists have used operando techniques to observe how solvated sodium ions embed themselves in electrodes.

Anatase titanium dioxide (TiO2) is a promising anode material for sodium-ion batteries due to its low cost, non-toxicity and abundance. However, the low electronic conductivity and sluggish ion diffusion kinetics at high rates are holding back practical applications.

A team of researchers from the College of Materials Science and Engineering at Qingdao University in China has demonstrated a sol-gel approach to the synthesis of thermally stable anatase nanoparticles with a carbon shell as anode materials for sodium-ion batteries. Hydrogen – Circular-Economy

When the synthesized anatase was tested in a half battery, the researchers found that the battery exhibited a reversible specific capacity of 228 mAh g-1 – at a current density of 0.05 A g g-1 with 100% capacity retention after 2,000 cycles at 1 A g-1.

In-situ X-ray diffraction and Raman spectroscopy results have revealed a nearly zero-strain characteristic of anatase during charge/discharge processes. In-situ transmission electron microscopy, ex-situ X-ray photoelectron spectroscopy and scanning electron microscopy results suggested an irreversible sodiation-activation process to form a sodiated-TiO2 phase during the initial discharge process.

A full coin cell assembled with anatase as the anode and Na3V2(PO4)3 as the cathode delivered an energy density of 220 Wh kg.The scientists reported their results in “Sodium-ion Storage Properties of Thermally Stable Anatase,” which was recently published in Energy Material Advances.

A joint research group from Helmholtz-Zentrum Berlin (HZB) and Humboldt-Universität zu Berlin, meanwhile, has used operando techniques to observe how solvated natrium ions embed themselves in electrodes.

The storage of ions, when accompanied by their solvation shell in a crystal lattice, is referred to as “co-intercalation.” Up to this point, this concept was limited to the negative electrode of the sodium-ion battery. Now, Berlin-based researchers have succeeded in extending the concept to the positive electrode of the battery.

“With titanium disulphide (TiS2) and graphite, we have for the first time combined two materials that absorb and release the same solvent during charging and discharging of the battery,” said Guillermo A. Ferrero, one of the researchers behind “Co-intercalation batteries (CoIBs): Role of TiS2 as electrode for storing solvated Na ions,” which was recently published in Advanced Energy Materials. Hydrogen – Circular-Economy

-Ingenia and IKA JV to claim foothold in US PVC industry

Ingenia Polymers and IKA Group have agreed in principle to the terms under which they will form a new venture to supply stabilisers into the US PVC sector.

The new venture will be a 50/50 partnership between Ingenia and IKA and will be located in the Greater Houston Metropolitan Area, Texas, USA.

The business of the venture will be the product development, production, trade and commercialisation of stabilisers and other additives for the PVC industry in North America.

In addition to each partners’ respective capital contribution, Ingenia and IKA have further agreed in principle to facilitate the development of the Corporation, especially in the first years of its operations.

Ingenia will facilitate operation and development of the Corporation and IKA will facilitate with technical service and marketing as well as with production and formulation technology. Hydrogen – Circular-Economy

“After forming IKA Group in 2020 via a Management Buy In, this important investment marks the next milestone for our ambitious international growth strategy“, Alexander Hofer, CEO of IKA said.

“With Ingenia, we are getting the most competent and capable partner to realise our plans and to continue with our technology leadership” said Dr. Timo Seibel, CTO of IKA.

Tony Butt, currently Senior Vice President at IKA Group, will serve as President and Chief Executive of the new venture. He said: “The teaming up of Ingenia and IKA is a perfect combination as both groups enrich each other and will allow broad synergies. IKA has new product ranges ready for the demanding North American Market including solutions for tin replacement”.

“The Joint Venture will also be an important step towards a diversification in the portfolio of Ingenia”, Thanassi Lefas, President of Ingenia added.

-Large Plastic Battery Enclosures Are Ready to Roll

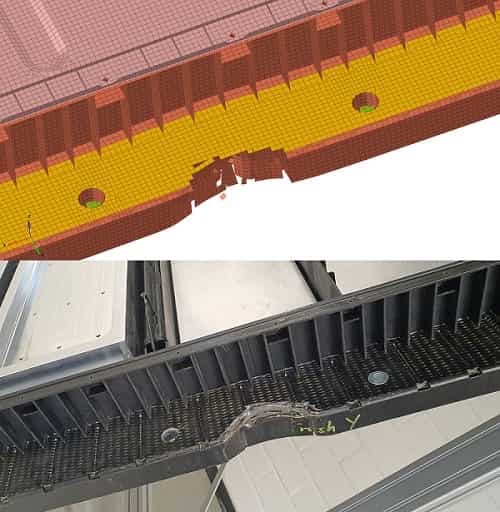

Technology demonstrator passes all major mechanical and thermal tests for high-voltage batteries in electric vehicles.

Engineering plastics such as polyamide (PA) 6 offer numerous benefits for the design of battery enclosures for electric vehicles in terms of sustainability, manufacturing costs, weight savings, and economical functional integration. However, there were lingering doubts about whether these large and complex components are also able to meet the very demanding requirements in relation to mechanical strength and flame-retardant properties. Hydrogen – Circular-Economy

Kautex Textron and Lanxess have now carried out a comprehensive examination of this using a jointly developed technology demonstrator made from PA 6. Lanxess was responsible for the material development and Kautex Textron for the engineering, design, and manufacturing process of the demonstrator.

“The near-series demonstrator passes all mechanical and thermal tests that are relevant for such enclosures. In addition, solutions for the thermal management and leak tightness of the enclosure, for example, have been developed. All this has proven the technical feasibility of these safety components, which are complex and subject to high levels of stress,” explained Dr. Christopher Hoefs, Project Manager, e-Powertrain, at Lanxess. Currently, a battery enclosure prototype is being road tested to verify its suitability for daily use. “We are currently jointly tackling development projects with automotive manufacturers in order to implement the new technology in series production,” said Felix Haas, Director, Product Development, at Kautex Textron.

Smaller carbon footprint

“Calculations revealed that the carbon footprint of the plastic enclosure is over 40% lower than an aluminum design. The lower energy use in the production of PA 6 compared with metal, as well as other factors — such as the omission of time-consuming cathodic dip painting to prevent corrosion where steel is used — help to minimize the carbon footprint,” said Hoefs. The thermoplastic component design also makes recycling the enclosure easier compared with thermoset materials, such as sheet molding compounds, for example.

The tests on the technology demonstrator were carried out in accordance with internationally recognized standards for battery-powered electric vehicles, such as Europe’s ECE R100 and Chinese standard GB 38031. The large-format, all-plastic battery enclosure, which measures around 1,400 mm in both length and width, demonstrated its performance in all relevant tests.

For example, it meets the requirements of the mechanical shock test, which is used to examine component behavior in the event of severe shocks, and the crush test, which developers use to examine the resistance of the battery enclosure in the event of slow deformation. The results of the drop and vibration tests were also positive, as was the bottom impact test. This test examines the stability of the batteries, which are mostly accommodated in the vehicle floor, in the event of ground contact of the vehicle structure or impact from sizeable stones. “All test results corroborate the previous simulations and calculations. A critical failure of the plastic enclosure would not have occurred in any of the load cases,” explained Haas. The demonstrator also proved its resistance to external sources of fire underneath the vehicle, in accordance with ECE R100 (external fire).

Lower weight, lower manufacturing costs

The demonstrator was developed based on the aluminum battery housing of a mid-size electric vehicle and designed for mass production. It is manufactured in a single-stage compression molding process with a molding compound based on PA 6 Durethan B24CMH2.0 from Lanxess and does not require any further rework. Crash-relevant areas are specially reinforced with locally placed blanks made from Tepex dynalite 102-RGUD600 continuous-fiber-reinforced, PA 6–based composite. Hydrogen – Circular-Economy

A weight saving of around 10% compared with an aluminum design is delivered, which is advantageous for the range and, therefore, the carbon footprint of the vehicle.

-How trading recycled plastics will help build a sustainable future

To enable global circularity, UAE-based Rebound has launched a global B2B digital trading platform for recycled plastic

Plastics and its relationship with the modern world cuts both ways. While it is an extremely useful material for society and serves several purposes, its consumption and subsequent disposal are endangering the environment and impacting the world in more ways than one.

Despite pledges on organisational and national levels, adverse climatic changes and grim forecasts have called for renewed commitment on multiple fronts. Green investments as well as greater cross-border cooperation are some of the examples to preclude a looming environmental crisis. Hydrogen – Circular-Economy

According to an OECD report, the annual production of plastics has doubled over the last two decades, from 234 million tonnes (Mt) in 2000 to 460 Mt in 2019. Meanwhile, plastic waste has more than doubled, from 156 Mt in 2000 to 353 Mt in 2019, of which only 9 per cent was recycled. As much as 19 per cent was incinerated, almost 50 per cent went to sanitary landfills and the residual 22 per cent was disposed of in uncontrolled dumpsites, burned or leaked into the environment. This suggests that the current plastics lifecycle is anything but sustainable.

Local initiatives

The UAE has taken key initiatives to mitigate the usage of plastics. Dubai launched the citywide sustainability movement in February to encourage the use of refillable bottles through the installation of drinking water stations. By September, the initiative had seen a reduction in the usage of an equivalent of over 3.5 million 500ml single-use plastic water bottles.

The neighbouring emirate of Abu Dhabi also announced the introduction of a range of installations at high footfall locations to collect single-use plastic bottles for recycling. It also banned the use of single-use plastic bags from June 1, while Dubai levied a Dhs0.25 tariff per bag a month later.

However, addressing plastic products and their impact from a lifecycle perspective is equally imperative. To enable global circularity, Rebound, a subsidiary of Abu Dhabi-based International Holding Company launched a global B2B digital trading platform for recycled plastics.

Hydrogen – Circular-Economy