Nylon6-PCR – Carbon-Fiber-Recycling 02-03-2022 - Arhive

Nylon6-PCR – Carbon-Fiber-Recycling

-Long Fiber Composites Based on Nylon Reclaimed from End-of-Life Fishing Nets

Avient’s new Complēt R long fiber-reinforced composites incorporate nylon 6 PCR from discarded fishing nets. A long fiber-reinforced composite based on nylon 6 reclaimed from end-of-life fishing nets is newly available from Avient. According to Avient’s general manager for long fiber technologies Eric Wollan, this is the first long fiber composite material in a planned larger portfolio based on recycled resin. Formulations are available globally in a standard black color at typical weight percentages of long glass fiber, long carbon fiber, or hybrid combinations.

Levels of post-consumer resin content vary within the offerings, which allows end products to meet different performance and sustainability requirements.

Potential structural market applications for Complēt R include next-generation vehicles that go further using fewer energy resources, recycled-content office furnishings that contribute towards LEED certification for buildings, and lighter-weight adventure gear for outdoor recreation. Nylon6-PCR – Carbon-Fiber-Recycling

The new material is said to provide stiffness, strength, and toughness performance on par with standard nylon 6 long fiber formulations using virgin nylon 6 resin. Using these composites as a metal replacement also fosters significant weight reductions along with the time and cost savings benefits of single-step injection molding.

-Teijin to Partner with Fuji Design in Carbon-Fiber Recycling

Precision pyrolysis technology will be applied to recycling of composites via removal of matrix resins. Nylon6-PCR – Carbon-Fiber-Recycling

Teijin Ltd. plans to form a business alliance with Fuji Design Co., Ltd., a Japanese manufacturer of recycled carbon fibers, to establish a basis for the production, supply, and commercialization of carbon-fiber-reinforced plastic (CFRP) products made from recycled carbon fibers using a low environmental impact process.

Fuji Design’s proprietary “precision pyrolysis” technology produces high-quality carbon fibers from used CFRP by removing matrix resins. As a green technology, it produces some 90% fewer CO2 emissions than carbon fibers made with virgin raw materials. Fuji Design, which is operating a commercial plant partially subsidized by Japan’s Ministry of the Environment, has been looking to expand the business by developing new applications for its technology.

Teijin, meanwhile, has been striving to lower its groupwide environmental impact, including by reducing its fiscal 2018-level CO2 emissions by 30% as of fiscal 2030 and to net-zero by fiscal 2050. Along with efforts to reduce in-house energy consumption, Teijin also has been developing technologies to recycle materials including carbon fibers. Nylon6-PCR – Carbon-Fiber-Recycling

Lightweight and high-strength CFRP already is used widely in aircraft, industrial, and sporting goods applications. Demand is expected to increase as a solution for improving the fuel efficiency of vehicles and other products.

-SAN and SMA Copolymers Based on Renewable Feedstocks

Ineos Styrolution’s NAS Eco and Luran Eco product ranges have a carbon footprint reduction of 77% and 99% compared to fossil-based styrenics.

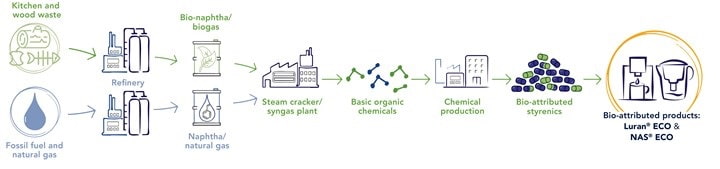

Two new biobased styrenic resin series intended as a drop-in for their fossil-based counterparts have been launched by Ineos Styrolution.

Luran Eco and NAS Eco are transparent styrenics specialty materials based on a mass balance process certified by ISCC Plus. Nylon6-PCR – Carbon-Fiber-Recycling

The products are based on styrene being produced using renewable feedstock that is not in competition with food production, such as kitchen waste and wood waste. The carbon footprint reduction for the new products varies between 77% and 99% when compared to the respective fossil-based products, depending on the amount of renewable feedstock used to produce a material.

Luran Eco is a SAN (a styrene acrylonitrile copolymer) boasts a well-balanced property profile ranging from good transparency and excellent chemical resistance to high stiffness, extraordinary heat resistance as well as very good dimensional stability. These attributes make these resins a material of choice for a variety of household and cosmetics packaging applications.

NAS Eco is a stiff, amorphous SMMA (styrene methyl methacrylate) copolymer for demanding applications requiring excellent transparency such as water tanks, displays, food containers or boxes. Nylon6-PCR – Carbon-Fiber-Recycling

-Borouge starts up fifth polypropylene unit in Ruwais

The new facility will increase Borouge’s polypropylene production capacity by more than 25 per cent to 2.24 million tonnes per year

Borouge, a joint venture between Abu Dhabi’s ADNOC and Austria’s Borealis, has announced the start up of its new fifth polypropylene unit (PP5) in Ruwais.

The new unit will boost the UAE’s polypropylene production to meet the growing demand for manufactured products in the recyclable advanced packaging, infrastructure, and other industrial sectors. Nylon6-PCR – Carbon-Fiber-Recycling

Built within the Borouge 3 plant, the new unit will deliver 480,000 tonnes per year (t/y) and increase Borouge’s polypropylene production capacity by more than 25 per cent to 2.24 million t/y, and its total polymer capacity of polyolefins by 11 per cent from 4.5 to 5 million t/y. The new facility will have the annual capacity to manufacture raw materials to produce enough pipes for the water supply networks for the equivalent of 6,500 Burj Khalifa buildings.

-CPL deficits enlarge, expecting turnarounds in March

By the end of February 2022, nylon industry players in China have been relatively indifferent to the performance of the crude oil market recently, and their interpretation of crude oil is more about the possible bearish fall in a medium and long term, rather than the short-term rally. This phenomenon is similar in the polyester circle. This also shows that chemical fiber downstream market shares a coldness after the Spring Festival. Players have the concern about high oil prices, and the pandemic situation, and their operating rate and order taking have not fully recovered. Nylon6-PCR – Carbon-Fiber-Recycling

In nylon 6 chain, the price of caprolactam has fallen below the low rate in January (before the Spring Festival), and has been a relatively weak product among the major chemical fiber raw materials.

But in the author’s opinion, the main problem is still as mentioned in the previous article “Unexpected weakening CPL after the Spring Festival”, that the expectations of each link for the market are too bearish. In a state of general lack of confidence, even if the social inventory is not high, it is not easy to raise prices, unless supply is reduced to a very tight state. Nylon6-PCR – Carbon-Fiber-Recycling

The weakness in CPL market is mainly due to a weak stance in the supply-demand relationship, while CPL inventory is not high. The reason for a stabilizing market at the end of last week (Feb 21-25) is simple: CPL is under rising deficits.

-Impact of the escalating Russian-Ukrainian conflict on PE market

On Feb 24, the conflict between Russia and Ukraine has escalated to military action. Affected by this, international oil prices soared, with crude oil rising 9% intraday, breaking through $100/barrel for the first time since 2014. So, what effect do the conflict have on the PE market? Nylon6-PCR – Carbon-Fiber-Recycling

First of all, seeing from the current market, although PE price has rebounded slightly since Feb 24, it is mainly driven by the high cost of crude oil. Due to the relatively loose fundamentals of PE market, the increase is not obvious. At present, as the oil price is above $90/barrel, the real-time cash flow of PE has hit -800-(-)700yuan/mt. Although the petrochemical group has oil reserves, the impact of high oil prices on the market will be gradually highlighted as time advances. Currently, petrochemical plants are required not to control the overall price trend from the ex-works price link. As for the operating rate, some plants of Sinopec Maoming PC have operated with lower rates under the influence of the conflict, while other petrochemical plants did not reduce their operating rate for the time being. Nylon6-PCR – Carbon-Fiber-Recycling

Nylon6-PCR – Carbon-Fiber-Recycling