Oil next year – Enzyme found in laundry detergent could help recycle plastic 06-02-2024

Oil next year

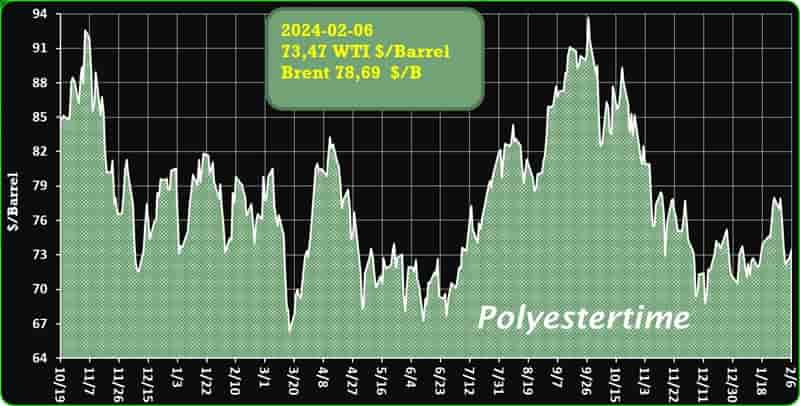

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Kuwait is strategically targeting a robust deficit reduction of KD 2.5 billion in its upcoming budget, emphasizing the need to achieve an oil production level of 2.8 million barrels per day to generate an estimated KD 22 billion

The proposed budget, commencing from April 1 at KD 25 billion, reflects a significant KD 2 billion reduction compared to the current budget, with the primary objective being the alleviation of a projected KD 6 billion ($18 billion) deficit.

In a noteworthy move, the government has disclosed its equilibrium price, anchoring the budget on a conservative crude oil price of $70 per barrel. However, skepticism surrounds the practicality of this benchmark, with prevailing expectations favoring a more realistic range of $75 to $80 per barrel. Despite acknowledged efforts to trim government expenses, the spotlight shifts towards the creation of over 24,000 job opportunities within the next 12 months. Oil next year

A critical gap in the budget lies in the lack of transparency regarding Kuwait’s projected crude oil production for the upcoming year, a pivotal determinant for deficit mitigation. To achieve the targeted deficit reduction, it is imperative to aim for an estimated oil production of 2.8 million barrels per day, equivalent to KD 22 billion.

The key to a deficit-free budget involves setting a crude oil price of $80 per barrel and maintaining a production level of 2.8 million barrels, obviating the need for oil prices to reach the ambitious $91 per barrel threshold. Addressing the KD 6 billion shortfall presents challenges, with potential solutions including international bank borrowings, leveraging sovereign wealth funds, or exploring unconventional paths such as privatizing certain oil companies.

Privatization emerges as a promising solution, injecting immediate cash into government coffers and fostering private sector growth. Successful execution requires collaborative efforts between the government and the private sector, positively impacting national graduates’ recruitment and development and contributing to the overall economy. The sustainability of reduced expenditure levels remains a critical question, with hopes pinned on the new government adeptly navigating challenges without resorting to borrowing. This marks the initiation of a new era, with collective aspirations for positive results shaping Kuwait’s economic trajectory in the years ahead. Oil next year

China’s textile industry profits up 7.2 pct in 2023

As of 2023, China’s textile industry experienced a notable surge in profits, marking a 7.2 percent year-on-year increase, according to official data released by the Ministry of Industry and Information Technology on February 3, 2024. Major textile enterprises in the country collectively recorded profits amounting to 180.2 billion yuan, equivalent to approximately 25.38 billion U.S. dollars. Oil next year

Despite a marginal decrease of 0.8 percent in combined operating revenue, totaling 4.70 trillion yuan compared to the previous year, the industry’s profitability exhibited resilience. The Ministry’s report indicated a noteworthy rebound in the textile and garment sector’s export performance. In 2023, China’s textile and garment exports reached 293.6 billion dollars, though experiencing an 8.1 percent decline from the preceding year.

Interestingly, the data unveiled a positive shift in December 2023, with textile and garment exports resuming expansion. During this period, exports witnessed a 2.6 percent year-on-year increase, amounting to 25.3 billion dollars. This positive trend at the end of the year suggests a potential recovery and increased momentum in the global demand for Chinese textile and garment products. Oil next year

Overall, the 2023 performance underscores the robustness of China’s textile industry, showcasing adaptability and resilience amid economic fluctuations.

With the launch of project STOPP, the European Union is taking significant strides to combat plastic waste in the packaging sector

This three-year initiative targets the entire food packaging value chain, encompassing the agricultural food industry, with the goal of reducing packaging waste by 2030 in accordance with the EU’s Packaging and Packaging Waste Directive.

Involving 14 partners from seven countries, the project aims to establish circular strategies for plastic usage and processing. The collaborative effort will also implement awareness campaigns through a multi-actor network. Oil next year

Key actions include analyzing the impact of plastic waste in various ecosystems, monitoring current plastic usage in the food packaging industry, creating a sustainable business model for replication, enhancing recycling practices, and conducting a comprehensive customer voice study.

The VTT Technical Research Centre of Finland spearheads this innovative scheme, with notable partners such as the University of Vaasa, the National Institute of Chemistry of Slovenia, Remondis Recycling, GreenDelta, Plastics Recyclers Europe, Veolia, Braskem, and reCIRCLE. Together, these entities aim to generate results that can inform the European decision-making process concerning future packaging strategies. The STOPP project reflects the EU’s commitment to fostering sustainable practices and mitigating the environmental impact of plastic waste in the packaging sector. Oil next year

European Polyamide Prices Decline in January, Reasoning Subdued Demand

The Polyamide market witnessed a descending price trend as the first quarter of 2024 commenced. This decline was primarily attributed to bearish demand conditions originating from the downstream automotive and electrical sectors within the European market. The weakened demand from these key sectors exerted downward pressure on Polyamide prices, reflecting broader economic challenges or specific industry-related issues. Moreover, the feedstocks for Polyamide i.e., Caprolactam and Adipic Acid, also played a role in the descending price pattern. The decline in feedstocks prices contributed to the overall reduction in production costs for Polyamide, subsequently influencing the pricing dynamics in the downstream market. Oil next year

In terms of demand, the Polyamide market faced challenges as fresh orders from potential customers remained weak. Additionally, trading activities in the international market experienced a reduction, primarily attributed to disruptions in ocean routes. These disruptions, which may include factors like shipping delays, port closures, or logistical challenges, had a consequential impact on the global trading dynamics of Polyamide.

In January, manufacturers in the Eurozone exhibited a less aggressive approach towards reducing their purchasing activities.

This suggests a moderation in the extent to which they scaled back procurement of raw materials and components for their production processes. The market participants, potentially influenced by economic uncertainties or geopolitical events, exercised caution in their purchasing decisions. Oil next year

Enzyme found in laundry detergent could help recycle plastic

With a simple chemical tweak, chemists have created robust enzymes that break down single-use bioplastic into its building blocks within two days

Researchers at King’s College London have found a way to break down plastics into their building blocks for recycling. The process takes less than 40 hours and uses an enzyme commonly found in bio-based laundry detergents.

The advance reported in the journal Cell Reports Physical Science could lead to an efficient way to recycle the single-use plastic called polylactic acid (PLA). “We have chosen polylactic acid as this plastic does not have any real way of properly recycling it,” says chemistry professor Alex Brogan. Oil next year

“Our development changes this, as we have been able to convert the plastic to its constituent building blocks in less than 40 hours at 90°C.”

Although PLA is made from renewable sources such as corn starch and sugar cane, it is just as big an environmental problem as petroleum-derived plastics. It is the most common commercial bioplastic—the world produced 457,000 tons in 2021—and is used mainly to make disposable food containers, cups, and utensils.

Most of these items end up in landfills, where they do not biodegrade. PLA can only biodegrade in industrial compost settings, where it takes 12 weeks to break down at 60°C. This makes industrial composting “a fairly energy intensive and time-consuming process of converting the plastic to fertilizer or mulch,” Brogan says. Oil next year

Eni to Build Third Biorefinery in Italy

Eni SPA said it is awaiting government clearance to begin construction of its third biofuel production plant in Italy, proposed to rise in the port city of Livorno.

“The project, first announced in October 2022 and followed by an application for Environmental Impact Assessment in November 2022, is awaiting official authorizations and includes the construction of three new facilities for the production of hydrogenated biofuels: a biogenic feedstock pre-treatment unit; a 500,000 tonnes/year Ecofining plant; and a facility to produce hydrogen from methane gas”, the Italian state-controlled energy major said in a recent news release. Ecofining is a trademarked technology developed by Eni and Honeywell UOP to transform biogenic raw materials into biofuels.

Eni has set a goal of raising its biorefining capacity from the current 1.65 million tons per annum (MMtpa) to over 5.0 MMtpa as part of efforts to become a carbon-neutral company by 2050. Oil next year

The proposed project wants to transform the Livorno industrial site in Tuscany region on the Italian northeastern coast.

Its two biorefineries in operation in Italy had been converted from fossil fuel refineries. The Porto Marghera biorefinery in the northern coastal city of Venice started production June 2014 as the world’s first project to successfully transform a traditional refinery into a biorefinery according to Eni.

Its processing capacity has been raised from an initial 360,000 MMtpa to 400,000 MMtpa, according to information from Eni’s website. Oil next year

The other refinery, which faces the Mediterranean Sea in the Sicilian city of Gela, opened August 2019 with a 750,000-MMtpa processing capacity according to Eni.

Arburg, the renowned German manufacturer, is set to showcase cutting-edge technology at Mecspe in Bologna

The exhibition will feature two injection molding machines, with one displayed at Mecspe Lab – Innovation Space in the central hall. Additionally, a third machine will be dedicated to additive manufacturing.

At Arburg’s booth in Pavilion 36, the spotlight will be on the Allrounder 520 A 1500 electric press, configured for medical applications in an ISO 7 cleanroom environment. Specifically designed for rapid and complex processes, this Ultimate version will be equipped with a Kebo 4-cavity mold to produce polypropylene syringe bodies (Bormed RF825MO by Borealis) in a swift 9-second cycle. Oil next year

The machine is complemented by the latest-generation Gestica control, featuring digital functions and apps to meet stringent medical traceability and quality requirements. It also incorporates operator assistance and Industry 4.0 packages, along with connectivity to the proprietary MES for real-time production data acquisition and analysis.

Arburg’s booth will also debut the Innovatiq TiQ5 Pro 3D printer, boasting an open material platform for large-scale components (500 x 400 x 450 mm). The vacuum bed and active heating chamber ensure reliability in extended or challenging jobs with various materials, including hard or soft, and fiber-reinforced or high-temperature plastics.

The printer features the CoreLine print head, a dual extruder reaching 400 °C, and a vacuum bed for enhanced stability and adhesion, improving the finished product’s quality. The SmartStart function, with automatic leveling and nozzle calibration, optimizes the start of each print, making the TiQ5 Pro ideal for a range of industrial applications from rapid prototyping to complex component production. Oil next year

Moreover, Arburg will contribute to the Mecspe Lab Innovation Space at the Service Center with the hybrid Allrounder 470H 1000 290 Comfort press, which debuted last year on the company’s centennial. This machine, equipped with a metal 3D-printed mold, will manufacture a component for GPS devices used in avalanche rescue during the exhibition.

Oil next year