PET-Bottle recycling technologies – The Swiss Battery Breakthrough: 1-Minute Recharge, 10x Longer Lifespan, and More 04-09-2023 - Arhive

PET-Bottle recycling technologies

Petrochemicals PSF PET-Bottle – Will the European EVcar market only speak Chinese?

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

TotalEnergies Corbion Unveils Advanced rPLA Grade at Interplas Exhibition

Anticipation is building for the upcoming Interplas event scheduled from September 26 to 28 in Birmingham, UK, where TotalEnergies Corbion is set to unveil a groundbreaking PLA grade infused with up to 30% recycled content, poised to captivate the UK market. The innovative rPLA series is ingeniously crafted not only to align with the UK’s recent regulations curtailing the use of single-use plastics but also to address the Plastics Packaging Tax introduced on April 1, 2022, which mandates that packaging in the UK must integrate at least 30% recycled plastic content to avoid taxation.

As the UK intensifies its commitment to environmental sustainability, TotalEnergies Corbion is making a resolute statement at Interplas, championing its rPLA range as an embodiment of ecological responsibility and innovation. While these materials impeccably adhere to the newly introduced legal framework, their contribution to sustainability far surpasses mere compliance. PET-Bottle recycling technologies

The concept of circularity takes center stage as TotalEnergies Corbion delves into the science behind the rPLA grades. Conventional mechanical recycling of PLA is a well-known approach, yet the company is pushing boundaries by embracing chemical recycling as well. Operating from its state-of-the-art facility in Thailand, TotalEnergies Corbion pioneers chemical recycling for PLA, ushering in a paradigm shift in waste management and resource regeneration.

Within this cutting-edge process, PLA waste, having undergone meticulous sorting and cleansing, undergoes depolymerization through a controlled hydrolysis procedure. The polymer chain undergoes hydrolysis under specific, mild conditions, disintegrating into its elemental monomer, lactic acid. This remarkable feat of selective transformation culminates in the creation of pristine lactic acid, ready to be reincarnated as new feedstock for rPLA production. The brilliance of this method lies in its ability to facilitate a closed loop: materials that once served their purpose can be resurrected to fulfill identical applications, even those involving food contact – an accomplishment that overcomes a significant limitation associated with mechanical recycling. PET-Bottle recycling technologies

TotalEnergies Corbion underscores the unique attributes of aliphatic polyesters like PLA, which permit direct conversion of polymer chains into lactic acid monomers. The inherent selectivity of this process, coupled with its minimal temperature requisites, contribute to its effectiveness in the pursuit of sustainability.

Luminy PLA, a product championed by TotalEnergies Corbion, emerges as a standout contender against traditional counterparts, particularly conventional PS products. Its functional performance mimics that of standard options while leaving an astoundingly low carbon footprint, approximately 75% less than that of conventional plastics. Frank Duijzer, the business development manager at TotalEnergies Corbion, emphasizes the forward-thinking nature of their solutions, which are poised to meet the rising tide of demand for reusable and recyclable alternatives, even extending to everyday items like cutlery. This duality of convenience and environmental consciousness underscores the company’s commitment to harmonizing human activities with ecological stewardship.

Duijzer emphasizes the scope of TotalEnergies Corbion’s contributions, noting that their materials transcend single-use cutlery, reshaping the landscape of food packaging itself with their compostable solutions. Aligning seamlessly with the UK’s regulations targeting plastics used for prepacked food, TotalEnergies Corbion’s biobased, compostable materials present an array of choices for sustainable packaging strategies, promoting a holistic approach to environmental protection. PET-Bottle recycling technologies

In a resounding testament to its dedication and innovation, TotalEnergies Corbion is set to grace Hall 4 Booth E24 at the Interplas exhibition in Birmingham from September 26 to 28, 2023. The event promises to be a pivotal juncture, offering a glimpse into the future of packaging solutions that seamlessly intertwine necessity, convenience, and a profound sense of environmental mindfulness.

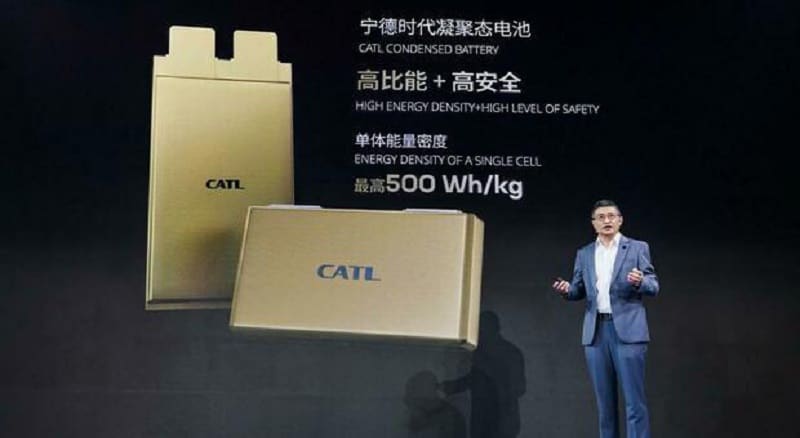

Catl Unveils Revolutionary 700 km Range Battery with 4C Charging Capability

In a groundbreaking announcement reported by carnewschina.com, Catl, a prominent supplier for Tesla, revealed the remarkable features of their latest lithium iron phosphate battery, the Shenxing. Set to hit the market in the first quarter of 2024, this battery represents a quantum leap in electric vehicle (EV) technology. With its adaptability to various vehicle types, innovative management system, new graphite anode, and an updated electrolyte formulation, the Shenxing battery promises to redefine the boundaries of EV performance. PET-Bottle recycling technologies

The headline feature of the Shenxing battery is its astounding 700-kilometer range on a single charge. This exceptional range is a testament to Catl’s commitment to pushing the envelope in battery technology. As electric vehicles continue to gain popularity, the demand for longer ranges has grown, and Catl’s Shenxing battery aims to meet and exceed these expectations.

One of the most exciting developments is the Shenxing battery’s rapid charging capability. According to reports, it can provide enough energy to cover a 400-kilometer distance in just 10 minutes of charging. This is a remarkable advancement in the world of EVs, as it effectively eliminates the range anxiety often associated with electric vehicles. With such swift charging times, EV owners can enjoy the convenience of quick pit stops for energy top-ups, similar to refueling a conventional gasoline-powered vehicle.

What sets the Shenxing battery apart is its ability to achieve this incredible 4C charging rate, which, as carnewschina.com reports, is a first for a lithium iron phosphate battery. This achievement is a testament to Catl’s dedication to advancing battery technology and providing EV owners with a seamless and efficient charging experience.

Furthermore, Catl has addressed the challenge of charging in low temperatures. The Shenxing battery can be charged to 80% capacity in just 30 minutes, even when the temperature drops to -10°C. This means that EV drivers in colder climates can rely on their vehicles even in harsh winter conditions, without experiencing significant charging delays. PET-Bottle recycling technologies

The Shenxing battery’s debut will be marked by a partnership between Catl and Avatr, a joint venture that also involves Changan and Huawei. This collaboration underscores the industry’s recognition of Catl’s technological prowess and its potential to transform the electric vehicle landscape. Avatr will be the first automaker to benefit from the Shenxing battery’s impressive features, solidifying Catl’s reputation as an innovative industry leader.

In conclusion, Catl’s unveiling of the Shenxing battery represents a major milestone in the electric vehicle industry. With its groundbreaking 700-kilometer range, lightning-fast 4C charging capability, and resilience in low temperatures, it is set to redefine the expectations of EV enthusiasts worldwide. As electric vehicles become increasingly prominent in the automotive market, Catl’s Shenxing battery is poised to play a pivotal role in driving the adoption of sustainable and efficient transportation. With the Shenxing battery, the future of electric mobility looks brighter than ever before.

Goodbye solvents: sustainable synthesis and recycling with mechanochemistry

Being both innovative and sustainable in the chemical industry is a real challenge. Can new materials be synthesised without the use of solvents? Ana Mangas, researcher in Mechanochemistry and Reactive Extrusion at AIMPLAS, the Plastics Technology Centre, writes.

Mechanochemistry is the answer. Based on its 12 principles, green chemistry offers an unprecedented opportunity to change ourunderstanding of chemistry and its environmental impact. The ability to provide safer, cleaner and moreefficient and sustainable processes also makes mechanochemistry one of the most promising areas ofgreen chemistry.

Mechanochemistry is a branch of chemistry that is rapidly going forward as an efficient, sustainable alternative to traditional solvent-based methods. Its origins date back to the 1970s, when researchersbegan exploring how mechanical forces could trigger chemical reactions. PET-Bottle recycling technologies

Advances in technology in recent decades have led to the development of more sophisticated equipment and techniques, which have increased interest in this discipline and its application in different fields.Unlike conventional methods, mechanochemistry does not involve the use of solvents to carry out reactions, thus avoiding problems associated with solvent quality and purity, not to mention toxic solvent waste. This technique helps achieve faster synthesis and, in some cases, can be carried out as acontinuous process rather than in batches, which makes it ideal for large-scale production applications.

Mechanochemistry can also be used to produce materials with unique properties that are difficult or impossible to obtain by other means, thus making it a valuable tool for research and development of new materials with applications in electronics, energy and medicine, among other sectors. New horizons Given its versatility, mechanochemistry is being used in a growing range of industries. It is not only one of the most sophisticated and cost-effective technologies, but has also become an alternative preparation method, which could help minimize the use and formation of hazardous materials and reduce the energy requirements of the process.

The Swiss Battery Breakthrough: 1-Minute Recharge, 10x Longer Lifespan, and More

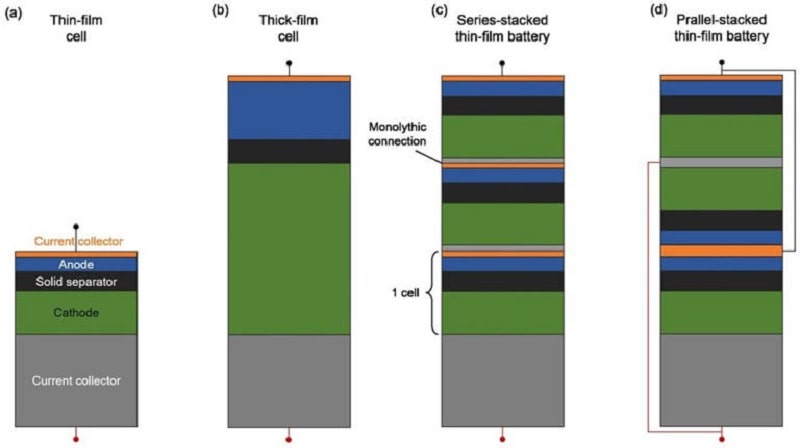

In the world of electric mobility, one Swiss innovation is poised to revolutionize the way we think about batteries. Imagine a battery that can recharge in just one minute, boasts a lifespan ten times longer than current options, and performs flawlessly in extreme temperatures, be it scorching heat or freezing cold. This groundbreaking technology is being developed by the Department of Thin Membranes at the Swiss Laboratory for Materials Science and Technology (EMPA). They’ve created a solid-state lithium metal battery that is not only incredibly efficient but also non-flammable, promising a seismic shift in energy storage. PET-Bottle recycling technologies

The brainchild of two visionary engineers, Abdessalem Aribia and Moritz Futscher, this innovation has given birth to a spin-off company named BTRY, a playful play on the word “battery.” Their battery employs thin-film solid-state technology, a concept dating back to the 1980s. These cells are remarkably compact, measuring a mere one millimeter in thickness and three millimeters in length. While this technology existed before, it suffered from limited energy storage capabilities. Aribia and Futscher, however, have ingeniously stacked these cells to boost overall capacity, propelling this technology into a new era.

Aribia explains, “We are working to create a 1 cm2 battery with two or three layers. It will still be strictly a laboratory product, but it will be the first step in demonstrating that the product is scalable and capable of having a commercial outlet.”

The secret to achieving such thin cells lies in their production process, which unfolds in a vacuum. This environment allows for precise and controlled distribution of the desired materials in layers. Interestingly, this method bears similarities to the production of next-generation chips and semiconductors. Futscher notes that this advantage is due to the availability of machinery and technologies already present in the market. Moreover, this production technique eliminates the need for toxic solvents, contributing to a battery with a smaller environmental footprint. PET-Bottle recycling technologies

However, there is an economic hurdle to overcome. This type of battery is relatively expensive to produce. Aribia acknowledges this fact, stating, “Our batteries will cost more, but the benefits they offer are worth the higher price.” The game-changing potential of these batteries becomes evident when applied to devices like smartphones, where the cost of the battery represents only a fraction of the total. But the possibilities extend beyond portable electronics, with potential applications in satellites and even future electric vehicles.

While BTRY faces economic challenges, their unwavering commitment to innovation continues to garner support. The company secured funding from Innosuisse and became part of the European Space Agency’s business incubator, signaling the tremendous promise of their achievements. The future of energy storage looks brighter than ever, with the prospect of rapid recharges, extended lifespans, and superior performance, all made possible by Swiss ingenuity.

Credits : © InsideEVs

On September 1, 2023, in a collaborative effort, Technip Energies and Versalis have united their strengths to advance plastic waste recycling technologies

Technip Energies, a prominent company in the field of engineering and technology for the energy transition, has joined forces with Versalis, Eni’s chemical division, to ink an agreement aimed at seamlessly integrating Versalis’ Hoop® technology with Technip Energies’ Pure.rOilTM and Pure.rGasTM purification technologies. This joint endeavor will result in the development of a cutting-edge technological platform designed for the advanced chemical recycling of plastic waste. PET-Bottle recycling technologies

The primary objective of this project is to establish a virtually infinite recycling loop for plastic materials, producing fresh, high-quality polymers suitable for a wide range of applications that are indistinguishable from polymers derived from fossil-based raw materials.

Versalis will bring its Hoop® technology to the table, a pyrolysis process renowned for its ability to efficiently recover mixed plastic waste, boasting impressive yields, recovery rates, and adaptability in managing diverse feedstocks.

On the other hand, Technip Energies will leverage its extensive experience in ethylene furnace and steam cracker design, with over 700 steam crackers operating globally under its licensure. In addition, they will contribute their proprietary purification technologies, Pure.rGasTM and Pure.rOilTM, ensuring a secure, reliable, and optimized integration with both existing and new crackers.

The amalgamation of these technologies from Versalis and Technip Energies will play a pivotal role in fostering a circular economy, thereby reducing the overall carbon footprint in the polymer value chain.

Marco Villa, the Chief Operating Officer of Technip Energies, expressed his satisfaction, stating, “We are delighted to collaborate with Versalis to bring our combined plastic waste recycling technologies to the commercial forefront. This partnership will fortify Versalis’ and Technip Energies’ positions as leaders in the transformation of conventional basic chemicals and polymers into sustainable, decarbonized products, facilitating the shift towards a circular economy.” PET-Bottle recycling technologies

Adriano Alfani, the Chief Executive Officer of Versalis, emphasized the effectiveness of the partnership model, saying, “We believe that collaborative partnerships are powerful drivers of growth, converting synergies into the robust foundation we require to make our industry increasingly sustainable. This alliance with Technip Energies, which melds the innovative technologies of both companies in chemical recycling with their significant industrial expertise, will accelerate the implementation of tangible and effective solutions for combating plastic waste on a global scale, wherever it is needed.”

Scientists from the University of Auckland have developed a mechanochemical destruction method to destroy per- and polyfluoroalkyl substances (PFAS) from soil contaminated with firefighting foam

Per- and polyfluoroalkyl substances (PFAS), most commonly known as ‘forever chemicals’, resist water, oil and heat, and are present in everything from pizza boxes to toilet paper, from water to human blood. PFAS are also found in substantial concentrations in aqueous film-forming foam (AFFF), or firefighting foam, which has been applied to land at firefighting-training sites globally for decades. This has led to significant contamination of soil at facilities like refineries, airports, military bases, and potentially many more unknown sites. PET-Bottle recycling technologies

A team of scientists from the University of Auckland in New Zealand has now developed a mechanochemical destruction (MCD) method to destroy PFAS from soil contaminated with firefighting foam. The method uses ball milling to grind down the forever chemicals and works similarly to a mortar and pestle but at an extremely high intensity, ‘with the balls moving at incredible speeds to degrade the PFAS at molecular level’, lead researcher Dr Kapish Gobindlal said in a statement.

The team, collaborating with the U.S. Environmental Protection Agency, did laboratory benchtop experiments from 2018 to 2023 to prove the concept, colliding 10 to 30 small metal balls in heavily modified shipping containers.

The method was applied to PFAS in soil from a decommissioned New Zealand Defence Force firefighting training site, AFFF, and in media such as activated carbon, which is used to remove PFAS from water. The only additive employed for MCD treatment was quartz sand, which was used only for the liquid AFFF sample, with no additives required for the destruction of PFASs in the contaminated soil. Destruction efficiencies of target PFAS subgroups reportedly ranged from 99.88% to 100%. PET-Bottle recycling technologies

“We’ve established proof-of-concept and believe this method can be scaled up faster and cheaper than alternatives,” said Gobindlal. That the grinding process did not require expensive additives is a promising sign, as additives play a crucial role in ramping up cost and thereby in slowing down economies of scale. “There is a massive need – the U.S. alone has thousands of contaminated sites and regulation is shifting toward mandating remediation of these sites,” Gobindlal continued.

U.S. President Joe Biden said in March that cleaning up PFAS from the environment is a ‘massive task that will require our continuous and dedicated investment in the coming years’. The U.S. Department of Defence estimating in 2021 that its clean-up could cost $31 billion.

PET-Bottle recycling technologies