PET Bottles Recycling – China’s Ministry of Commerce declared the imposition of anti-dumping duties on Taiwanese polycarbonate imports, effective from April 20 for five years 29-04-2024

PET Bottles Recycling

r-PET Packaging – Polymer prices: Upward trend continues due to higher feedstock costs

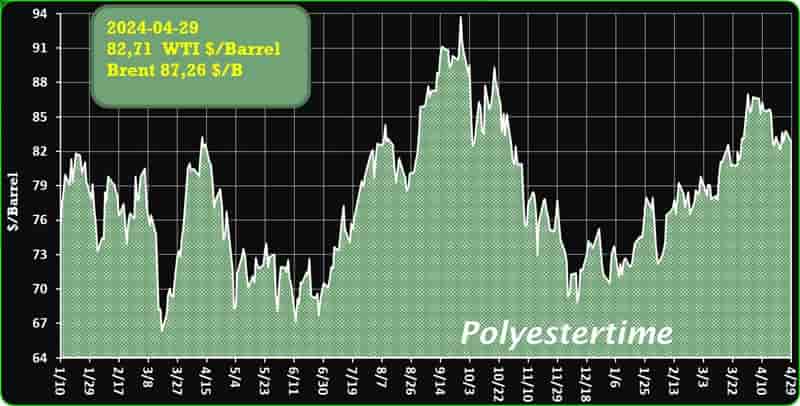

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Axpo and electric utility Rhiienergie have inaugurated Switzerland’s largest green hydrogen production facility in Graubünden canton

Situated alongside the Reichenau hydropower plant in Domat/Ems, this 2.5-megawatt facility can generate up to 350 tonnes of green hydrogen annually. This venture marks a significant step in integrating hydrogen into the national energy landscape to enhance future supply security.

Constructed over approximately a year, this plant employs water electrolysis powered by adjacent hydroelectricity, thus producing hydrogen without CO2 emissions. The resulting hydrogen, which can offset up to 1.5 million liters of diesel each year, is compressed for easy transportation to refueling stations and industrial clients. PET Bottles Recycling

The project’s opening ceremony drew political and business leaders, including local council members, Graubünden Cantonal Councillor and Energy Minister Dr. Carmelia Maissen, and National Councillor Martin Candinas. Dr. Maissen praised the plant’s alignment with regional green hydrogen ambitions and broader climate objectives.

Both Axpo CEO Christoph Brand and Rhiienergie CEO Christian Capaul underscored the critical role of green hydrogen in sustainable energy transition. Capaul highlighted the facility’s status as a flagship project for the region. Brand acknowledged existing challenges but remained optimistic about the potential of this renewable energy resource, emphasizing its sustainability credentials. PET Bottles Recycling

TOMRA has secured long-term agreements with OMV and Borealis to supply high-quality raw materials for their recycling operations, enhancing the circular economy for plastics

Under these agreements, TOMRA Feedstock will deliver consistent feedstock to OMV’s ReOil® plants in Austria and to Borealis’ mechanical recycling facilities across Europe. Volker Rehrmann, Executive Vice President and Head of TOMRA Recycling, highlighted the significance of this collaboration in leveraging technology to reclaim post-consumer plastics, preventing their incineration and promoting reuse.

The feedstock will originate from a new, pioneering sorting facility in Germany, set to open at the end of 2025 with an annual input capacity of 80,000 metric tonnes. This facility will specialize in transforming mixed post-consumer plastic waste into clean, specific polymer types for further processing. PET Bottles Recycling

Daniela Vlad, OMV Executive Vice President Chemicals & Materials, emphasized that the agreement supports their ReOil® technology in producing sustainable materials, contributing significantly to a circular plastics economy. Meanwhile, Borealis will utilize the feedstock in its Borcycle™ M technology, creating high-performance polymers from polyolefin-based waste for diverse industries such as automotive and healthcare.

Craig Arnold, Borealis Executive Vice President, reaffirmed their commitment to increasing recycled content in products, enabling customers to enhance their use of recycled plastics. This partnership marks a substantial advancement in sustainable plastic production and recycling, signifying a major stride towards closing the loop in plastic utilization.

PET Bottles Recycling

China’s Ministry of Commerce declared the imposition of anti-dumping duties on Taiwanese polycarbonate imports, effective from April 20 for five years

The ministry’s final determination followed an investigation which confirmed that dumping by Taiwan was harming China’s polycarbonate industry. Taiwan’s exports of this material to China last year were valued at around US$830 million, constituting 78.5 percent of its total polycarbonate exports, as per Taiwan’s Customs Administration.

Polycarbonate, used in electronics, automotive, optics, packaging, medical devices, and safety equipment, was listed in the 2010 Economic Cooperation Framework Agreement between Taiwan and China. The decision to apply these duties is seen as part of China’s strategy amidst broader geopolitical tensions. PET Bottles Recycling

The anti-dumping investigation began in November 2022, with preliminary results in August indicating significant harm to the Chinese industry. Initial duties were set at up to 22.4 percent. Specific duties announced include 9 percent for Taiwan Chemical Fiber Corp and Idemitsu Chemicals Taiwan Corp, 12.2 percent for Chimei Corp and Chi Lin Technology Co., Ltd, and 22.4 percent for other firms.