PET film – Sorting-technology – Battery 07-02-2023 - Arhive

PET film – Sorting-technology – Battery

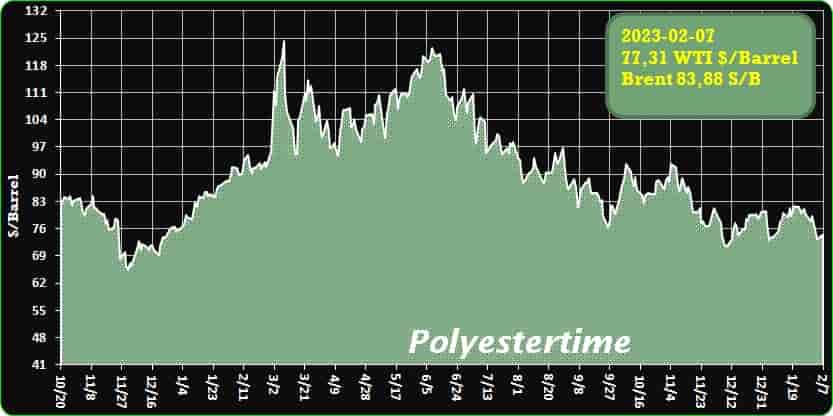

Crude Oil Prices Trend

Crude Oil Prices Trend

-PET film producer Evertis obtains the Retray certification, quantifying recycled content from the tray-to-tray loop

RETRAY is the Ecosense Foundation’s certification scheme to consolidate a circular economy model in the value chain of thermoformed PET packaging by quantifying the content of recycled material, from the tray-to-tray circuit and other sources, in accordance with the EN 15343 standard and the verification of its recyclability according to the guidelines published by the foundation.

Evertis, present in the polymer industry since 1959, is specialized in the production of monolayer and multilayer PET film for food packaging applications. The purpose of the company has always been to offer packaging solutions that close the loop and contribute to a circular economy in the PET thermoform sector.

Their sustainability strategy integrates the UN Sustainable Development Goals and boosts the product innovation in terms of circularity, recyclability and eco-design, as is the case of their latest product launches, Ecobar™ and Ecoseal™. PET film – Sorting-technology – Battery

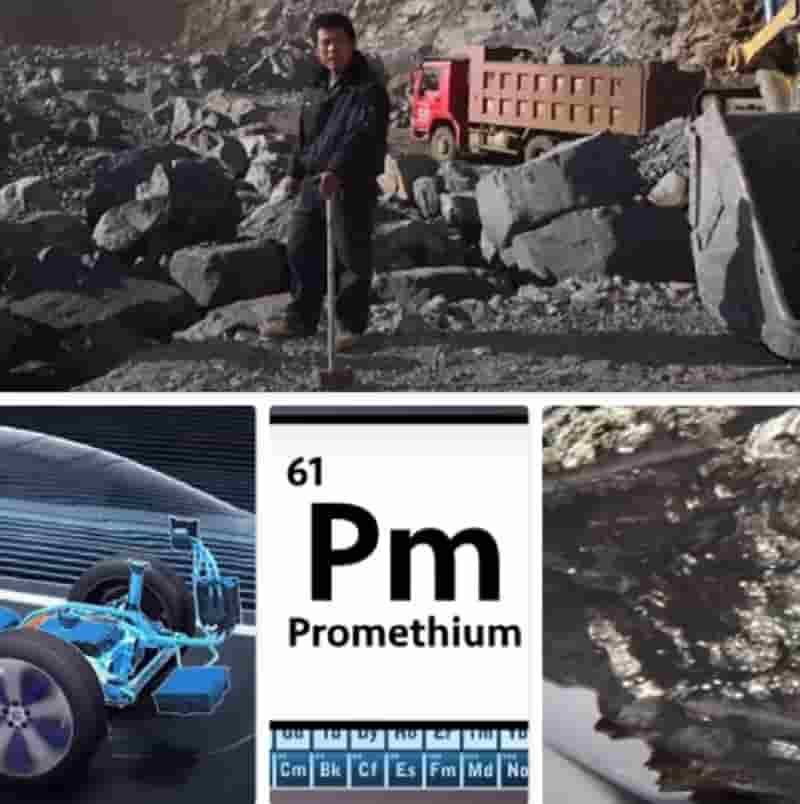

-The ecological transition? It’s unsustainable. The necessary minerals wreak havoc on the environment

“The planet cannot afford the energy transition.” Lapidary Giovanni Brussato, mining engineer among the leading experts on the environmental impact of the mining industry.

His analyzes lead to a truth that is difficult for the environmental Taliban to chew: the extraction of minerals necessary for the ecological transition would have a worse impact on the environment than the damage it seeks to repair: the patch is worse than the hole.

For example, the amount of copper that would be needed in the next few years would be greater than that mined in five thousand years. PET film – Sorting-technology – Battery

Then there are concrete, steel and zinc for wind turbines, silicon, glass and aluminum for solar panels, nickel, lithium and cobalt for batteries: resources that are not infinite. Leaving aside the prices that skyrocket, is it possible to plunder the mineral reserves of the Earth in a few years? What about future generations?

In addition and more compelling there is the environmental impact. For a kilo of lithium tons of rock are excavated, disfiguring the landscape and consuming quantities of water that we do not have.

We have just rejoiced at the discovery of the largest European deposit of rare earths in Sweden, only to understand immediately that the extraction will be extremely polluting and that the subsequent processing, incompatible with European environmental standards, will perhaps be located in China.

Last but not least, social sustainability. It is not difficult to find merciless images of young African miners, even minors, on the net.

How compatible are they with the nobility of who wants to drive an electric car to save the planet from warming? In addition to the unsustainability of the transition, the fact remains that many peoples cannot in fact pursue it. PET film – Sorting-technology – Battery

Emissions of greenhouse gases, responsible for warming, have increased dramatically this century, as the population has increased from six to eight billion and as one billion people have been lifted out of absolute poverty.

We are more but we starve less, for the first time in history, because we produce more wealth using coal and oil. It’s not difficult: I prefer to live.

This does not mean that greenhouse gases should not be limited. It’s just not conceivable to do it by turning a switch and eliminating thermal cars and gas heaters.

We have looked for the remedy to a complex problem in the magic wand of ideology and now we find that it doesn’t work.

There are solutions but they are more demanding and perhaps longer. One is the circular economy, i.e. shifting part of the industrial activity from new production to the recovery and renewal of products for reuse. PET film – Sorting-technology – Battery

Another is the European development model, which produces around 5 tonnes of CO2 per capita per year, compared to over 14 in the United States: two similar economies with very different environmental impacts.

Europe, whose emissions have been declining since 1980 and today weigh very little, instead of pursuing further and improbable suicidal transitions, should promote the adoption of its industrial and economic model among emerging and developing countries.

The transition must be based on science not ideology, or it will end before it even begins.

-Recycleye’s $17 million in Series A funding to help enable scaling of sorting technology

Recycleye has raised $17 million in a Series A financing round, led by deep-tech venture capital firm DCVC.

Recycleye uses AI-powered waste-picking robots to lower the cost of sorting materials. The sorting technology helps deliver essential data for decision-making in a material recovery facility (MRF). The new investment will be used to further improve the uncommon accuracy of Recycleye’s sorting.

DCVC led the funding round, with existing investors increasing their stakes. Promus Ventures, Playfair Capital, MMC Ventures, Creator Fund, and Atypical were joined by new Madrid-based investors Seaya Andromeda. The series A funding follows $5 million previously raised in 2021 and $2.6 million secured to date in European and U.K. government innovation funding. PET film – Sorting-technology – Battery

-Nissan to launch first solid-state EV in 2028

Firm is in a ‘class-leading position’ to introduce cost-saving, liquid-free batteries with 2025-bound production plant

Nissan will launch its first solid-state EV in 2028, believing itself to be in a “class-leading position” regarding the technology

Firm is in a ‘class-leading position’ to introduce cost-saving, liquid-free batteries with 2025-bound production plant

Read our review Back to top “If you can put in energy three times faster, is it any different to filling a [petrol] vehicle?” said Moss.is put through its paces – can this distinctive Chinese EV make the cut in the UK? Features Piers Ward is off to Saudi Arabia to meet the mechanics who make the infamous Dakar Rally happen.Autocar writers’ cars of 2022: Kia Picanto The opinions and analysis of our team of experts and star columnists will guide you through the debates shaping the design, manufacture and ownership of the cars we love. PET film – Sorting-technology – Battery

New electric cars 2023: what’s coming when The two-seater features a unique set of wheels, along with a big open-air vent in place of a front grille.

-New venture to develop workwear polyester recycling

A new venture, Stuff4Life Workwear, has been set up to develop a recycling process for polyester to reduce the amount of workwear going to landfill.

It has been created by Hull-based safety wear and equipment specialist Arco jointly with Stuff4Life, a start-up which is developing its own patent-pending chemical recycling process towards full-scale commercialisation. PET film – Sorting-technology – Battery

Based on Teesside, Stuff4Life Workwear aims to create a circular supply chain for polyester, reducing the amount of unwanted workwear going to landfill as well as carbon emissions related to raw materials used in their production.

The joint venture builds on a relationship with Teesside University and its Net Zero Industry Innovation Centre as well as the Centre for Process Innovation at Wilton, part of the UK Government’s High Value Manufacturing Catapult.

-Fluence Analytics, a Pioneer in Digitalizing the Monitoring of Polymerization Reaction Processes, Acquired by Yokogawa

Yokogawa Electric Corporation announced the acquisition of Fluence Analytics, Inc., a US-based startup that provides real-time analytics solutions to polymer and biopharmaceutical companies worldwide. Since signing investment and collaboration agreements in August 2021, the two companies have been exploring potential business opportunities.

Through this acquisition, Fluence Analytics will integrate its operations with Polymerization Reaction ProcessesYokogawa’s existing business and further enhance its technological capabilities. Fluence Analytics will operate as Yokogawa Fluence Analytics from now on.

Fluence Analytics is a global leader in polymerization reaction monitoring and control, and its automatic continuous online monitoring of polymerizations (ACOMP) product is the only commercially available system that can measure and analyze multiple polymer properties in real time. PET film – Sorting-technology – Battery

ACOMP’s data streams provide new insights into material properties that enable customers to optimize and control polymerization processes, leading to improved product quality, greater yields, and less energy consumption and material waste.

Based on the average size of a polymer reactor, the ACOMP system is estimated to deliver US$1.5 million in value per year, estimated by Fluence Analytics based on the following operating conditions: Annual production 15,000 tons (300 batches/year, 50 tons per batch), USD 3,000 per ton.

Initial agreements between the two companies in August 2021 generated strong interest from global chemical companies seeking to transform their operations with automated digital technologies. Fluence Analytics is currently developing the next-generation ACOMP product, which will become part of Yokogawa’s OpreX offering. The two companies are exploring how to integrate the next-generation ACOMP with Yokogawa’s advanced control solutions and the digital technologies of KBC, another Yokogawa Group company. Yokogawa’s global network will perform engineering and system integration tasks and provide after-sales field services for the ACOMP system. PET film – Sorting-technology – Battery

In addition to ACOMP, the Fluence Analytics product portfolio includes a lab instrument designed to accelerate and optimize the development of novel biotherapeutics. The instrument enables the rapid assessment and real-time monitoring of the stability of therapeutic proteins, peptides, and other biopolymers under various thermal, mechanical, and chemical stress conditions.

-Sabic to launch thin-wall transparent copolymer resins at MD&M West

SABIC, a global expert in the chemical industry, will introduce two new LNP CRX polycarbonate (PC) copolymer resins offering a combination of robust chemical and impact resistance, thin-wall transparency, dimensional stability and processability at MD&M West 2023. PET film – Sorting-technology – Battery

In device applications such as clear covers, screens and display lenses, the new materials can overcome key drawbacks of incumbent PC resins and co-polyester resins when exposed to disinfectants or aggressive chemicals. Options include LNP ELCRES™ CRX1314TW copolymer or its bio-based equivalent, LNP ELCRIN CRX1314BTW copolymer, which offers up to a 42% reduction in carbon footprint based on life cycle assessment (LCA). Both grades feature limited biocompatibility according to ISO 109931 and coverage under SABIC’s healthcare product policy, which provides stringent management of change processes.

PET film – Sorting-technology – Battery