PET plastic – “The Hidden Risks of Sunlight on Plastic Water Bottles” 26-09-2023

PET plastic

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Denmark has opted to discontinue its support for hydrogen-powered vehicles, a decision that has generated both debate and contemplation about the future of eco-friendly transportation

Electric vehicles have unequivocally gained the upper hand over hydrogen in the realm of ecological transition, prompting Denmark to close down all hydrogen (H2) fuel distributors.

The absence of hydrogen distributors in Denmark has created an opportunity for electric counterparts to flourish. The dominance of electric cars over their hydrogen counterparts is not a mere inference but a fact substantiated by sales figures and production quantities across various automotive brands. As a result, Denmark is on the brink of shutting down all H2 distribution points. PET plastic

While it was conceivable for both eco-friendly fuels to coexist, much like the historical coexistence of Diesel, LPG, methane, and petrol, the commercial advantage overwhelmingly tilts towards lithium-ion-powered vehicles.

The closure of hydrogen infrastructure in Denmark is further expedited by the events of 2020 when the energy company Everfuel acquired control over all hydrogen distribution points in the country, with the optimistic aspiration of making a lucrative investment. Regrettably, this ambition did not materialize as expected, leading the company to reconsider its commercial strategies and explore alternative avenues within the realm of green energy. PET plastic

The trend away from hydrogen vehicles extends beyond Denmark and permeates the broader European landscape. In Italy, for instance, over 27,000 electric vehicle charging stations are operational or in the process of installation, while only two active hydrogen refueling stations exist. This demonstrates a lack of enthusiasm for hydrogen-powered cars among Italians. Furthermore, the European Union’s skepticism toward hydrogen is evident as it allocates 352 million euros for mobility, with a focus on creating 12,000 new high-speed charging points for battery electric vehicles (EVs) compared to just 18 hydrogen refueling stations throughout Europe. These numbers unequivocally endorse the preference for electric mobility in Brussels.

Even automobile manufacturers have aligned with this inclination, with only two brands venturing into the production of hydrogen cars: the Toyota Mirai and the Hyundai Nexo, the latter of which has only recently been introduced to the Australian market.

“The Hidden Risks of Sunlight on Plastic Water Bottles”

Introduction: It may come as a surprise, but the water bottle you carry with you throughout the day to stay hydrated might be doing more harm than good. While plastic water bottles, commonly made from polyethylene terephthalate (PET), are generally considered safe for water storage, there’s a dark side to their use when exposed to sunlight and heat.

The Impact of Sunlight on PET Plastic: PET plastic, indicated by the number 1 within recycling arrows on the bottle, is believed to be safe for water storage. However, it’s essential to understand that these bottles were not designed to withstand prolonged exposure to sunlight or high temperatures. Sunlight contains UV radiation, which can break down chemical bonds in plastics like PET, causing them to decompose rapidly. This degradation process leads to the release of various chemicals into the water or beverage inside the bottle. PET plastic

Environmental Conditions Matter: Many people are unaware of the environmental conditions for which these plastic bottles were designed. PET bottles are not meant to be exposed to direct sunlight or stored in hot environments, such as inside a car or at the beach. Sunlight, elevated temperatures, high humidity, and oxygen levels—all present when PET bottles are exposed to the weather—contribute to the breakdown of plastic and the release of harmful chemicals.

Health Risks Associated with Chemical Leaching: The Endocrine Society warns that plastics, including PET, contain and leach hazardous chemicals, including endocrine-disrupting chemicals (EDCs). These EDCs can disrupt the body’s hormone systems, potentially leading to serious health issues like cancer, diabetes, reproductive disorders, and neurological impairments in fetuses and children. There is substantial evidence linking the toxic chemical additives in plastics to specific health impacts on the endocrine system.

Understanding Chemical Migration: Chemical migration from plastic into water or beverages depends on factors like the substance’s nature, contact temperature, and contact time. When PET bottles are used as intended, the amount of chemical migration is minimal and not considered a health risk. However, misuse, such as using plastic bottles for purposes beyond their design, can lead to increased chemical migration.

Temperature and Time Matter: Migration of chemicals from plastic bottles increases with higher temperatures and prolonged contact time. Although this may not necessarily pose an immediate health risk, it can alter the taste, color, and odor of the water, making it less appealing for consumption. PET plastic

Misuse and Health Risks: Using PET water bottles in direct sunlight or heat contradicts their intended use and can result in greater chemical migration than expected. Scientific studies on the safety and low-level chemical leaching of these bottles are only applicable when they are not exposed to heat and sunlight.

Common Misconceptions: Unfortunately, discussions about the safety of PET plastic bottles often overlook the impact of UV radiation and heat. Some sources, like Livestrong and the CDC, downplay the risks associated with sunlight and heat exposure, despite evidence suggesting that these conditions can change the organoleptic properties of water and may pose health risks.

Conclusion: While plastic water bottles are a convenient way to stay hydrated, it’s crucial to be aware of their limitations. Prolonged exposure to sunlight and heat can lead to chemical leaching, potentially affecting your health. To ensure the safety of your water, it’s best to use PET bottles as intended and avoid exposing them to direct sunlight and high temperatures. Your well-being should always be a top priority when it comes to staying hydrated on the go. PET plastic

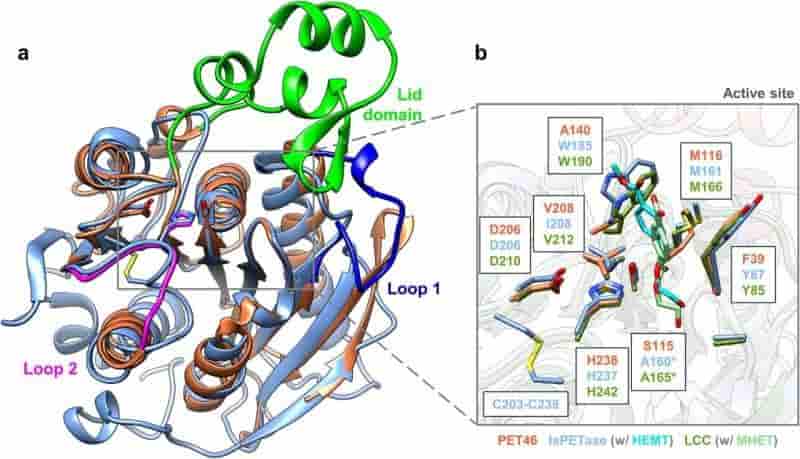

A recently unearthed enzyme from the depths of the ocean is capable of breaking down PET plastic, a crucial discovery in the battle against plastic pollution plaguing our coasts and oceans

This groundbreaking finding emerges from a collaborative study led by Professor Ruth Schmitz-Streit’s research team at Kiel University, with significant contributions from researchers at the University of Hamburg and the Heinrich-Heine-University Düsseldorf.

The study represents a pivotal advancement in our comprehension of PET-degrading enzymes, their underlying mechanisms, and their evolutionary significance within the global ocean ecosystem. These groundbreaking results have been published in the journal Communications Chemistry, where the research team not only explores potential biotechnological applications but also underscores the enzyme’s profound relevance in biogeochemical processes both in oceanic and terrestrial environments.

What sets this PET-degrading enzyme apart is its unique origin.

Professor Ruth Schmitz-Streit, the head of the Molecular Biology of Microorganisms working group at the Institute of General Microbiology (IfAM) and a member of the Kiel Marine Science (KMS) research priority area at Kiel University, explains, “In our study, we have unveiled a novel genetic resource derived from deep-sea archaea, previously unknown in this context.” PET plastic

Until now, most PET-degrading enzymes, numbering around 80, were primarily associated with bacteria or fungi.

“Our findings significantly contribute to a better understanding of the ecological role played by deep-sea archaea and their potential impact on PET waste degradation in marine environments,” adds the microbiologist.

This newly discovered enzyme, named PET46, was identified and comprehensively characterized using a metagenomic approach. The research team isolated the gene from a deep-sea sample based on genetic similarities to known sequences, synthesized the corresponding coding gene, produced the enzyme in Escherichia coli bacteria, and meticulously studied its biochemical and structural properties.

PET46 exhibits a multitude of distinctive traits, expanding the repertoire of PET-active enzymes. Its structural divergence from previously documented enzymes is particularly noteworthy. PET plastic

For instance, PET46 demonstrates the exceptional ability to break down both long-chain PET polymers and short-chain PET oligomers, enabling continuous degradation.

One of the enzyme’s standout features is its novel substrate-binding mechanism, distinguished by a unique “lid” consisting of 45 amino acids positioned above the enzyme’s active center. In contrast, other PET enzymes typically employ aromatic amino acids in proximity to their active sites for binding.

At the molecular level, PET46 shares remarkable similarities with another enzyme called ferulic acid esterase, which naturally degrades lignin in plant cell walls. Given the structural similarities between lignin and PET, these naturally occurring PET-degrading enzymes may play a vital role in the decomposition of wood, such as in forest soil composting. PET plastic

The remarkable biochemical attributes of PET46 position it as a promising candidate for various applications, encompassing marine and terrestrial plastics, as well as biotechnology. Notably, PET46 exhibits superior efficiency at 70°C compared to reference enzymes from bacteria and composting plants, which function optimally at their respective temperatures.

This groundbreaking research was conducted under the auspices of the PLASTISEA project, led by Professor Ute Hentschel Humeida of the GEOMAR Helmholtz Center for Ocean Research in Kiel. Dr. Jennifer Chow from the University of Hamburg and Dr. Pablo Pérez-Garcia, a research assistant in Schmitz-Streit’s group, jointly contributed as the first authors of the study. PET plastic

China’s high-tech materials firm to help renovate textile industry

BEIJING-A Chinese leading manufacturer, which specialises in textiles auxiliaries and organic silicone products, has joint hands with local partners to bring technological innovation support to the textile printing and dyeing industry in Pakistan.

“As the pillar industry of Pakistan, textile industry is currently facing two major constraints, namely energy and cotton yarn shortage. The fabric categories of some local printing and dyeing factories are gradually transitioning to a large proportion of polyester. Chinese chemical fiber suppliers can provide the most suitable chemical fiber raw materials for unique textile categories to match needs,” said Xing Pingping, Overseas Sales Manager of Ningbo Runhe High-tech Materials Co., Ltd. PET plastic

According to Xing, recently, his company joined hands with Pakistani agent FairChem International to hold a textile seminar in Faisalabad, in which China and Pakistan partners jointly discussed the future direction of local textile printing and dyeing industry. More than 150 local practitioners participated to explore new opportunities. According to data released by Pakistan Customs, in fiscal year 2022, Pakistan’s total exports of textiles reached USD19.32 billion, a year-on-year increase of 25.3 percent from the previous fiscal year, and accounted for nearly 61 percent of Pakistan’s total merchandise exports. Pakistan, which has a relatively complete industry chain, owns more than 2,000 cotton binding, spinning, and textile factories, China Economic Net (CEN) reported.

However, “Pakistan’s textile category structure is obviously different from other countries in South Asia. Many major fabric categories use larger amounts of cotton, yet have lower profit margins,” Xing said, “Which has largely affected the competitiveness of Pakistani textiles in the international market. PET plastic

“In response to the energy shortage I mentioned earlier, growth in the coming years will be driven largely by the digital textile printing market,” Xing emphasized, “the market for digital textile printing in Pakistan is increasing as it offers better and high-definition textile print design possibilities, lower water, effluent, emissions and energy use.

Besides, the technological level of Pakistani textile enterprises is increasing day by day, thus some small-scale factories also have advanced textile materials and technologies, such as polyurethane coating, aramid finishing, waterproof finishing, etc. There are also many printing and dyeing factories that have digital printing machinery. Regarding current shortage of cotton yarn, local companies have generally increased the proportion of polyester applications. For these chemical fiber materials, our cutting-edge chemical fiber silicone emulsion can come in handy. In addition, professional chemical fiber finishing solutions and polyester cotton-like and wool-like finishing solutions can also provide assistance to our local partners.” PET plastic

JPMorgan’s energy guru warns oil prices are headed to $100 per barrel. ‘Put your seatbelts on, it’s going to be a very volatile supercycle’

Oil production cuts by Russia and the Organization of the Petroleum Exporting Countries (OPEC) have helped push Brent crude prices up some 10% over the past month to roughly $93 per barrel. Christyan Malek, JPMorgan’s head of EMEA energy equity research, fears it’s just the beginning of an era of higher prices.

“Put your seatbelts on. It’s going to be a very volatile supercycle,” the energy guru told Bloomberg Friday when discussing what to expect next for the oil market.

Malek, like a growing number of his peers on Wall Street, believes that a lack of investment in new oil production, coupled with production cuts from OPEC and other top oil producers, will lead to higher crude prices for years to come.

“The flow of capital into new oil supply is just not what it was like in the last 30 years,” he said. PET plastic

“So what that’s doing is driving the long-term price, the back end of the curve, up to $80, or north of $80. We think it probably normalizes around $100.”

Although a major psychological milestone, $100 oil isn’t what it used to be because of inflation. A barrel that today costs $100 is the equivalent, in real dollars, to a $71 barrel in 2010 and a $56 barrel in 2000.

Malek noted that for decades oil producers benefited from low borrowing costs, but with the Federal Reserve and many other central banks worldwide raising interest rates to fight inflation, it’s now far more costly to finance new oil production projects. “You need at least $80 [per barrel] to invest in marginal new oil [production],” he explained. “We call it the cash break-even.”

Despite U.S. and European recession fears, which would normally lead oil prices to fall as investors anticipate fading consumer demand, crude oil prices have surged in 2023 due to this lack of new oil production as well as production cuts from the world’s largest producers. PET plastic

The 13 member nations of OPEC, which produce roughly 80% of all crude, are now producing less oil than at any time since August 2021. Saudi Arabia and Russia also both decided this summer to cut their oil production by 1 million and 300,000 barrels per day, respectively, through the end of the year. And on Thursday, Russian officials enacted a temporary ban on exports of gasoline and diesel to all countries outside of four ex-Soviet states in an attempt to stabilize their domestic fuel market.

The good news, according to Malek, is that although oil prices might rise to $100 per barrel, it’s unlikely they will soar much higher than that because OPEC isn’t willing to miss out on sales due to fading demand. When oil prices surge too far, too fast, consumers and businesses are eventually unable to keep up with the rising costs, leading to a reduction in demand for the product. PET plastic

“They [OPEC] have a sort of fiduciary duty to make sure they’re stabilizing the price [of oil],” Malek explained. “I think what they’re trying to do is make sure it stays within a range. So by definition, if we see a very cold winter or hurricanes and prices spike very quickly, they’ll be managing the upside just the way they’re managing the downside.”

The Plastics Fair 2023, organized by Mikrocentrum, was a comprehensive event that provided valuable insights into the plastics and rubber industry

Attendees were treated to a wealth of information, tips, and sustainable highlights from the industry during the event held at Brabanthallen.

One noteworthy announcement came from Sandra Onwijn, Head of the Circular Economy Department at the Ministry of Infrastructure and Water Management. She highlighted the impending national regulations aimed at accelerating circular plastic chains and introduced a promising initiative known as the “circular plastic standard.” Under this standard, companies would receive financial support, which was hailed as a significant opportunity for the industry. PET plastic

Ms. Onwijn emphasized the need to delve into the details of the scheme, especially given the heightened climate and environmental targets. The circular plastic standard would not only entail stricter rules and controls but also incentive policies, creating a favorable environment for the sector to thrive.

The Plastics Fair also showcased its broader relevance, with the presence of representatives from organizations like Urgenda, the Plastic Free Sea Foundation, and knowledge institutions from around the world. Sustainability and innovation were central themes throughout the event.

The fair featured an array of lectures and presentations, totaling fifty in number, catering to diverse interests within the industry. Topics ranged from renewable resources and waste prevention to reducing CO2 emissions and the importance of high-quality recycling, biobased materials, and effective product design. PET plastic

The Machinery Square, a key attraction, displayed state-of-the-art technology for the plastics and rubber industry. Sustainability remained a focal point here, with a notable example being Ferromatik’s fully electric injection molding machine, which garnered significant interest due to its potential for energy savings.

Sandra Onwijn, in her interactions at the fair, expressed optimism about the Netherlands’ standing in the global circular plastic landscape. While she couldn’t provide exact rankings, she highlighted the country’s ambition to lead in this area. The Netherlands is actively working on setting standards for circular plastics in Europe, offering an opportunity for businesses to seize a frontrunner position and access substantial financial support for their circularity efforts. PET plastic

In conclusion, the Plastics Fair 2023 was not just a showcase of industry innovations but also a platform for discussions on sustainability, innovation, and government initiatives. It emphasized the potential benefits of the upcoming circular plastic standard, positioning the Netherlands as a frontrunner in the circular plastics movement.

INDA partners with the Waterloo Filtration Institute

CARY – INDA, the Association of the Nonwoven Fabrics Industry, has joined forces with the Waterloo Filtration Institute to present the FiltXPO technical program scheduled for October 10-11, 2023, in Chicago, Illinois.

The Waterloo Filtration Institute played a pivotal role in suggesting program topics and bringing world-class presenters on board. This collaboration aims to provide engineers, scientists, and industry professionals with the latest insights into filtration and separation topics that are currently shaping the industry and will continue to do so in the future. Detailed information about the conference, including the list of speakers, can be found on the FiltXPO website. PET plastic

The program encompasses a wide range of presentations, including discussions on filter media technologies, advancements in filtration machinery and equipment, innovations in clean air solutions for both residential and urban environments, standards and testing procedures, emerging industry trends, new developments, as well as challenges and opportunities in the field of filtration.

This year’s keynote address, titled “IAQ Is the New Black,” will be delivered by Suzanne Shelton, President & CEO of Shelton Group. Shelton will share the latest consumer data on health, safety, the environment, and society, providing participants with valuable insights into the filtration sector’s opportunities and the communication challenges faced by manufacturers in showcasing the value of their products.

A sneak peek at some of the subject matter experts lined up for the event includes:

- AAF Flanders – Discussing “Air Filter Standards Activity and Its Impact on Innovation” PET plastic

- Ahlstrom – Exploring “Enhancing Wetlaid Filtration Media Performance Through Innovation”

- Air Techniques International – Examining the “Application of Automated Filter Tester in Quality Control Testing: The Significance of Consistent Aerosol Particle Size Distribution”

- American Truetzschler, Inc. – Shedding light on “How to Produce Exceptional Filter Media”

- CEREX Advanced Fabrics – Presenting “The Antimicrobial Advantages of Nylon”

- Elsner Engineering Works, Inc. – Delving into “The Right Time for Automation”

- Hollingsworth & Vose – Discussing “Accelerating Membrane Adoption with ROI in Mind”

- INDA – Exploring “Beyond Porter’s Five Forces: The Impact of Regulation on Markets” PET plastic

- Mann+Hummel – Unveiling “Filtration for Cleaner Urban Mobility: Introducing Horizon Europe Innovation Action AerosolFD”

- NatureWorks – Optimizing “Biopolymers to Enhance Filter Performance: A Range of Approaches and Opportunities”

- Palas GmbH – Analyzing the “Influence of Temperature and Humidity on Filter Efficiency and Dust Holding Capacity”

- Ptak Consulting – Evaluating “Residential Filtration: Performance in the Face of Infectious Aerosols”

- The University of Georgia – Presenting “Recent Advances in Melt Blown Nonwovens and Filter Media Research”

New to FiltXPO this year are Lightning Talks, offering a platform for quick presentations on emerging trends, products, innovations, and ideas, with speakers changing every eight minutes. Participating companies include Ahlstrom, Elsner Engineering Works, Inc., Gottlieb Binder GmbH, TSI, and the Waterloo Filtration Institute.

The FiltXPO exhibition will run from October 10 to 12, coinciding with the technical program. To register or stay updated on program developments, please visit the FiltXPO website. PET plastic

PET plastic