PET polyester recycling – H&S completes set-up of a recycling plant for end-of-life mattresses 09-02-2024

PET polyester recycling

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

End life tires chemical recycling – Enviro and Antin announces final investment decision for plant in Uddevalla

Enviro and Antin, along with Michelin, have announced the final investment decision for the construction of an end-of-life tire recycling plant in Uddevalla, Sweden. This joint venture has secured equity financing and signed multi-year agreements for the supply and offtake of end-of-life tires, recovered carbon black, and oil products, valued at approximately MEUR 180 (SEK 2 billion) over 5 to 10 years. The customers include leading manufacturers in tire, rubber, oil, and chemicals industries.

The Uddevalla plant will be the first full-scale recycling facility based on Enviro’s patented technology. Construction is set to commence in the first quarter of 2024, with operations expected to begin in 2025. PET polyester recycling

The necessary approvals have been obtained, allowing the joint venture to proceed with material and machinery orders and subcontractor engagements.

Agreements have been finalized for the delivery of end-of-life tires to the Uddevalla plant and for the supply of recovered carbon black and oil. These agreements, with an aggregate value of MEUR 180 (SEK 2 billion), span 5 to 10 years and involve key players in various industries.

The joint venture aims to construct recycling plants across Europe, targeting an annual capacity of up to one million metric tons of end-of-life tires by 2030. Enviro will receive remuneration for its investments, with half of the amount paid in cash and the remainder converted to a stake in the joint venture. Enviro also has an option to acquire approximately 30 percent ownership in the joint venture. PET polyester recycling

With the groundwork laid for the Uddevalla plant, the joint venture is poised to expand its operations swiftly across Europe, supported by a solid financing plan and strategic partnerships.

Car compound in Morocco

Repsol and Ravago have jointly inaugurated a new technopolymer plant in Tangier, Morocco, aimed at producing compounds for automotive applications.

Situated in the Tangier Automotive City (TAC) free zone within the port area, the plant spans 24,000 square meters, a project promoted by the Moroccan Government.

With an annual production capacity of 18,500 tonnes, the plant focuses on polypropylene, polyamides, and PBT compounds, with the flexibility for expansion based on future demand trends. PET polyester recycling

This initiative aligns with supporting the local automotive industry, catering to OEMs like Renault and Stellantis operating in Tangier, Kenitra, and Casablanca.

These manufacturers were involved in the project’s inception.

Local media reports suggest an investment of approximately 20 million euros into the venture.

By establishing this facility, Repsol and Ravago aim to contribute to the growth of the automotive sector in Morocco while meeting the region’s demand for high-quality technopolymers. PET polyester recycling

This collaboration not only underscores the commitment to local industrial development but also signifies a strategic move in leveraging Morocco’s potential as a hub for automotive manufacturing.

Exploring the Vibrant World of Ultramarine Pigments: Insights & Trends 2024-2034

The ultramarine pigment industry, renowned for its vivid hues and diverse applications, plays a significant role in various sectors, including paints and coatings, plastics, cosmetics, and textiles.

It is anticipated that the ultramarine pigment market would reach US$ 240.5 million by 2024. Sales of ultramarine pigment are expected to climb at a CAGR of 3.9% between 2024 and 2034. By 2034, it’s projected that the market for ultramarine pigments would be worth US$ 352.5 million. PET polyester recycling

Because the product is widely used in paints, coatings, polymers, and textiles, the market is expected to grow. The market is anticipated to rise as a result of growing consumer demand for high-performance pigments and growing awareness of environmentally friendly choices.

Production Process and Composition:

Ultramarine pigments are synthetic inorganic compounds derived from a complex chemical process. Historically, ultramarine blue was extracted from lapis lazuli gemstones, but modern production methods involve heating mixtures of clay, sulfur, and other raw materials at high temperatures to create the distinctive blue pigment. Variations in the production process yield different shades of ultramarine pigments, including blue, violet, and green. PET polyester recycling

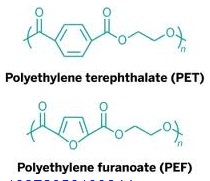

Barrier Biopolymer PEF Propelled by Performance, Potential, and Sustainability

The packaging subsegment for polyethylene furanoate (PEF), which is projected to grow at the fastest CAGR during the forecast period 2023 to 2028, will see a PEF juice bottle at retail in 2024.

Momentum continues for biopolymers, which are seen as sustainable alternatives to conventional plastics sourced from plants and other renewable materials.

Polyethylene furanoate is among a growing wave of biopolymer options. The PEF market is projected to reach $28 million by 2028, at a compound annual growth rate (CAGR) of 8.1 % from $19 million in 2023. PET polyester recycling

That’s according to a global PEF market study released in January by MarketsAndMarkets. It reports that the bioplastic’s growth is primarily driven by government regulation and policies along with increasing demand for PEF bottle production.

In fact, the PEF bottles subsegment is projected to grow at the fastest CAGR, in terms of value, during the forecast period.

That’s where the biopolymer will gain traction this year when European retailer Albert Heijn debuts high-barrier fruit juice bottles on shelf. The polymer is sourced from Avantium while Refresco, a global independent beverage solutions provider for brands, produces the bottle. Albert Heijn is the largest supermarket chain in the Netherlands. PET polyester recycling

PEF can replace PET in food and beverage packaging.

PEF’s applicability extends beyond beverage bottles to the broader packaging sector market due to its wide-ranging advantages, including as a sustainable substitute for conventional packaging materials such as polyethylene terephthalate (PET).

H&S completes set-up of a recycling plant for end-of-life mattresses

Together with the Dutch recycling company RetourMatras, H&S has implemented a plant for the chemical recycling of discarded PU mattresses, enabling the recovery of high-quality recycled polyols.

H&S Anlagentechnik GmbH has successfully completed commissioning of an industrial-scale reactor plant for RetourMatras, a Dutch recycling company specialized in dismantling of mattresses and their transformation into circular resources. The newly installed recycling plant uses an advanced depolymerization recycling technology to produce high-quality recycled polyol (Repolyol) from polyurethane foam (PU) from end-of-life mattresses. PET polyester recycling

Polyol is one of the key building blocks of polyurethane foam, the main cushioning material in mattresses. Its recovery without compromising on its quality enables its reuse as a circular raw material for the production of new PU foam and thus for new mattresses and other upholstered furniture — a significant step to circularity. “The H&S process allows us to chemically recycle different foam from various mattress manufacturers, supporting our ambition to secure that no mattress goes to waste by transforming it into circular resources,” emphasizes Chico van Hemert, Managing Director at RetourMatras. Commissioning took place in May 2023 in Lelystad (NL)allowing the newly built recycling plant to convert PU foam from 200,000 mattresses into repolyols annually using the cutting-edge recycling technology of H&S. PET polyester recycling

Recently, RetourMatras also partnered with IKEA Retail to find a circular solution for the end-of-life of their mattresses in line with IKEA’s approach to products made from recycled or renewable materials.

PET polyester recycling is gaining significant traction, with major companies spearheading efforts to establish a robust fibre-to-fibre recycled PET polyester (FFrPET) industry

According to a report by Textiles Intelligence, such initiatives are crucial for the textile and clothing sector to attain environmental sustainability. Despite the increasing usage of alternative fibres, PET polyester is projected to remain the dominant fibre type, with production expected to exceed 80 million tons by 2030. PET polyester recycling

Several large-scale projects are underway to facilitate FFrPET production, leveraging the advantages of established companies over startups, including operational scale and funding capabilities. Eastman, for instance, is investing in methanolysis-based recycling plants, with plans to triple its capacity by 2026. Similarly, Suez and SK Geo Centric are collaborating on a PET plastic and fibre recycling plant in France, while Indorama and Carbios are working on an enzymatic PET bio-recycling production plant capable of processing 50,000 tons of post-consumer PET waste annually.

Furthermore, Andritz Group is engaged in mechanical recycling projects in France, and Inditex has partnered with Ambercycle to support the construction of a textile regeneration factory. Ambercycle’s chemical process breaks down polyester into constituent monomers for regenerated polyester fibre production, with Inditex committing to purchasing a significant portion of the fibres’ annual output.PET polyester recycling

These initiatives signify the growing momentum towards establishing a circular PET polyester ecosystem. The report, “Fibre innovations aid the creation of circular textile and apparel supply chains,” offers comprehensive insights into these developments and is available for purchase from Textiles Intelligence and Textile Outlook International.

Nitin Gupta, Co-founder and Chief Executive Officer of Attero, emphasized the critical need for India to adopt a sustainable approach towards recycling lithium-ion batteries amidst the burgeoning electric vehicle (EV) production

Omega Seiki Private Ltd (OSPL) recently announced a strategic partnership with Attero, an e-waste management firm, aimed at recycling lithium-ion batteries. The collaboration aims to recycle over 100MWh of batteries within the next 3-4 years.

This initiative extends beyond the domestic market, covering the ASEAN and African regions as well. PET polyester recycling

OSPL, renowned for its Omega Seiki Mobility (OSM) brand electric vehicles with over 10,000 units currently in operation, views Attero’s expertise as pivotal in repurposing batteries for energy storage. This aligns with their shared commitment to addressing the complete lifecycle of EV components and ensuring responsible battery solutions. Attero boasts a processing capacity of 1,45,000 metric tonnes of e-waste and 11,000 metric tonnes of battery waste annually, with plans to increase this to 15,000 metric tonnes soon.

OSPL’s ambitious plans include deploying EV batteries totaling over 1-GWH within the next five years, paralleled by a collective target with Attero to recycle over 100 MWh of batteries in the upcoming years. This collaboration not only addresses environmental concerns but also acknowledges the economic value of extracting rare materials from spent lithium-ion batteries. Overall, the partnership signifies a significant step towards promoting sustainable practices in the burgeoning EV industry while also addressing pressing environmental challenges. PET polyester recycling

Green-hydrogen H2 – Partnership in advanced recycling of waste plastic announced 08-02-2024

PET polyester recycling