Petrochemicals EV-Cars – Slow or fast charging: what is better for the “health” of the battery? 16-10-2023

Petrochemicals EV-Cars

Petrochemicals r-PET Resin –Has the electric car won the war against the hydrogen car?

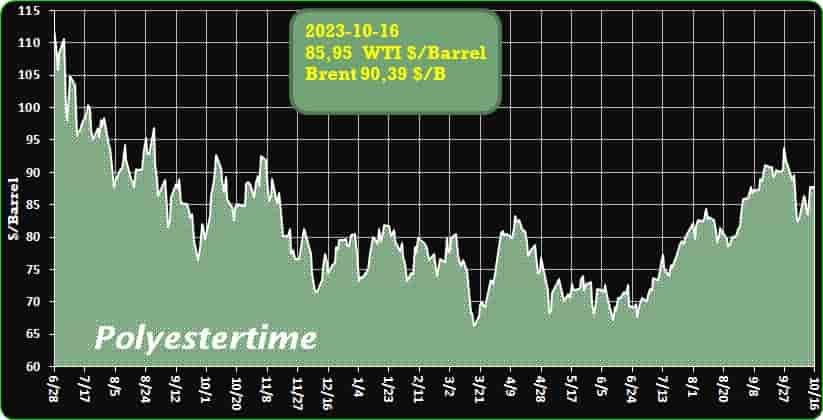

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Electric cars – Slow or fast charging: what is better for the “health” of the battery?

When it comes to charging electric car batteries, slow charging is better than fast charging.

This is because slow charging reduces the heat and pressure that accompanies charging your battery, which benefits the long-term health of your electric car battery 1.

Frequent charging cycles from 0% to 100% can cause your vehicle’s battery to degrade, especially if you’re using rapid or ultra-rapid chargers often, as these refill the battery at a much faster rate 2.

However, according to a study carried out by Recurrent, an independent company that provides reports on the health of batteries and projections on their autonomy, examining over 12,500 Tesla Model 3 and Model Y vehicles, the software and safety mechanisms of the battery management system are actually able to prevent any damage caused by disorderly charging processes or counterproductive habits. Petrochemicals EV-Cars

The study compared cars that are connected to fast charging (effectively Superchargers) for at least 90% of the time and those that use it in 10% of cases (or less).

For the Model 3 (produced since July 2017), the period considered by Recurrent covers more than five years and the graphs seem to indicate a substantially similar level of degradation between the two types of charging, at least at the level of the final “balance”: in both cases, we start from an autonomy close to 100% with a charged battery and end up around 89% after five years, with continuous “overtaking” between the two methods.

In the case of Model Y (in production since January 2020), however, the study period drops to just under three years and highlights a slight difference between the two types of charging 1. Petrochemicals EV-Cars

Low demand and high imports endanger the European plastics recycling industry

The European plastics recycling industry has been destabilized throughout 2023 due to low demand and high imports of materials from outside the EU. Since the beginning of the year, prices of recyclates have decreased by up to 50%1. The PET industry has been hit the hardest, with PET imports to the EU increasing by 20% from Q2 2022 to Q2 2023, resulting in low demand for EU rPET. Consequently, these disruptive market dynamics led to an estimated 10% decrease in rPET over the same period1.

If urgent measures are not taken to alleviate the pressure on recyclers, there is a risk that Europe will fall short of achieving its legally binding and newly proposed recycling and recycled content targets. Petrochemicals EV-Cars

Ton Emans, PRE president, commented that “the future of the recycling industry is at stake and immediate action in form of enforcement measures is needed to avoid a shutdown of recycling plants across Europe. Ceasing recycling activities would have knock-on effects on jobs, overall economy in Europe and the environment” 1.

With the targets set by the Single Use Plastics Directive nearing, the pressure to boost the use of recycled content in PET beverage bottles is high. However, rather than supplying the demand with rPET produced in Europe, this has given rise to non-transparent imports from non-European countries1. Legislation has proved itself as one of the most effective instruments in setting the course for a circular plastic future. However, enforcement measures are a must for its effective implementation. Without this, Europe risks untraceable, unverified imports of plastics participating toward the European recycling targets1. Petrochemicals EV-Cars

1 / 4

Cabopol Polymer announces new production unit in Monterrey, Mexico

We are delighted to announce that Cabopol – Polymer Compounds, a leading European company in the production of thermoplastic & crosslinked compounds, is expanding its global presence with the opening of a new production unit in Monterey, Mexico. This new unit is part of our long-term strategy to provide our clients with even better products and services and to reach new markets.

This new production unit represents our commitment to growth and innovation in the polymer industry. With an initial configuration of 2 production lines and the potential for expansion, we expect to achieve a production capacity of 25,000 tons per year.

Notably, this is the first production unit in the American continent, paving the way for our expansion in this region. It follows the successful operations of our production units in Serbia, Morocco, and Portugal. Petrochemicals EV-Cars

With an expected conclusion date of December 2023, this new production unit, located in the heart of Monterey’s industrial zone, will cover an area of 10,000 square meters. Equipped with the latest technology and equipment, it will enable us to produce high-quality polymer compounds at a competitive cost. This expansion will significantly increase our production capacity, improve supply chain efficiency, and reduce lead times for our customers in the Mexican and American markets.

In response to this significant development, the Sales Director of Cabopol Polymer Compounds, Anselmo Mendes, expressed his enthusiasm: “The opening of our new production unit in Monterey, Mexico, marks a pivotal moment for Cabopol. We are dedicated to delivering the highest-quality polymer compounds, and this expansion allows us to further our commitment to excellence. We are excited to better serve our customers and contribute to the growth of the local economy.”

We look forward to working closely with our partners and new customers in the region and to building lasting relationships. Petrochemicals EV-Cars

The energy sector has undergone a significant transformation in recent years, with the advent of new technologies and innovations.

In this article, we will discuss the six key innovations in the energy sector that have revolutionized the way we produce, store, and consume energy.

- Renewable Energy: Renewable energy is a form of energy that is derived from natural resources such as sunlight, wind, rain, and geothermal heat. It is a clean and sustainable source of energy that has gained significant traction in recent years. According to the International Energy Agency (IEA), renewable energy sources accounted for 29% of global electricity production in 20201. The increasing adoption of renewable energy sources has helped reduce carbon emissions and mitigate climate change. Petrochemicals EV-Cars

- Energy Storage: Energy storage is an essential component of the energy sector that enables us to store excess energy generated from renewable sources. It helps balance the supply and demand of electricity and ensures a stable power supply. Energy storage systems such as batteries, flywheels, and pumped hydro storage have gained significant attention in recent years due to their ability to store large amounts of energy efficiently2.

- Smart Grids: Smart grids are an advanced version of traditional power grids that use digital technology to manage electricity supply and demand more efficiently. They enable two-way communication between power generators and consumers, allowing for better management of electricity consumption. Smart grids also help reduce power outages and improve the reliability of the power supply3.

- Electric Mobility: Electric mobility refers to the use of electric vehicles (EVs) powered by batteries or fuel cells instead of traditional fossil fuel-powered vehicles. EVs are environmentally friendly and emit fewer greenhouse gases than traditional vehicles. The increasing adoption of EVs has led to a significant reduction in carbon emissions from the transportation sector4.

- Energy Efficiency: Energy efficiency refers to the efficient use of energy to achieve maximum output with minimum input. It involves using energy-efficient appliances, lighting systems, and building materials that reduce energy consumption without compromising on performance. Energy efficiency measures have gained significant attention in recent years due to their ability to reduce carbon emissions and save costs. Petrochemicals EV-Cars

- Green Hydrogen: Green hydrogen is a form of hydrogen produced using renewable energy sources such as wind or solar power. It is a clean and sustainable source of fuel that can be used in various applications such as transportation, heating, and power generation. The increasing adoption of green hydrogen has the potential to reduce carbon emissions significantly.

In conclusion, the six key innovations in the energy sector have revolutionized the way we produce, store, and consume energy. The increasing adoption of renewable energy sources, energy storage systems, smart grids, electric mobility, energy efficiency measures, and green hydrogen has helped reduce carbon emissions and mitigate climate change. Petrochemicals EV-Cars

Monash University scientists unveil sustainable lithium-sulfur battery with enhanced efficiency

Researchers at Monash University have unveiled a new lithium-sulfur (Li-S) battery design that aims to reduce costs, lower environmental impact, and enhance recycling options.

In particular, this innovative battery design introduces a nanoporous polymer-coated lithium foil anode, effectively reducing the amount of lithium required in each battery, and offering a host of advantages. Petrochemicals EV-Cars

In a news release, the university said Li-S batteries are emerging as a highly efficient energy storage solution that can deliver more energy per gram than traditional lithium-ion batteries.

However, these batteries typically contain a lithium anode and a sulfur cathode, which undergo significant stress during the charging and discharging process.

Additionally, lithium, while efficient, comes with the environmental cost of mining and transportation.

In their research paper, a team of scientists from Monash University, led by PhD student Declan McNamara, and including Professor Matthew Hill and Professor Mainak Majumder, in collaboration with Dr Makhdokht Shaibani of RMIT University, demonstrated that applying a nanoporous polymer coating directly to the lithium foil anode can address these issues.

McNamara introduced a thin polymer coating on the lithium anode, significantly enhancing the battery’s cycling capacity. Petrochemicals EV-Cars

“The polymer contains tiny holes less than a nanometre in size – one billionth of a metre – which allow lithium ions to move freely while blocking other chemicals that would attack the lithium. The coating also acts as a scaffold for lithium, and helps it charge and discharge repeatedly,” he explained.

Professor Majumder emphasised the importance of Li-metal protection technologies, particularly in lithium metal-based energy storage systems.

“The study establishes a new framework to protect Li-metal from rapid decay or catastrophic failure which has been an Achilles heel for Li-S batteries,” he said.

Meanwhile, Professor Hill highlighted the immediate potential of this technology, especially in the growing markets of electric vehicles, drones, and electronic devices.

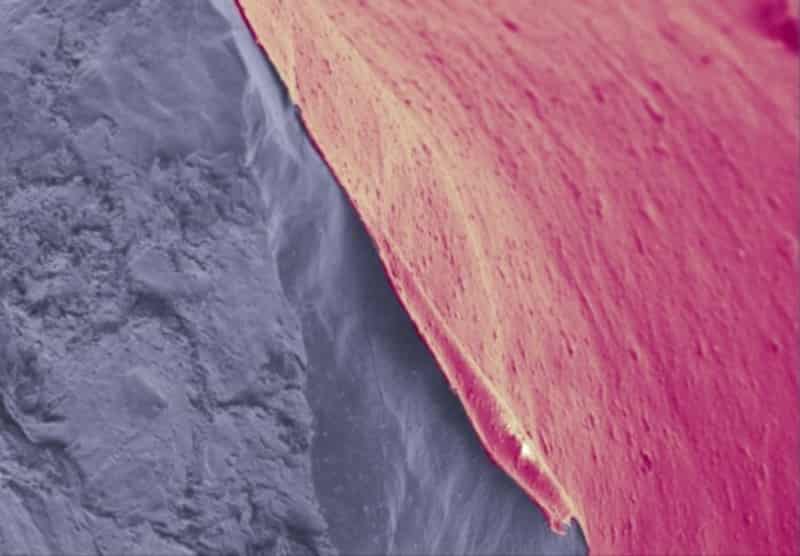

From fibre to fibre: polyester textiles recycling

Over half of the world’s clothes are made from polyester. With most of these garments failing to be recycled, Resource explains the problem with polyester textiles recycling and what barriers are being overcome to mainstream it. Petrochemicals EV-Cars

In the absence of clear signposting or legislation, such as the Strategy for Sustainable and Circular Textiles being developed in the EU, the UK public is largely confused as to where is best to dispose of waste textiles – and what types of textiles can be reused or recycled.

The issue of sorting and separating textiles extends to the industry itself too. The textile waste stream is comprised of many different types of material between cotton, wool, synthetic fibres and so on – all of which need to be sorted for different recycling techniques. Progress in the area of sorting is being made through novel sorting methods, such as the infrared technology ‘Fibersort’ being developed and used by SATCoL – the trading company of the Salvation Army – which is able to sort ‘textiles by fibre type, blend and colour for recycling back into the circular textiles supply chain’.

Other projects, such as the Trace4Value initiative, are working to create Digital Product Passports (DPPs) for textiles which will increase traceability and transparency in the textile industry. Petrochemicals EV-Cars

The pilot is set to align with the EU textiles strategy which mandates the introduction of DPPs for textiles sold in Europe by 2030. This legislation will make it much easier to track and sort textiles based on their respective components.

However, tracking and sorting the different fabrics is just one part of the challenge – they then have to be recycled. Synthetic fibre ‘polyester’ accounts for 65 per cent of the global fibre market but there is yet to be any real use of textile-to-textile polyester recycling in the fashion industry.

But loads of brands sell ‘recycled polyester’ clothing?

There is a general misconception about polyester recycling – clothing items that are marketed as ‘recycled polyester’ are almost never made from other polyester textiles, but usually from other sources of polyester such as PET bottles. Petrochemicals EV-Cars

Polyethylene terephthalate (PET) is the chemical name for polyester. After cleaning and sorting into respective colours, the bottles are shredded into flakes, melted down and extruded – a squeezing process – into plastic filaments. The filaments are then spun into a yarn which can be used to produce clothing. This is a mechanical recycling process which is relatively simple and used in many industries. Textile-to-textile polyester recycling requires a more complex process – chemical recycling.

Georgia Parker, Innovation Platform Director at Amsterdam-based Fashion for Good, explains: “The chemical recycling of textiles, as the name suggests, uses chemical processes to break down textile waste to a molecular level. The different outputs of chemical recycling offer multiple points of re-entry into the fashion supply chain and allow for a more versatile product range than mechanical recycling. Chemical recycling is also thought to increase the purity of the output products in comparison to mechanical recycling. Petrochemicals EV-Cars

“Most of the recycled polyester on the market is actually made from plastic bottle sources rather than textiles. As such, the fashion industry is currently trying to ease the reliance on the bottling industry and push for circularity by investing in innovations in textile-to-textile polyester recycling.”

To summarise the problem, ‘recycled polyester’ is very different from recyclable polyester. Turning polyester fabric back into polyester fabric – i.e. textile-to-textile, fibre-to-fibre recycling –is yet to be deployed extensively in the fashion industry.

Recycling polyester textiles at scale

Considered by many to be one of the key changes needed to make the textiles industry sustainable, there are many projects around the world trialling polyester textile-to-textile recycling at scale. Petrochemicals EV-Cars

SATCoL’s Project Re:claim – a joint venture with Project Plan B – launched plans for the first commercial-scale, post-consumer polyester recycling plant in the UK this year. The exclusive textile-to-textile polyester recycling system uses a thermomechanical recycling process through what they call the ‘Thermo Mechanical Extrusion Recycler’ (TMER) machine and recycles polyester garments and offcuts into rPET pellets made from textiles. SATCoL installed the machine at one of its processing centres in Kettering which already sorts and processes around 65,000 tonnes of donated textiles every year. SATCoL says that the first trials, which began this September, will give it an understanding of how the quality of feedstock affects the output. Petrochemicals EV-Cars

To maximise the volume and potential of the recycling process, SATCoL cannot rely on clothing bank donations alone and is calling for corporate partners to commit to donating 100 per cent polyester textiles. The project already has several retail and commercial customers, with many of the partnerships focused on the long-term goal of a fibre-to-fibre circular model. Commercially, it hopes to partner in the future with organisations that have excess polyester such as the NHS and the laundry industry which both use large amounts of polyester products.

Petrochemicals EV-Cars