Petrochemicals – Nylon6 – rPET 09-01-2023 - Arhive

Petrochemicals – Nylon6 – rPET

-Petrochemicals – Nylon6-chips – rPET

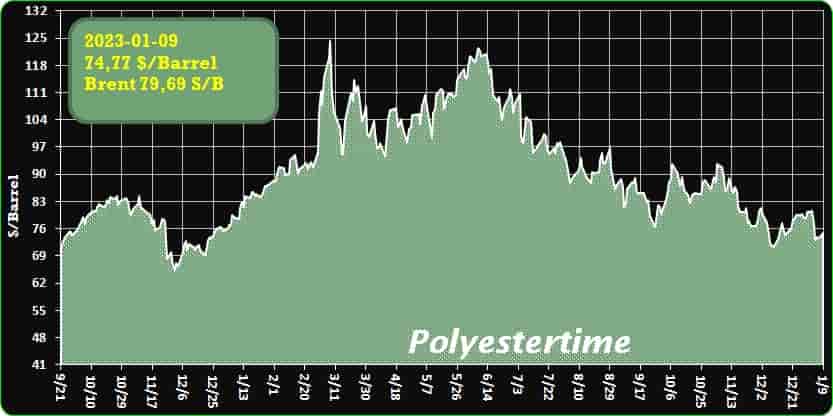

Crude Oil Prices Trend

Crude Oil Prices Trend

-bneGREEN NEO: Petrochemical companies should step up the fight against plastic waste

Plastic waste has become a key issue in the fight against climate change. As experts and activists debate the merits of recycling versus reducing plastics overall, petrochemical companies should speed up their plans to turn plastic into a circular material.

At the COP27 conference on climate change last month, leading UN representatives sounded the alarm on the devastating global impact of plastic pollution. Less than 10% of plastic waste is currently recycled, according to various estimates. The bulk of the remainder ends up in landfills, incinerated in a high-emissions process or leaks into the environment, with up to 14mn tonnes of plastic waste entering aquatic ecosystems each year. Petrochemicals – Nylon6 – rPET

Environmental activists argue that recycling doesn’t go far enough to deal with current levels of plastic waste and have called for an overall reduction, or even a ban, on new plastic production.

But this is easier said than done. Plastics play a key – and often indispensable – role across most modern industries, from food packaging to construction to medical equipment, and alternatives to plastic may not necessarily be better for the environment. In a 2022 study, McKinsey found that plastics contributed fewer greenhouse gas emissions than non-plastic alternatives in 13 out of 14 cases of at-scale use.

The solution, industry players argue, is to produce a higher share of new plastic from plastic waste.

To that end, the world’s largest petrochemical companies such as Dow Chemical, SABIC, Shell and Total Energies are investing in technology to reuse plastic waste in their production. This process, known as advanced, or chemical, recycling, melts down existing plastic back into its chemical components from where it can be used to produce new polymers. While activists claim that chemical recycling may cause additional pollution and CO2 emissions, more than 40 industry majors have begun adopting this circular approach, which may offer a more realistic path to reducing plastic waste in the short to medium term. Petrochemicals – Nylon6 – rPET

Major oil and chemical companies are also partnering on a global scale to reduce their impact on the environment. Firms including ExxonMobil, Dow and Chevron Phillips Chemical have created the Alliance to End Plastic Waste, whose members committed to investing $1.5bn in waste management infrastructure by 2024. This initiative, however, was recently criticised by Bloomberg News for insufficient efforts and elements of “greenwashing”. It’s now up to petrochemical companies to respond to this criticism by speeding up their recycling efforts and contributing to the reduction of plastic pollution.

Fighting plastic pollution is a truly global challenge that should involve all parties. Despite political tensions, Russian petrochemical producer Sibur took part in COP27 and pressed ahead with its circular economy transformation, which its management team continues to implement after CEO Dmitry Konov stepped down in early 2022 due to EU sanctions. In September, Sibur launched the production of “green” PET granules, which are used to make plastic bottles, with up to 30% recycled plastic content.

With plastics having become one of the most widely used materials in the world today, producers are poised to play a leading role in addressing the plastic waste crisis. Advanced recycling offers one solution, though it must be scaled up and further developed to reach meaningful capacity. But recent company efforts suggest that the plastics industry has taken a decisive step towards adopting a circular economy model, in which used plastics will be funnelled back into production for the benefit of the environment.

Instead of curbing plastic production, we need to get smarter about how plastics are made. Petrochemicals – Nylon6 – rPET

The steel industry is an example of how this could work: 85% of collected steel scrap is recycled and used as a raw material for about a third of global steel production. The plastics industry can similarly harness opportunities to boost the use of recycled materials in its production as a major step towards combating plastic waste.

-Twine Solutions cuts a third of its workforce

The company, which develops digital thread and yarn dyeing technology, is laying off 30 employees in total

Israeli company Twine Solutions, which develops digital thread and yarn dyeing technology, is laying off 30 employees, accounting for a third of its workforce. Twine Solutions raised $28 million at a $90 million valuation in May 2021.

Twine Solutions has raised over $50 million to date, including from Menora Mivtachim, Meitav Dash, Analyst, Landa Ventures, New Era Capital Partners, Maverick Ventures Israel, COATS Group, HP tech Ventures, and others. Petrochemicals – Nylon6 – rPET

Twine Solutions has developed a digital thread and yarn dyeing technology that dyes white/raw/recycled polyester thread and yarn using a waterless process. With Twine dyeing systems and inks, brands and manufacturers are able to dye their thread in-house, on-demand, ready for immediate use for their sewing, knitting and embroidery needs.

“2022 was challenging for the entire industry. In order to preserve the company’s activity during an economic recession, the company’s management implemented several steps to streamline and cut back, including also very regretfully parting with employees,” the company said in a statement.

“This is a difficult decision, but we believe that with hard and joint work we will overcome this period and continue to provide the textile world with the necessary revolution provided by Twine’s technology.” Petrochemicals – Nylon6 – rPET

-Simple, Cheap Hybrid Technology Joins Galvanized Steel and Polymers

The technique discovered by researchers at the University of Tokyo does not use harsh chemicals or complicated procedures.

Composite materials are popular in automotive and other applications to reduce the weight of components while enhancing durability. Petrochemicals – Nylon6 – rPET

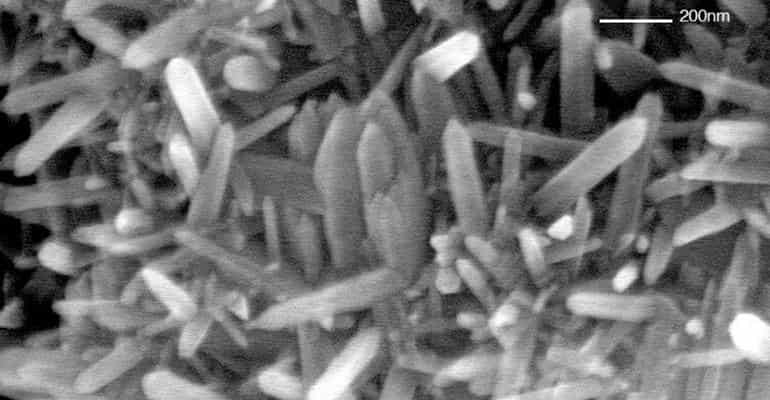

Bonding polymers with galvanized steel poses some problems, however, as it requires harsh chemicals and specialized equipment, and is ill-suited to mass production processes, according to researchers at the Institute of Industrial Science at the University of Tokyo. They have developed what they call a cheap and simple hybrid joining technology based on injection molding and a hot-water treatment. The technique is described in a paper published in the Journal of Manufacturing Processes. Petrochemicals – Nylon6 – rPET

The bonding method entails pre-treating the galvanized steel with an acid wash and dipping it in hot water. Petrochemicals – Nylon6 – rPET

The acid wash strips the outer passive layer on the zinc coating of the steel, allowing the hot water to form rough nanoscale needle structures on the true surface, explained a press release on the university website. When a polymer is applied to the treated metal in a process called injection-molded direct joining, it fills in the tiny gaps and ridges between and within the needle structures, thereby creating very strong mechanical linkages. “We found that immersion in hot water was a simple and effective method for producing nanoscale structures on the zinc coating for the polymer to adhere to, but that prior acid-washing to remove the passive layer was a necessary step for this to occur,” explained the paper’s lead author, Weiyan Chen.

The group also showed how the tensile-shear strength increased with the complexity of the nanoscale structures on the galvanized steel surface. By optimizing the hot water temperature and treatment time to achieve peak complexity in the nanoscale structuring, the team was able to significantly increase the tensile-shear strength compared with untreated metal. Petrochemicals – Nylon6 – rPET

“We successfully obtained strong joints of [galvanized high-strength steel] and polybutylene terephthalate (PBT) via HWT [hot-water treatment] with minimal damage to the zinc coating,” the researchers write in the paper abstract. “The effects of HWT conditions on the tensile shear strength were evaluated and the optimized strength reached 23 MPa.”

The process can be adapted for a range of hybrid joining applications in which metal and plastic parts need to be permanently bonded, said senior author Yusuke Kajihara. “Furthermore, our method does not use harsh chemicals or complicated procedures and, thus, is suited to the scale-up required for industrial applications,” added Kajihara. This work could lead to optimization of polymer-metal joining, which would be a significant asset to the manufacturing industry. Petrochemicals – Nylon6 – rPET

-Textile dye market expected to reach US $ 11.25 billion by 2026

The increased demand in the apparel industry is expected to propel the textile dye market and it is expected to reach US $ 11.25 billion by 2026, growing at a CAGR of 6.59 per cent. Currently it is worth around US $ 8.72 billion.

A report of Research and Markets claims that Asia-Pacific was the largest region in the textile dyes market in 2021 while North America is expected to be the fastest-growing region in the forecast period. Simple, Cheap Hybrid Technology Joins Galvanized Steel and Polymers Petrochemicals – Nylon6 – rPET

The garment industry has a significant raw material base that includes all types of natural and synthetic fibre dyes, which has helped it achieve global prominence.

The report also adds that new technology is a key trend gaining popularity in the textile dyes market. The textile dyes sector is constantly innovating and adopting new advanced dyeing technologies to become a more sustainable industry.

The use of nanotechnology to create more scientific clothing, such as fire-repellent, self-cleaning and water-repellent clothes, has resulted in significant advancement in the textile industry. Major companies operating in the textile dyes sector are focused on new technologies to sustain their position in the market. Petrochemicals – Nylon6 – rPET

In recent times, waterless smart dyeing technology is being adopted by most of the textile dyeing companies.

Archroma, Atul Ltd, Colorant Ltd, Vipul Organics Ltd, Zhejiang Runtu Co., Ltd and Alchemie Technology are among few of the leading companies in this segment.

-Neometals extends North American battery recycling deal

ASX-listed Neometals’ joint venture Primobius has expanded a technology and battery recycling JV option agreement with leading steel producer Stelco Holdings to allow it time to buy into its lithium-ion battery special purpose vehicle. The amendment follows a 2021 agreement for the duo to establish a long-term commercial recycling relationship in North America – one of the fastest growing sectors in terms of lithium-ion battery production.

ASX-listed Neometals’ joint venture Primobius has expanded a technology and battery recycling JV option agreement with leading steel producer Stelco Holdings to allow it time to buy into its lithium-ion battery special purpose vehicle.

The amendment follows a 2021 agreement for the duo to establish a long-term commercial recycling relationship in North America – one of the fastest growing sectors in terms of lithium-ion battery production. Petrochemicals – Nylon6 – rPET

Primobius GmbH is a jointly held company between Neometals and leading German engineering outfit SMS Group with the partners holding equal ownership rights to the offspring joint venture company Primobius.

The special purpose vehicle, or “SPV,” will be used to source significant quantities of end-of-life automobiles as scrap steel feedstocks under the terms of the deal that Primobius GmbH and Stelco originally inked about two years ago. The group plans on recycling lithium-ion batteries in a proposed 50 tonne per day operation at Stelco’s Lake Erie Works hydrometallurgical refinery in Ontario, Canada.

Neometals said at the time of the original agreement that the union would allow each party to play to their respective strengths with Stelco focusing on the SPV’s feedstock and approval work whilst Primobius oversees demonstration trials, engineering studies and its commercial disposal operation in Germany. Petrochemicals – Nylon6 – rPET

Under the revised treaty Primobius picks up the right to obtain between 25 and 50 per cent of the equity in the Stelco special purpose vehicle on or before 31 December 2023.

Neometal’s recent venture appears to be strategically focused on meeting the safe battery recycling and disposal needs of the white-hot electric vehicle market, an industry that global accounting firm Deloitte predicts will increase at a compound annual growth rate of 29 per cent over the next decade.

In a sign of the times, electric vehicle juggernaut Tesla Corporation recently tabled its 2022 sales figures that pointed to 1.3 million car sales globally. The metric is a new record for the company and eclipses the 900,000 plus sold in 2021.

The recycling of lithium-ion batteries is quickly becoming an important factor for manufacturers as demand for electric vehicles continues to grow at unprecedented rates. The statistic means companies with battery recycling facilities such as Neometals could play a massive part in treating end-of-life devices, particularly in regions experiencing significant adoption rates such as North America.

-Tesla sales in China slump as competition intensifies as cheaper electric vehicles take over car market

Tesla has grown rapidly in China but is facing increasingly stiff competition from companies like BYD, which sells well-regarded cars at lower prices and is the country’s No. 1 electric vehicle brand. BYD sales including hybrid vehicles more than doubled in December from a year earlier, and rose 2% in December from November, according to the Passenger Car Association’s data. Petrochemicals – Nylon6 – rPET

TeslaTesla sales in China, the world’s largest car market and a crucial element of the company’s fortunes, slumped at the end of 2022 as domestic manufacturers like BYD gained ground with lower-priced electric vehicles, according to data published Thursday.

Tesla sold around 56,000 cars in China last month, a decline of 21% from a year earlier and 44% from the previous month. For the full year, Tesla’s Chinese sales rose nearly 50%, according to data published by the China Passenger Car Association.

China accounts for roughly 40% of Tesla’s sales. Concern about the carmaker’s performance there has been a significant factor in the precipitous decline of Tesla’s share price last year. The company’s stock closed down about 3% Thursday.

Tesla has grown rapidly in China but is facing increasingly stiff competition from companies like BYD, which sells well-regarded cars at lower prices and is the country’s No. 1 electric vehicle brand. BYD sales including hybrid vehicles more than doubled in December from a year earlier, and rose 2% in December from November, according to the Passenger Car Association’s data. Petrochemicals – Nylon6 – rPET

China is considered key to Tesla’s global ambitions. In contrast to the United States and Europe, overall auto sales there are still rising because many people do not own cars or own just one vehicle. The Chinese government has heavily promoted electric-vehicle ownership as a solution to urban air pollution, though it has slashed subsidies recently.

“When you are not active in the largest market in the world, you are nowhere,” Axel Schmidt, a senior managing director at Accenture who oversees the consulting firm’s automotive division, said before publication of the sales figures.

Tesla’s factory in Shanghai is considered one of the company’s most efficient plants and supplies cars to Europe and other parts of Asia in addition to China. The figures published Thursday include exports. The Shanghai factory was forced to shut down repeatedly during 2022 because of supply-chain problems and pandemic lockdowns.

China is in the midst of a pandemic crisis after the government abandoned its “zero COVID” policy in the face of public protests, lifting draconian quarantine and lockdown measures and triggering a surge in cases.

The Tesla sales decline has to be viewed “in the context of the massive COVID outbreak” in December, Gary Black, managing partner of the Future Fund, an investment firm that owns Tesla shares, said on Twitter.

Overall, sales of hybrids and cars powered solely by batteries in China were flat in December compared with November, the association said.

There have been other signs that Tesla was suffering from softening demand for its products in China. The company has cut prices for the Model Y and Model 3, the two vehicles it makes in Shanghai. The company’s website says vehicles can be delivered in as little as a week — last year, waits stretched to months.

Analysts say Tesla could be vulnerable to political tensions between the United States and China. Elon Musk, the company’s CEO, has courted the Chinese government, suggesting, for example, that Taiwan become a special administrative zone of China as a way of ceding more control to Beijing. Taiwan refuses to relinquish any control to China or compromise its independence, and Musk’s remark angered leaders in Taipei.

Another concern for Tesla: BYD and other Chinese automakers have begun selling cars in Europe. Their expansion could cost Tesla, Volkswagen and other automakers sales and market share when many European carbuyers are replacing combustion engine vehicles for battery-powered cars. Petrochemicals – Nylon6 – rPET

“The major worry now overhead for Tesla is that the demand story, especially out of China, is showing heavy cracks in the armor at a time that EV competition is steadily increasing,” Daniel Ives, an analyst at Wedbush Securities, said in a note to clients Wednesday.

Petrochemicals – Nylon6 – rPET