Petrochemicals PET-Bottle – DFRL, Mysuru develops biodegradable water bottles 02-09-2023

Petrochemicals PET-Bottle

- Polymers : PET – r-PET – Filament grade semidull chips -Filament grade bright chips – Ny6 – Ny66 – PP

- Feedstocks : PX – PTA – MEG – CPL – Adipic Acid – Benzene – ACN – Ethylene – Phenol – Naphtha

- Textile : Polyester POY – DTY – FDY – PSF – Recycled Polyester POY – Nylon POY – DTY – FDY Spandex 20-30-40 -Viscose Staple Fiber VSF Acrylic Staple Fiber Petrochemicals Polymers

| Polyestertime | |||

| ITEM | 25/09/2023 | 02/10/2023 | +/- |

| Bottle grade PET chips domestic market | 7,200 yuan/ton | 7,200 yuan/ton | – |

| Bottle grade PET chips export market | 905 $/ton | 900 $/ton | -5 |

| Filament grade Semidull chips domestic market | 7,150 yuan/ton | 7,100 yuan/ton | -50 |

| Filament grade Bright chips domestic market | 7,240 yuan/ton | 7,170 yuan/ton | -70 |

| Pure Terephthalic Acid PTA domestic market | 6,215 yuan/ton | 6,240 yuan/ton | +25 |

| Pure Terephthalic Acid PTA export market | 810 $/ton | 790 $/ton | -20 |

| Monoethyleneglycol MEG domestic market | 4,130 yuan/ton | 4,050 yuan/ton | -80 |

| Monoethyleneglycol MEG export market | 480 $/ton | 470 $/ton | -10 |

| Paraxylene PX FOB Taiwan market

Petrochemicals PET-Bottle |

1,133 $/ton | 1,117 $/ton |

-16 |

| Paraxylene PX FOB Korea market | 1,110 $/ton | 1,094 $/ton | -16 |

| Paraxylene PX FOB EU market | 1,250 $/ton | 1,250 $/ton | – |

| Polyester filament POY 150D/48F domestic market | 8,100 yuan/ton | 8,050 yuan/ton |

-50 |

| Recycled Polyester filament POY domestic market | 7,550 yuan/ton | 7,550 yuan/ton | – |

| Polyester filament DTY 150D/48 F domestic market | 9,450 yuan/ton | 9,350 yuan/ton | -100 |

| Polyester filament FDY 68D24F

Petrochemicals PET-Bottle |

9,300 yuan/ton | 9,200 yuan/ton | -100 |

| Polyester filament FDY 150D/96F domestic market | 8,700 yuan/ton | 8,650 yuan/ton | -50 |

| Polyester staple fiber 1.4D 38mm domestic market | 7,770 yuan/ton | 7,800 yuan/ton | +30 |

| Caprolactam CPL domestic market | 13,375 yuan/ton | 13,000 yuan/ton |

-375 |

| Caprolactam CPL overseas market | 1,600 $/ton | 1,600 $/ton | – |

| Nylon 6 chips overseas market | 1,830 $/ton | 1,830 $/ton | – |

| Nylon 6 chips conventional spinning domestic market | 14,450 yuan/ton | 14,050 yuan/ton | -400 |

| Nylon 6 chips high speed spinning domestic market

Petrochemicals PET-Bottle |

15,100 yuan/ton | 14,900 yuan/ton | -200 |

| Nylon 6.6 chips domestic market | 19,500 yuan/ton | 19,500 yuan/ton | – |

| Nylon6 Filament POY 86D/24F domestic market | 17,200 yuan/ton | 17,000 yuan/ton | -200 |

| Nylon6 Filament DTY 70D/24F domestic market | 19,400 yuan/ton | 19,150 yuan/ton- | -250 |

| Nylon6 Filament FDY 70D/24F | 18,150 yuan/ton | 18,100 yuan/ton | -50 |

| Spandex 20D domestic market

Petrochemicals PET-Bottle |

36,500 yuan/ton | 36,500 yuan/ton | – |

| Spandex 30D domestic market | 35,000 yuan/ton | 35,000 yuan/ton | – |

| Spandex 40D domestic market | 32,200 yuan/ton | 32,200 yuan/ton | – |

| Adipic Acid domestic market | 9,900 yuan/ton | 9,900 yuan/ton | – |

| Benzene domestic market

Petrochemicals PET-Bottle |

8,075 yuan/ton | 8,240 yuan/ton | +165 |

| Benzene overseas market | 980 $/ton | 975 $/ton | -5 |

| Ethylene South East market | 870 $/ton | 870 $/ton | – |

| Ethylene NWE market | 783 $/ton | 785 $/ton | +2 |

| Acrylonitrile ACN domestic market

Petrochemicals PET-Bottle |

9,700 yuan/ton | 10,000 yuan/ton | +300 |

| Acrylonitrile ACN overseas market | 1,200 $/ton | 1,200 $/ton | – |

| Acrylic staple fiber ASF domestic market | 14,100 yuan/ton | 14,100 yuan/ton | – |

| Viscose Staple Fiber VSF domestic market | 13,400 yuan/ton | 13,400 yuan/ton | – |

| PP Powder domestic market

Petrochemicals PET-Bottle |

7,550 yuan/ton | 7,600 yuan/ton | +50 |

| Naphtha overseas market | 719 $/ton | 711 $/ton | -8 |

| Phenol domestic market | 9,407 yuan/ton | 9,477 yuan/ton | +70 |

r-PET high end eco-friendly chips =7,800 yuan/ton — 7,800 yuan/ton –

- Carbon capture EVcar – INEOS announces the acquisition of the Eastman Texas City Site for ~$500 million 30-09-2023

- New enzyme technology for environmentally friendly plastic recycling

Petrochemicals PET-Bottle

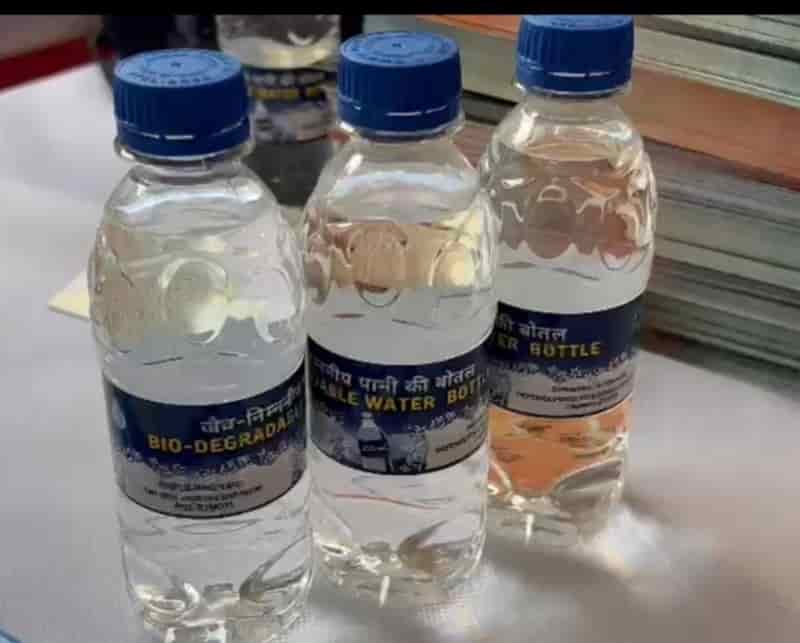

DFRL, Mysuru develops biodegradable water bottles

Mysuru: The Mysuru-based Defence Food Research Laboratory (DFRL), a DRDO lab, has developed a biodegradable water bottle, in an effort to reduce the overall carbon footprint in the environment.

These bottles, developed in a limited quantity, were launched by Union Minister of State for Defence and Tourism Ajay Bhat, here on Friday during the two-day national seminar at SDM College.

According to the release issued by DFRL-DRDO, these bio-degradable are compostable as per the ISO 17088-2021 and IS 17899 T: 2022 standards. These bottles are absolutely safe for food and beverage contact applications and what more, even the bottle cap and label are also compostable.

These bottles look like those other bottles as they too are transparent. Besides, these are durable and strong as any other plastic bottle.

With an aim to check plastic pollution that has become a menace due to indiscriminate littering and also insufficient recycling, these bottles have been developed in collaboration with M/s Konkan Specialty Polyproducts Ltd, Mangaluru. The technology that has been used to develop these bottles is the poly lactic acid manufactured using injection blow moulding technique.

These bottles are yet to be developed for commercial use as the availability of raw materials is scarce, it is said.

Sidel unveils StarLITE®R – a new, ultra-efficient 100% rPET bottle for carbonated soft drinks

To help carbonated soft drink (CSD) packaging producers embrace material circularity, Sidel has launched StarLITE®R – a 100% rPET bottle. Sidel’s signature StarLITE® family is evolving to address the challenges associated with working with recycled content.StarLITE®R allows CSD producers to switch to rPET bottle production with ease and efficiency, while significantly reducing the impact on product quality or packaging integrity.

Embracing 100% rPET

With over 45 years of experience in the blowing and PET packaging sector, Sidel has developed a deep understanding of recycled PET resin characteristics and its impact on bottle production. Laurent Naveau, Packaging Innovator Leader at Sidel, comments on the challenge rPET resin can present the packaging industry:

“The characteristics of rPET are impacted by several factors. Firstly, by seasonality. Consumption habits fluctuate over the course of the year impacting the product category mix. And secondly, by different PET collection models which means that post-consumer PET material bales will vary from region-to-region and even country-to-country. The recycling process and equipment used will also influence PET resin. All these factors can pose new challenges for manufacturers looking to produce bottles with rPET content.”

In addition to common CSD bottle manufacturing challenges such as stress cracking, roll out and bursting during blowing, a higher temperature is also required to process rPET. Consequently, packaging manufacturers can experience reduced control over rPET material stretching and distribution of the substance in the bottle-making process.

Traditionally, greater variability in rPET resin leads to a narrower process window and lower bottle quality.

However, Sidel’s innovative base, StarLITE®R uses leading technologies to ensure efficient rPET bottle production by restoring a much wider process window. The StarLITE®R design is easier to blow as it can be done within a wider range of parameter settings on the blower achieving a much higher quality bottle.

High performance rPET bottle base

To achieve a high performing rPET bottle base, StarLITE®R features an optimised mould base profile and uses an advanced stretch rod end design.

The new mould base profile allows for perfect material distribution through advanced stretching and a high base clearance for optimum stability. The advanced stretch rod end design has improved the preform end-cap material stretching and ensures accurate injection gate centering on the bottle. Finally, the perfect combination of grooves and venting holes allows for high-precision base feet formation.

The new bottle solution also utilises dual external and internal bottle base cooling to ensure a perfect shape. Externally, the process uses a mould base cooling circuit that focuses on the warmer bottle base zones and internally a hollow-stretch rod requiring no additional air supply is used.