PLA – Biodegradable – Plastics-Harmful 27-12-2022 - Arhive

PLA – Biodegradable – Plastics-Harmful

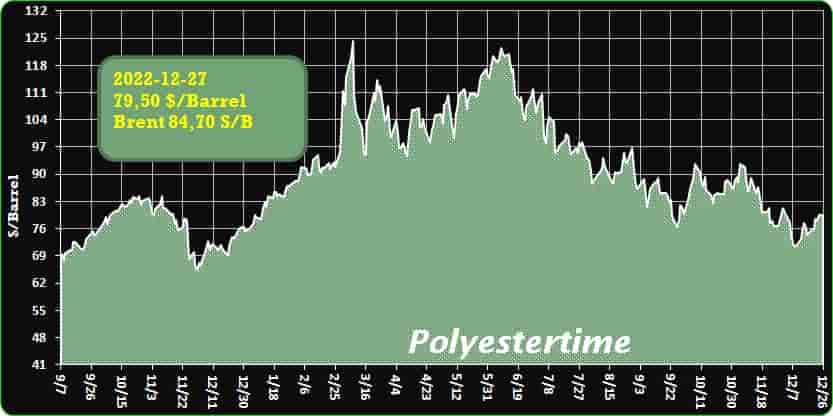

Crude Oil Prices Trend

Crude Oil Prices Trend Polyestertime

-Crude oil prices rise above USD100 per barrel February 24

Following reports that Russian forces further invaded Ukraine on Thursday,February 24, the front-month futures price of both Brent and West Texas Intermediate (WTI) crude oil have increased to more than USD100 per barrel (b), said Hydrocarbonprocessing.

The front-month Brent contract price closed just below USD115/b on Wednesday, March 2, after rising and settling above USD100/b on February 28. The Brent crude oil price last rose above USD100/b in late 2014. The front-month WTI contract price closed above USD110/b on March 2, after first settling above USD100/b on March 1.

Brent crude oil is a type of crude oil from the North Sea in Northwest Europe that is commonly used as a global benchmark. West Texas Intermediate crude oil is used as a U.S. benchmark. Recent trading of these benchmarks has been more volatile lately than in the past. For example, on February 24, the price of Brent crude oil ranged from a high of USD105.79/b to a low of $97.56/b, an intraday price range of USD8.23/b that is nearly four times the average range during 2021. The only other time since January 2021 that the range exceeded USD8/b was on November 26, in response to the World Health Organization’s identification of the coronavirus Omicron variant.

The Brent crude oil price decreased on February 25, but developments in the Ukraine-Russia conflict and new sanctions placed on Russia over the weekend contributed to an increase in the Brent price on February 28. Subsequent news about Russia’s further invasion has had significant effects on crude oil trading throughout the past week.

Russia is the third-largest petroleum and liquid fuels producer in the world, after the United States and Saudi Arabia. It is also a major exporter of crude oil. Since mid-January 2022, the geopolitical risk related to Russia’s further invasion of Ukraine has contributed to higher and more volatile crude oil prices. Stronger petroleum demand as the COVID-19 pandemic has begun to ease and slower crude oil production growth have also put upward pressure on global crude oil prices.

We remind, Transneft has received requests from Poland and Germany for oil in 2023, the state oil pipeline monopoly’s head told Rossiya-24 TV, adding that supplies via the Druzhba pipeline’s southern spur are expected to hold steady next year. The EU has pledged to stop buying Russian oil via maritime routes from Dec. 5, with Western nations also imposing price caps on Russian crude oil, but the Druzhba pipeline remains exempt from sanctions. Transneft’s comments are at odds with suggestions last month that Poland aimed to abandon a deal to buy Russian crude.

Crude oil prices rise above USD100 per barrel February 24

-GreenTech SA is merging with GreenFiber International

Merger aimed to achieve full consolidation of operations and centralization of management, for greater resource efficiency, reduction of costs and optimization of activities in the PET recycling chain.

Following the merger, GreenFiber International was renamed GreenTech, thus preserving the brand legacy of the PET recycler leader in Europe and still keeping GreenFiber as brand for the polyester staple fiber.

December 01st is the date when merger by absorption between GreenFiber International (absorbing company) and GreenTech (absorbed company) became effective and legally binding, formalizing a full integration of operations between two key players in the European circular economy of plastics, both part of GreenGroup.

As a result of the merger, the full patrimony of GreenTech (entity was dissolved, but not liquidated) was transferred to GreenFiber International. Furthermore, following the merger GreenFiber was renamed GreenTech, while also changing its main domain of activity, from producer of polyester staple fiber to recycler. PLA – Biodegradable – Plastics-Harmful

Absorbed company (GreenTech) was established in 2002 and in the last 20 years secured its position as European PET recycling leader and key producer of PET flakes, R-PET granules, and PET strap. Since the establishment of GreenFiber, in 2004, the two companies worked as an integrated team, as GreenTech was the key supplier of raw material to produce fibers. From the start, the companies shared the same management team.

Alina Genes, CEO GreenTech stated:

”The merger was a natural step towards bringing together two teams, that worked closely from the very beginning to offer an efficient solution for the recycling and circular economy of plastics. The new GreenTech is now strengthening its position on the European market as integrated PET recycler and circular economy enabler for plastics, with a unitary vision, consolidated portfolio of recycled products and perfect synergy between supply chain and production. This leads to improved efficiency and sustainability, thus better servicing the needs of our partners and industrial clients.”

GreenTech is an established brand on the European recycling market, celebrating 20 years of activity in 2022, having an installed processing capacity of 150.000 tons of PET/year, the equivalent of 2 billion PET bottles. GreenFiber will remain a commercial brand of products, integrated within the unitary portfolio of products made of PET by GreenTech.

www.green-tech-global.com www.green-group-europe.com

-Oxxynova is to cease production at its German DMT site at the end of 2022

Oxxynova is to cease production at its German dimethyl terephthalate (DMT) site at the end of 2022, primarily due to gas and electricity prices, said the company.

The 240,000 tonne/year plant in Luelsdorf, Germany is one of two in Europe, with Turkey’s 280,000 tonne/year SASA Polyester Sanayi plant in Adana left as the only remaining one.

Oxxynova is one of only two PX contract settlers on the buy side. Oxxynova’s indefinite exit may lead to imports of solid DMT or additional moves to purified terephthalic acid (PTA). PLA – Biodegradable – Plastics-Harmful

According to a letter understood to have been sent to customers, Oxxynova indicated it hopes to be able to play a role in the future business area of recycling, processing of chemical material and waste streams.

We remind, Oman Oil Company’s Oxea constructed its 60,000 tonnes/y dioctyl terephthalate (DOTP) facility at the site of Oxxynova in Steyerberg, Germany. Start-up of the project was in 2H 2019.

-Contract prices for extrusion PC in Europe decreased in December

Contract prices for extrusion polycarbonate (PC) fell in December in Europe from the previous month amid lower production costs and reduced inventories, ICIS said.

Prices decreased by EUR150 per tonne and EUR200 per tonne compared to the previous month in the lower and upper parts of the price range respectively.

Despite the fact that several players reported an extension in December, according to market sources, most of the agreements were concluded with a significant reduction in prices compared to November. Lower costs for electricity and production, combined with sustained low demand, affected the negotiations.

The reduction in inventories ahead of the end of the year not only made consumer demand weaker, but also prompted producers with large inventories to accept a significant decline in prices. PLA – Biodegradable – Plastics-Harmful

In Europe, negotiations on contract prices for the first quarter of 2023 are continuing. According to market sources, PC imports from Asia should remain high during the first quarter, which may have some impact on the course of negotiations.

Earlier it was reported that Roehm, a major European manufacturer of methyl methacrylate (MMA), in the first half of 2024 will acquire the production of polycarbonate films and sheets SABIC. The agreement does not apply to SABIC’s polycarbonate (PC) extrusion business, but includes the Functional Forms division, which offers a wide range of polycarbonate (PC) films and sheets, primarily sold under the LEXAN brand name.

According to MRC ScanPlast, in January-October 2022, the total estimated consumption of PC granulate in the Russian market (excluding imports and exports to Belarus) decreased by 2% and amounted to about 68.2 thousand tons against 69.3 thousand tons a year earlier.

-The Israeli startup turning garbage into gold – sort of

TripleW has developed a revolutionary idea to compost biological material – in this case, food waste

Israeli startup TripleW takes the phrase ‘trash to treasure’ incredibly literally – by using food waste to produce biomaterials.

“You take food waste, and you take all its ingredients and deconstruct it in the best way to make materials that we use in everyday life. For example, the production of bioplastics that are used in food packaging,” explained co-founder Tal Shapira, who also serves as the company’s CEO. PLA – Biodegradable – Plastics-Harmful

The material in question is a plastic known as PLA – biodegradable and made from foodstuffs, but until now was expensive to produce.

“Bioplastics were produced using sugarcane or corn, which are food crops — and they cost a lot. We can eliminate these costs using food waste. That’s not even a cost because you are getting paid to get rid of waste,” said Amir Oranim, who co-founded TripleW with Shapira and is the company’s COO.

TripleW has developed a way to compost biological material – in this case, food waste – by extracting biological compounds known as lactic acid using bacteria and then purifying that into useable plastics.

It’s a revolutionary idea that makes recycling more viable: traditional recycling needs to separate and then process raw materials for reuse, making it far more expensive than just dumping it somewhere. But in this biological process, it’s all done by the bacteria.

“It’s blended into a slurry, like in a traditional process, but the microorganisms are the ones targeting specific carbohydrates in the waste, fermenting those into the product, and then we separate the product from the rest,” Shapira clarified.

And not just an economical solution – the waste from this process is yet another valuable product since the leftovers, such as lipids and oil, can be burned as biogas to produce renewable electricity. PLA – Biodegradable – Plastics-Harmful

This means that this waste management could soon fill a very significant market need.

“The demand comes from two directions,” noted Oranim. “One is from governments that implement policies restricting the use of traditional plastics, and the other is from industry that understands that there’s only one direction for plastics, and that’s bioplastic.”

In Europe, TripleW isn’t operating out of a lab but is an industrial-scale company. Its Belgium facility processes countless tons of garbage – and turns out purified plastic which can be used for any sort of product the market demands.

-Are All Plastics Equally Harmful To The Environment?

Not all plastics are equally harmful to the environment. Thermoset plastic are strong and more durable, which makes them harder to recycle, as opposed to slimy thermoplastics. Furthermore, there is a Resin Identification Code (RIC) that grades which plastics can be recycled and how. Lastly, some plastics have chemicals, such as chlorines, that can be toxic to their surrounding environment.

In 1907, Leo Baekeland, a Belgian chemist, beat chemist James Swinburne to a patent office in Scotland by the mere margin of a day. There, Baekeland patented a material known as Bakelite. Bakelite was the first fully synthetic plastic in the world. It was a worthy predecessor to the types of plastic we use today. From food containers and baby bottles to electronic chip carriers, plastic is as ever-present as sunlight. Today, the market for plastic has never been larger. PLA – Biodegradable – Plastics-Harmful

During the Covid-19 pandemic, the logistical burden of the medical industry was almost single-handedly borne by synthetic polymers and common plastics. Millions of plastic gloves and masks were used every day.

Of course, plastic isn’t only evil in the world, but with so much of it around, what the heck do we do with all this plastic once we’re done with it?

What is plastic?

To understand what happens to plastic as garbage, we need to know what plastic is, chemically speaking.

Plastic is a polymer that, in the simplest of terms, is composed of small chemical blocks—monomers—attached to each other to make a large molecule, the polymer. The monomers form covalent bonds with other monomers. Monomers covalently link together to form chains, which together form a polymer.

It’s easier to think of a monomer as a brick. Multiple bricks are sequentially laid together to build a house. The house is a polymer. However, not all plastics are the same type of polymer. Plastics come in two types; thermoset plastics and thermoplastics. The difference lies in their chemical and physical properties. PLA – Biodegradable – Plastics-Harmful

Thermoset plastics are manufactured using processes called liquid molding processes. Polymers and other agents are heated to a liquid state, and as the mixture cools in the mold, it forms a thermoset plastic. This process encourages a chemical reaction known as cross-linkage. When the polymers in the mixture cross-link together, it prevents them from succumbing to the effects of heat. Thermosets such as polyester, polyimides, and polyurethane are therefore perfect for high-heat environments. The cross-links in thermoset plastics are also the reason they are impossible to recycle. Thermoplastics, on the other hand, are susceptible to the effects of heat and melt when exposed to high heat after the curing process. This makes them a bit easier to recycle. Polyethene is a good example of a thermoplastic.

What happens to all the plastic once we’re done with it?

One word: Recycled

Actually, it’s a bit more complicated than that. The problem with plastic is that we can’t transform it into another substance. Technically, it is possible to recycle plastics into fuel or oil, but this process results in the emission of toxic pollutants—a no-win situation.

Most plastics are not biodegradable. They break down into smaller pieces, but not simpler substances (i.e., organic or biological materials). These smaller pieces of plastic are called microplastics.

To prevent plastics from turning into microplastics, the ideal solution is to recycle them. However, many weird problems come up when we try scaling up plastic recycling.

Plastics and objects made of plastic are each assigned a Resin Identification Code (RIC). This code helps us identify the type of plastic used to make an object. Based on this code, each plastic item can belong to 1 of 7 classes. RIC Classes 1 (things made of PETE/PET) and 2 (things made of HDPE) can be recycled. RIC Classes 3-7 can possibly be recycled (depending on where you live). PLA – Biodegradable – Plastics-Harmful

The headache doesn’t end there. Specific cases like two-layered objects (your coffee cup) make plastic recycling harder. Plastic fused to another material (paper) cannot be recycled. The two materials need to be separated and then processed.

Additionally, some plastic items can only be recycled a maximum of 2 or 3 times, because every time plastic is recycled, the monomeric chains that make up the plastic reduce in length. This directly affects the quality and strength of the resultant plastic.

Weirdly enough, most recycled plastic is reinforced with new or “virgin” plastic to make up for the loss of quality incurred during recycling. This goes directly against the very point of recycling—to use less of it. One may rightfully question if this should count as recycling at all.

So, are all types of plastic bad for the environment?

Not really.

RIC Class 1 and 2 plastics are the most extensively recycled plastics. Hence, they’re also less likely to contribute to the production of microplastics. Generally, they are also used to make simple single-layered products, such as water bottles (100% PET).

In terms of harm done, they’re as innocent as plastics can get. Classes 3-6 are a bit trickier to judge, as the processes required to recycle them do exist, but depending on where you live, they’re not always recyclable. PLA – Biodegradable – Plastics-Harmful

Plus, for some plastics, such as PVCs or polystyrenes, multiple complex processes (pyrolysis, hydrolysis, heating, etc.) are required to successfully recycle them.

Dubiously, we must also be wary of Class 7 plastics. All plastics that fall into the Class 7 category of plastics meet one basic requirement: They do not fit anywhere else. If the object in question doesn’t find a place amongst the first 6 classes, it is simply dumped in class 7. It is a literal landfill of unidentifiable plastics. This makes all plastic items in Class 7 difficult to recycle, as not much is known about their composition.

Conclusion

In the end, some types of plastics, like Polyvinyl chlorides and Polysterenes, are more dangerous than others. Many of the processes used in recycling PVCs attempt to remove the hazardously high levels of chlorine and additives added to it. In fact, the WHO has classified PVC as a carcinogen.

The real problem is the dangerously small amount of plastic being recycled at all. Worldwide, only 9% of plastic is actually recycled.

We need to figure out a better way to increase the scale and quantity of plastic recycling. Unless we figure that out, the type of plastic doesn’t really matter, as most of the plastic that is produced will eventually end up breaking up into microplastics, since they won’t be recycled in the first place. PLA – Biodegradable – Plastics-Harmful

To end on a lighter note, it’s not all doom and gloom. Chemists and engineers are working tirelessly to synthesize new-age bioplastics, which are synthesized from renewable and biodegradable raw materials like vegetable oil, yeast, or corn. Capable of biodegradability, bioplastics present a source of optimism for plastic management in the near future.

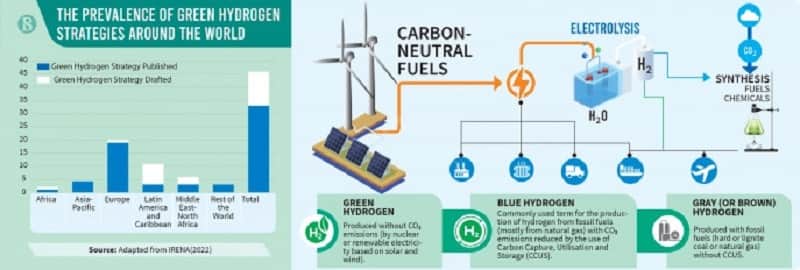

-Green hydrogen: The answer to the world’s energy woes?

Green hydrogen is a green fuel that is showing a lot of promise. Despite the recent large investments in this industry, there are challenges aplenty

A revolution is swiping across the gulf states and the rest of the world is sitting up and taking notice. We are of course talking about the green hydrogen revolution.

In 2021, the UAE inaugurated the Gulf’s first ever “green hydrogen” plant. KSA based ACWA Power, has nearly completed financing for a $5bn green-hydrogen project. Oman, whose oil reserves are smaller and more expensive to extract than those of its larger neighbours, the country is considering investing $30 billion in what could be the largest hydrogen factory in the world. In fact, it has launched a state-owned entity to offer green-hydrogen projects concessions in its special economic zones.

These Gulf states are also looking to expand their horizons. UAE’s state owned Masdar is funding a green hydrogen initiative in Egypt with $10 billion, building 4 gigawatts (GW) of green hydrogen and renewables projects in Azerbaijan, and investing in a green hydrogen start-up in northern England. PLA – Biodegradable – Plastics-Harmful

ACWA Power plans to invest billions of dollars in green hydrogen projects in Egypt, South Africa, and Thailand. The United Arab Emirates and Saudi Arabia have set a goal of controlling 25% or more of the clean hydrogen export market by 2030.

So, what is ‘green’ hydrogen? Green hydrogen (GH2) is being dubbed as the next big stepping stone in the journey towards a successful transition from fossil fuel to fuels that are not killing the planet. What makes green hydrogen special is the fact that not only it can be used to produce climate-neutral fuel and could power hard-to-decarbonise sectors like steel manufacturing, aviation and shipping.

Green hydrogen is a type of hydrogen that is produced through the electrolysis of water using renewable energy sources, such as solar or wind power. The process involves splitting water molecules into hydrogen and oxygen using electricity, with the oxygen being released into the atmosphere and the hydrogen being collected and stored for use as a fuel.

As long as the hydrogen is extracted using renewable energy and not fossil fuels, it produces no CO2 emissions and is considered green. Hydrogen fuel produces about 33.33 kWh of energy per kilogram, while gasoline and CNG only produce 12 kWh/kg and 14.7 kWh/kg, respectively. A kilogram of hydrogen can power a fuel cell vehicle for 100 to 131 kilometre, while a kilogram of gasoline will only get you 16 kilometre.

There are potential uses aplenty for green hydrogen. The usages include but not limited to:

Transportation: Green hydrogen can be used as a fuel for vehicles, like cars, trains, and even aeroplanes. It can be used in fuel cell vehicles, which use a chemical reaction between hydrogen and oxygen to produce electricity, or it can be burned in internal combustion engines. The first fleet of hydrogen fuel cell trains have already started operating in Germany. PLA – Biodegradable – Plastics-Harmful

Hyundai has announced that it will be manufacturing 5,00,000 hydrogen vehicles by 2030. In several European cities, waste collection vehicles are already powered by this technology.

- Electricity generation: green hydrogen can be used to generate electricity through fuel cells or by burning it in a gas turbine.

- Heating: Green hydrogen can be used to heat buildings and homes, either by burning it directly or by using it to generate electricity for heating systems.

- Industrial processes: Green hydrogen can be used in a variety of industrial processes, such as the production of chemicals, metals, and cement.

- Agriculture: Green hydrogen can be used to power farm machinery and to produce fertilisers.

- Storage: Green hydrogen can be used as a means of storing excess renewable energy, such as wind and solar power, when it is not being used.

- Trade: Green hydrogen can be produced in countries with abundant renewable energy resources and then exported to countries that do not have such resources. In February 2022, the first shipment of liquefied hydrogen from Australia to Japan took place. This was a big step toward building an international market for hydrogen. Based on the projects that are being built with the goal of exporting in mind, it is estimated that 12 Mt of hydrogen could be exported every year by 2030, with 2.6 Mt/yr planned to start up by 2026.

Green hydrogen has a long way to go, however. The production of low-emission hydrogen was less than 1 Mt in 2021, practically all of it coming from plants using fossil fuels with carbon capture, utilisation and storage (CCUS) PLA – Biodegradable – Plastics-Harmful

Challenges

There are several challenges and limitations to the widespread adoption of green hydrogen as a fuel and energy source. The biggest challenge to the mass adoption of green hydrogen is cost. Currently, the production of green hydrogen is more expensive than the production of hydrogen from fossil fuels.

The high expense of producing GH2 limits its use in industry. For instance, many businesses are hesitant to switch to GH2 despite the fact that the steel and chemical sectors utilise a lot of hydrogen. The current market situation sees more expensive green products competing with more established, less expensive grey alternatives, especially in capital-intensive industries with slim profit margins.

For producers of grey hydrogen using steam methane reforming, with 44kWh of natural gas required for every kilogram of hydrogen produced, costs now sit at $3.30 per kilogram of hydrogen while green hydrogen was $3.80-$5.80/kg before the war in Ukraine. However, as the technology improves and economies of scale are achieved, the cost is expected to decrease.

Green hydrogen production costs should drop to below $2/kg by 2030 if current trends in investment remain steady. PLA – Biodegradable – Plastics-Harmful

There is also currently a lack of infrastructure in place to support the widespread use of green hydrogen as a fuel. This includes a lack of hydrogen fuel stations, hydrogen storage facilities, and hydrogen-compatible vehicles. This is also going to need considerable investment.

According to the Energy Transitions Commission (ETC) decarbonising energy and other industries globally using hydrogen will require investment of almost $15 trillion between now and 2050.

In addition to the 90,000 terawatt hours (TWh) required for decarbonisation in general, the production of green hydrogen will require an additional 30,000 TWh of carbon-free power supply by 2050, according to the ETC.

This will necessitate investments of approximately $15 trillion, peaking at around $800 billion per year in the late 2030s, not only for hydrogen production but also for the electricity supply to handle the large growth in hydrogen use.

Approximately 85 percent of the required investment would be allocated to power generating, while 15 percent would be allocated to electrolysers, hydrogen production facilities, and transport and storage infrastructure. One cost cutting measure that experts suggest might be worth a look is repurposing natural gas pipelines for the transmission of hydrogen. This can cut investment costs 50%-80%, relative to the development of new pipelines. PLA – Biodegradable – Plastics-Harmful

Given the limited capacity and high cost of compressed hydrogen containers, large-scale geological storage will be required for the produced hydrogen. The lowest cost option is storing hydrogen in salt caverns, although doing so would need around 4,000 caverns of the “average” size if 5% of the world’s annual hydrogen consumption in 2050 needed to be stored. For now this is a question mark.

One inherent problem with Hydrogen is the fact that it is a highly flammable gas, and there are concerns about the safety of storing and transporting it.

The process of producing green hydrogen through electrolysis is not 100% energy efficient, as some energy is lost in the process. The existing technology operates at 75% or less efficiency (52.5kWh/kg). On the bright side there are new technologies like Hysata’s capillary-fed electrolyser (CFE) on the horizon that promise an efficiency of up to 95%.

While green hydrogen itself does not produce carbon dioxide emissions when it is burned, the production of green hydrogen does generate some emissions, primarily from the production of electricity used in the electrolysis process.

Green Hydrogen also represents significant opportunities for the global south including countries like Bangladesh. Countries in the Global South are likely to benefit from the new ways to industrialise that a switch to GH2 would open up. This would lead to more jobs and more welfare benefits. PLA – Biodegradable – Plastics-Harmful

In Chile, for instance, auctions have been held to help pay for the first 388 MW of GH2. Colombia’s GH2 strategy includes steps to boost both the country’s export goals and its ability to ship hydrogen to meet expected international demand. It also promotes Colombia as a potential logistics hub in the Caribbean.

The global energy crisis caused by the Ukraine war has led Bangladesh to focus more on green energy and green hydrogen is an important piece of that puzzle.

Bangladesh Council of Scientific and Industrial Research (BCSIR) is already working on Bangladesh’s first hydrogen fuel production plant. Using a technique known as biomass gasification and electrolysis of water, the facility will manufacture hydrogen by turning municipal garbage and water into highly flammable fuel.

The BCSIR has already established one unit of the plant, and the process to establish another is in full motion. Once both units are operational, they will create around 5.8 kg of hydrogen fuel per day. The volume might reach 29 kg if the plants operate continuously.

The Bangladesh Hydrogen and Fuel Cell Association (BHFCA) is an organisation that promotes the development of hydrogen and fuel cell technologies in Bangladesh. The organisation has worked with the Bangladesh Atomic Energy Commission to develop a roadmap for the deployment of green hydrogen in the country.

On 27 October 2022, State Minister for Power, Energy and Mineral Resources Nasrul Hamid announced that Bangladesh is going to follow ‘hydrogen policy’ to tackle the power problem which is prevailing in the country. Informing members of the press, “The policy-making works are already underway.” PLA – Biodegradable – Plastics-Harmful

PLA – Biodegradable – Plastics-Harmful