Plastic packaging – Pressolysis: is the Pressolysis a Sustainable Recycling Method for Plastics and Composites? 27-12-2023

Plastic packaging

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

Germany’s producer prices decline 7.9% YoY in November 2023

INSIGHTS

- In November 2023, Germany’s industrial product prices fell 7.9 per cent YoY, an improvement from October’s 11 per cent drop, as per Destatis.

- The decline is mainly due to lower energy costs, with a significant 21.4 per cent decrease in energy prices.

- Excluding energy, prices slightly rose by 0.3 per cent YoY but fell 0.1 per cent from October.

The producer prices of industrial products in Germany experienced a 7.9 per cent decrease in November 2023 compared to the same month in 2022, according to a recent update from the Federal Statistical Office (Destatis). This change, albeit significant, marks an improvement from the 11 per cent year-on-year (YoY) drop seen in October 2023. The fluctuation is largely attributed to a base effect resulting from the high price levels in the previous year. Plastic packaging

The decrease in November 2023, compared to October 2023, was more modest at 0.5 per cent. This downward movement in prices is primarily driven by a notable decrease in energy costs, which have been the primary factor behind the YoY decline in producer prices.

Energy prices in November 2023 were significantly lower than the previous year, down 21.4 per cent. Plastic packaging

BYD has officially chosen Hungary as the location for its inaugural European factory, marking a historic move as the first Chinese automaker to directly produce cars on the continent

The longstanding speculations surrounding BYD’s intentions have been confirmed, with Szeged in Hungary selected as the site for the groundbreaking facility. This strategic decision reflects a shift in pace for the Shenzen-based group.

The implementation of this pivotal plan will unfold through several phases, commencing with the establishment of a robust supply chain involving numerous suppliers, many of which are affiliated with BYD. Plastic packaging

The overarching goal is the creation of a “local green ecosystem.” BYD envisions the generation of thousands of new jobs in Hungary, citing the country’s favorable geographical position, well-connected infrastructures, and established industrial base, underscored by the presence of renowned car manufacturers such as Audi, Mercedes Opel, and Suzuki, along with key suppliers like Bosch, Continental, Delphi, Denso, Michelin, Hankook, Lear, and Luk. Germany and France were also contenders for the factory, especially given BYD’s existing European research and development center in Germany.

While specific dates for the construction of the BYD plant and details about the models to be produced remain uncertain, it is confirmed that the focus will be on plug-in hybrid and electric cars. Plastic packaging

The assembly process will take place on cutting-edge production lines equipped with the latest technologies. Currently, BYD is engaged in productive operations in Hungary, specifically for electric buses and trucks in Kamarom, near the northern border with Slovakia. The automotive plant, however, is slated for construction in Szeged, situated on the northern border of Hungary, neighboring Serbia and Romania.

Despite BYD’s global threat to Tesla in the electric car sales arena, its European footprint is still burgeoning, with only 13 thousand units sold in the region. Nevertheless, BYD boasts a presence in 19 countries through 230 dealers, showcasing the company’s commitment to expanding its influence in the European automotive market. Plastic packaging

Coca-Cola Philippines accelerates efforts to achieve circular economy on plastic packaging, water security

Coca-Cola Philippines concludes 2023 with significant progress in its commitment to environmental sustainability and enters 2024 with an increased resolve to accelerate its efforts. This year, the company continued to strengthen its initiatives to meet its World Without Waste targets and launched “May Ikabobote Pa”, a brand-led initiative aiming to inspire behavior change among consumers regarding recycling.

This includes expanding partnerships with organizations sharing a commitment to advancing a circular economy for plastic packaging. Plastic packaging

The Coca-Cola Company also unveiled its 2030 Water Security Strategy, which aims to achieve 100% circular water use across 175 facilities globally. Additionally, the company plans to partner with like-minded organizations to enhance the health of 60 critical watersheds and return a cumulative total of 2 trillion liters of water to nature and communities between 2021 and 2030.

“We are grateful for all our projects this year, which demonstrate our dedication to conducting our business more sustainably and empowering the communities where we operate and serve,” said Tony del Rosario, President of Coca-Cola Philippines.

“We recognize our responsibility to continue making a positive impact in communities and the environment and acknowledge that we still have a long way to go and that we cannot do this alone. Plastic packaging

We encourage everyone to join us in these efforts.”

Introduction to Biodegradable and Compostable Plastics

Biodegradable and compostable plastics have gained significant attention in recent years as the world grapples with the environmental impact of traditional plastics. These innovative materials offer a potential solution to the problem of plastic waste, but many people are still confused about the differences between biodegradable and compostable plastics. In this article, we will explore the various types of bioplastics and shed light on the distinctions between biodegradable and compostable plastics.

Bioplastics are derived from renewable sources such as plants, vegetable oils, and starches. They are designed to break down naturally over time, reducing their impact on the environment. Plastic packaging

However, not all bioplastics are created equal. There are different types of bioplastics, each with its own unique properties and characteristics.

One type of bioplastic is biodegradable plastic. Biodegradable plastics are made from organic materials that can be broken down by microorganisms such as bacteria or fungi. These plastics break down into natural elements like water, carbon dioxide, and biomass. Biodegradable plastics can be a suitable alternative to traditional plastics, as they do not accumulate in landfills or oceans, reducing the overall environmental impact.

Compostable plastics, on the other hand, are a specific subset of biodegradable plastics. Compostable plastics are designed to break down in a composting environment, where they can decompose alongside other organic matter. Composting is a natural process that turns organic waste into nutrient-rich soil. Plastic packaging

Compostable plastics break down into non-toxic components, leaving behind no harmful residues. They are an excellent choice for products that are likely to end up in composting facilities, such as food packaging or disposable cutlery.

Pressolysis: A Sustainable Recycling Method for Plastics and Composites

Plastics and composites are widely used materials in various industries, such as packaging, automotive, aerospace, construction, and electronics. However, they also pose significant environmental challenges, as they are often difficult to recycle and end up in landfills or oceans, causing pollution and harming wildlife. According to a 2017 study, only 9% of the global plastic waste was recycled, 12% was incinerated, and 79% was accumulated in landfills or the natural environment1. Plastic packaging

To address this problem, researchers and innovators have been developing various recycling methods that can recover valuable materials from plastic and composite waste, and reduce their environmental impact. One of these methods is pressolysis, a pressure-based technology that uses only steam to separate and recover organic materials from waste streams2. Pressolysis is also known as thermo-cyclic pressolysis, as it involves cyclic heating and cooling of the waste materials under high pressure3.

How does pressolysis work?

Pressolysis is a chemical recycling method that breaks down the molecular bonds of plastic and composite materials, and converts them into reusable monomers or oligomers. The process consists of four main steps3:

- Preparation: The waste materials are shredded and mixed with water in a reactor vessel. Plastic packaging

- Heating: The reactor is heated to a high temperature (around 300°C) and pressurized to a high pressure (around 200 bar) using steam. This causes the water to become supercritical, meaning it has both liquid and gas properties, and can act as a solvent and a catalyst for the depolymerization reaction.

- Cooling: The reactor is rapidly cooled to a low temperature (around 100°C) and depressurized to a low pressure (around 1 bar) using cold water. This causes the depolymerized products to separate from the water and form two phases: an organic phase and an aqueous phase. Plastic packaging

- Recovery: The organic phase, which contains the monomers or oligomers, is collected and purified for further use. The aqueous phase, which contains water and some dissolved salts, is recycled back to the reactor.

Taiwan’s Paraxylene Industry Faces Uncertainties with Tariff Adjustment

On December 20th, 2023, the Tariff Commission of China’s State Council announced a suspension of tariff concessions on specific products covered by the Cross-Strait Economic Cooperation Framework Agreement. Beginning January 1, 2024, tariff rates for 12 imported products, including Paraxylene (PX) from Taiwan, will no longer receive concessions. The current 0% tariff on Paraxylene will be adjusted to 2%. This new 2% tariff will be applicable on Paraxylene imports from Taiwan, same as that from other countries expect for the ASEAN market. Plastic packaging

Taiwan’s sole Paraxylene producer, FCFC (Formosa Chemicals & Fibre Corp.), mainly supplies its Paraxylene exports to the PTA plant in Ningbo, Zhejiang Province in China and sells some Paraxylene to other PTA plants.

In the period of January-November 2023 alone, Paraxylene imports from Taiwan represented 14% of the total, with an average monthly volume of 106kt. With the introduction of a 2% tariff, it is estimated that the cost of importing Paraxylene from Taiwan will likely increase and the competitiveness of Taiwan’s Paraxylene will decline. Presently, Paraxylene imports from Taiwan benefit from a favorable 0% tariff policy, resulting in relatively low import costs. Plastic packaging

Although, in practical transactions, both buyers and sellers often share the tariff reduction benefits, buyers still enjoy an advantage of approximately 1% tariff reduction compared to imports from Japan and South Korea. Therefore, with the implementation of 2% tariff, Paraxylene imports from Taiwan will no longer be able to enjoy this 1% reduction advantage, leading to an increase in the cost of importing from Taiwan. This may prompt buyers to turn to Paraxylene from ASEAN countries or imports from Japan and South Korea. Plastic packaging

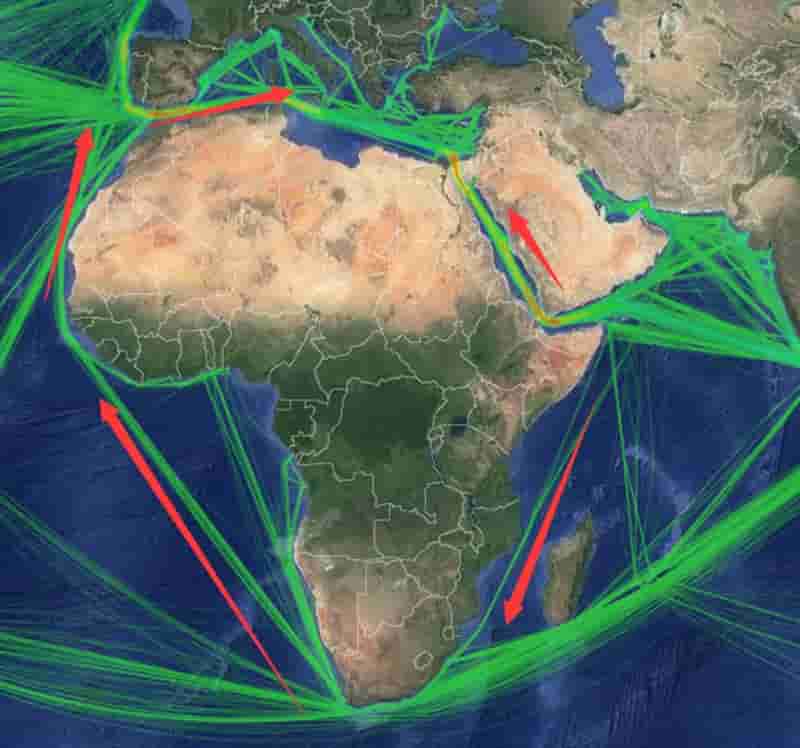

Freight on the Red Sea route soars, and China’s polyester exports to North Africa stagnate

Recent developments in the Red Sea have gained global attention, with many shipping companies announcing suspensions of service or a halt in offering new slots. Previously, the four major container shipping giants in Europe had all suspended services that required passing through the Red Sea route. As a result, shipping costs between Asia and Europe, as well as between Asia and Africa, have significantly increased in the short term. The current freight cost for a 20-feet standard container from China to North Africa has risen to around $3,500, an increase of several hundred dollars compared to before. However, shipping companies are actually unable to provide available slots, and their pricing adjustments are mainly opportunistic. Plastic packaging

Even if factories are willing to accept the higher rates, it does not necessarily guarantee the availability of slots.

Historically, disruptions in the Suez Canal have led to longer shipping distances and higher prices. In March 2021, the grounding of the MV Ever Given in the Suez Canal caused a six-day blockage, resulting in significant losses. Therefore, it is important to assess the potential impact of the “Red Sea Crisis.”

The Red Sea-Suez Canal route is one of the busiest shipping routes in the world, with approximately 12% of global cargo transportation passing through the Red Sea and the Suez Canal.Plastic packaging

The recent suspensions of Red Sea navigation by the four international shipping companies (Germany’s Hapag-Lloyd, Denmark’s Maersk Line, Mediterranean Shipping Company, and France’s CMA CGM) account for 53% of global container trade volume.

Plastic packaging